设计简介

摘要

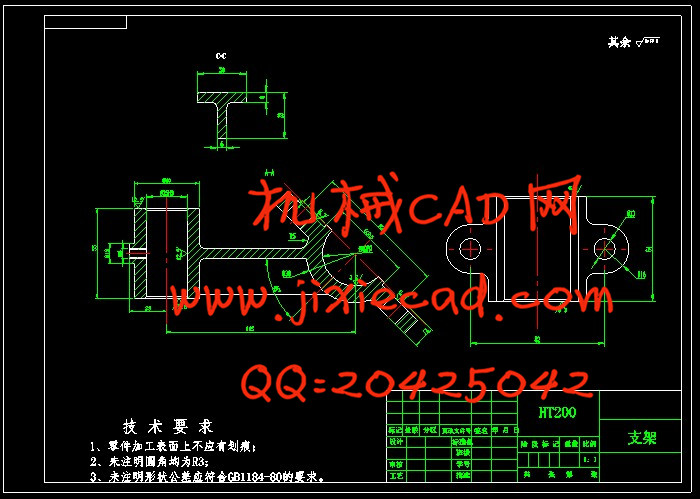

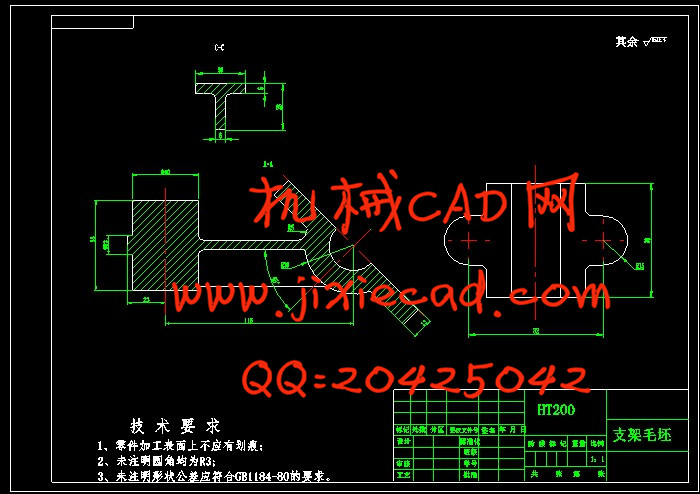

本次设计是对支架零件的加工工艺规程及一些工序的专用夹具设计。支架零件的主要加工表面是平面及孔。由加工工艺原则可知,保证平面的加工精度要比保证孔的加工精度容易。所以本设计遵循先面后孔的原则。并将孔与平面的加工明确划分成粗加工和精加工阶段以保证加工精度。基准选择以支架大外圆端面作为粗基准,以支架大外圆端面与两个工艺孔作为精基准。主要加工工序安排是先以支架大外圆端面互为基准加工出端面,再以端面定位加工出工艺孔。在后续工序中除个别工序外均用端面和工艺孔定位加工其他孔与平面。整个加工过程均选用机床。关键词:支架,加工工艺,专用夹具

Abstract

The design of a wide range of knowledge concerning the manufacturing process and mechanical design of jigs and fixtures , metal -cutting machine tools , tolerance and measurement. Fork fixture design process planning and milling machining parts that include process design, process design, and special fixture design of three parts. In the process of designing the parts to be the first analysis to understand the parts of the process re-design the structure of the blank , and select the machining datum good parts , the design process route parts ; then the part of each step of the process to calculate the size of a key is to determine the technical equipment and cutting the amount of each process ; then dedicated fixture design , select the design of the various components of the fixture , such as positioning elements , clamping elements , guiding element , clamp connections and machine parts and other components ; positioning error generated when calculating the fixture , analytical rationality and inadequacies fixture structure and attention to improving the design in the future . Keywords : fork , processes, cutting the amount of clamping

The design of a wide range of knowledge concerning the manufacturing process and mechanical design of jigs and fixtures , metal -cutting machine tools , tolerance and measurement. Fork fixture design process planning and milling machining parts that include process design, process design, and special fixture design of three parts. In the process of designing the parts to be the first analysis to understand the parts of the process re-design the structure of the blank , and select the machining datum good parts , the design process route parts ; then the part of each step of the process to calculate the size of a key is to determine the technical equipment and cutting the amount of each process ; then dedicated fixture design , select the design of the various components of the fixture , such as positioning elements , clamping elements , guiding element , clamp connections and machine parts and other components ; positioning error generated when calculating the fixture , analytical rationality and inadequacies fixture structure and attention to improving the design in the future . Keywords : fork , processes, cutting the amount of clamping

