设计简介

摘 要

本文对变速箱前盖螺纹孔的加工工艺进行了详细的分析,就其孔的加工提出了“一次装夹,单工位加工,达到产品图样的精度要求”的思路。根据这一思路设计了单工位攻丝组合机床。该组合机床由立柱、立柱底座、中间底座、液压滑台、动力箱、多轴箱等组成。本文对各部分的设计进行了详细的计算和论证。在了解组合机床的、基本配置方式、工艺范围、加工精度、经济分析及发展趋势的基础上,在了解组合机床的各通用部件的功能及特点的基础上,进行组合机床的总体设计。所设计的机床用来进行变速箱前盖攻丝,年产量为六万台。要做的具体工作是分析影响组合机床方案制定的主要因素,制定工艺,确定机床配置型式及结构方案,选择切削用量三要素,选择刀具,确定切削力、切削扭矩、切削功率,完成被加工零件工序图、加工示意图、机床联系尺寸图、机床生产率计算卡。

关键词:攻丝组合机床 刀具 三图一卡

ABSTRACT

This paper analyzes the manufacturing process detail of threading holes of a gear-box. The idea is once clamping the work. The accuracy can be satisfied the demand of drawing. According above idea, the machine tool has been designed. This paper presents the design and calculating of each part of this machine tool. This machine tool include the headstock, the column, the Hydraulic slider sets,the power box and the multiple-Spindle box.Learn about the category of modular mother machine, the basical configuration, process range, machining accuracy, economic analysis, development trends. Further, comprehend the function and feature of every general components of the modular mother machine. And then, carry out entire design . The modular mother machine designed is used to thread holes on the gear-box and about sixty thousand pieces needs to be produced.what do we need to do is to analyze the major factors which affect the selection on proposal, to prepare process proposal, to decide the configuration and the cutting force, torque , power and the durability of tools, to complete three graphs and one card.

