设计简介

摘要

用与车外圆、端面和镗孔等加工的机床叫车床。车削很少在其他种类的机床上进行,因为其他机床都不能像车床那样方便地进行车削加工。由于车床除了用于车外圆外还能用于镗孔、车端面、钻孔和铰孔,车床的多功能性可以使工件在一次定位安装中完成多种加工。这就是在生产中普遍使用各种车床比其他种类的机床都要多的原因。车床的主要部件:床身、主轴箱组件、尾架组件、拖板组件、变速齿轮箱、丝杠和光杠

大多数车床的刀架安装在复式刀座上,刀座上有底座,底座安装在横拖板上。可绕垂直轴和上刀架转动;上刀架安装在底座上,可用手轮和刻度盘控制一个短丝杠使其前后移动。

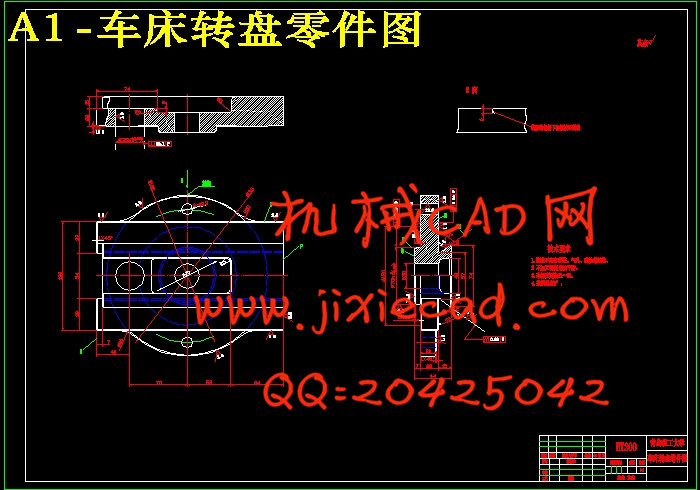

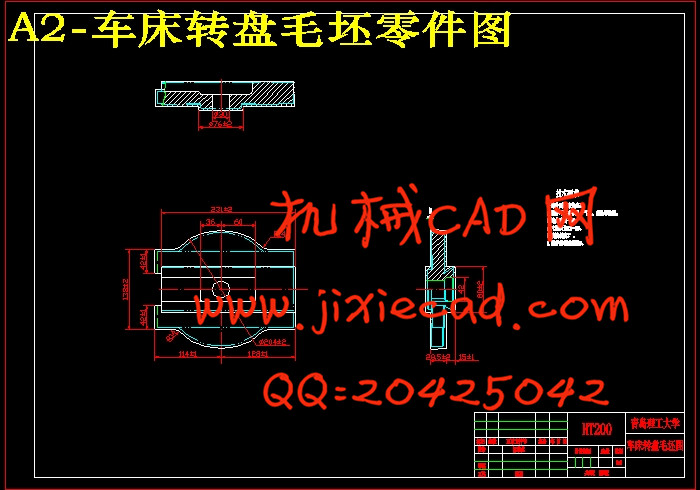

转盘用螺栓与中滑板紧固在一起,松开螺母,可使其在水平面内扳转任意角度,小滑板沿转盘上的导轨可以做短距离的移动,当转盘扳转某一角度后,小滑板便可带动车刀做相应的斜向移动。普通车床的转盘位于上刀架和下刀架之间,它是上刀架的导向件,当需要用小刀架车锥面时,可通过赚盘相对于下刀架的转动来调整锥角,

