设计简介

本设计要求“以质量求发展,以效益求生存”,在保证零件加工质量的前提下,提高了生产率,降低了生产成本,是国内外现代机械加工工艺的主要发展方面方向之一。通过对LH157QMJ-B变速箱箱体零件图的分析及结构形式的了解,从而对变速箱体进行工艺分析、工艺说明及加工过程的技术要求和精度分析。然后再对变速箱体的结合面以及该组加工面上孔系的加工进行夹具设计与精度和误差分析,该工艺与夹具设计结果能应用于生产要求。

关键词 变速箱体 加工工艺 定位 夹具设计

Abstract

This Paper requires that" with quality beg development, with benefits seek to live on to store ", under the prerequisite of guaranteeing the quality of element processing , have raised productivity and reduced production cost, is one of mainly direction of domestic and international modern machining technology developing. Through knowing and analysis the configuration of the casing part drawing for WH212 gear reducer, so as to analysis the process, make process explanation and analysis the technical requirement and the precision of gear reducer. Then, carry out the design of clamping apparatus and analysis the precision and error for the processing of bearing hole and the base hole of the casing of gear reducer, this technology and the design result of clamping apparatus can apply in production requirement.

Keywords Principal axis Processing technology

Fixed position Tongs design

目 录

1 引言 1

2 生产纲领 3

2.1 计算生产纲领决定生产类型 3

2.2 计算生产节拍 4

3 零件的分析 5

3.1 零件的作用 5

3.2 零件的工艺分析 5

4 工艺规程设计 7

4.1 确定毛坯的制造形式 7

4.2 基面的选择 7

4.3 制订工艺路线 9

4.4 机械加工余量、工序尺寸及毛坯尺寸的确定 14

4.5 确定切削用量及基本工时 17

4.6 小结. 46

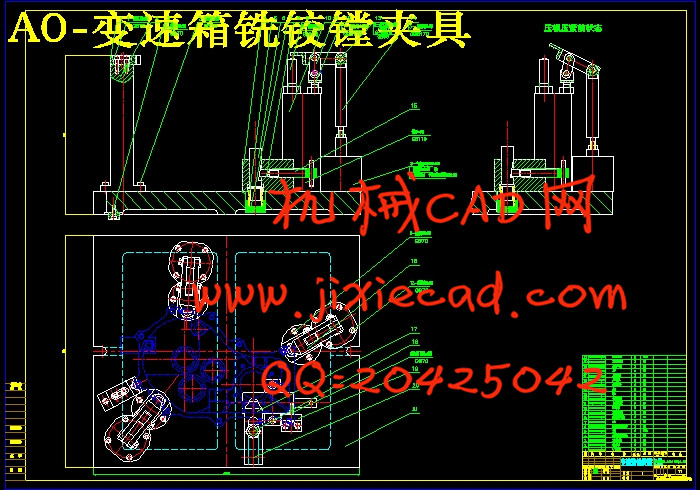