Keywords :Modular machine tool;Gross assembly drawing;Three graphs and one card

目 录

中文摘要 I

英文摘要 II

第1章 前 言 1

第2章 工艺方案分析 3

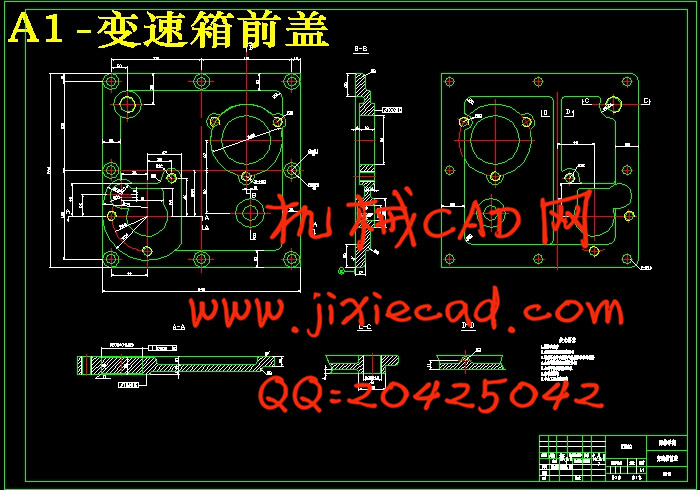

2.1 零件分析 3

2.2定位基准和夹压部位的选择 4

2.3配置形式及结构方案 4

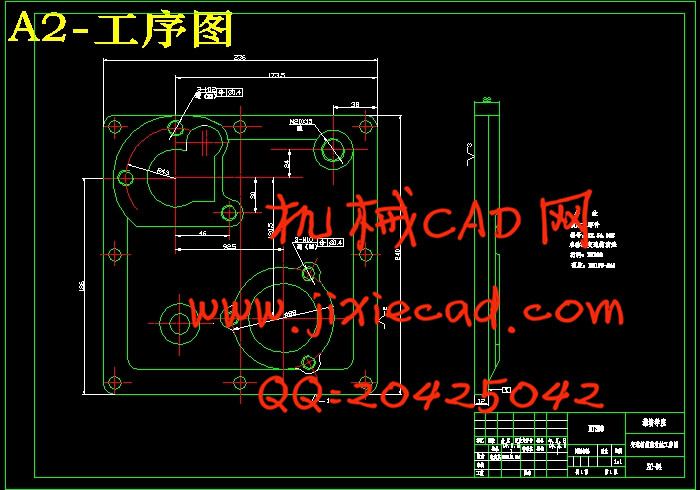

第3章 “三图一卡”的编制 5

3.1加工工序图 5

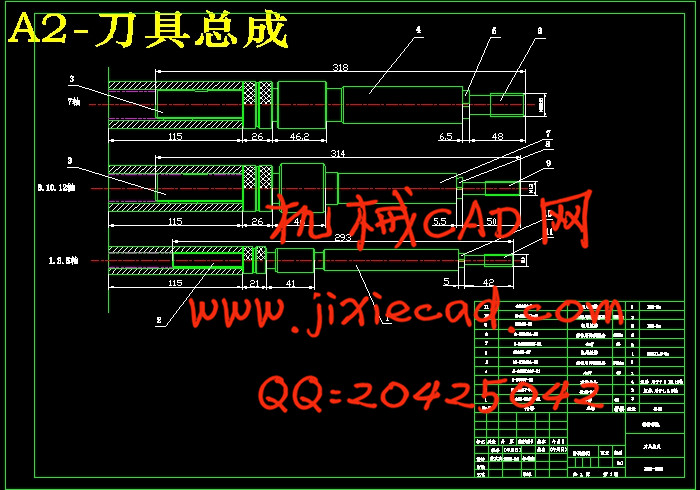

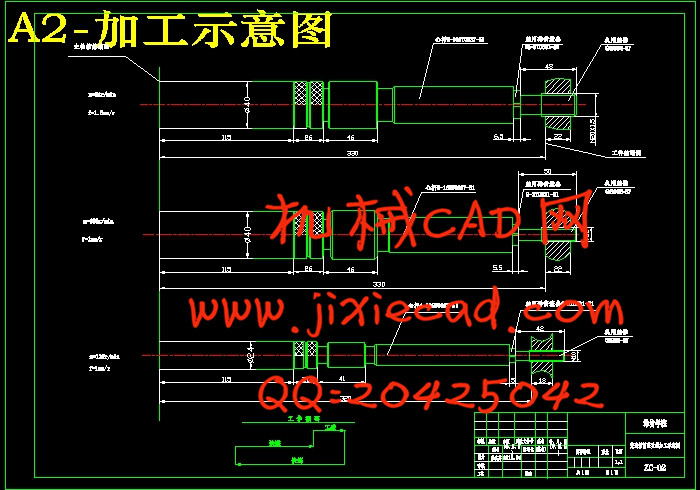

3.2加工示意图 6

3.2.1加工示意图概述 6

3.2.2 绘制加工示意图有关计算 7

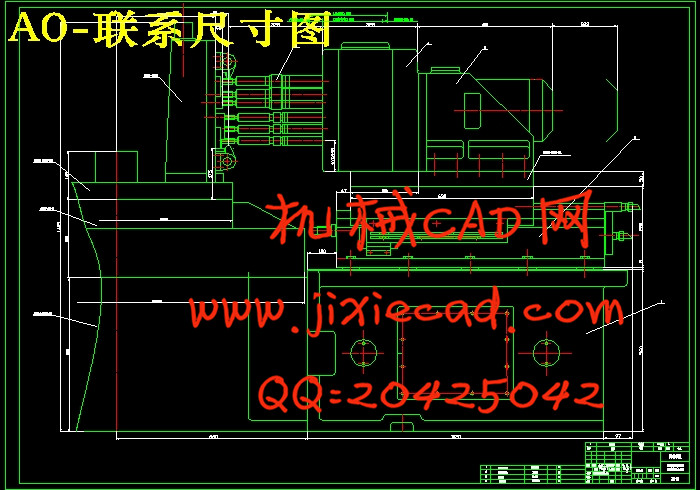

3.3 机床联系尺寸图 9

3.3.1动力滑台的选择 9

3.3.2 动力箱的选用 10

3.3.3确定装料高度 11

3.3.4 确定夹具轮廓尺寸 12

3.3.5 中间底座轮廓尺寸 12

3.3.6初步确定多轴箱轮廓尺寸 12

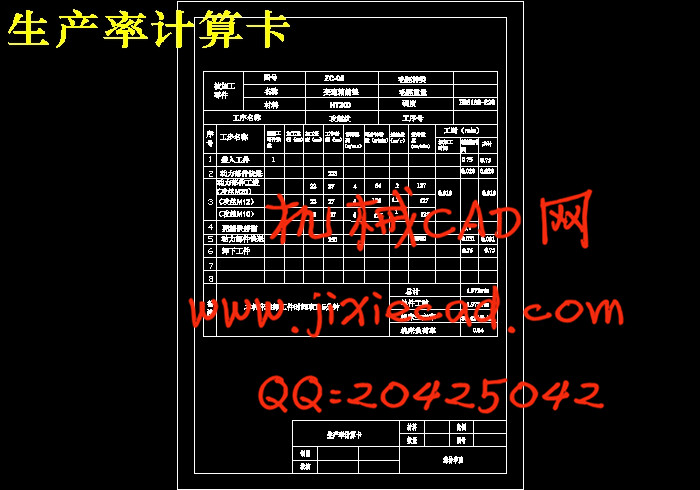

3.4 生产率计算卡 14

结论 16

参考文献 17

致谢 18