设计简介

摘要

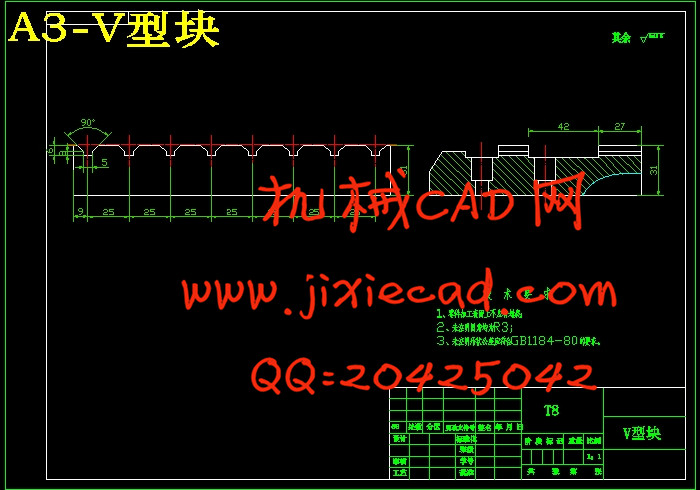

杠杆的加工工艺规程及其夹具设计包括零件加工的工艺设计、工序设计以及专用夹具的设计三部分。在工艺设计中要首先对零件进行分析,了解零件的工艺,并选择好零件的加工基准,设计出零件的工艺路线;接着对零件各个工步的工序进行尺寸计算,关键是决定出各个工序的工艺装备及切削用量;然后进行专用夹具的设计,选择设计出夹具的各个组成部件,如定位元件、夹紧元件、引导元件、夹具体与机床的连接部件以及其它部件。夹具设计时应根据对零件的分析,选取合适的定位元件、夹紧元件等,要准确确定它们的精度等级,以满足零件的加工精度。之后计算出夹具定位时产生的定位误差,分析夹具结构的合理性与不足之处,并在以后设计中注意改进。