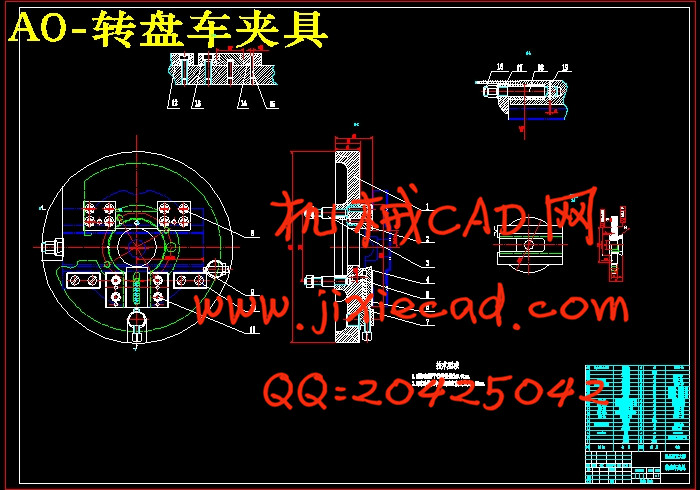

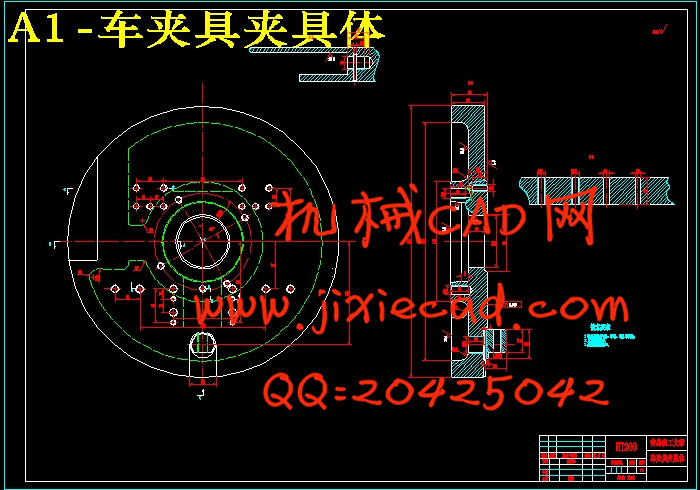

本说明书堆车床转盘零件的作用,零件的工艺过程,夹具设计做了比较系统完整的分析和论证。对工艺规程的设计做了详细的说明,并制定了合理的加工工艺路线,编制了一整套的机械加工工艺卡片。对关键工序的加工余量、工序尺寸、工序公差、切削用量等进行了计算。对机械加工工艺过程中需要的夹具具进行了设计分析,保证整个工艺过程的完整性。

关键词:金属切削;转盘;精度;工艺规程;公差

Abstract

The basic machines that are designed primarily to do turning, facing and boring are called lathes. Very little turning is done on other types of machine tools, and none can do it with equal facility. Because lathe can do boring, facing, drilling, and reaming in addition to turning, their versatility permits several operations to be performed with a single setup of the workpiece. These accounts for the fact that lathes of various types are more widely used in manufacturing than any other machine tool.Lathe Construction: The essential components of a lathe are depicted in the block diagram. These are the bed, headstock assembly, tailstock assembly, carriage assembly, quick-change gear box, and the lea & crew and feed rod.

On most lathes the tool post actually is mounted on a compound rest. This consists of a base, which is mounted on the cross slide so that it can be pivoted about a vertical axis, and an .upper casting. The upper casting is mounted on ways on this base .so that it can be moved back and forth and controlled by means of a short lead screw operated by a hand-wheel and a calibrated dial.

The turntable is fastened to the middle slip board by bolts. Loose the nut, we can make the turntable rotated in the level for no mater what angle. The minor slip board can move along the rail of turntable for a short distance. When the turntable rotates an angle, the minor slip board will make a sidelong displacement carrying.

Generally, the turntable locates between the up and down knife rest, it is the up knife rest’s oriented member. When we want to cut the cone by using the minor, we can rotate the turntable.

This essay will cover an integrated analyzing and demonstrates about the turntable’s function, mechanical workout techniques and the design of clamp used. It will give a detailed illuminate about the technical procedure, set down a reasonable technical routings, and work out a complete set of card for mechanical workout techniques.

Keywords: Metal cutting; Turntable; Precision; Technical schedule; Tolerance

目录

摘要 IAbstract II

目录 III

第1章 绪论 1

1.1课题研究的意义及现状 1

1.2论文主要研究内容 1

2.1零件的作用 2

2.2零件的工艺分析 2

第3章 机械加工工艺规程的设计 3

3.1机械加工工艺规程的定义 3

3.2机械加工工艺过程的组成 3

3.3机械加工工艺规程的作用 3

3.4机械加工工艺规程的设计原则、步骤和内容 4

3.5计算生产纲领确定生产类型 4

3.6.确定毛坯的制造形式 5

3.7.基准的选择 5

3.8制定工艺路线 7

3.9机械加工余量,工序尺寸及毛坯尺寸的确定 7

3.10确定切削用量及基本时间 11

第4章 机床夹具设计 26

4.1机床夹具介绍 26

4.2夹具设计 32

结论 35

参考文献 36

致谢 37