设计简介

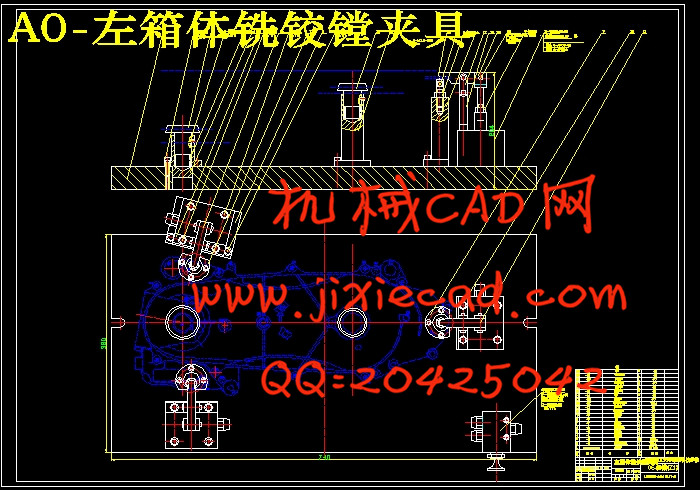

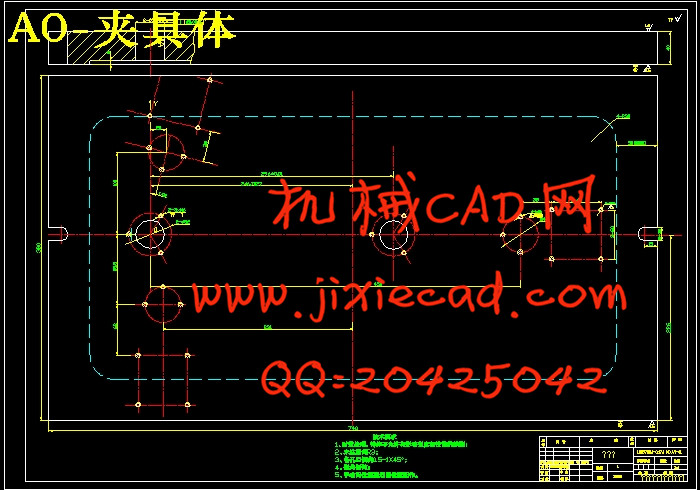

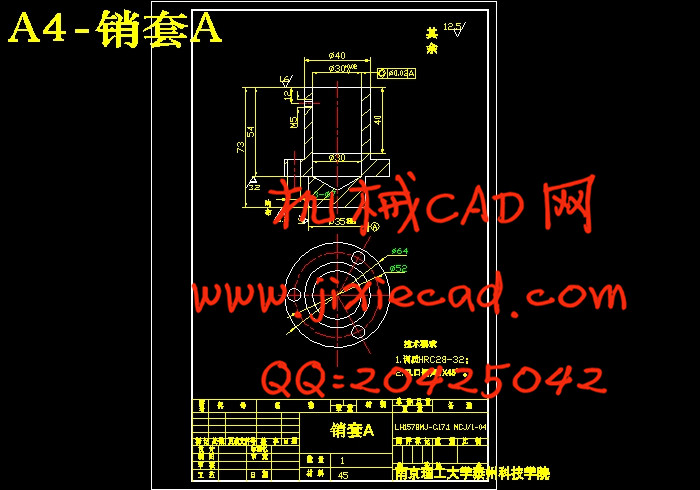

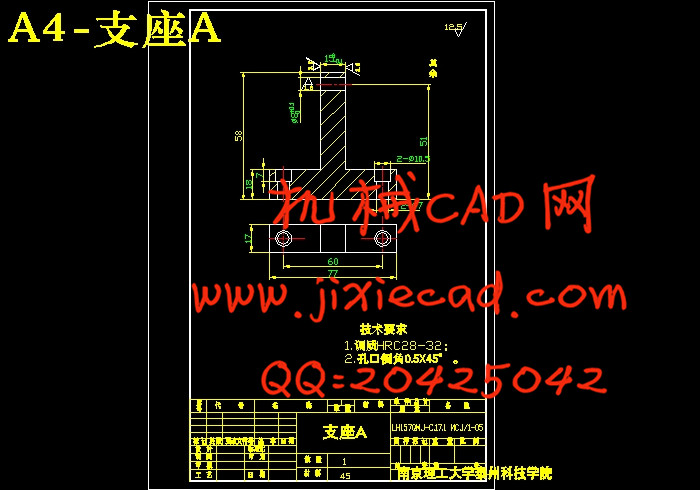

本次设计制定了LH157QMJ-C左箱体工序卡及第一道工序的夹具。从审题到完成一般都要经过类似过程,分析如下:工件加工工艺路线;各个工序的内容及采用的机床和工艺装备;工件的检验项目及检验方法;切削用量;工时定额及工人的技术等。机床夹具是在机床上用以正确确定工件的位置,并可靠而迅速的将工件夹紧的机床附加装置。它主要有以下几个基本部分组成: 定位元件及定位装置、对刀及导引元件、夹紧装置、联接元件、夹具体及其他装置等。

关键词 加工工艺 夹具设计

Abstract

The school has designed a LH157QMJ-C left box processes cards and process the first fixture. Question from the trial to go through a similar process to complete normally, as follows: work piece processing line; all the content and processes used in machine tools and processing equipment; parts of test items and test methods; Cutting; the fixed hours of work and workers in the technology. Machine tool fixture is in the machine tools used to determine the correct position of the work piece, and a reliable and fast machine tool work piece clamping attachments. It mainly has the following basic components: positioning components and positioning device, tool and guidance components, clamping device, connected components, specific folders, and other devices.

Keywords Processing craft Jig design

目 录

1 引言 1

2 生产纲领 2

2.1 计算生产纲领决定生产类型 2

2.2 计算生产节拍 3

3 零件的分析 4

3.1 零件的作用方案设计 4

3.2 零件的工艺分析 4

4 工艺规程设计 5

4.1 确定毛坯制造形成 5

4.2 基面的选择 6

4.3 制定工艺路线 7

4.4 机械加工余量、工序尺寸及毛坯尺寸的确定 11

4.5 确定切削用量及基本工时 12

5 夹具的设计 38

5.1 问题的提出 38

5.2 夹具的设计 38

总结语 42

致谢 43

参考文献 44

关键词 加工工艺 夹具设计

Abstract

The school has designed a LH157QMJ-C left box processes cards and process the first fixture. Question from the trial to go through a similar process to complete normally, as follows: work piece processing line; all the content and processes used in machine tools and processing equipment; parts of test items and test methods; Cutting; the fixed hours of work and workers in the technology. Machine tool fixture is in the machine tools used to determine the correct position of the work piece, and a reliable and fast machine tool work piece clamping attachments. It mainly has the following basic components: positioning components and positioning device, tool and guidance components, clamping device, connected components, specific folders, and other devices.

Keywords Processing craft Jig design

目 录

1 引言 1

2 生产纲领 2

2.1 计算生产纲领决定生产类型 2

2.2 计算生产节拍 3

3 零件的分析 4

3.1 零件的作用方案设计 4

3.2 零件的工艺分析 4

4 工艺规程设计 5

4.1 确定毛坯制造形成 5

4.2 基面的选择 6

4.3 制定工艺路线 7

4.4 机械加工余量、工序尺寸及毛坯尺寸的确定 11

4.5 确定切削用量及基本工时 12

5 夹具的设计 38

5.1 问题的提出 38

5.2 夹具的设计 38

总结语 42

致谢 43

参考文献 44