设计简介

摘 要

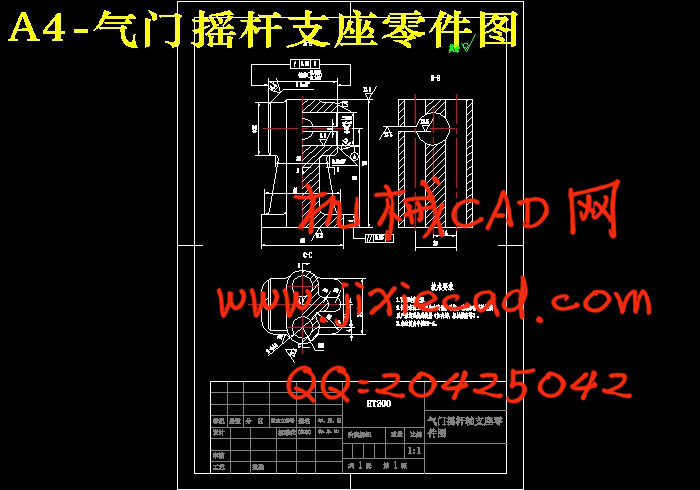

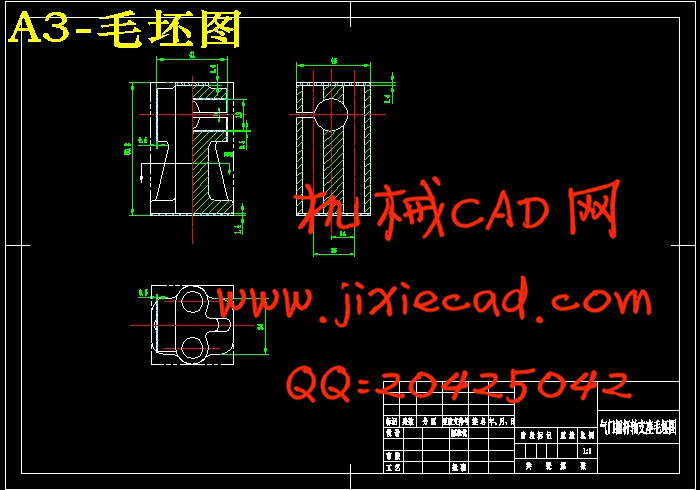

本设计所设计的零件是柴油机中摇杆结合部分的气门摇杆轴支座,气门摇杆轴支座是柴油机摇杆座的结合部分,它是柴油机一个重要零件。其中摇杆轴装在 mm孔中,轴上两端各装一进气门摇杆;摇杆座通过两个∅13孔用M12螺杆与汽缸盖相连,3mm轴向槽用于锁紧摇杆轴,使其不能转动。汽缸盖内每缸四阀使燃烧室充气最佳,气门由摇杆凸轮机构驱动,摩擦力小且气门间隙由液压补偿。这种结构可能减小燃油消耗并改善排放。

mm孔中,轴上两端各装一进气门摇杆;摇杆座通过两个∅13孔用M12螺杆与汽缸盖相连,3mm轴向槽用于锁紧摇杆轴,使其不能转动。汽缸盖内每缸四阀使燃烧室充气最佳,气门由摇杆凸轮机构驱动,摩擦力小且气门间隙由液压补偿。这种结构可能减小燃油消耗并改善排放。

机床夹具按其使用范围可分为以下五种基本类型:

(1)通用夹具:通用夹具具有一定的通用性。

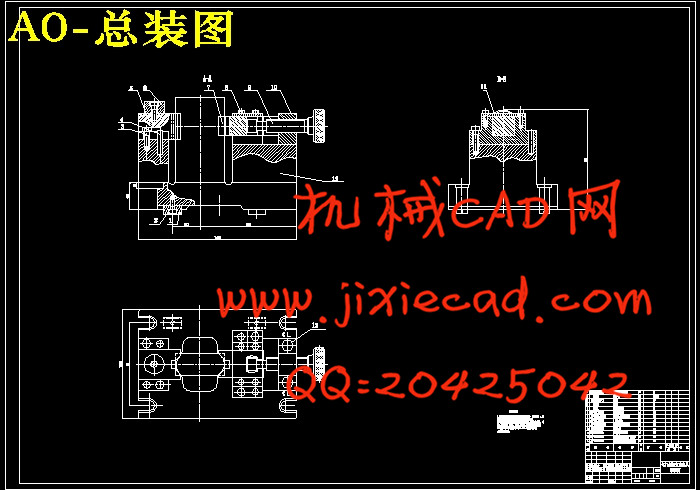

(2)专用夹具:专用夹具是针对某一种工件的某一个工序而专门设计的。

(3)通用可调整夹具和成组夹具:通用可调整夹具和成组夹具的特点是夹具的部分元件可以更换,部分装置可以调整,以适应不同零件的加工。

(4)组合夹具:组合夹具是由一套完全标准化的元件,根据零件的加工要求拼装而成的夹具。组合夹具的适用范围可从以下不同角度来谈:从产品的批量来看,组合夹具最适于新产品研制、试制、单件和小批量生产。因此,对于产品变化频繁、该型周期短、产品类型多的企业选用组合夹具最为适宜,能收到最显著的经济效果;从加工工序来看,组合夹具应用极为广泛,它可以方便的组成各类机床使用的夹具;从加工工件的几何形状和尺寸看,组合夹具一般不受工件形状的限制。

