设计简介

摘 要

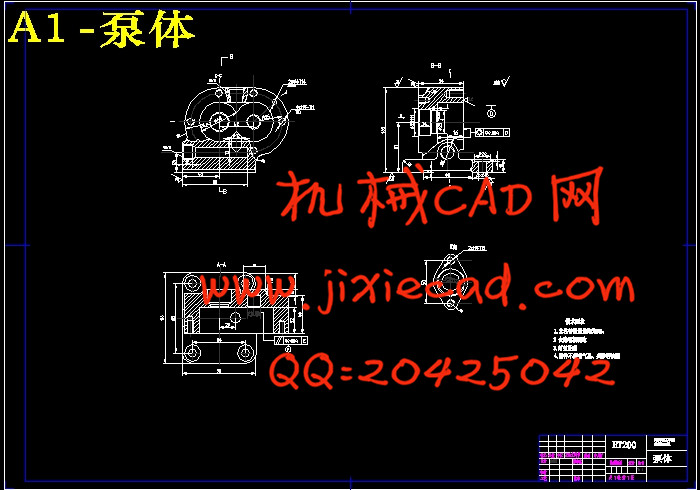

泵依靠旋转叶轮对液体的作用把原动机的机械能传递给液体。由于泵的作用液体从叶轮进口流向出口的过程中,其速度能和压力能都得到增加,被叶轮排出的液体经过压出室,大部分速度能转换成压力能,然后沿排出管路输送出去,这时,叶轮进口处因液体的排出而形成真空或低压,吸水池中的液体在液面压力(大气压)的作用下,被压入叶轮的进口,于是,旋转着的叶轮就连续不断地吸入和排出液体。

