设计简介

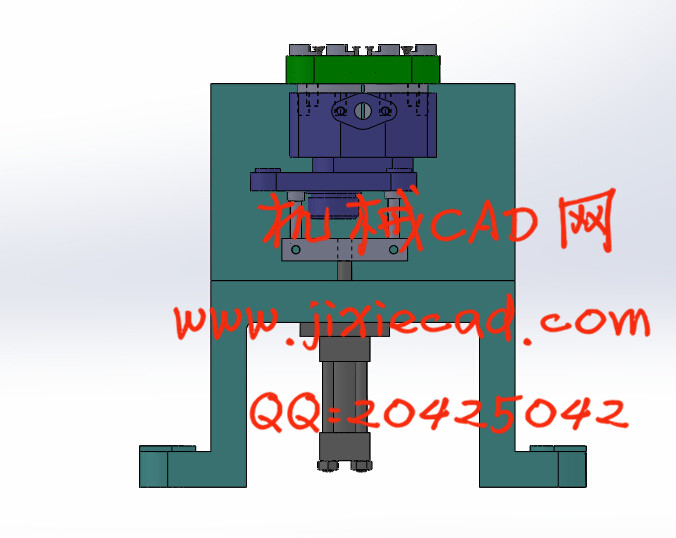

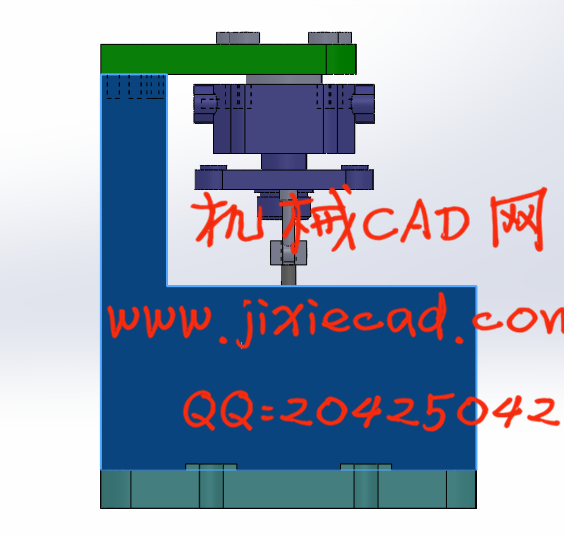

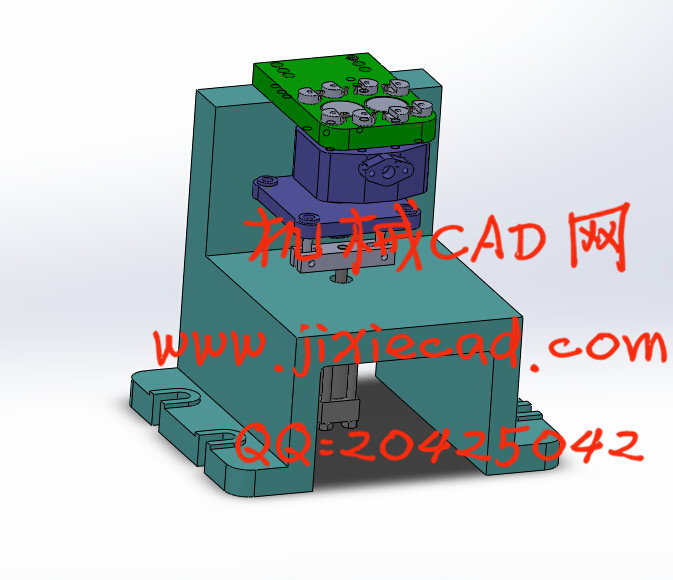

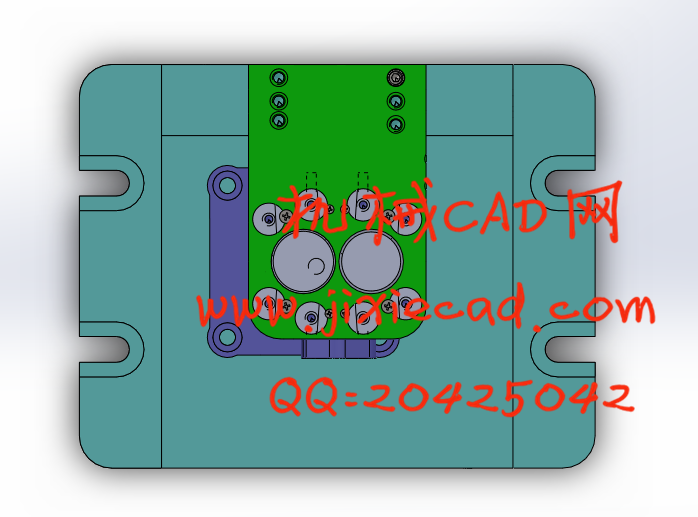

基于在A型齿轮油泵泵体轴颈方向上钻孔的前提下,为了满足加工精度的需要而设计一套钻床组合夹具。组合夹具属于柔性夹具,柔性夹具是以组合夹具为基础的能适用于不同的机床、不同的产品或同一产品不同规格型号的机床夹具。柔性夹具元件具有较好的互换性和较高的精度及耐磨性,可根据不同机床和不同零件的加工要求,选用配套中的部分元件组装成所需要的夹具。首先要分析加工零件的工艺以及技术要求,运用柔性夹具设计的基本原理和方法,拟定夹具设计方案以达到对A型齿轮油泵泵体进行合理的安装、定位、夹紧的目的。在完成夹具草图以后,进一步考虑元件之间的连接关系和固定方式,设计合理的结构实现各零部件间的相对运动。然后,运用soildworks进行零件三维图的绘制以及装配体的装配,并完成装配体的二维图。最后进行论文的撰写、整理、修改和工艺规程卡的编写。

关键词 夹具;专用夹具;钻床夹具;精度;soildworks

关键词 夹具;专用夹具;钻床夹具;精度;soildworks

Based on the premise of drilling in the A type gear pump shaft direction, a drill fixture designed to meet the needs of machining accuracy. Modular fixture is flexible fixture, flexible fixture on the basis of modular fixture is suitable for different products or the same products in different specifications of different machine tools, machine tool fixture. Flexible fixture components with interchangeable precision and wear resistance and high effective, according to the different tools and different parts of the processing requirements, selection of components supporting assembly fixture needed. The first analysis of the processing requirements of parts of the process and technology, using the basic principle and method of flexible fixture design, fixture designing scheme to achieve the intended installation, positioning, clamping on the reasonable A type gear pump to. After the completion of the fixture sketch, to further consider the connections between components and fixed mode, design reasonable structure to realize the relative motion between the parts. Then, use SoildWorks to draw 3D parts and assembly of the assembly, and complete the two-dimensional drawing assembly. Finally, the thesis writing, organize, modify and process card writing.