目 录

摘要 II

目 录 IV

第1章 序言 1

1.1 机械加工工艺概述 1

1.2机械加工工艺流程 1

1.3夹具概述 2

1.4机床夹具的功能 2

1.5机床夹具的发展趋势 3

1.5.1机床夹具的现状 3

1.5.2现代机床夹具的发展方向 3

第2章 支架加工工艺规程设计 5

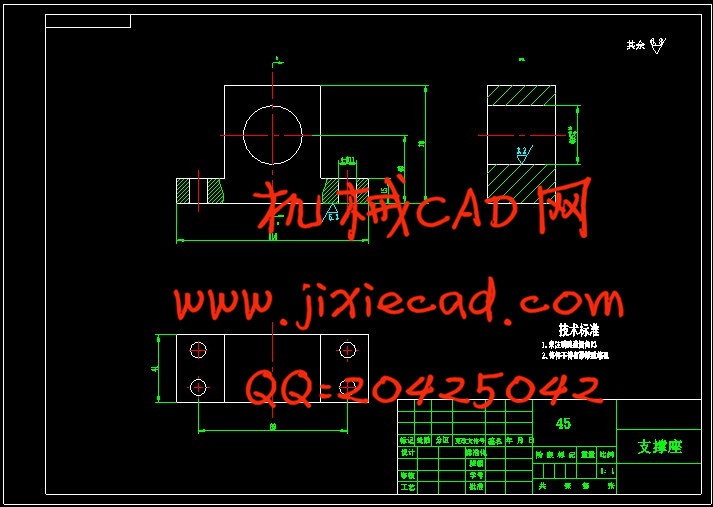

2.1零件的分析 5

2.1.1零件的作用 5

2.1.2零件的工艺分析 5

2.2工艺过程设计所应采取的相应措施 5

2.3支架加工定位基准的选择 6

2.3.1 确定毛坯的制造形式 6

2.3.2粗基准的选择 6

2.3.3精基准的选择 6

2.4 工艺路线的制定 6

2.4.1 工艺方案一 7

2.4.2 工艺方案二 7

2.4.3 工艺方案的比较与分析 8

2.5机械加工余量、工序尺寸及毛坯尺寸的确定 9

2.6确定切削用量及基本工时(机动时间) 10

2.7时间定额计算及生产安排 22

2.8 本章小结 24

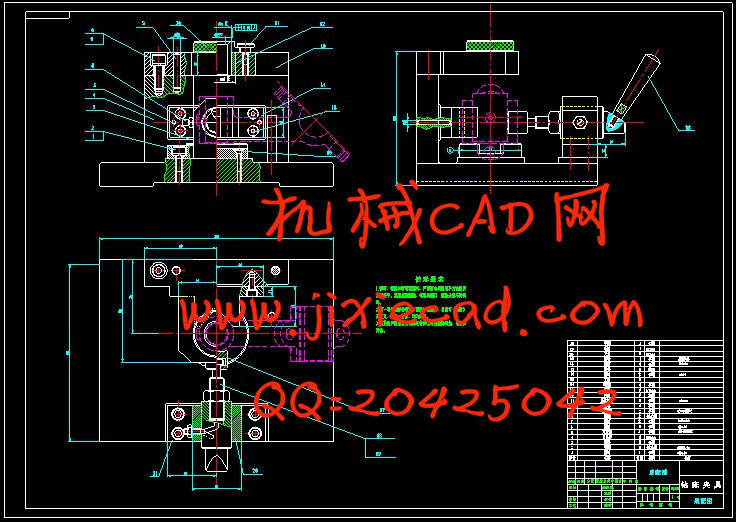

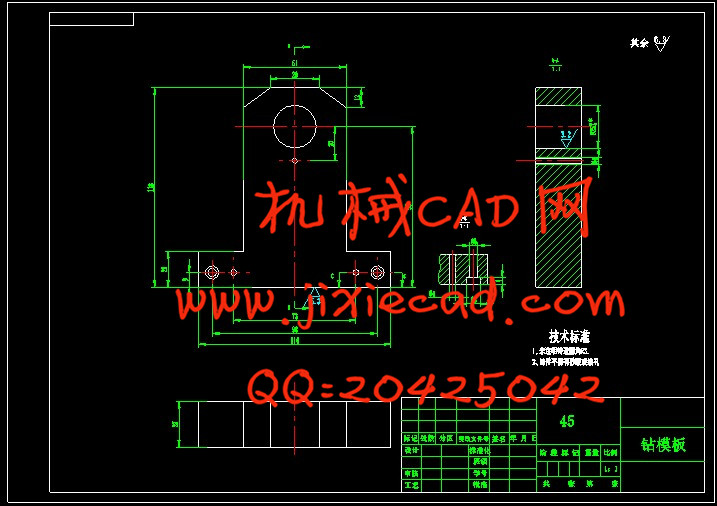

3 钻孔夹具设计 25

3.1 夹具的夹紧装置和定位装置 25

3.2 夹具的导向 26

3.3 定位方案分析与比较(列举了3种方案) 26

3.4钻孔与工件之间的切屑间隙 28

3.5 钻模板 29

3.6定位误差的分析 29

3.7 钻套、衬套、钻模板设计与选用 30

3.8确定夹具体结构和总体结构 32

3.9 夹具设计及操作的简要说明 33

结论 34

致谢 35

参考文献 36