设计简介

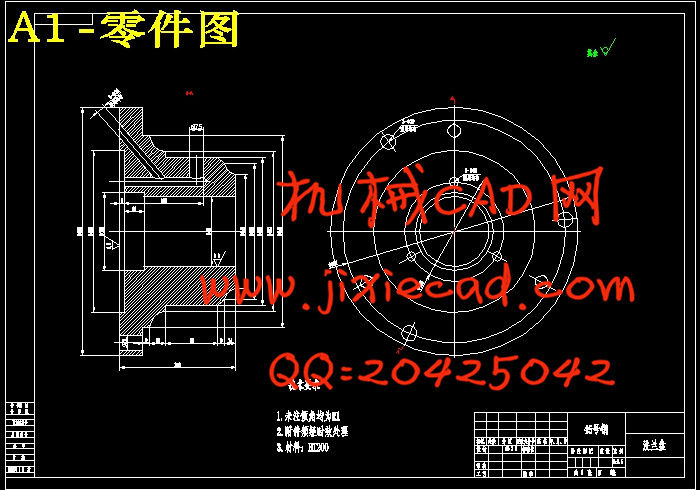

法兰盘只是一个统称,通常是指在一个类似盘状的金属体的周边开上几个固定用的孔,用于连接其它东西。法兰联接在机械上应用很广泛,所以样子也千奇百怪的。本文主要是针对CA6140车床法兰盘的加工工艺以及主要孔的工艺装备设计进行论述。通过本文可以了解该法兰盘的构造和它的整个加工过程以及其在加工过程中的注意事项。其次从侧面了解到夹具设计的主要程序。最后还有针对该零件加工的组合机床设计。从各组件的选择到加工参数的确定反映了目前该零件的市场价值以及发展前景。

关键词 法兰盘 加工效率 切削用量 钻套

Flange is a generic name,usually refers to that in a similar discoid metal body surrounding the opening of the hole with a few fixed, it’s used to connect other things. Flange connection in a wide range of application of mechanical, So it looks strange. This article is mainly directed against flange CA6140 lathe processing technology and the main hole of the process and equipment design on. You can learn flange of the entire structure and its process and notes through this article. Second through this question that you can from the side of the main procedures for fixture design. Finally, there are parts for the processing of a combination of machine tool design. From the choice of components to determine the processing parameters, this article reflects the current market value of the parts, as well as prospects for development.