Keywords: fixture; fixture; drilling jig; precision; SoildWorks

目 录

1 绪 论 1

1.1 夹具的组成 1

1.2 常用定位元件及选用 2

1.2.1工件以平面定位 2

1.2.2工件以外圆柱定位 3

1.2.3工件以内孔定位 3

1.2.4对定位元件的基本要求 3

1.2.5常用定位元件所能限制的自由度 4

2 夹具的设计步骤 5

2.1 设计方案、设计方法、设计手段 5

2.1.1 研究原始资料 5

2.1.2 拟订夹具的结构方案 5

2.2 SolidWorks设计软件介绍 6

2.2.1 SolidWorks简介 6

2.2.2 SolidWorks的设计思路 7

3 钻床夹具的总体设计 9

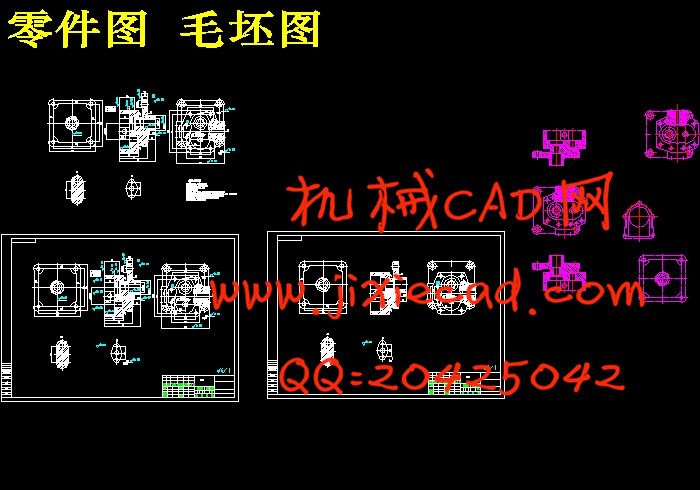

3.1 设计任务 9

3.2总体方案的确定 9

3.2.1 定位方案 9

3.2.2 夹紧机构 10

3.2.3 选择导向装置 11

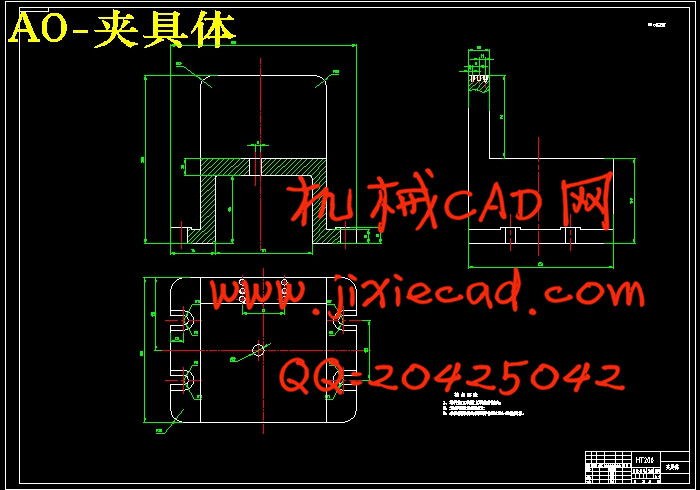

3.2.4 夹具体 12

3.3绘制夹具装配图 13

3.4夹具精度的验算 17

3.4.1误差分析 17

3.4.2误差计算 17

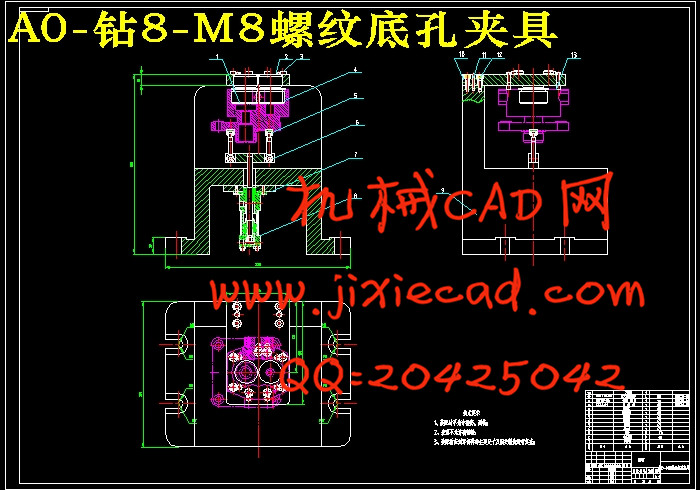

4 加工8XM8夹具设计 19

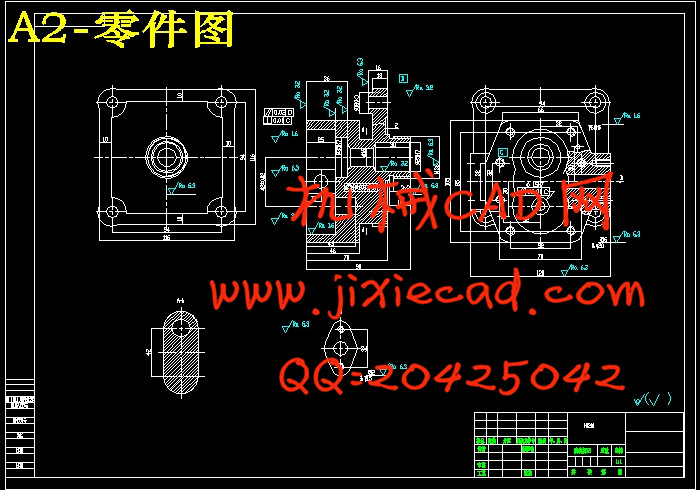

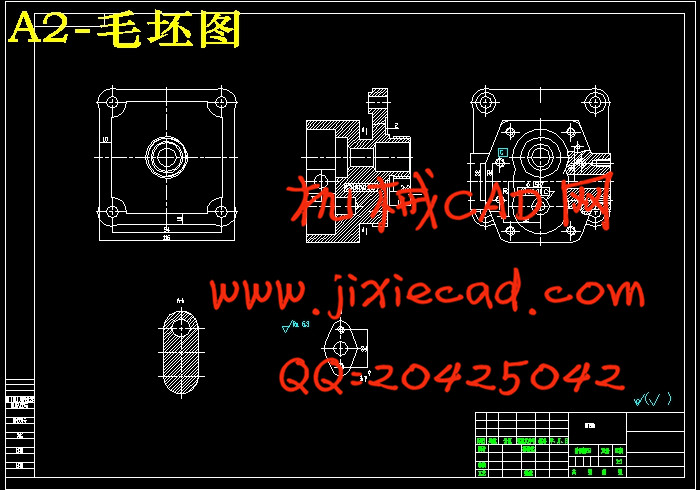

4.1 研究原始质料 19

4.2 定位、夹紧方案的选择 20

4.3 切削力及夹紧力的计算 20

4.3.1 液压缸的直径确定 23

4.3.2 液压缸的选型 25

4.4 误差分析与计算 26

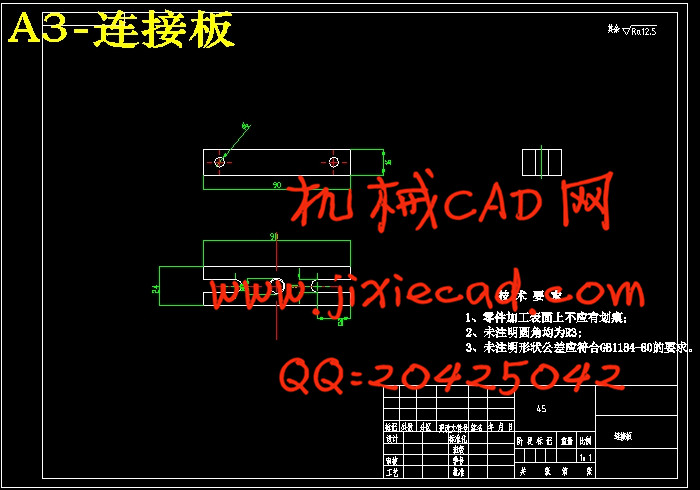

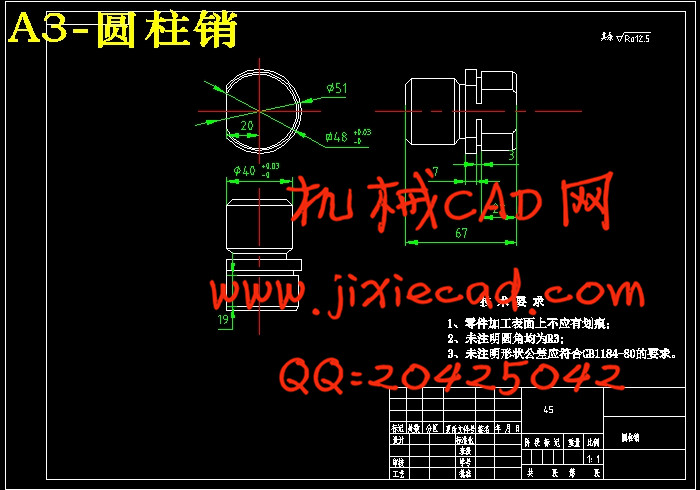

4.5定位销选用 27

4.6 钻套、衬套、钻模板设计与选用 27

4.7 确定夹具体结构和总体结构 29

4.8夹具设计及操作的简要说明 30

5 方案设计论证 33

5.1设计思路 33

