设计简介

摘 要

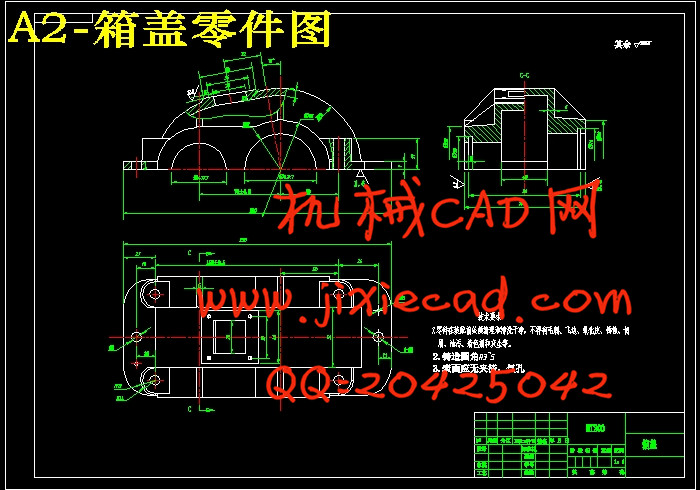

本文是在减速器箱体的图样分析后进行减速器箱体的机械加工工艺路线的设计,同时按照其中的加工工序的要求设计夹具。减速器箱体的主要加工内容是表面和孔。其加工路线长,加工时间多,加工成本高,零件的加工精度要求也高。按照机械加工工艺要求,遵循先面后孔的原则,并将孔与平面的加工明确划分成粗加工和精加工阶段以保证加工精度。基准选择以底面作为粗基准,以底面与两个工艺孔作为精基准,确定了其加工的工艺路线和加工中所需要的各种工艺参数。

在零件的夹具设计中,主要是根据零件加工工序要求,分析应限的自由度数,进而根据零件的表面特征选定定位元件,再分析所选定位元件能否限定应限自由度。确定了定位元件后还需要选择夹紧元件,最后就是确定专用夹具的结构形式。

关键词:减速器箱体;加工工艺;工序;专用夹具

Abstract

This paper is the design of mechanical line processing of the gearbox in the pattern analysis of the gearbox after, at the same time according to the design process of the fixture requirements.

The main content is the processing of the gearbox surface and the hole. The processing route is long, processing time, high processing cost, the machining precision requirement is high. In accordance with the requirements of the machining process, follow the principle of the surface after the first hole, and the hole and the plane processingclearly divided into roughing and finishing stages of processing to ensure accuracy. The basis choice to the bottom as a rough benchmark, the bottom with two hole as abenchmark, various parameters needed to process its processing and processing of.

In parts of fixture design, mainly according to the requirements of machining process, analysis of the number of degrees of freedom should be restricted, and then according to the surface features of parts of the selected positioning element, then analysis the selected components can be defined positioning should be limited degrees of freedom. Determine the location components also need to select the clamping element, finally is to determine the structure of special fixture.

Keywords: reducer; processing technology; process; special fixture

目 录The main content is the processing of the gearbox surface and the hole. The processing route is long, processing time, high processing cost, the machining precision requirement is high. In accordance with the requirements of the machining process, follow the principle of the surface after the first hole, and the hole and the plane processingclearly divided into roughing and finishing stages of processing to ensure accuracy. The basis choice to the bottom as a rough benchmark, the bottom with two hole as abenchmark, various parameters needed to process its processing and processing of.

In parts of fixture design, mainly according to the requirements of machining process, analysis of the number of degrees of freedom should be restricted, and then according to the surface features of parts of the selected positioning element, then analysis the selected components can be defined positioning should be limited degrees of freedom. Determine the location components also need to select the clamping element, finally is to determine the structure of special fixture.