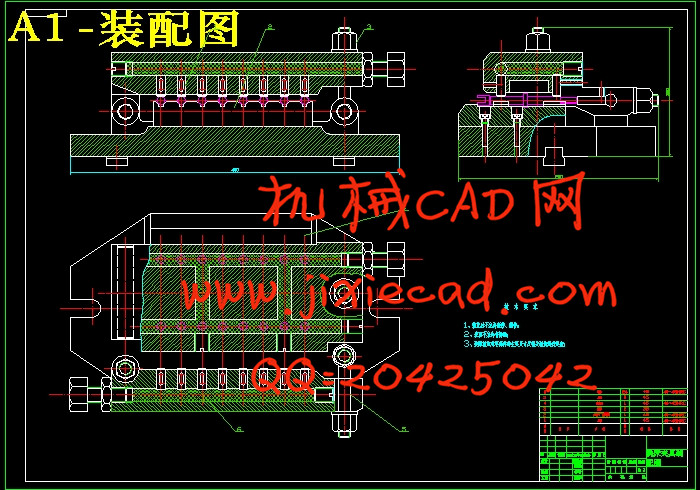

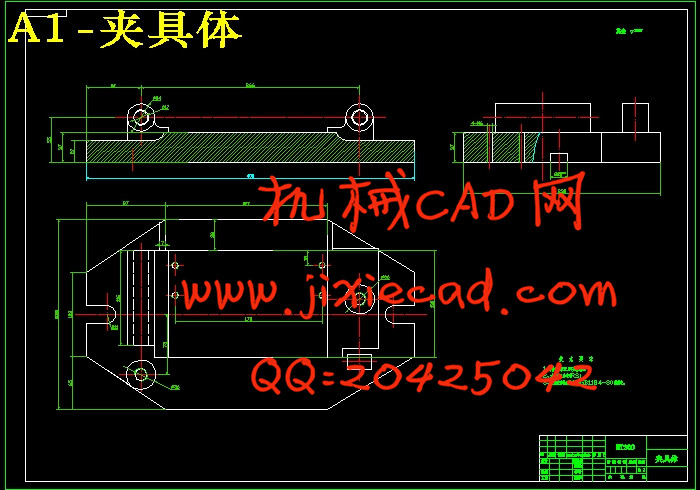

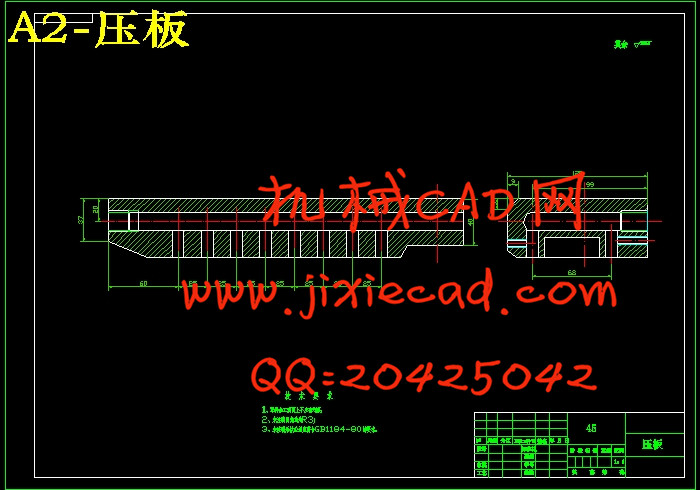

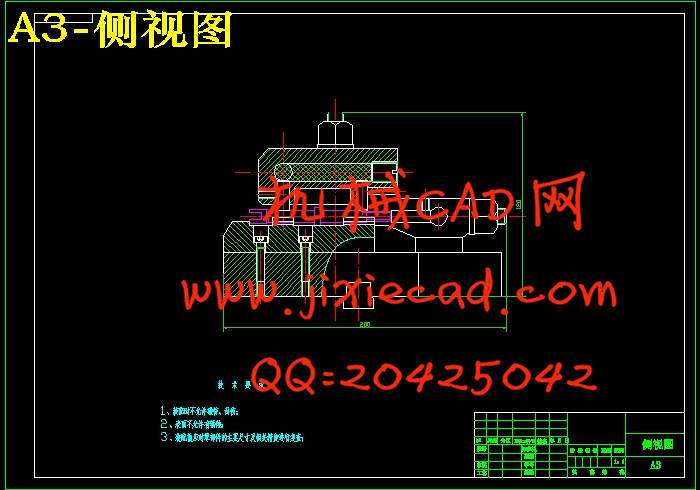

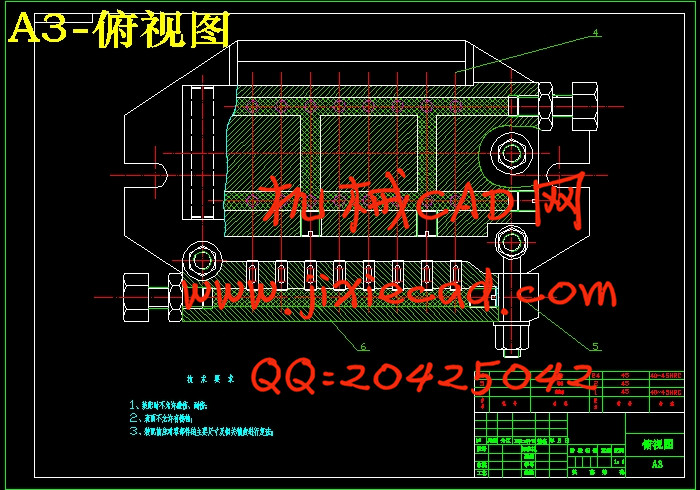

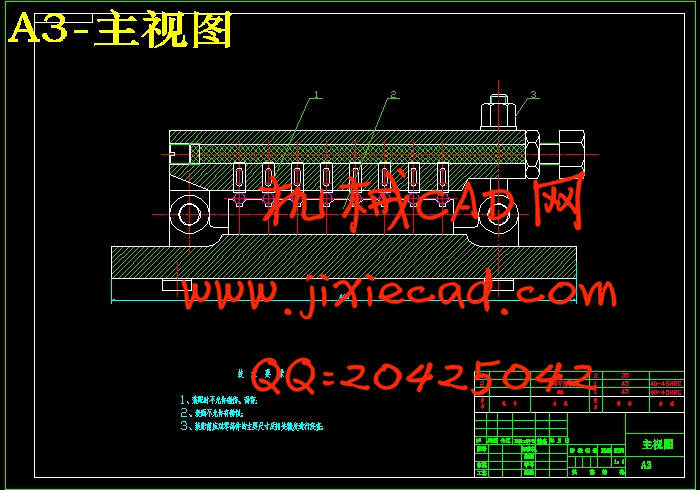

夹具设计有很多种方案,本次设计是V型块定位,滚性塑料夹紧,利用联动夹紧机构同时夹紧多个零件并使夹紧力均匀分布。采用这套夹具可以有效的提高生产效率,而且结构简单紧凑,在节省资源的同时有效的提高了劳动生产力。

关键词: 定位机构、联动夹紧机构、夹具设计

杠杆的加工工艺规程及其夹具设计包括零件加工的工艺设计、工序设计以及专用夹具的设计三部分。在工艺设计中要首先对零件进行分析,了解零件的工艺,并选择好零件的加工基准,设计出零件的工艺路线;接着对零件各个工步的工序进行尺寸计算,关键是决定出各个工序的工艺装备及切削用量;然后进行专用夹具的设计,选择设计出夹具的各个组成部件,如定位元件、夹紧元件、引导元件、夹具体与机床的连接部件以及其它部件。夹具设计时应根据对零件的分析,选取合适的定位元件、夹紧元件等,要准确确定它们的精度等级,以满足零件的加工精度。之后计算出夹具定位时产生的定位误差,分析夹具结构的合理性与不足之处,并在以后设计中注意改进。

