设计简介

摘 要

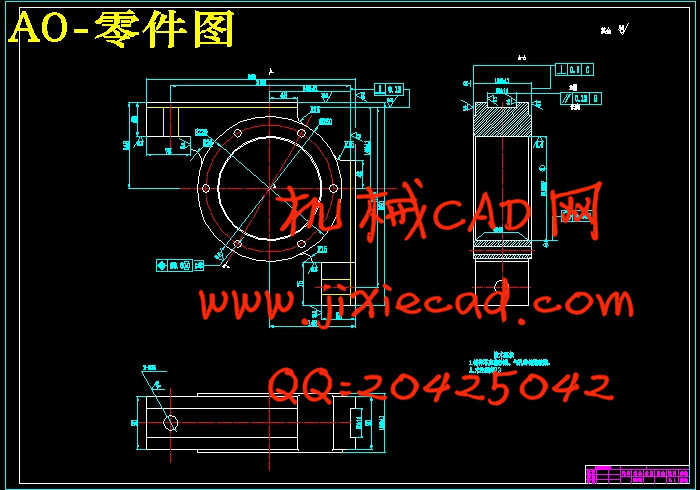

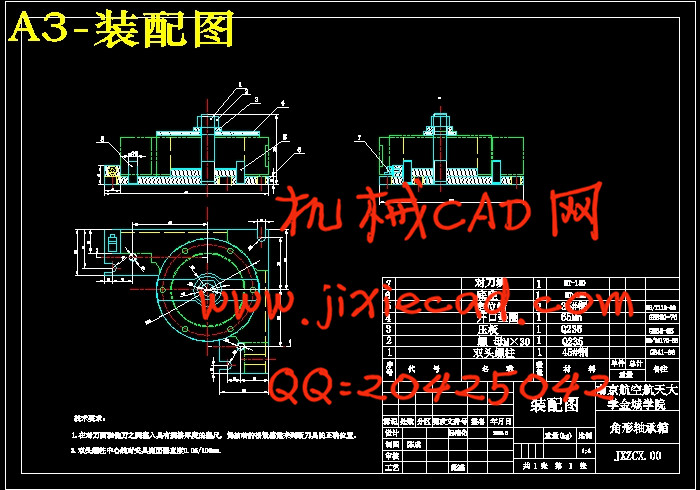

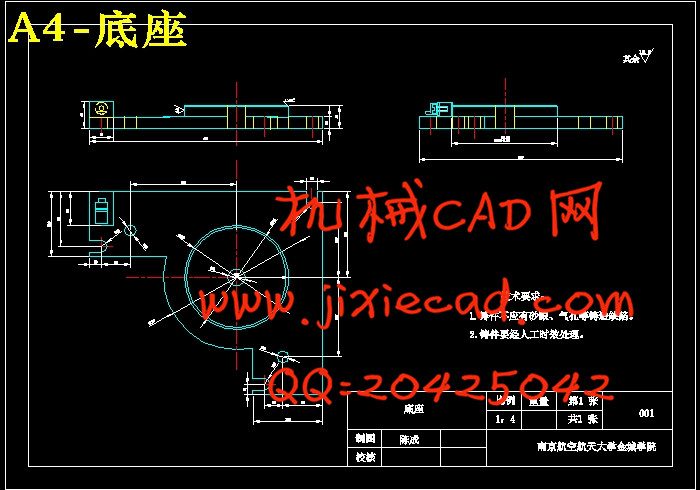

本课题的目的就是对JS56角形轴承箱零件的机械加工工艺规程和顶部和左侧安装平面铣削夹具设计。首先先进行零件加工工艺分析,根据零件制订加工工艺规程,并对典型工序进行切削用量的计算和制定工艺卡片。这需要对制造工艺学和机床夹具设计学有较深入的学习研究。在这几个月里,通过查询和阅读大量有关的文献资料,在指导老师的辅导下,学生逐步完成了各项任务并和完善了该毕业设计。关键词:角形轴承箱;工艺过程;切削用量;工时:夹具设计。

Abstract

The purpose of this paper is the fixture design of diagonal bearing box process planning and fixture. First of all, analyze the machining process, according to the parts for processing procedures, and calculate the amount of cutting and the development of process card for typical process. It is necessary to learn more in-depth study of manufacturing technology and machine tool fixture design. In the last few months, reading a lot of relevant documents and materials through the query and, under the guidance of the instructor, students gradually completed the tasks and improve the graduation design.

Keywords: angular bearing box; process; cutting; time: fixture design.

目 录

摘 要 I

Abstract II

1 零件的分析 1

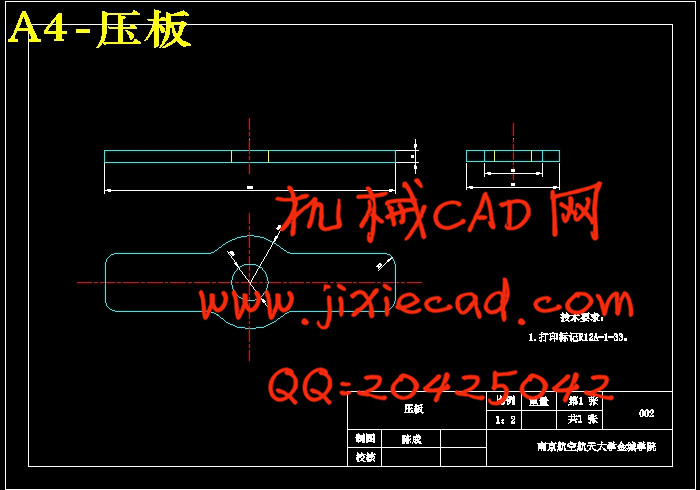

1.1 零件的结构分析 1

1.2 零件的技术要求分析 1

1.3 计算生产纲领,确定零件的生产类型 2

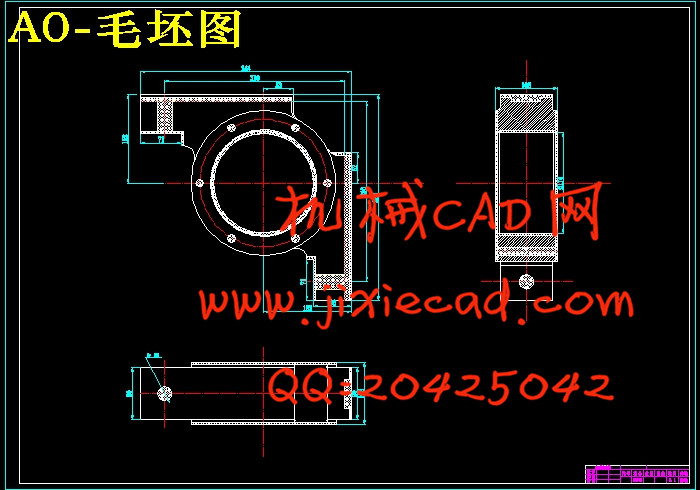

2 确定毛坯,画毛坯图 3

2.1 铸件尺寸公差 3

2.2 铸件机械加工余量 3

2.3 毛坯图 4

3 工艺规程设计 5

3.1 选择定位基准 5

3.1.1 粗基准的选择 5

3.1.2 精基准的选择 5

3.2 零件表面加工方法的选择 6

3.3 制定工艺路线 6

3.4 机械加工余量、工序尺寸的确定 9

4. 确立切削用量及基本工时 10

5 夹具设计 39

总 结 48