设计简介

摘 要

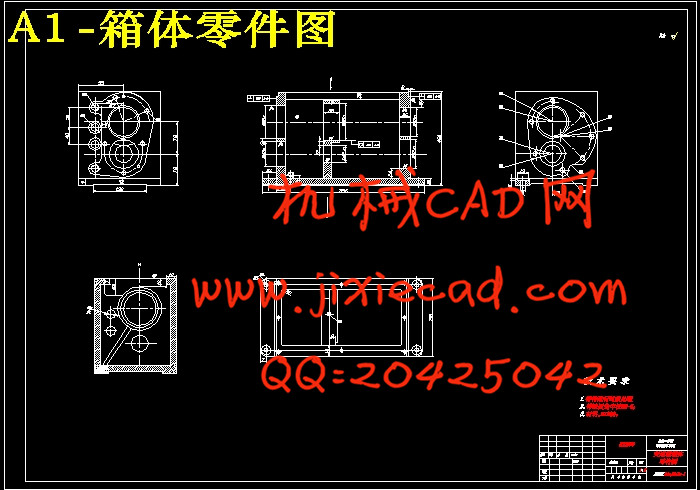

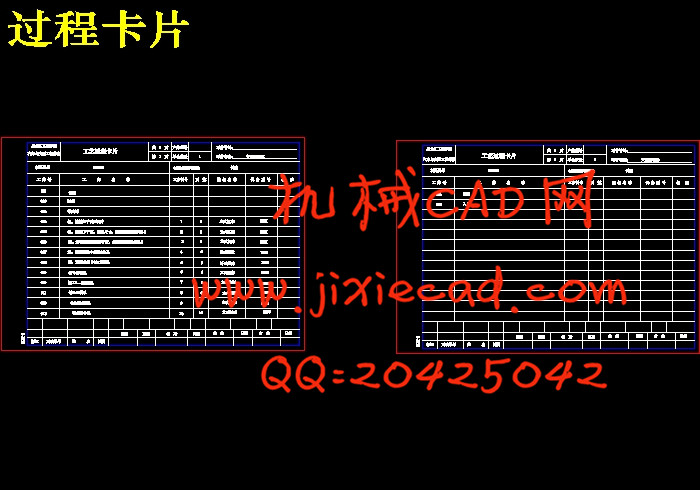

本次设计是汽车变速箱箱体零件的加工工艺 规程及一些工序的专用夹具设计。汽车变速箱箱体零件的主要加工表面是平面及孔系。保证平面的加工精度要比保证孔系的加工精度容易。因此,本设计遵循先面后孔的原则。并将孔与平面的加工明确的划分为粗加工和精加工阶段,以保证孔系的加工精度。基准选择以变速箱箱体的输入轴与输出轴的支承孔作为粗基准,以顶面与两个工艺孔作为精基准。主要加工工序安排先以支承孔系定位加工出上表面。再以顶平面与支承孔系定位加工出孔。整个加工过程均选用组合机床,夹具选用专用夹具夹紧。加紧方式多选用手动夹紧,夹紧可靠。

本设计要求“以质量求发展,以效益求生存”,在保证零件加工质量的前提下,提高了生产率,降低了生产成本,是国内外现代机械加工工艺的主要发展方面方向之一。通过对变速箱体零件图的分析及结构形式的了解,从而对变速箱体进行工艺分析、工艺说明及加工过程的技术要求和精度分析。然后再对变速箱体的底孔、轴承孔的加工进行夹具设计与精度和误差分析,该工艺与夹具设计结果能应用于生产要求。

关键词:变速箱;加工工艺;定位;夹紧;夹具设计

A BSTRACT

This design is car gear-box parts processing procedure and some process of special jig design. Auto gear-box parts of the main processing surface is flat and hole department. Ensure the machining precision of the plane than guarantee hole machining precision of the easy is. Therefore, this design follow the principle of after make face first hole. And the pores and plane into rough machining clear and precise machining stage, to ensure that the hole is processing precision. Benchmark choose to gear-box input shaft and output axis holes as coarse benchmark, supported by end face and two craft hole as fine a benchmark. Main processing procedure in supporting hole is scheduled to produce the surface. Location Then with the plane and supporting hole is positioning processed from holes. The whole process are chosen combination machine tools, clamping fixture choose special jig. Stepping up way many choose manual clamping, clamping reliable.

