设计简介

摘要:夹具是机械加工不可缺少的部件,在机床技术向高速、高效、精密、复合、智能、环保方向发展的带动下,夹具技术正朝着高精、高效、模块、组合、通用、经济方向发展。

该毕业设计任务是钻削汽车前拖钩φ17mm、φ13mm、Ra3.2粗糙度的两个通孔。工件以台阶面、侧面和圆弧面为定位基准,工件材料45#钢,数量为中批量。由于该零件属于中批量生产,钻孔精度有要求,因此设计一个专用的钻床夹具,保证零件的加工质量,提高加工效率。

本夹具采用移动式结构是为了工件在一次安装中钻两较大的孔时,可以极为方便地确定钻套对刀具的位置,从而节省找正夹具的时间,减少钻套与刀具的磨损。

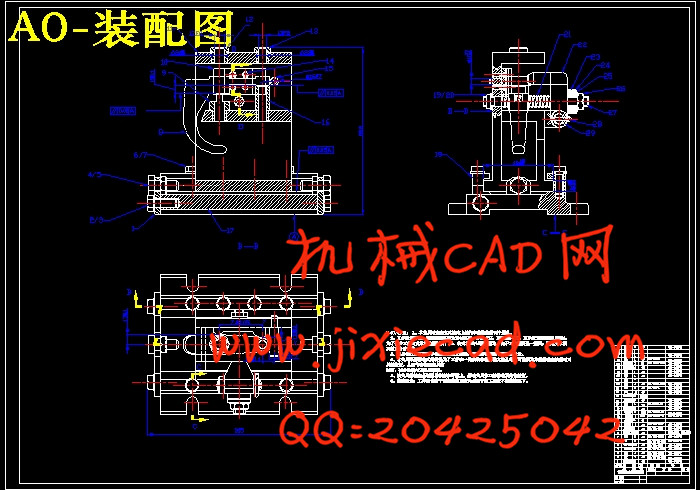

完成钻床夹具的所有设计后,用PRO/E进行三维图形的绘制,首先画装配图,然后从装配图上拆画零件图,标注相关尺寸及技术要求,最后进行论文的撰写、整理、修改完成该毕业设计。

关键词 夹具;钻床夹具;精度;CAD

Title Car ex- design for dragging along hook to drill a hole tongs

Abstract

The tongs is a machine to process an indispensable parts, at tool machine technique to the high speed, efficiently, nicety, compound, intelligence, environmental protection direction development of arouse under, tongs technique just toward the high Jing, efficiently, mold piece, combination, in general use and economic direction development.

The graduation design's task is two bores that drill to drag along to hook φ 17 mms, φ 13 mms and Ra3.2 roughnesses before paring a car.The work piece takes step noodles, on the side and arc noodles as to position basis, the work piece material is 45# steels, amount is medium batch quantity.That spare parts belongs to medium batch quantity production and drills a hole accuracy to contain request, therefore design drilling of an appropriation bed tongs, promise processing of spare parts quality, the exaltation processes an efficiency.

This tongs adoption ambulation type structure for the sake of work piece while drilling two bigger bores in a gearing, can extremely and expediently make sure to drill a set to the position that the knife has, save time of seeking the positive tongs thus, the decrease drills set and knife to have of wear away.

The completion after drilling all designs of bed tongs carries on drawing of two-dimensional sketch with AutoCAD, the painting assembles diagram first, then from assemble the diagram up dismantle painting spare parts diagram and mark related size and technique request, finally carrying on a compose, tidying up of thesis and modifying completion should graduate a design.