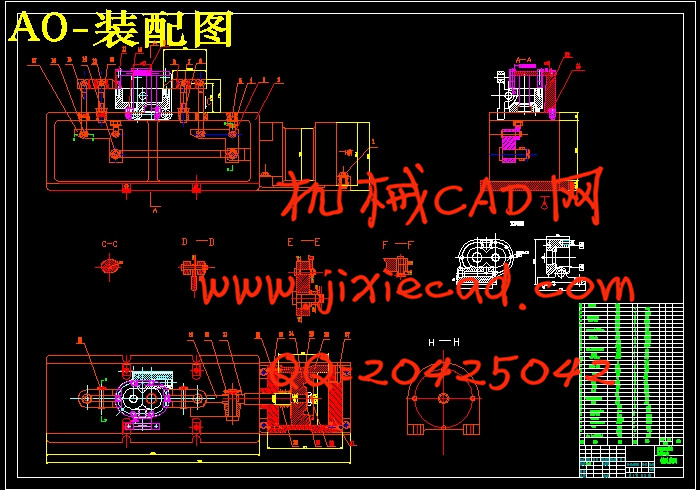

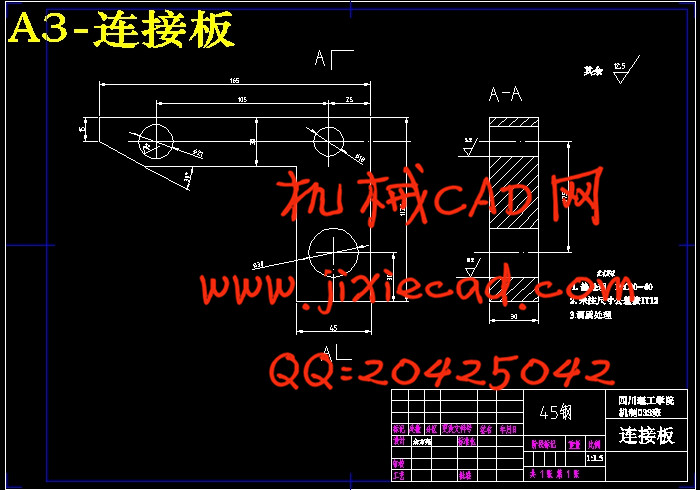

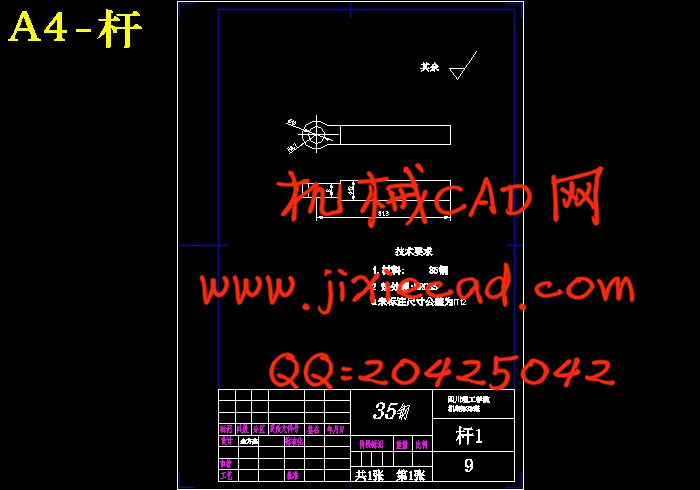

本次设计了泵体工艺规程及钻孔夹具的基本过程,包括五章:第一章,绪论;第二章,工艺设计;第三章,工序设计;第四章,夹具设计;第五章,设计总结。

以便清楚明了表达泵体在生产中的应用、机械加工工艺过程及机床夹具设计的基本步骤,文中插入了相关表格和简图,详细叙述了泵体加工定位基准面、工序尺寸的计算过程,夹具元件设计等。

关键词:毛坯余量、工艺、工序、切削用量、夹具、定位、误差。

ABSTRCT

The pump depends the effect which revolving impeller works on liquid in transferring mechanical energy to liquid. Owing to pump, when the liquid flow out of the impeller, its speed energy and stress energy both develop much, the liquid debarred by the impeller , most speed energy is transferred to stress energy ,and then it is transported through pipeline .At this moment ,the entry of the impeller become vacuum or low-pressure , hydraulic pressure (pneumatic pressure ) effect on the liquid in the absorbing pool, and the liquid is pulled into the entry of the impeller , so ,the rotating impeller continuous inhalants and Drainage liquid.

This time has designed the pump body's processing craft and the pump design unit process which including five chapters, first chapter, exordium; The second chapter, technics design; The third chapter, working procedure design; The fourth chapter,jig design and the last chapter,design conclusion.

In order to understand clearly expresses the pump in production application, machine-finishing technological process and the engine bed jig design basic step, in the article has inserted the related form and the diagram, narrated the pump to process the localization reduced plane, the working procedure size computational process in detail, the jig cell design and so on.

Keywords: rough allowance, working procedure, techniques, cutting dosage, jig allocation, error

泵依靠旋转叶轮对液体的作用把原动机的机械能传递给液体。由于泵的作用液体从叶轮进口流向出口的过程中,其速度能和压力能都得到增加,被叶轮排出的液体经过压出室,大部分速度能转换成压力能,然后沿排出管路输送出去,这时,叶轮进口处因液体的排出而形成真空或低压,吸水池中的液体在液面压力(大气压)的作用下,被压入叶轮的进口,于是,旋转着的叶轮就连续不断地吸入和排出液体。

本次设计了泵体工艺规程及钻孔夹具的基本过程,包括五章:第一章,绪论;第二章,工艺设计;第三章,工序设计;第四章,夹具设计;第五章,设计总结。

以便清楚明了表达泵体在生产中的应用、机械加工工艺过程及机床夹具设计的基本步骤,文中插入了相关表格和简图,详细叙述了泵体加工定位基准面、工序尺寸的计算过程,夹具元件设计等。

关键词:毛坯余量、工艺、工序、切削用量、夹具、定位、误差。

ABSTRCT

The pump depends the effect which revolving impeller works on liquid in transferring mechanical energy to liquid. Owing to pump, when the liquid flow out of the impeller, its speed energy and stress energy both develop much, the liquid debarred by the impeller , most speed energy is transferred to stress energy ,and then it is transported through pipeline .At this moment ,the entry of the impeller become vacuum or low-pressure , hydraulic pressure (pneumatic pressure ) effect on the liquid in the absorbing pool, and the liquid is pulled into the entry of the impeller , so ,the rotating impeller continuous inhalants and Drainage liquid.

This time has designed the pump body's processing craft and the pump design unit process which including five chapters, first chapter, exordium; The second chapter, technics design; The third chapter, working procedure design; The fourth chapter,jig design and the last chapter,design conclusion.