气门摇杆轴支座的加工工艺规程及其铣50底面与粗车、半精车、精车16孔的夹具设计是在学完了机械制图、机械制造技术基础、机械设计、机械工程材料等进行设计之后的下一个教学环节。正确地解决一个零件在加工中的定位,夹紧以及工艺路线安排,工艺尺寸确定等问题,并设计出专用夹具,保证零件的加工质量。本次设计也要培养自己的自学与创新能力。因此本次设计综合性和实践性强、涉及知识面广。所以在设计中既要注意基本概念、基本理论,又要注意生产实践的需要,只有将各种理论与生产实践相结合,才能很好的完成本次设计.`本次设计水平有限,其中难免有缺点错误,敬请老师们批评指正。

关键词:工艺装备,夹紧,定位,夹具设计。

本设计所设计的零件是柴油机中摇杆结合部分的气门摇杆轴支座,气门摇杆轴支座是柴油机摇杆座的结合部分,它是柴油机一个重要零件。其中摇杆轴装在

机床夹具按其使用范围可分为以下五种基本类型:

(1)通用夹具:通用夹具具有一定的通用性。

(2)专用夹具:专用夹具是针对某一种工件的某一个工序而专门设计的。

(3)通用可调整夹具和成组夹具:通用可调整夹具和成组夹具的特点是夹具的部分元件可以更换,部分装置可以调整,以适应不同零件的加工。

(4)组合夹具:组合夹具是由一套完全标准化的元件,根据零件的加工要求拼装而成的夹具。组合夹具的适用范围可从以下不同角度来谈:从产品的批量来看,组合夹具最适于新产品研制、试制、单件和小批量生产。因此,对于产品变化频繁、该型周期短、产品类型多的企业选用组合夹具最为适宜,能收到最显著的经济效果;从加工工序来看,组合夹具应用极为广泛,它可以方便的组成各类机床使用的夹具;从加工工件的几何形状和尺寸看,组合夹具一般不受工件形状的限制。

气门摇杆轴支座的加工工艺规程及其铣50底面与粗车、半精车、精车16孔的夹具设计是在学完了机械制图、机械制造技术基础、机械设计、机械工程材料等进行设计之后的下一个教学环节。正确地解决一个零件在加工中的定位,夹紧以及工艺路线安排,工艺尺寸确定等问题,并设计出专用夹具,保证零件的加工质量。本次设计也要培养自己的自学与创新能力。因此本次设计综合性和实践性强、涉及知识面广。所以在设计中既要注意基本概念、基本理论,又要注意生产实践的需要,只有将各种理论与生产实践相结合,才能很好的完成本次设计.`本次设计水平有限,其中难免有缺点错误,敬请老师们批评指正。

关键词:工艺装备,夹紧,定位,夹具设计。

ABSTRACT

This design of parts is the rocker in combination with part of the diesel engine valve rocker shaft bearings, valve rocker shaft bearing is the combination of diesel engine rocker seat section, it is an important diesel engine parts. With the rocker shaft in ∅ 20 (+ 0.06 + 0.06) in the hole, at each end to a inlet valve rocker shaft; 13 holes with rocker base through the two ∅ M12 screw connected to the cylinder cover, 3 mm axial groove is used to lock rocker shaft, make it can't turn. Within the cylinder cover four valves per cylinder combustor best, inflatable valve driven by rocker CAM mechanism, friction small, by the hydraulic valve clearance compensation. This structure can reduce fuel consumption and improve emissions.

Machine tool fixture according to its using range can be divided into the following five basic types:

(1) general fixture: universal fixture has a certain universality.

(2) special fixture, special fixture for a certain artifacts specifically designed a process.

(3) general adjustable clamp and grouping: general adjustable clamp and the characteristic of group fixture is part of the components can be replaced, part of the device can be adjusted, so as to adapt to different parts of processing.

(4) the modular fixture: modular fixture is composed of a set of completely standardized components, according to the machining requirements of parts assembled into the fixture. Scope of application of modular fixture is to talk about from the following perspectives: from the perspective of the batch of product, modular fixture is the most suitable for the new product development, trial production, single piece and small batch production. Therefore, for the product change frequently, the cycle is short, the product type more enterprises choose modular fixture is the most suitable, to receive the most remarkable economic effect; From the point of processing operations, modular fixture application is very extensive, it can be composed of various kinds of machine tools using fixture; From the geometric shape and size of machining, modular fixture is generally not restricted by the shape of the workpiece.

Valve rocker shaft bearing of machining process planning and milling 50 underside, half fine cars, fine and coarse car 16 holes fixture design is finished learning mechanical drawing, mechanical manufacturing technology foundation, mechanical design, mechanical engineering materials to carry on the design after the next teaching link. Correctly solve a part in the processing of positioning, clamping and craft route, process determine the problem such as size, and special fixture design, guarantee the quality of parts. This design also want to develop their ability of self-study and innovation. So this design is a comprehensive and practical strong, involves broad scope. So in the design should not only pay attention to the basic concepts, basic theory, and attention should be paid to the need of production practice, only will be a variety of theory combined with production practice, can be very good to complete the design. ` this design level is limited, the hard to avoid disadvantages as errors, teachers please comment.

Key words: valve rocker shaft support; technology; processing technology