Keywords Flange Processing efficiency Cutting Drill sets

目 录

1 引言 1

1.1 设计的目的 2

1.2 法兰盘工艺设计的概况 3

2 生产纲领和生产类型 4

3 法兰盘零件分析 5

3.1 零件工艺分析 5

3.2 零件的作用 5

4 工艺规程的设计 6

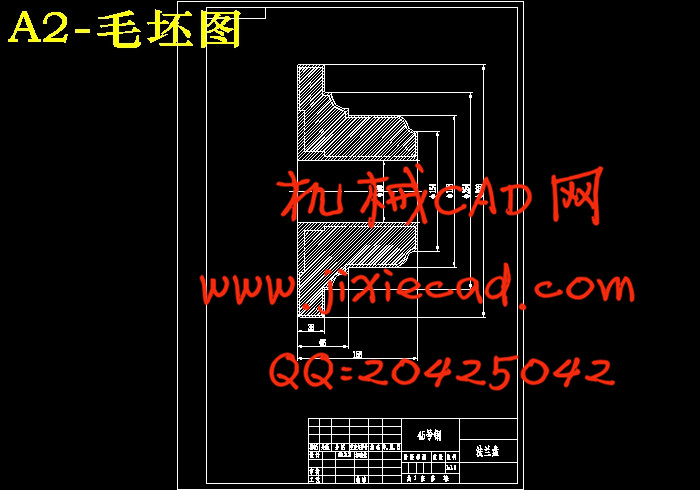

4.1 确定毛坯的制造形式 6

4.2 毛坯的选择及制备 6

4.3 工艺路线的选择 7

4.4 粗加工时切削用量的选择原则 9

4.5 精加工时切削用量的选择原则 10

5 加工工序的确定 10

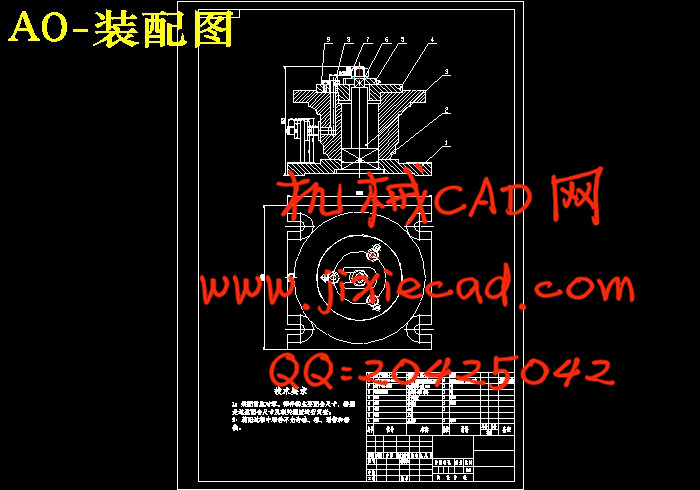

6 夹具设计 14

6.1 定位基准的选择 15

6.2 问题的提出 15

6.3 定位误差分析 16

6.4 夹具设计及操作的简要说明 16

6.5 机床夹具的基本组成部分 16

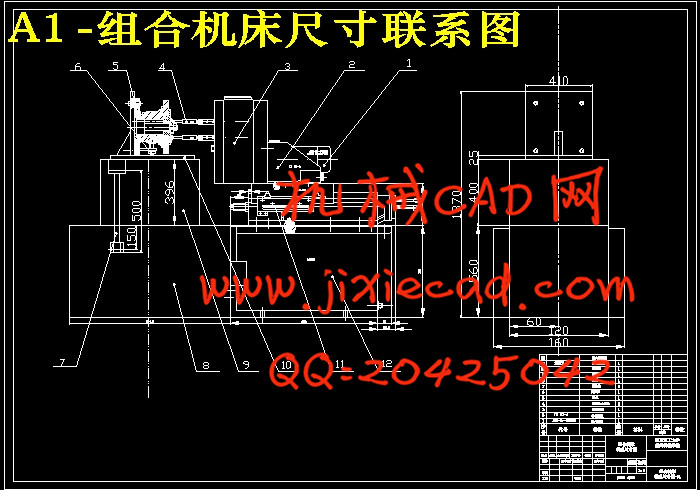

7 组合机床设计 18

7.1 组合机床总体设计----“三图一卡” 18

结束语 23

致 谢 24

参考资料 25

关键词 法兰盘 加工效率 切削用量 钻套

Flange is a generic name,usually refers to that in a similar discoid metal body surrounding the opening of the hole with a few fixed, it’s used to connect other things. Flange connection in a wide range of application of mechanical, So it looks strange. This article is mainly directed against flange CA6140 lathe processing technology and the main hole of the process and equipment design on. You can learn flange of the entire structure and its process and notes through this article. Second through this question that you can from the side of the main procedures for fixture design. Finally, there are parts for the processing of a combination of machine tool design. From the choice of components to determine the processing parameters, this article reflects the current market value of the parts, as well as prospects for development.

Keywords Flange Processing efficiency Cutting Drill sets

目 录

1 引言 1

1.1 设计的目的 2

1.2 法兰盘工艺设计的概况 3

2 生产纲领和生产类型 4

3 法兰盘零件分析 5

3.1 零件工艺分析 5

3.2 零件的作用 5

4 工艺规程的设计 6

4.1 确定毛坯的制造形式 6

4.2 毛坯的选择及制备 6

4.3 工艺路线的选择 7

4.4 粗加工时切削用量的选择原则 9

4.5 精加工时切削用量的选择原则 10

5 加工工序的确定 10

6 夹具设计 14

6.1 定位基准的选择 15

6.2 问题的提出 15

6.3 定位误差分析 16

6.4 夹具设计及操作的简要说明 16

6.5 机床夹具的基本组成部分 16

7 组合机床设计 18

7.1 组合机床总体设计----“三图一卡” 18

结束语 23

致 谢 24

参考资料 25