This design requirements "with quality beg development, with benefits of survival", ensure parts processing quality premise, higher productivity and reduced production cost, is domestic and international modern machining technology is one of the main development direction. Based on the analysis of the body parts drawing variable structure and form of understanding, thus the process of speed changing process explanation and analysis, the processing of technical requirements and precision analysis. Then in the variable speed cabinet of bearing hole and the clamping fixture design and precision machining procedure and the error analysis, this technology and fixture design results can be applied to production requirements.

Key words: gearbox; Processing technology; positioning; Fixture design; Clamping force

目 录

摘要………………………………………………………………………………………Ⅰ

Abstract ………………………………………………………………………………Ⅱ

第1章 绪论 …………………………………………………………………………1

1.1 选题背景 …………………………………………………………………………1

1.2 选题选题的目的及意义 …………………………………………………………1

1.3 国内外发展现现状 ………………………………………………………………2

1.4 设计内容及方法 …………………………………………………………………3

第2章 变速箱体加工工艺规程设计 ……………………………………………4

2.1 零件的分析 ………………………………………………………………………4

2.1.1 零件的作用 ………………………………………………………………4

2.1.2 变速箱箱体的结构特点 …………………………………………………4

2.2 变速箱箱体的工艺性 ……………………………………………………………5

2.2.1 零件的工艺性分析 ………………………………………………………5

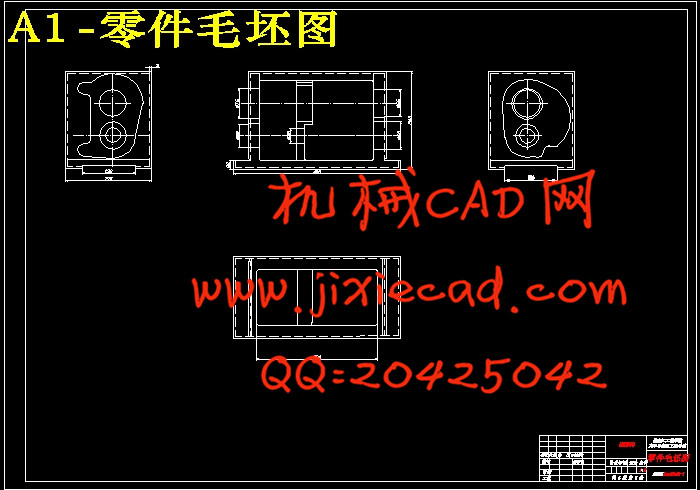

2.2.2 箱体的材料、毛坯及热处理 ……………………………………………5

2.2.3 毛坯的材料热处理 ………………………………………………………6

2.2.4 确定毛坯的制造形式 ……………………………………………………6

2.2.5 基面的选择 ………………………………………………………………6

2.2.6 确定工艺路线 ……………………………………………………………7