Keywords: reducer; processing technology; process; special fixture

摘 要..................................................................................................... I

Abstract................................................................................................. II

1 绪论..................................................................................................... 1

1.1 本课题的研究内容和意义.............................................................. 1

1.2 国内外的发展概况........................................................................ 2

1.3 本课题应达到的要求..................................................................... 3

2 零件工艺的分析.................................................................................... 4

2.1 零件的工艺分析............................................................................ 4

2.2 箱体零件的结构工艺性.................................................................. 4

3 工艺规程设计....................................................................................... 7

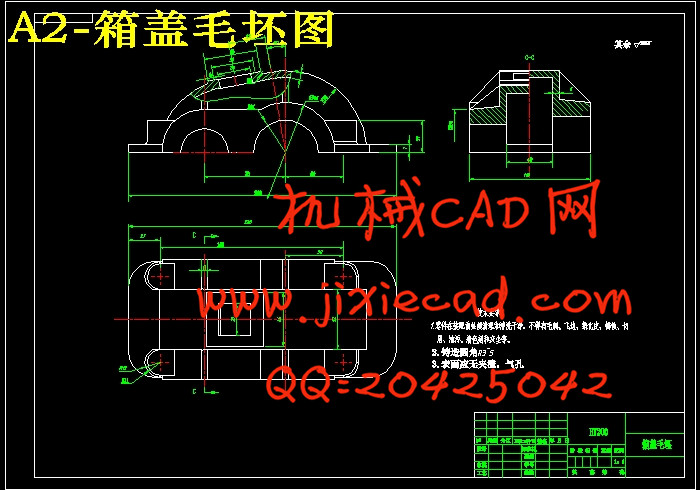

3.1 确定毛坯的制造形式..................................................................... 7

3.2 定位基准的选择............................................................................ 8

3.2.1 粗基准的选择................................................................... 8

3.2.2 精基准的选择................................................................... 9

3.3 拟定工艺路线............................................................................. 10

3.3.1 划分加工阶段................................................................. 10

3.3.2 安排加工顺序................................................................. 11

3.3.3 拟定加工工艺路线.......................................................... 12

3.4 机械加工余量、工序尺寸及毛坯尺寸的确定................................. 13

4 确定切削用量及基本工时.................................................................... 15

4.1 粗铣上窥视孔面.......................................................................... 15

4.2 粗铣结合面................................................................................. 16

4.3 磨分割面.................................................................................... 17

4.4 钻孔........................................................................................... 18

5 铣左右端面夹具设计........................................................................... 20

5.1 设计要求.................................................................................... 20

5.2 夹具设计.................................................................................... 20

5.2.1 定位基准的选择............................................................ 20

5.2.2 切削力及夹紧力的计算................................................ 20

5.3定位误差的分析.......................................................................... 23

5.4夹具设计及操作的简要说明......................................................... 24

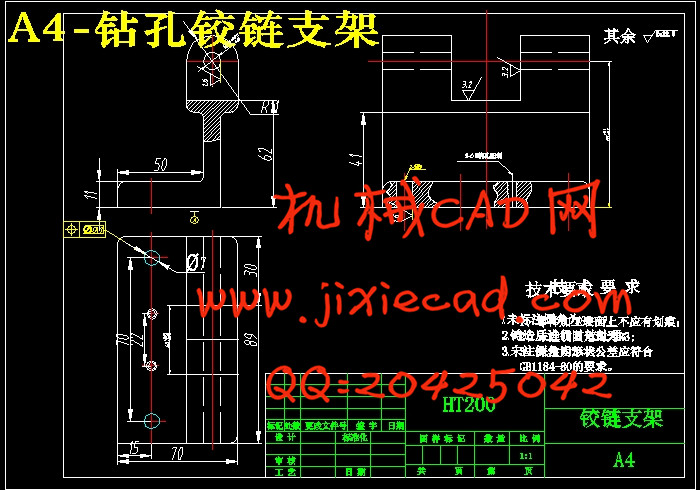

6 钻孔夹具设计..................................................................................... 25

6.1设计分析..................................................................................... 25

6.2设计方案论证.............................................................................. 25

6.3切削力及夹紧力的计算................................................................ 25

6.4 设计及操作的简要说明................................................................ 26

6.5 结构分析.................................................................................... 26

6.6 夹具的公差................................................................................. 28

6.7 工序精度分析............................................................................. 29

总 结..................................................................................................... 30

参考文献.............................................................................................. 32

致谢...................................................................................................... 33