设计简介

目 录

1 绪 论... 1

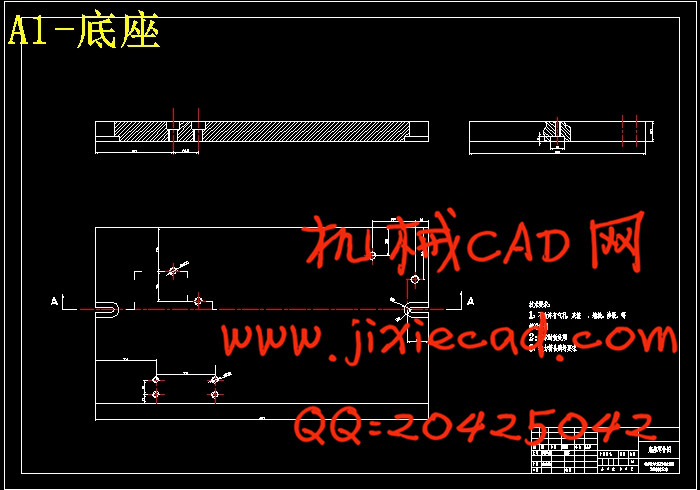

2 拨叉的加工工艺规程设计... 4

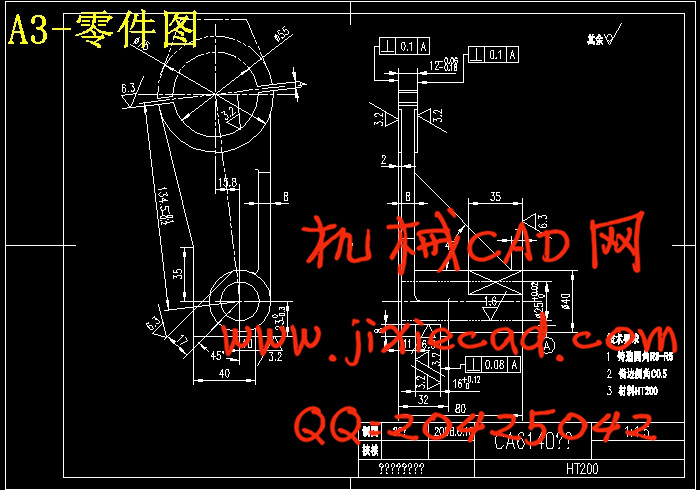

2.1、零件的分析... 4

2.1.1零件的作用... 4

2.1.2零件的工艺分析... 6

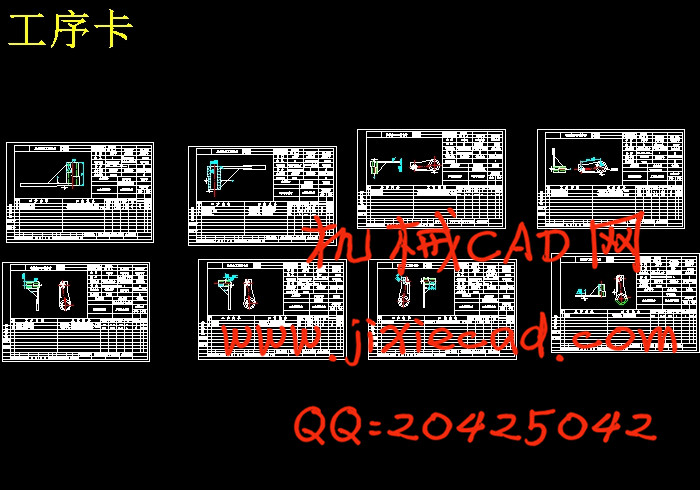

2.2、工艺规程的设计... 8

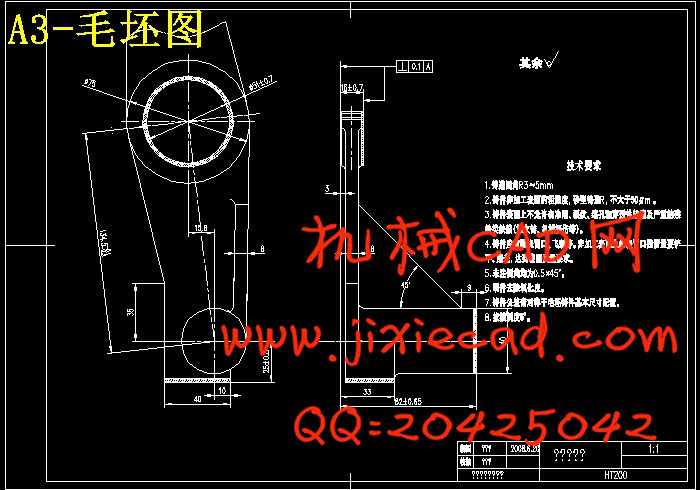

2.2.1确定毛坯的制造形式... 8

2.2.2 基准的选择... 8

2.2.3制定工艺路线... 9

2.2.4 机械加工余量、工序尺寸及毛皮尺寸的确定... 11

2.2.5 确定切削用量及基本工时... 15

确定切削用量及基本工时... 15

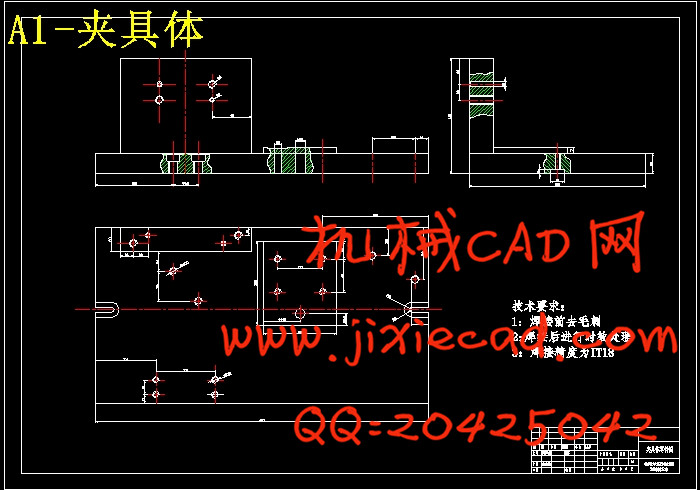

3 专用夹具设计... 31

3.1 机床夹具介绍... 31

3.2 现代机床夹具的发展方向... 31

3.3 机床夹具的定位及夹紧... 31

3.3.1 概述... 32

3.3.2 机床夹具的组成... 32

3.3.3 机床夹具的分类... 33

3.3.4 机床夹具在机械加工中的作用... 34

3.4 工件的装夹方式... 34

3.5基准及其分类... 35

3.6工件的定位... 36

3.7 工件的夹紧... 37

3.7.1 夹紧装置的组成... 37

3.7.2对夹紧装置的基本要求... 37

3.7.3 夹紧力的确定... 38

3.8夹具的设计... 38

4 小结... 40

致 谢... 41

参考文献... 42

附录:... 43

摘 要

此次设计是对拨叉零件的加工工艺和夹具的设计,其零件为锻件,具有体积小,零件复杂的特点。由于面比孔易加工,在制定工艺规程时,就先加工面,再以面为基准来加工其他,其中各工序夹具都采用专用夹具,特别的对于加工大头孔、槽和钻小头斜面小孔的工序中,选一面两销的定位方式,并以操作简单的手动夹紧方式夹紧,其机构设计简单,方便且能满足要求。

关键词 拨叉,加工工艺,专用夹具,设计

Abstract

The design Plectrum parts of the process and fixture design, and its parts forgings, small size, complex parts due to the surface hole Yi processing, the development of the technological procedure, on the first machined surface, and then to the surfaceprocessing as a benchmark to other, in which the process fixture with special fixtures, special process for processing the bulk of holes, slots and slant hole drilling small head positioning, the election of two sells, and simple to operate manual clampingclamping manner, its structure is simple, convenient and can meet the requirements.