2.2.7 机械加工余量、工序尺寸及毛坯尺寸的确定 …………………………8

2.2.8 确定切削用量 ……………………………………………………………9

2.3 本章小结 ………………………………………………………………………20

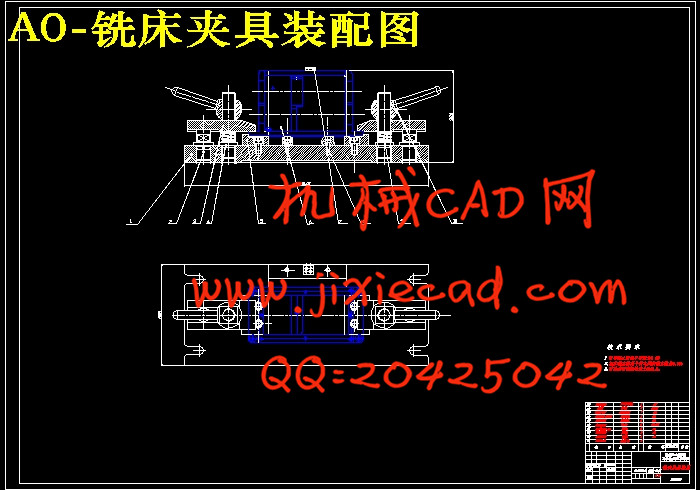

第3章 铣床夹具设计 ………………………………………………………………21

3.1铣箱体上平面夹具图…………………………………………………21

3.1.1 定位基准的选择 …………………………………………………………21

3.1.2定位元件的设计 …………………………………………………………21

3.1.3 定位误差分析 ……………………………………………………………22

3.1.4 铣削力与夹紧力计算 ……………………………………………………22

3.1.5 夹具体槽形与计对刀装置设 ……………………………………………23

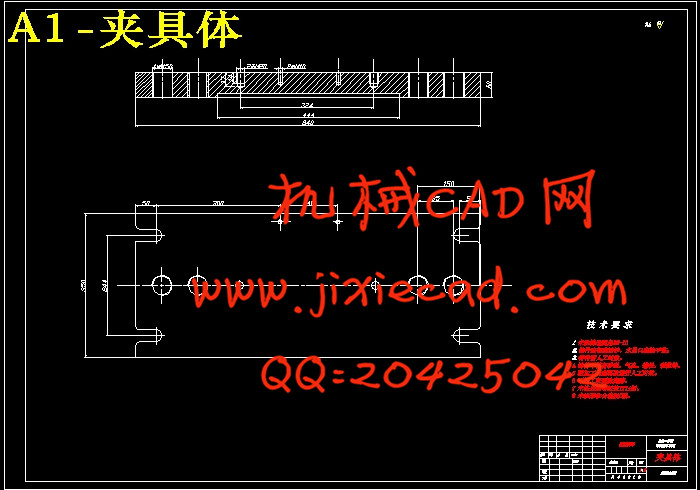

3.1.6 夹紧装置及夹具体设计 …………………………………………………26

3.1.7 夹具设计及操作的简要说明 ……………………………………………26

3.2本章小结 ………………………………………………………………………27

第4章 专用刀具量具的选择………………………………………………………28

4.1刀具的选择 ………………………………………………………………………28

4.1.1 刀具材料的选择 …………………………………………………………29

4.1.2 确定合理的切削方式及工作角度 ………………………………………29

4.1.3妥善解决刀具的排屑,容屑,断屑问题 ………………………………29

4.1.4合理的确定刀具的结构参数……………………………………………29

4.1.5 正确选择刀具的轮廓 ……………………………………………………30

4.2专用量具的选择 …………………………………………………………………30

4.2.1 量规工作尺寸的确定 ……………………………………………………30

4.2.2 量规的技术要求 …………………………………………………………31

4.3本章小结 …………………………………………………………………………31

结论 ………………………………………………………………………………………32

参考文献 …………………………………………………………………………33

致谢 ……………………………………………………………………………………34

本次设计是汽车变速箱箱体零件的加工工艺 规程及一些工序的专用夹具设计。汽车变速箱箱体零件的主要加工表面是平面及孔系。保证平面的加工精度要比保证孔系的加工精度容易。因此,本设计遵循先面后孔的原则。并将孔与平面的加工明确的划分为粗加工和精加工阶段,以保证孔系的加工精度。基准选择以变速箱箱体的输入轴与输出轴的支承孔作为粗基准,以顶面与两个工艺孔作为精基准。主要加工工序安排先以支承孔系定位加工出上表面。再以顶平面与支承孔系定位加工出孔。整个加工过程均选用组合机床,夹具选用专用夹具夹紧。加紧方式多选用手动夹紧,夹紧可靠。

本设计要求“以质量求发展,以效益求生存”,在保证零件加工质量的前提下,提高了生产率,降低了生产成本,是国内外现代机械加工工艺的主要发展方面方向之一。通过对变速箱体零件图的分析及结构形式的了解,从而对变速箱体进行工艺分析、工艺说明及加工过程的技术要求和精度分析。然后再对变速箱体的底孔、轴承孔的加工进行夹具设计与精度和误差分析,该工艺与夹具设计结果能应用于生产要求。