5.2设计方法与结果 33

参考文献 34

致 谢 36

Based on the premise of drilling in the A type gear pump shaft direction, a drill fixture designed to meet the needs of machining accuracy. Modular fixture is flexible fixture, flexible fixture on the basis of modular fixture is suitable for different products or the same products in different specifications of different machine tools, machine tool fixture. Flexible fixture components with interchangeable precision and wear resistance and high effective, according to the different tools and different parts of the processing requirements, selection of components supporting assembly fixture needed. The first analysis of the processing requirements of parts of the process and technology, using the basic principle and method of flexible fixture design, fixture designing scheme to achieve the intended installation, positioning, clamping on the reasonable A type gear pump to. After the completion of the fixture sketch, to further consider the connections between components and fixed mode, design reasonable structure to realize the relative motion between the parts. Then, use SoildWorks to draw 3D parts and assembly of the assembly, and complete the two-dimensional drawing assembly. Finally, the thesis writing, organize, modify and process card writing.

Keywords: fixture; fixture; drilling jig; precision; SoildWorks

目 录

1 绪 论 1

1.1 夹具的组成 1

1.2 常用定位元件及选用 2

1.2.1工件以平面定位 2

1.2.2工件以外圆柱定位 3

1.2.3工件以内孔定位 3

1.2.4对定位元件的基本要求 3

1.2.5常用定位元件所能限制的自由度 4

2 夹具的设计步骤 5

2.1 设计方案、设计方法、设计手段 5

2.1.1 研究原始资料 5

2.1.2 拟订夹具的结构方案 5

2.2 SolidWorks设计软件介绍 6

2.2.1 SolidWorks简介 6

2.2.2 SolidWorks的设计思路 7

3 钻床夹具的总体设计 9

3.1 设计任务 9

3.2总体方案的确定 9

3.2.1 定位方案 9

3.2.2 夹紧机构 10

3.2.3 选择导向装置 11

3.2.4 夹具体 12

3.3绘制夹具装配图 13

3.4夹具精度的验算 17

3.4.1误差分析 17

3.4.2误差计算 17

4 加工8XM8夹具设计 19

4.1 研究原始质料 19

4.2 定位、夹紧方案的选择 20

4.3 切削力及夹紧力的计算 20

4.3.1 液压缸的直径确定 23

4.3.2 液压缸的选型 25

4.4 误差分析与计算 26

4.5定位销选用 27

4.6 钻套、衬套、钻模板设计与选用 27

4.7 确定夹具体结构和总体结构 29

4.8夹具设计及操作的简要说明 30

5 方案设计论证 33

5.1设计思路 33

5.2设计方法与结果 33

参考文献 34

致 谢 36