Key Word Fork, processing technology, special fixtures,

1 绪 论... 1

2 拨叉的加工工艺规程设计... 4

2.1、零件的分析... 4

2.1.1零件的作用... 4

2.1.2零件的工艺分析... 6

2.2、工艺规程的设计... 8

2.2.1确定毛坯的制造形式... 8

2.2.2 基准的选择... 8

2.2.3制定工艺路线... 9

2.2.4 机械加工余量、工序尺寸及毛皮尺寸的确定... 11

2.2.5

3 专用夹具设计... 31

3.1 机床夹具介绍... 31

3.2 现代机床夹具的发展方向... 31

3.3 机床夹具的定位及夹紧... 31

3.3.1 概述... 32

3.3.2 机床夹具的组成... 32

3.3.3 机床夹具的分类... 33

3.3.4 机床夹具在机械加工中的作用... 34

3.4 工件的装夹方式... 34

3.5基准及其分类... 35

3.6工件的定位... 36

3.7 工件的夹紧... 37

3.7.1 夹紧装置的组成... 37

3.7.2对夹紧装置的基本要求... 37

3.7.3 夹紧力的确定... 38

3.8夹具的设计... 38

4 小结... 40

致 谢... 41

参考文献... 42

附录:... 43

摘 要

此次设计是对拨叉零件的加工工艺和夹具的设计,其零件为锻件,具有体积小,零件复杂的特点。由于面比孔易加工,在制定工艺规程时,就先加工面,再以面为基准来加工其他,其中各工序夹具都采用专用夹具,特别的对于加工大头孔、槽和钻小头斜面小孔的工序中,选一面两销的定位方式,并以操作简单的手动夹紧方式夹紧,其机构设计简单,方便且能满足要求。

关键词 拨叉,加工工艺,专用夹具,设计

Abstract

The design Plectrum parts of the process and fixture design, and its parts forgings, small size, complex parts due to the surface hole Yi processing, the development of the technological procedure, on the first machined surface, and then to the surfaceprocessing as a benchmark to other, in which the process fixture with special fixtures, special process for processing the bulk of holes, slots and slant hole drilling small head positioning, the election of two sells, and simple to operate manual clampingclamping manner, its structure is simple, convenient and can meet the requirements.

Key Word Fork, processing technology, special fixtures,