关键词:变速箱;加工工艺;定位;夹紧;夹具设计

A BSTRACT

This design is car gear-box parts processing procedure and some process of special jig design. Auto gear-box parts of the main processing surface is flat and hole department. Ensure the machining precision of the plane than guarantee hole machining precision of the easy is. Therefore, this design follow the principle of after make face first hole. And the pores and plane into rough machining clear and precise machining stage, to ensure that the hole is processing precision. Benchmark choose to gear-box input shaft and output axis holes as coarse benchmark, supported by end face and two craft hole as fine a benchmark. Main processing procedure in supporting hole is scheduled to produce the surface. Location Then with the plane and supporting hole is positioning processed from holes. The whole process are chosen combination machine tools, clamping fixture choose special jig. Stepping up way many choose manual clamping, clamping reliable.

This design requirements "with quality beg development, with benefits of survival", ensure parts processing quality premise, higher productivity and reduced production cost, is domestic and international modern machining technology is one of the main development direction. Based on the analysis of the body parts drawing variable structure and form of understanding, thus the process of speed changing process explanation and analysis, the processing of technical requirements and precision analysis. Then in the variable speed cabinet of bearing hole and the clamping fixture design and precision machining procedure and the error analysis, this technology and fixture design results can be applied to production requirements.

Key words: gearbox; Processing technology; positioning; Fixture design; Clamping force

目 录

摘要………………………………………………………………………………………Ⅰ

Abstract ………………………………………………………………………………Ⅱ

第1章 绪论 …………………………………………………………………………1

1.1 选题背景 …………………………………………………………………………1

1.2 选题选题的目的及意义 …………………………………………………………1

1.3 国内外发展现现状 ………………………………………………………………2

1.4 设计内容及方法 …………………………………………………………………3

第2章 变速箱体加工工艺规程设计 ……………………………………………4

2.1 零件的分析 ………………………………………………………………………4

2.1.1 零件的作用 ………………………………………………………………4

2.1.2 变速箱箱体的结构特点 …………………………………………………4

2.2 变速箱箱体的工艺性 ……………………………………………………………5

2.2.1 零件的工艺性分析 ………………………………………………………5

2.2.2 箱体的材料、毛坯及热处理 ……………………………………………5

2.2.3 毛坯的材料热处理 ………………………………………………………6

2.2.4 确定毛坯的制造形式 ……………………………………………………6

2.2.5 基面的选择 ………………………………………………………………6

2.2.6 确定工艺路线 ……………………………………………………………7

2.2.7 机械加工余量、工序尺寸及毛坯尺寸的确定 …………………………8

2.2.8 确定切削用量 ……………………………………………………………9

2.3 本章小结 ………………………………………………………………………20

第3章 铣床夹具设计 ………………………………………………………………21

3.1铣箱体上平面夹具图…………………………………………………21

3.1.1 定位基准的选择 …………………………………………………………21

3.1.2定位元件的设计 …………………………………………………………21

3.1.3 定位误差分析 ……………………………………………………………22

3.1.4 铣削力与夹紧力计算 ……………………………………………………22

3.1.5 夹具体槽形与计对刀装置设 ……………………………………………23

3.1.6 夹紧装置及夹具体设计 …………………………………………………26

3.1.7 夹具设计及操作的简要说明 ……………………………………………26

3.2本章小结 ………………………………………………………………………27

第4章 专用刀具量具的选择………………………………………………………28

4.1刀具的选择 ………………………………………………………………………28

4.1.1 刀具材料的选择 …………………………………………………………29

4.1.2 确定合理的切削方式及工作角度 ………………………………………29

4.1.3妥善解决刀具的排屑,容屑,断屑问题 ………………………………29

4.1.4合理的确定刀具的结构参数……………………………………………29

4.1.5 正确选择刀具的轮廓 ……………………………………………………30

4.2专用量具的选择 …………………………………………………………………30

4.2.1 量规工作尺寸的确定 ……………………………………………………30

4.2.2 量规的技术要求 …………………………………………………………31

4.3本章小结 …………………………………………………………………………31

结论 ………………………………………………………………………………………32

参考文献 …………………………………………………………………………33

致谢 ……………………………………………………………………………………34