设计简介

摘 要

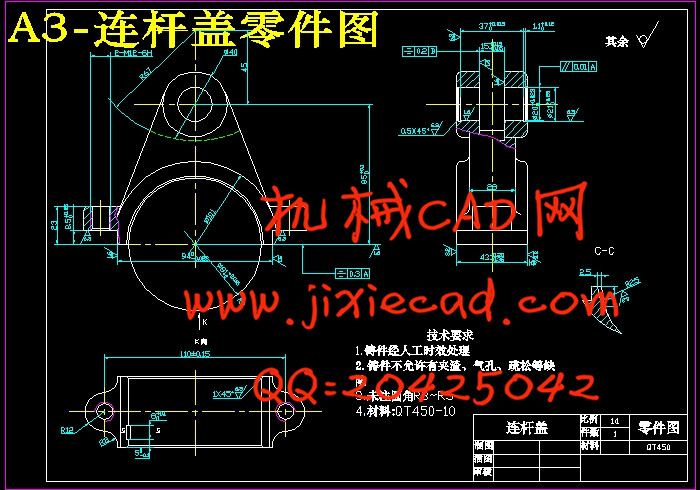

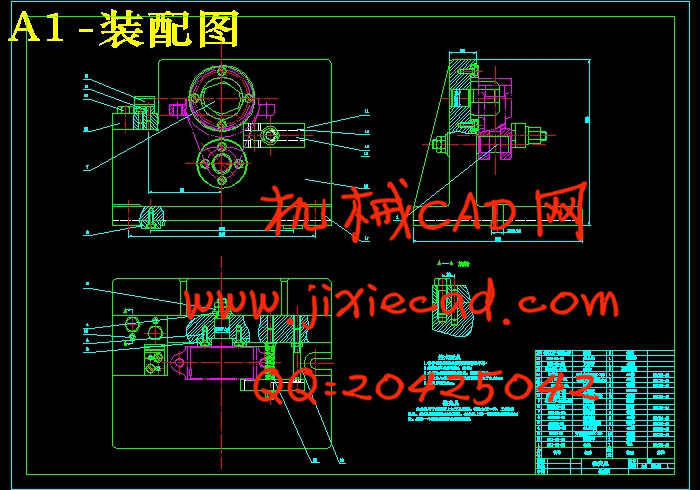

我设计的是基于连杆盖零件的加工工艺和自设计一些工序的专用夹具设计。平面及孔系是这个零件的主要加工表面。通常情况下是这样做的。平面的加工精度要比孔系的加工精度更加容易掌控制。由此我们可以得出。我的设计按先面后孔的顺序。基准选择以连杆盖的输入轴和输出轴的支承孔作为粗基准。以底面与两个工艺孔作为精基准。我在此采用坐标法镗孔对支承孔系作出加工。组合机床贯穿于设计的整个加工性过程。我选用的专用夹具,它的结构可以不必自锁,由此我们可以得出生产效率较高,我的设计适合大数量、流水线上的加工。

关键词:连杆盖类零件;工艺;夹具;

ABSTRACT

My design is the chemical pipe parts machining process and special fixture design process design based on self. The plane and a series of hole is the main processing surface of the part. As is usually the case to do so. The accuracy of the flat surface to machining accuracy than holes easier control. We can draw. My design on the surface after the first hole sequence. Datum selection to the supporting hole seat angle gear input shaft and the output shaft as a rough benchmark. Main processes arrangements to support holes for positioning and processing the top plane.The bottom surface and the two holes as a precision technology base. I hereby use coordinate boring to make processing of bearing hole. Combination machine tool throughout the machining process design. Special fixture I use, its structure can not be locked, so we can get high production efficiency, I design suitable for processing large quantity, on the assembly line.

Keywords: chemical pipe parts; technology; fixture;

目 录

摘 要 II我设计的是基于连杆盖零件的加工工艺和自设计一些工序的专用夹具设计。平面及孔系是这个零件的主要加工表面。通常情况下是这样做的。平面的加工精度要比孔系的加工精度更加容易掌控制。由此我们可以得出。我的设计按先面后孔的顺序。基准选择以连杆盖的输入轴和输出轴的支承孔作为粗基准。以底面与两个工艺孔作为精基准。我在此采用坐标法镗孔对支承孔系作出加工。组合机床贯穿于设计的整个加工性过程。我选用的专用夹具,它的结构可以不必自锁,由此我们可以得出生产效率较高,我的设计适合大数量、流水线上的加工。

关键词:连杆盖类零件;工艺;夹具;

ABSTRACT

My design is the chemical pipe parts machining process and special fixture design process design based on self. The plane and a series of hole is the main processing surface of the part. As is usually the case to do so. The accuracy of the flat surface to machining accuracy than holes easier control. We can draw. My design on the surface after the first hole sequence. Datum selection to the supporting hole seat angle gear input shaft and the output shaft as a rough benchmark. Main processes arrangements to support holes for positioning and processing the top plane.The bottom surface and the two holes as a precision technology base. I hereby use coordinate boring to make processing of bearing hole. Combination machine tool throughout the machining process design. Special fixture I use, its structure can not be locked, so we can get high production efficiency, I design suitable for processing large quantity, on the assembly line.