In order to understand clearly expresses the pump in production application, machine-finishing technological process and the engine bed jig design basic step, in the article has inserted the related form and the diagram, narrated the pump to process the localization reduced plane, the working procedure size computational process in detail, the jig cell design and so on.

Keywords: rough allowance, working procedure, techniques, cutting dosage, jig allocation, error

目录

中文摘要·····························································Ⅰ

英文摘要·····························································Ⅱ

第一章 绪论··························································4

第二章 工艺设计························································5

2.1 零件分析···························································5

2.1.1 零件的作用·······················································5

2.1.2 零件的工艺分析···················································5

2.2 毛坯的选择与设计加工余量的确定·····································5

2.2.1确定毛坯制造形式···············································5

2.2.2 基准的选择·····················································6

2.3 工艺规程的设计·····················································6

2.3.1制定工艺路线···················································6

2.3.2工艺方案的比较和分析···········································10

第三章 工序设计························································12

3.1 工序尺寸与毛坯尺寸的确定··········································12

3.2 确定切削用量及时间定额·············································13

3.2.1 工序Ⅲ:铣端面φ70mm···········································13

3.2.2 工序Ⅶ:镗2-φ48H8孔···········································15

3.2.3 工序Ⅺ:钻6-M8-7H孔············································15

第四章 夹具设计························································18

4.1夹具的设计·······················································18

4.1.1 夹紧方案及夹紧元件选择·······································18

4.1.2 导向装置及导向元件选择·······································19

4.2切削力与夹紧力的计算··············································19

4.2.1 切削力的计算··················································19

4.2.2 夹紧力的计算··················································20

4.2.3 气压系统主要参数的计算········································18

4.2.3.1 活塞式气缸·················································18

4.2.3.2 气缸的密封·················································22

4.3 夹具零件·························································22

4.3.1 固定式定位销··················································22

4.3.2 螺栓··························································24

4.3.3 螺母··························································24

4.3.4 垫圈··························································25

4.3.5 镗套··························································26

4.3.6 标准型弹簧垫圈················································26

4.4 定位误差的分析····················································27

4.5 夹具设计与操作的简要说明··········································29

4.5.1 夹具的组成····················································29

4.5.2 夹具的操作····················································30

第五章 设计总结······················································31

参考文献······························································32

致谢··································································33

中文摘要·····························································Ⅰ

英文摘要·····························································Ⅱ

第一章 绪论··························································4

第二章 工艺设计························································5

2.1 零件分析···························································5

2.1.1 零件的作用·······················································5

2.1.2 零件的工艺分析···················································5

2.2 毛坯的选择与设计加工余量的确定·····································5

2.2.1确定毛坯制造形式···············································5

2.2.2 基准的选择·····················································6

2.3 工艺规程的设计·····················································6

2.3.1制定工艺路线···················································6

2.3.2工艺方案的比较和分析···········································10

第三章 工序设计························································12

3.1 工序尺寸与毛坯尺寸的确定··········································12

3.2 确定切削用量及时间定额·············································13

3.2.1 工序Ⅲ:铣端面φ70mm···········································13

3.2.2 工序Ⅶ:镗2-φ48H8孔···········································15

3.2.3 工序Ⅺ:钻6-M8-7H孔············································15

第四章 夹具设计························································18

4.1夹具的设计·······················································18

4.1.1 夹紧方案及夹紧元件选择·······································18

4.1.2 导向装置及导向元件选择·······································19

4.2切削力与夹紧力的计算··············································19

4.2.1 切削力的计算··················································19

4.2.2 夹紧力的计算··················································20

4.2.3 气压系统主要参数的计算········································18

4.2.3.1 活塞式气缸·················································18

4.2.3.2 气缸的密封·················································22

4.3 夹具零件·························································22

4.3.1 固定式定位销··················································22

4.3.2 螺栓··························································24

4.3.3 螺母··························································24

4.3.4 垫圈··························································25

4.3.5 镗套··························································26

4.3.6 标准型弹簧垫圈················································26

4.4 定位误差的分析····················································27

4.5 夹具设计与操作的简要说明··········································29

4.5.1 夹具的组成····················································29

4.5.2 夹具的操作····················································30

第五章 设计总结······················································31

参考文献······························································32

致谢··································································33