设计简介

摘 要

工艺学是以研究机械加工工艺技术和夹具设计为主技术学科,具有很强的实践性,要求学习过程中应紧密联系生产实践,同时它又具有很强的综合性,本次设计的课题是左摆动杠杆的加工工艺规程及铣8mm槽的专用夹具设计,主要内容如下:

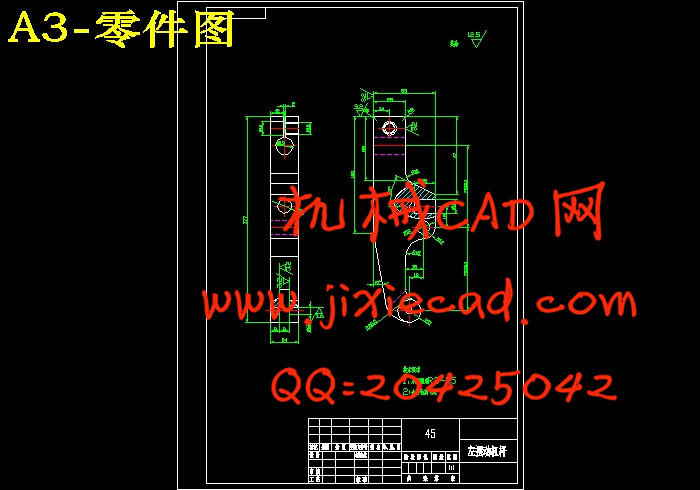

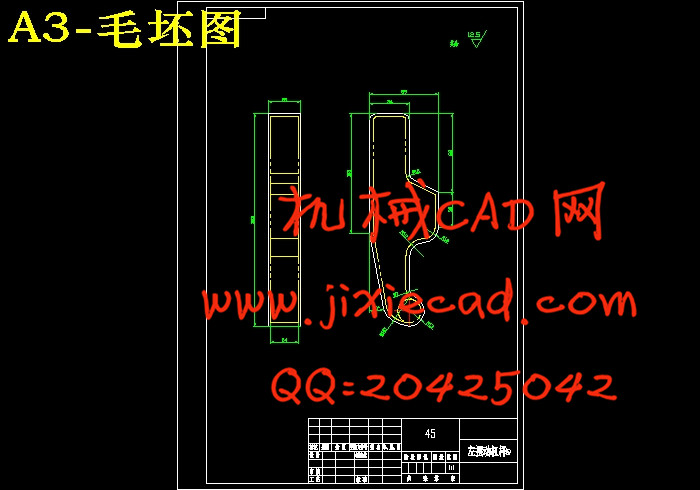

首先,对零件进行分析,主要是零件作用的分析和工艺分析,通过零件分析可以了解零件的基本情况,而工艺分析可以知道零件的加工表面和加工要求。根据零件图提出的加工要求,确定毛坯的制造形式和尺寸的确定。

第二步,进行基面的选择,确定加工过程中的粗基准和精基准。根据选好的基准,制订工艺路线,通常制订两种以上的工艺路线,通过工艺方案的比较与分析,再选择可以使零件的几何形状、尺寸精度及位置精度等技术要求得到合理的保证的一种工序。

第三步,根据已经选定的工序路线,确定每一步的切削用量及基本工时,并选择合适的机床和刀具。对于粗加工,还要校核机床功率。

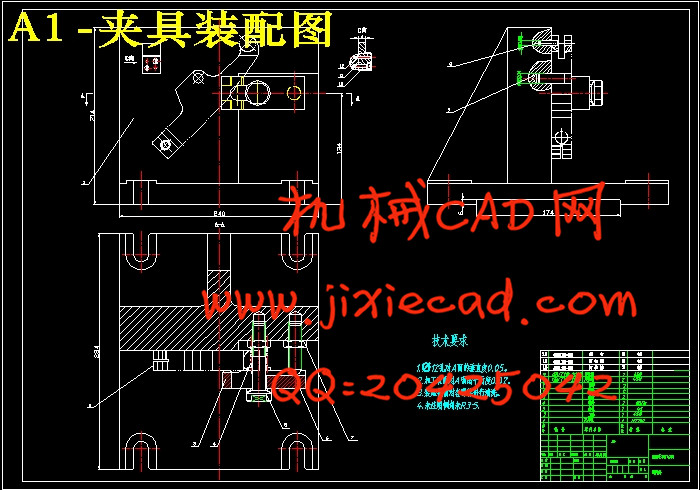

最后,设计铣8mm槽的—铣床专用夹具设计。先提出设计问题,再选择定位基准,然后开始切削力、夹紧力的计算和定位误差的分析。然后把设计的过程整理为图纸。

通过以上的概述,整个设计基本完成。

Abstract

Technology is to study the mechanical processing technology and fixture design technology, has a strong practical, requires the study process should be closely linked with the production practice, but it also has a strong comprehensive,

The topic of this design is the machining process of the left swing lever and the special fixture design of the milling 8mm groove:

First of all, the analysis of parts, mainly analysis and process analysis of the function of the part by part analysis to understand the basic situation of parts, and process analysis can know the surface machining and processing requirements. According to the processing requirements of the parts drawing, the determination of the form and size of the blank.

The second step, the choice of the base surface to determine the processing of coarse and fine reference base. According to the datum chosen, make the craft route, usually for two or more of the process route through the comparison and analysis of process plan, and then choose a process can make the shape, size precision and position precision parts of the technical requirements to be a reasonable assurance of.

The third step, according to the selected process route, determine the amount of cutting each step and the basic working hours, and select the appropriate machine tools and cutting tools. For rough machining, but also check the power of the machine.

Finally, the design of special fixture for milling 8mm groove milling machine is designed. First, the design problem, and then select the positioning reference, and then began cutting force, clamping force calculation and positioning error analysis. And then put the design process in order as the drawing.

Through the above overview, the basic completion of the entire design.

目录

摘 要 IAbstract II

一、左摆动杠杆的工艺分析 3

1.1左摆动杠杆的用途 1

1.2左摆动杠杆的技术要求 1

1.3左摆动杠杆的工艺分析 2

1.4确定左摆动杠杆的生产类型 2

二、确定毛坯、绘制毛坯简图 3

2.1选择毛坯 3

2.2确定毛坯的尺寸公差和机械加工余量 3

三、拟定左摆动杠杆工艺路线 4

3.1定位基准的选择 4

3.2表面加工方法的确定 5

3.3加工阶段的划分 5

3.4工序的集中与分散 6

3.5工序顺序的安排 6

3.6确定工艺路线 6

四、加工余量、工序尺寸、和公差的确定 8

4.1选择加工设备与工艺设备 8

4.2加工余量工序尺寸及公差的确定 9

五、切削用量、时间定额的计算 12

5.1粗精铣宽24mm,毛坯28mm,的下表面 12

5.2孔的加工 14

5.3 铣槽 18

5.4时间定额的计算 18

6、夹具的设计 21

6.1、提出问题 21

6.2、设计思想 21

6.3、零件本工序的加工要求分析 21

6.4、确定定位方案 22

6.5、定位误差计算 24

6.6、确定夹紧方案,选择夹紧元件和夹紧结构 24

7、夹具结构设计 25

总 结 27

致 谢 28

参考文献 29