Keywords: chemical pipe parts; technology; fixture;

目 录

ABSTRACT III

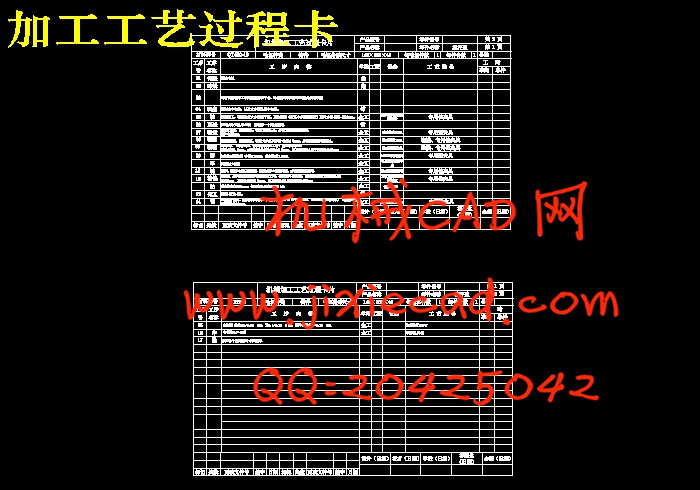

第1章 机械加工工艺规程设计 2

1.1 零件的分析 2

1.1.1 零件的作用 2

1.1.2 零件的工艺分析 2

1.2 连杆盖问题和工艺过程措施 3

1.2.1 孔和平面的加工顺序 3

1.2.2 孔系加工方案选择 3

1.3 连杆盖加工定位基准的选择 3

1.3.1 粗基准的选择 3

1.3.2 精基准的选择 3

1.4 连杆盖加工主要工序安排 4

1.5 机械加工余量数值、工序尺寸及毛坯尺寸的确定 7

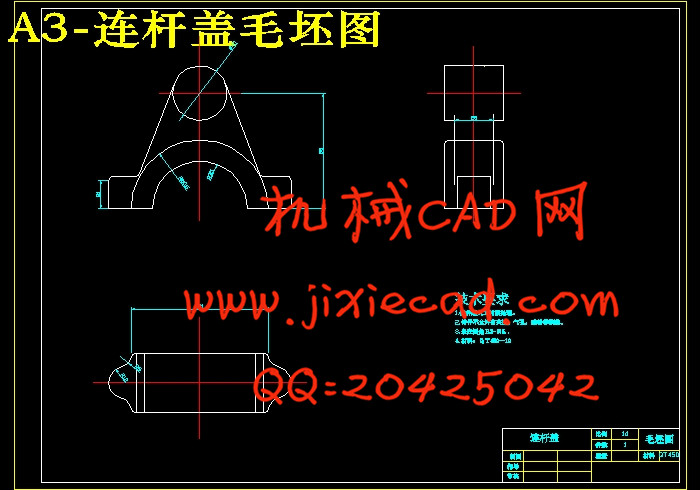

1.6 毛坯种类的选择 8

1.7 选择加工设备和工艺装备 8

1.7.1 机床选用 8

1.7.2 选择刀具 8

1.7.3 选择量具 8

