设计简介

摘 要

尾架体是车床上的重要的部件之一,是车床上用以支撑轴类零件车削加工和实施钻孔的主要车床附件。本文针对某类给定的尾架体进行了加工工艺与工装的设计,完成了以下工作:

1、概述了尾架体的技术和现状发展;

2、对尾架体进行了工艺分析;

3、编制了尾架体的工艺规程,完成了其工序卡的设计;

4、针对工艺中的两个重要工序,设计完成了一套镗孔夹具和一套钻孔夹具,包括定位元件,夹紧机构、对刀块、夹具体的设计并分析了定位误差。

关键词 设计;工装;工艺;尾架体

尾架体是车床上的重要的部件之一,是车床上用以支撑轴类零件车削加工和实施钻孔的主要车床附件。本文针对某类给定的尾架体进行了加工工艺与工装的设计,完成了以下工作:

1、概述了尾架体的技术和现状发展;

2、对尾架体进行了工艺分析;

3、编制了尾架体的工艺规程,完成了其工序卡的设计;

4、针对工艺中的两个重要工序,设计完成了一套镗孔夹具和一套钻孔夹具,包括定位元件,夹紧机构、对刀块、夹具体的设计并分析了定位误差。

关键词 设计;工装;工艺;尾架体

Abstract

stalk spare parts, the car pares to process the main lather enclosure that drills a hole with implementation.This text aims at a certain the tail body giving certainly carried on to process the design that craft and work pack and completed once work:

1.All said a tail the technique and present condition development of the body;

2.Carried on craft analysis to the tail body,

3.Drew up a tail body of craft regulations, completed the design of its work preface card;

4.Aim at a craft in of some important work preface, designed to complete a set of Xian slot tongs, including fixed position component, clipped tight organization, to the knife piece, clip a concrete design and analyzed a fixed position error margin.

Keywords:design;clamping;craft;tailstock

目 录stalk spare parts, the car pares to process the main lather enclosure that drills a hole with implementation.This text aims at a certain the tail body giving certainly carried on to process the design that craft and work pack and completed once work:

1.All said a tail the technique and present condition development of the body;

2.Carried on craft analysis to the tail body,

3.Drew up a tail body of craft regulations, completed the design of its work preface card;

4.Aim at a craft in of some important work preface, designed to complete a set of Xian slot tongs, including fixed position component, clipped tight organization, to the knife piece, clip a concrete design and analyzed a fixed position error margin.