Keywords Fixture; drilling fixture; accuracy; CAD

目 录

1 绪论 4

1.1 机床夹具的概述 4

1.2 机床夹具的分类 4

1.3 机床夹具的组成 5

1.4机床夹具在机械加工中的作用 5

1.5机床夹具的现状及发展方向 6

2 专用夹具的设计方法 7

2.1专用夹具的基本要求和设计步骤 7

2.1.1对专用夹具的基本要求 7

2.1.2 专用夹具设计步骤 7

2.2 夹具体的设计 8

2.2.1对夹具体的要求 8

2.2.2 夹具体毛坯的类型 10

3 钻床夹具的总体设计 11

3.1 设计任务 11

3.2 夹具的设计步骤 12

3.3钻床夹具的设计 14

4 钻床夹具的详细设计 16

4.1零件的工艺性分析 16

4.2 确定夹具类型 16

4.3 拟订定位方案和选择定位元件 16

4.4 确定夹紧方案 16

4.5 加工方法和步骤: 16

4.5.1零件加工工艺过程: 16

4.5.2设计任务 16

4.6 夹具设计方法和步骤 17

4.6.1夹具类型的确定 17

4.6.2选择定位元件 17

4.6.3 定位误差分析计算 18

4.6.4 夹紧装置的设计 18