1.8 机械加工余量、工序尺寸及毛坯尺寸的确定 8

1.9确定切削用量及基本工时【机动时间】 10

1.10 时间给定额度计算及生产安排 19

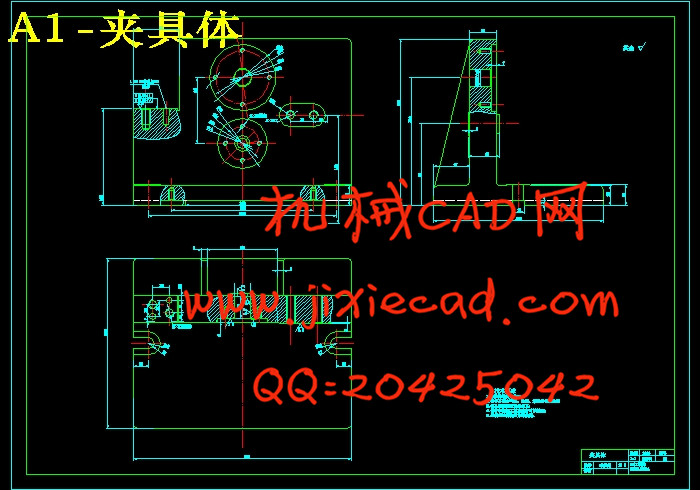

第2章 铣结合面夹具设计 21

2.1研究原始质料 21

2.2定位基准的选择 21

2.3 切削力及夹紧分析计算 21

2.4 误差分析与计算 22

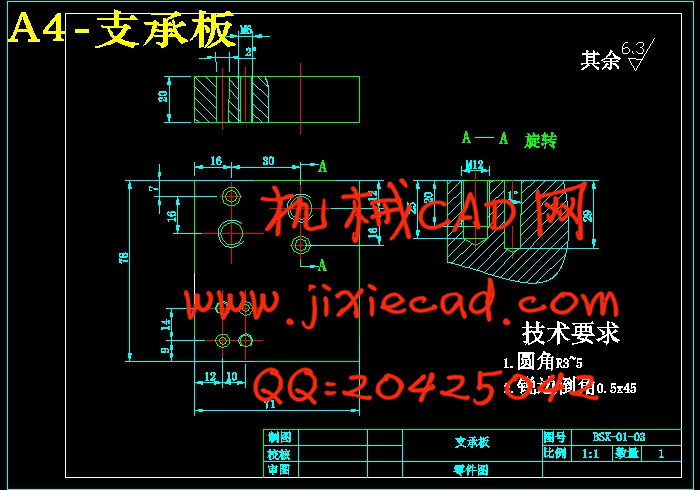

2.5 零、部件的设计与选用 23

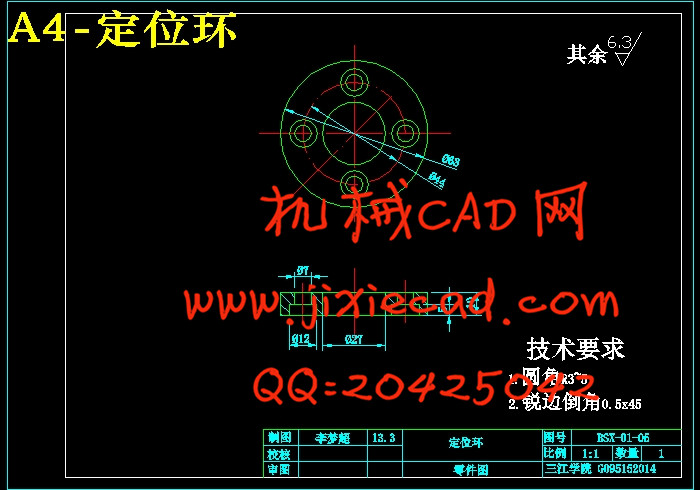

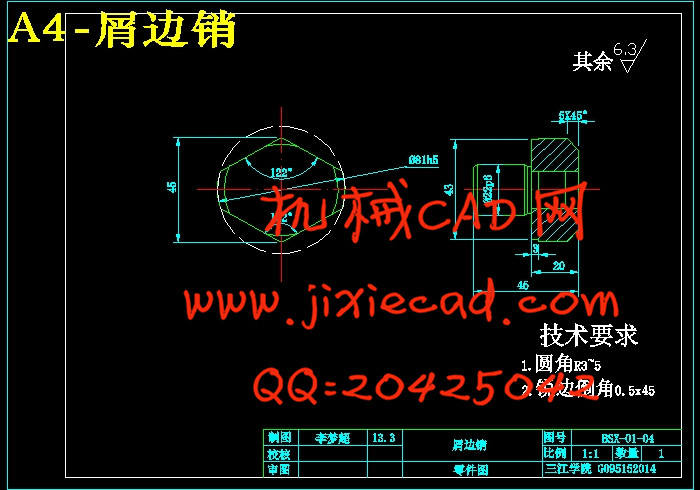

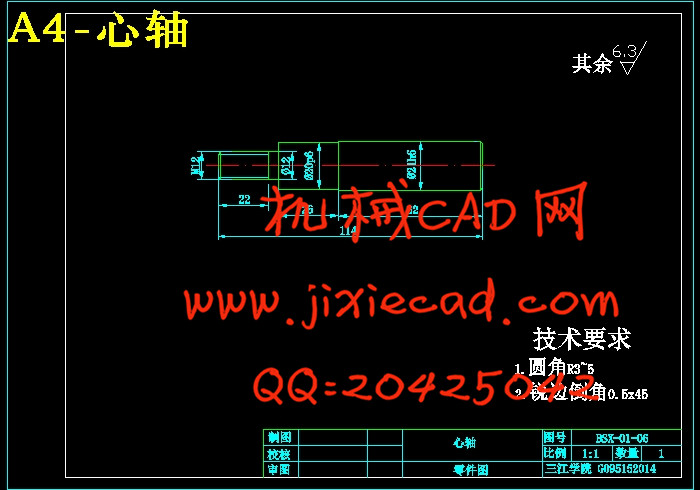

2.5.1定位销选用 23

2.5.2 定向键与对刀装置设计 24

2.6 夹具设计及操作的简要说明 25

总 结 27

参考文献 28

致 谢 29