Keywords:design;clamping;craft;tailstock

第一章 绪论............................................ 1

1.1 课题的背景及介绍......................................... 4

1.2 同类研究国内外工作现状、存在问题......................... 4

1.3 研究目标、内容和拟解决的关键问题......................... 4

1.4 拟采取的研究方法、步骤、技术路线......................... 4

第二章 机械加工工艺规程的设计.............................. 4

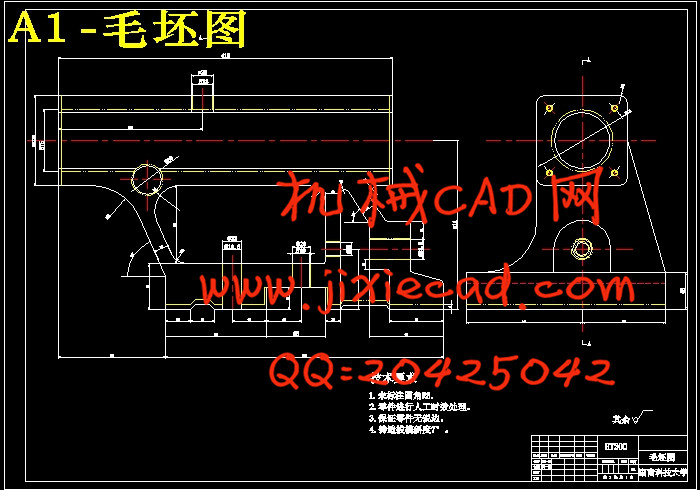

2.1 零件毛坯的确定........................................... 4

2.1.1 毛坯种类选择......................................... 4

2.1.2 确定毛坯的加工余量................................... 4

2.2 机械加工路线的拟定....................................... 5

2.2.1 选择零件表面的加工方法............................... 5

2.2.2 工序定位基准的选择................................... 6

2.2.3 工序数目和顺序的确定................................. 6

2.2.4 确定工序间的加工余量和工序尺寸及其公差............... 8

2.3 机床和工艺装备的选择和设计.............................. 13

2.3.1机床的选择.......................................... 13

2.3.2刀具的选择.......................................... 13

2.3.3量具的选择.......................................... 13

2.3.4夹具的选择和设计.................................... 14

2.4 切削用量的选择.......................................... 14

2.4.1背吃刀量的选择...................................... 14

2.4.2进给量f的选择...................................... 14

2.4.3切削速度的选择...................................... 15

2.4.4各代表工序的切削用量的选择.......................... 15

2.5 填写机械加工工艺文件.................................... 23

2.5.1机械加工工艺过程卡片................................ 23

2.5.2机械加工工序卡片.................................... 23

2.5.3检验卡片............................................ 23

第三章 专用夹具的设计................................. 24

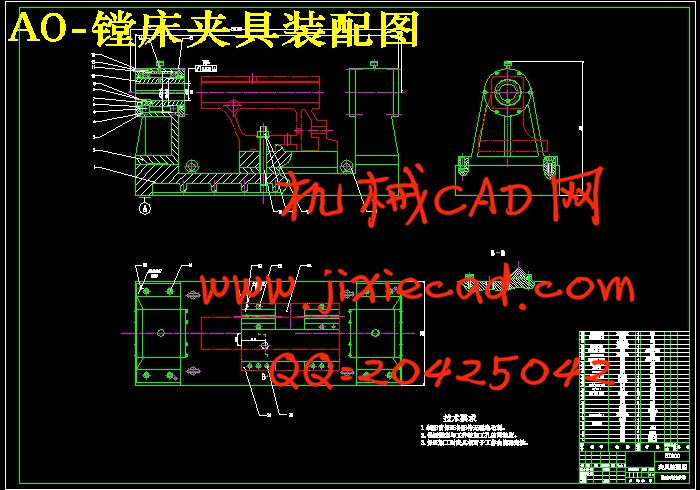

3.1 镗Φ75孔夹具设计........................................ 24