4.6.5 导向装置的设计及其他装置结构、夹具体的确定 19

4.6.6 绘制夹具结构图 20

4.6.7确定夹具技术要求和有关尺寸,公差配合 20

4.6.8 夹具精度分析与计算 20

4.6.9 夹具零部件的设计与选用 21

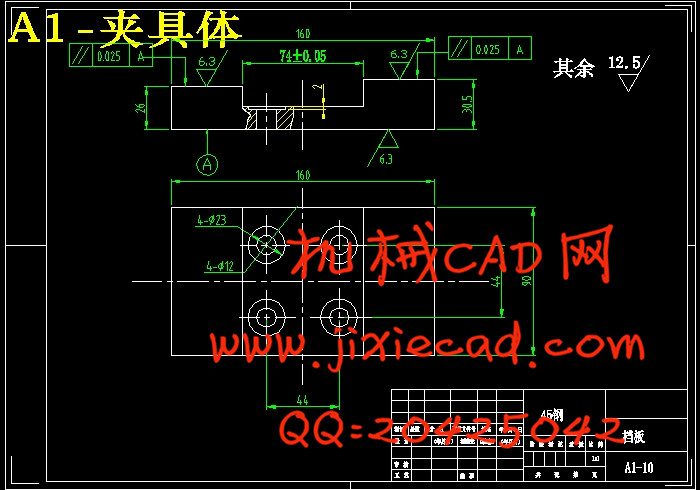

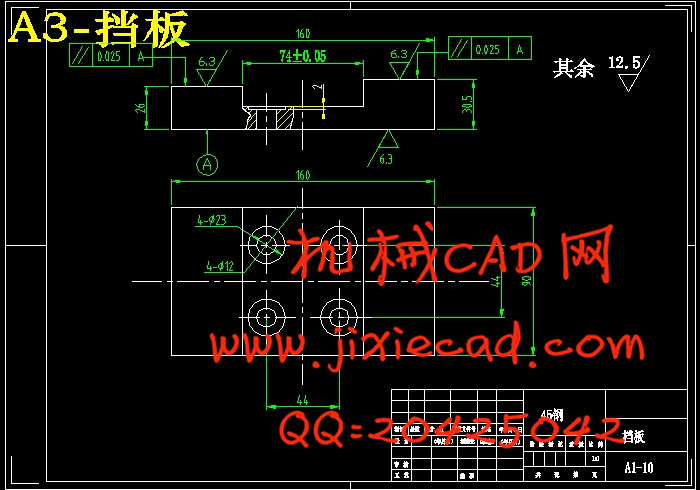

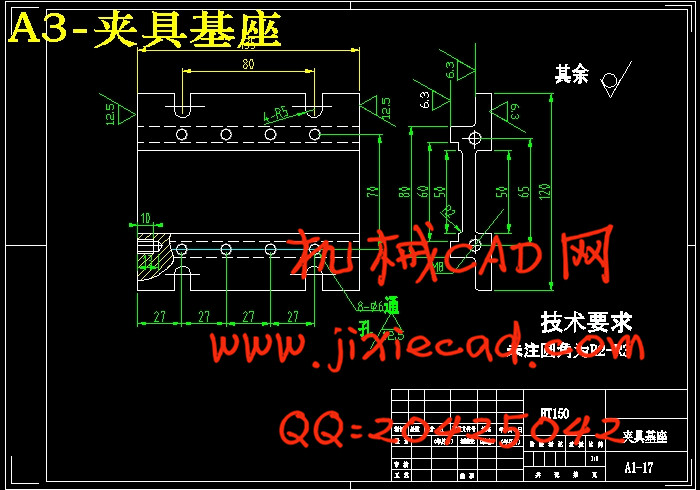

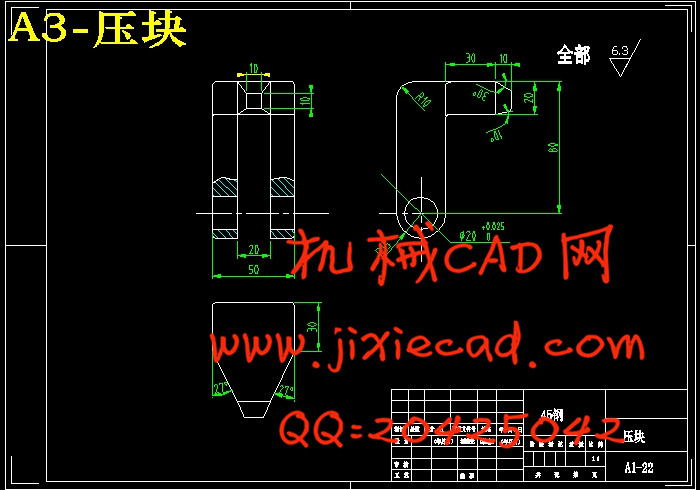

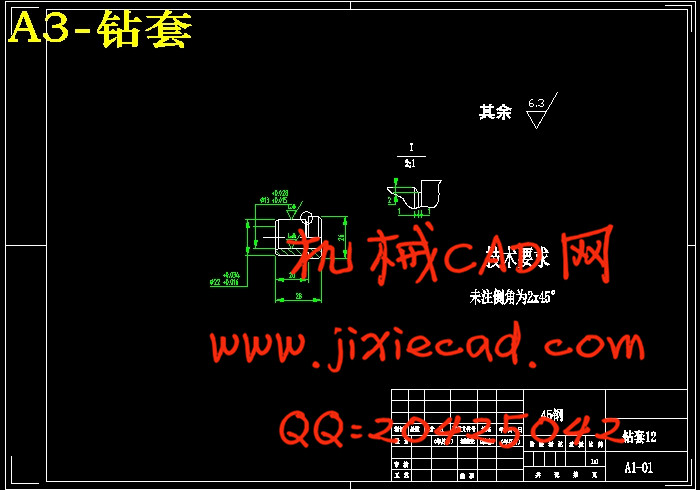

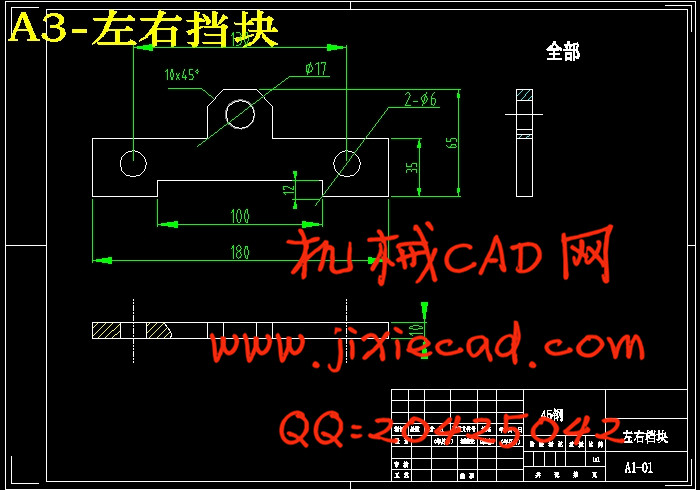

4.6.10 绘制夹具非标准零件(见图) 22

结论 23

致谢 24

参考文献 25

该毕业设计任务是钻削汽车前拖钩φ17mm、φ13mm、Ra3.2粗糙度的两个通孔。工件以台阶面、侧面和圆弧面为定位基准,工件材料45#钢,数量为中批量。由于该零件属于中批量生产,钻孔精度有要求,因此设计一个专用的钻床夹具,保证零件的加工质量,提高加工效率。