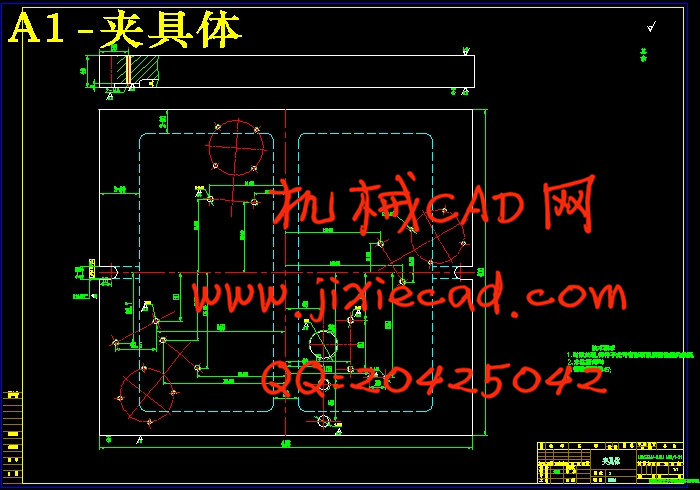

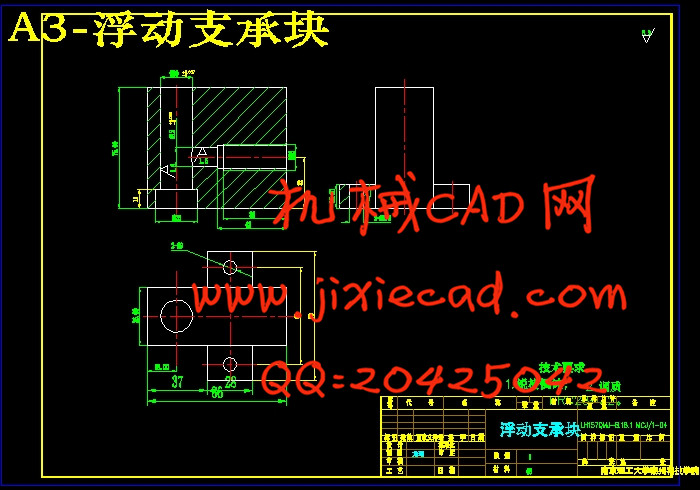

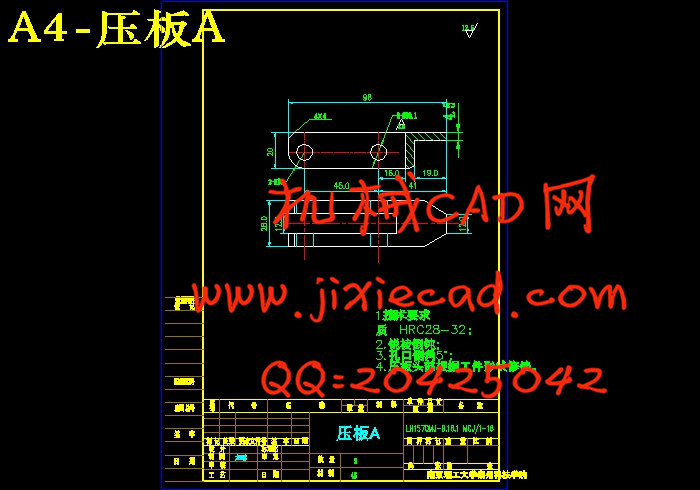

5 夹具的设计 47

5.1 问题的提出 47

5.2 夹具设计 47

5.3小结 50

结束语 51

致谢 52

参考文献 53

关键词 变速箱体 加工工艺 定位 夹具设计

Abstract

This Paper requires that" with quality beg development, with benefits seek to live on to store ", under the prerequisite of guaranteeing the quality of element processing , have raised productivity and reduced production cost, is one of mainly direction of domestic and international modern machining technology developing. Through knowing and analysis the configuration of the casing part drawing for WH212 gear reducer, so as to analysis the process, make process explanation and analysis the technical requirement and the precision of gear reducer. Then, carry out the design of clamping apparatus and analysis the precision and error for the processing of bearing hole and the base hole of the casing of gear reducer, this technology and the design result of clamping apparatus can apply in production requirement.

Keywords Principal axis Processing technology

Fixed position Tongs design

目 录

1 引言 1

2 生产纲领 3

2.1 计算生产纲领决定生产类型 3

2.2 计算生产节拍 4

3 零件的分析 5

3.1 零件的作用 5

3.2 零件的工艺分析 5

4 工艺规程设计 7

4.1 确定毛坯的制造形式 7

4.2 基面的选择 7

4.3 制订工艺路线 9

4.4 机械加工余量、工序尺寸及毛坯尺寸的确定 14

4.5 确定切削用量及基本工时 17

4.6 小结. 46

5 夹具的设计 47

5.1 问题的提出 47

5.2 夹具设计 47

5.3小结 50

结束语 51

致谢 52

参考文献 53