夹具设计有很多种方案,本次设计是V型块定位,滚性塑料夹紧,利用联动夹紧机构同时夹紧多个零件并使夹紧力均匀分布。采用这套夹具可以有效的提高生产效率,而且结构简单紧凑,在节省资源的同时有效的提高了劳动生产力。

关键词: 定位机构、联动夹紧机构、夹具设计

Abstract

Design and process design, processing procedure and fixture design including the lever parts processing process design and the three part special fixture. In the process of design should first of all parts to analyze, understand parts of the process, and the choice of processing benchmark good parts, design the process routes of the parts; then the parts each step process dimension calculation, the key is to determine the craft equipment and the cutting of various process parameters; then design special fixture, selection fixture for the various components of a design, such as the connecting part positioning device, clamping element, a guide element, clamp and the machine tool and other components. Fixture design should be based on the analysis of parts, select the positioning element, clamping element suitable, to accurately determine the accuracy grade of them, in order to satisfy the machining accuracy of parts. Then calculate the fixture positioning error is generated when, analysis of the rationality and deficiency of fixture structure, pay attention to improving and will design in.

There are many kinds of schemes of fixture design, this design is the location of V type block, roll plastic clamping, clamping mechanism using linkage and clamp a plurality of parts and the clamping force is uniform distribution. Using this fixture can effectively improve the production efficiency, simple and compact structure, at the same time to save resources effectively improve labor productivity.

Keywords: fixture design and positioning mechanism, a clamping mechanism, linkage

Design and process design, processing procedure and fixture design including the lever parts processing process design and the three part special fixture. In the process of design should first of all parts to analyze, understand parts of the process, and the choice of processing benchmark good parts, design the process routes of the parts; then the parts each step process dimension calculation, the key is to determine the craft equipment and the cutting of various process parameters; then design special fixture, selection fixture for the various components of a design, such as the connecting part positioning device, clamping element, a guide element, clamp and the machine tool and other components. Fixture design should be based on the analysis of parts, select the positioning element, clamping element suitable, to accurately determine the accuracy grade of them, in order to satisfy the machining accuracy of parts. Then calculate the fixture positioning error is generated when, analysis of the rationality and deficiency of fixture structure, pay attention to improving and will design in.

There are many kinds of schemes of fixture design, this design is the location of V type block, roll plastic clamping, clamping mechanism using linkage and clamp a plurality of parts and the clamping force is uniform distribution. Using this fixture can effectively improve the production efficiency, simple and compact structure, at the same time to save resources effectively improve labor productivity.

Keywords: fixture design and positioning mechanism, a clamping mechanism, linkage

目录

第1章 绪论 1

1.1 机械加工工艺概述 1

1.2机械加工工艺流程 1

1.3夹具概述 2

1.4机床夹具的功能 3

1.5机床夹具的发展趋势 4

1.5.1机床夹具的现状 4

1.5.2现代机床夹具的发展方向 4

第2章 工艺规程设计 6

2.1 零件的分析 6

2.1.1 零件的作用 6

2.1.2 零件的工艺分析 6

2.2 工艺规程设计 7

2.2.1 确定毛坯的制造形式 7

2.2.2 基面的选择 7

2.2.3 制定工艺路线 7

2.2.4 机械加工余量,工序尺寸及毛坯尺寸的确定 10

2.2.5 确定切削用量 11

2.2.6 基本工时 26

第3章 机床夹具的定位及夹紧 30

3.1 概述 30

3.1.1 机床夹具的概念 30

3.1.2 机床夹具的组成 30

3.1.3 机床夹具的分类 31

3.1.4 机床夹具在机械加工中的作用 32

3.2 工件的装夹方式 33

3.3 基准及其分类 33

3.4 工件的定位 34

3.5 工件的夹紧 35

3.5.1夹紧装置的组成及基本要求 35

3.5.2 夹紧力的确定 36

3.6 专用夹具设计 37

3.6.1对机床专用夹具的基本要求 37

3.6.2专用夹具设计方法和步骤 37

3.6.3夹具总图技术要求的制订 38

第4章 联动夹紧机构夹具设计 39

4.1问题的提出 39

4.2 定位基准的选择 39

4.2.1定位元件的选择 39

4.2.2夹紧元件以及夹具体的确定 40

4.2.3十四个滚动压块联动 40

4.3 切削力及夹紧力计算 41

第5章 定位精度分析及定位误差分析计算 43

5.1 定位精度分析 43

5.2 定位误差的基本概念及组成 44

5.3本次设计的定位误差分析及计算 47

第6章 经济性分析 49

结论 52

致谢 53

参考文献 54