本夹具采用移动式结构是为了工件在一次安装中钻两较大的孔时,可以极为方便地确定钻套对刀具的位置,从而节省找正夹具的时间,减少钻套与刀具的磨损。

完成钻床夹具的所有设计后,用PRO/E进行三维图形的绘制,首先画装配图,然后从装配图上拆画零件图,标注相关尺寸及技术要求,最后进行论文的撰写、整理、修改完成该毕业设计。

关键词 夹具;钻床夹具;精度;CAD

Title Car ex- design for dragging along hook to drill a hole tongs

Abstract

The tongs is a machine to process an indispensable parts, at tool machine technique to the high speed, efficiently, nicety, compound, intelligence, environmental protection direction development of arouse under, tongs technique just toward the high Jing, efficiently, mold piece, combination, in general use and economic direction development.

The graduation design's task is two bores that drill to drag along to hook φ 17 mms, φ 13 mms and Ra3.2 roughnesses before paring a car.The work piece takes step noodles, on the side and arc noodles as to position basis, the work piece material is 45# steels, amount is medium batch quantity.That spare parts belongs to medium batch quantity production and drills a hole accuracy to contain request, therefore design drilling of an appropriation bed tongs, promise processing of spare parts quality, the exaltation processes an efficiency.

This tongs adoption ambulation type structure for the sake of work piece while drilling two bigger bores in a gearing, can extremely and expediently make sure to drill a set to the position that the knife has, save time of seeking the positive tongs thus, the decrease drills set and knife to have of wear away.

The completion after drilling all designs of bed tongs carries on drawing of two-dimensional sketch with AutoCAD, the painting assembles diagram first, then from assemble the diagram up dismantle painting spare parts diagram and mark related size and technique request, finally carrying on a compose, tidying up of thesis and modifying completion should graduate a design.

Keywords Fixture; drilling fixture; accuracy; CAD

目 录

1 绪论 4

1.1 机床夹具的概述 4

1.2 机床夹具的分类 4

1.3 机床夹具的组成 5

1.4机床夹具在机械加工中的作用 5

1.5机床夹具的现状及发展方向 6

2 专用夹具的设计方法 7

2.1专用夹具的基本要求和设计步骤 7

2.1.1对专用夹具的基本要求 7

2.1.2 专用夹具设计步骤 7

2.2 夹具体的设计 8

2.2.1对夹具体的要求 8

2.2.2 夹具体毛坯的类型 10

3 钻床夹具的总体设计 11

3.1 设计任务 11

3.2 夹具的设计步骤 12

3.3钻床夹具的设计 14

4 钻床夹具的详细设计 16

4.1零件的工艺性分析 16

4.2 确定夹具类型 16

4.3 拟订定位方案和选择定位元件 16

4.4 确定夹紧方案 16

4.5 加工方法和步骤: 16

4.5.1零件加工工艺过程: 16

4.5.2设计任务 16

4.6 夹具设计方法和步骤 17

4.6.1夹具类型的确定 17

4.6.2选择定位元件 17

4.6.3 定位误差分析计算 18

4.6.4 夹紧装置的设计 18

4.6.5 导向装置的设计及其他装置结构、夹具体的确定 19

4.6.6 绘制夹具结构图 20

4.6.7确定夹具技术要求和有关尺寸,公差配合 20

4.6.8 夹具精度分析与计算 20

4.6.9 夹具零部件的设计与选用 21

4.6.10 绘制夹具非标准零件(见图) 22

结论 23

致谢 24

参考文献 25