3.1.1 定位基准和定位元件的选定........................... 24

3.1.2定位元件的选择....................................... 25

3.2 镗套的选择和设计.......................................... 25

3.2.1 导向装置的形式与特点................................ 25

3.2.2 镗套的材料.......................................... 26

3.3 镗杆的设计................................................ 26

3.3.1 镗杆的结构.......................................... 26

3.3.2 镗杆端部导向结构形式................................ 26

3.3.3 镗刀与镗刀孔的结构.................................. 27

3.3.4 镗杆的尺寸.......................................... 28

3.3.5 镗杆的材料.......................................... 28

3.4 夹紧装置的设计............................................ 30

3.4.1 夹紧装置的组成...................................... 30

3.4.2 对夹紧装置的要求.................................... 30

3.5 夹紧力的确定.............................................. 31

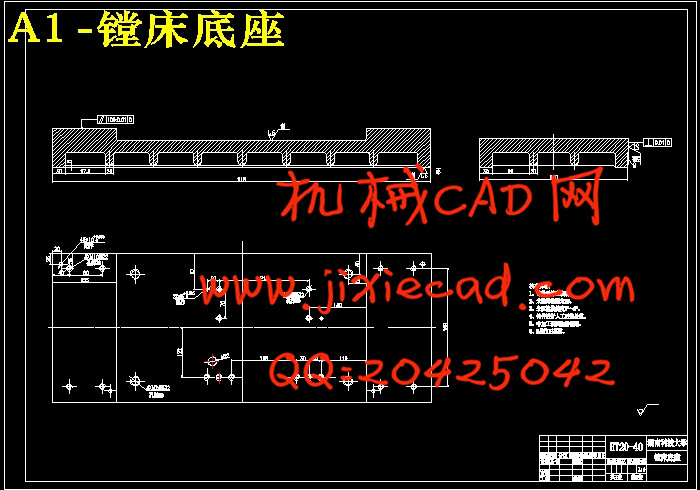

3.6 夹具体的设计.............................................. 32

3.7 夹具精度及定位误差分析.................................... 32

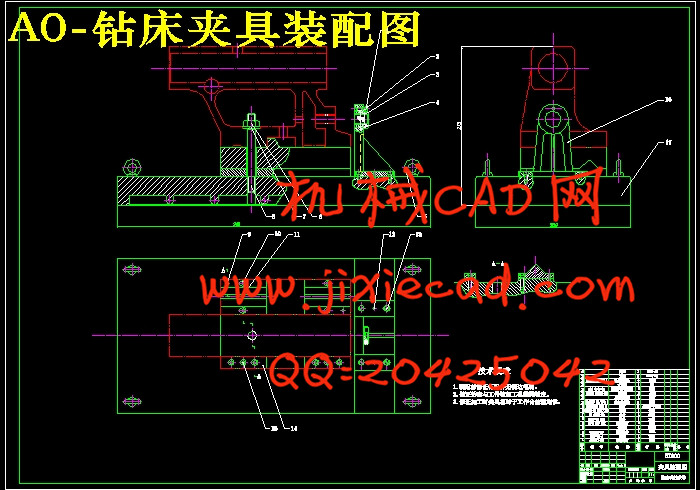

3.8 加工孔Φ24夹具设计........................................ 32

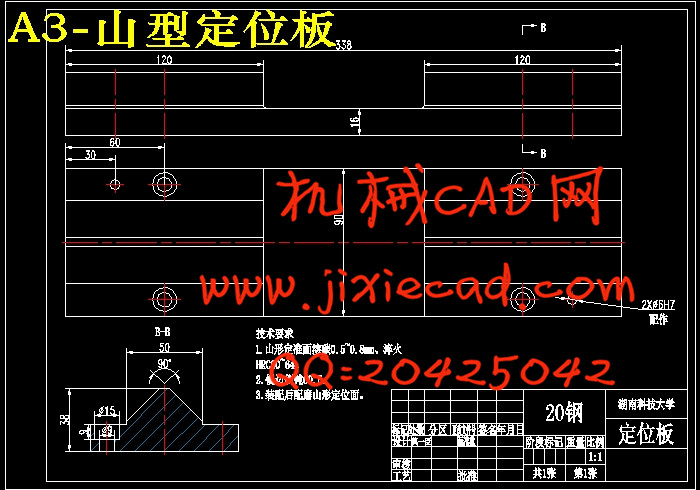

3.8.1定位基准的选择...................................... 33

3.8.2切削力的计算与夹紧力分析............................ 34

3.8.3夹紧元件及动力装置确定.............................. 35

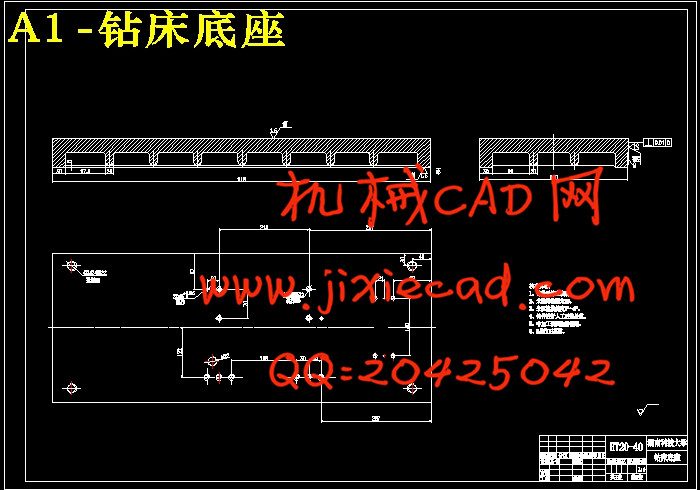

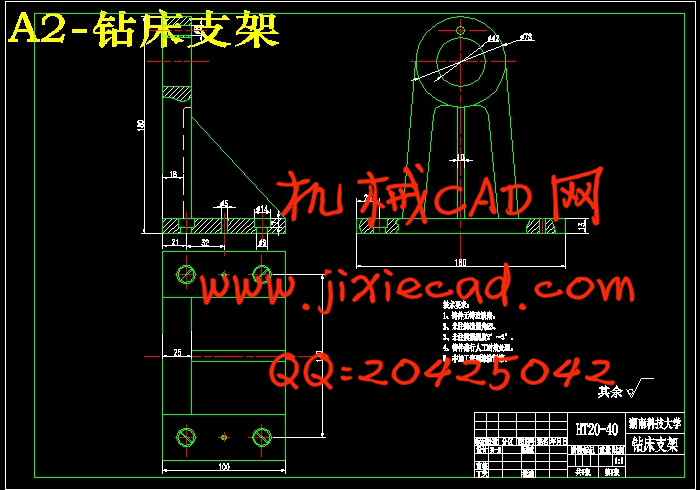

3.8.4钻套、衬套、钻模板及夹具体设计...................... 35

3.8.5夹具精度分析........................................ 36

第四章 结论................................................... 39

参考文献....................................................... 40

致谢............................................................ 41