设计简介

摘 要

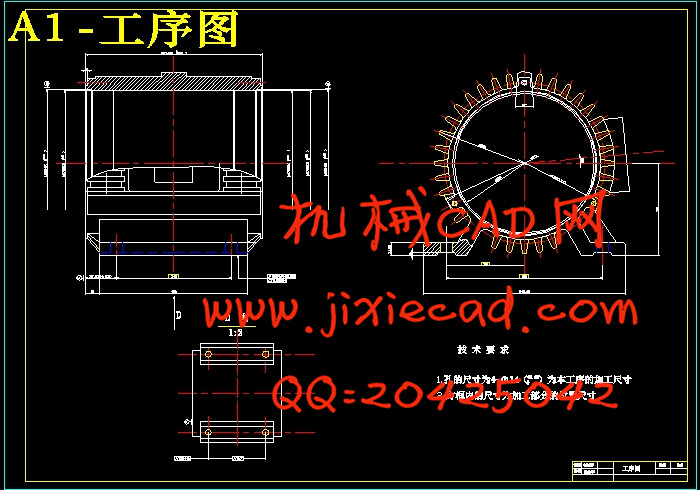

本次设计题目是加工电动机机座底面,钻孔4—Φ14。考虑到单个孔加工难以保证4个孔的位置公差,所以采用组合机床完成本次设计的工序。

组合机床一般采用多轴、多刀、多工序、多面或多工位同时加工的方式,生产效率比通用机床高几倍至几十倍。由于通用部件已经标准化和系列化,可根据需要灵活配置,能缩短设计和制造周期。目前,我国组合机床已广泛的用到大批,大量生产的行业,例如:汽车、拖拉机、柴油机、电动机和缝纫机等。

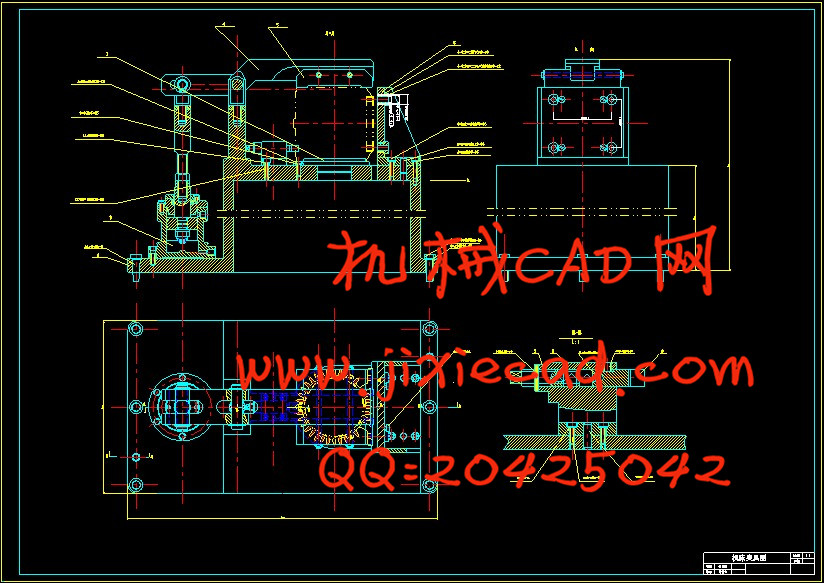

通过对零件的工艺性能的分析,制定出组合机床方案,绘制出零件的“三图一卡”、组合机床夹具图。

组合起床夹具是机床上用以装夹工件(和引导刀具)的一种装置。其作用是将工件定位,以使工件获得相对于机床和刀具的正确位置,并把工件可靠地夹紧。

夹具分为通用夹具,专用夹具,组合夹具和自动线夹具。机床夹具是机械制造过程中,用来固定加工对象,使之占有正确位置,以接受加工或检测并保证加工要求的机床附加装置。

关键词:夹具 组合机床 定位

ABSTRACT

This graduated design title is processing motor baseplate bottom, the 4 of drill hole — Φ 14. is hard to guarantee the location tolerance of 4 holes as far as single hole processing is concerned, so design with this complete of modular machine tool process.

Combination machine tools commonly used multi-spindle, multi-tool, process, or transfer processing ways at the same time, the production efficiency is higher than general machine tools several times or more. Because gm parts have standardization and seriation, can according to need to be flexible configuration, can shorten the design and manufacturing cycle. At present, our country combination machine tools has been widely used in large, mass production industries, such as: automobile, tractor, diesel engine, motor, sewing machine and so on.

Through the analysis of the parts of process performance, develop a plan of combined machine tool, draw a part of figure 1 "three CARDS", combination machine tool fixture.

Combination fixture is a machine used to getting up the clamping workpiece (and guide tool) of a device. Its role is the workpiece positioning, in order to make the workpiece gain relative to the correct position of the machine tools and cutting tools, and the workpiece clamping reliably.

Clamp is divided into general and special fixture, combination clamp and automatic line. Mechanical manufacturing process, machine tool fixture is used as a fixed processing objects, and make the possession of the correct position, to accept processing or testing and ensure the processing requirements of machine tool attachment.

Keyword: Fixture Modular Machine Tool Locate

本次设计题目是加工电动机机座底面,钻孔4—Φ14。考虑到单个孔加工难以保证4个孔的位置公差,所以采用组合机床完成本次设计的工序。

组合机床一般采用多轴、多刀、多工序、多面或多工位同时加工的方式,生产效率比通用机床高几倍至几十倍。由于通用部件已经标准化和系列化,可根据需要灵活配置,能缩短设计和制造周期。目前,我国组合机床已广泛的用到大批,大量生产的行业,例如:汽车、拖拉机、柴油机、电动机和缝纫机等。

通过对零件的工艺性能的分析,制定出组合机床方案,绘制出零件的“三图一卡”、组合机床夹具图。

组合起床夹具是机床上用以装夹工件(和引导刀具)的一种装置。其作用是将工件定位,以使工件获得相对于机床和刀具的正确位置,并把工件可靠地夹紧。

夹具分为通用夹具,专用夹具,组合夹具和自动线夹具。机床夹具是机械制造过程中,用来固定加工对象,使之占有正确位置,以接受加工或检测并保证加工要求的机床附加装置。

关键词:夹具 组合机床 定位

ABSTRACT

This graduated design title is processing motor baseplate bottom, the 4 of drill hole — Φ 14. is hard to guarantee the location tolerance of 4 holes as far as single hole processing is concerned, so design with this complete of modular machine tool process.

Combination machine tools commonly used multi-spindle, multi-tool, process, or transfer processing ways at the same time, the production efficiency is higher than general machine tools several times or more. Because gm parts have standardization and seriation, can according to need to be flexible configuration, can shorten the design and manufacturing cycle. At present, our country combination machine tools has been widely used in large, mass production industries, such as: automobile, tractor, diesel engine, motor, sewing machine and so on.

Through the analysis of the parts of process performance, develop a plan of combined machine tool, draw a part of figure 1 "three CARDS", combination machine tool fixture.

Combination fixture is a machine used to getting up the clamping workpiece (and guide tool) of a device. Its role is the workpiece positioning, in order to make the workpiece gain relative to the correct position of the machine tools and cutting tools, and the workpiece clamping reliably.

Clamp is divided into general and special fixture, combination clamp and automatic line. Mechanical manufacturing process, machine tool fixture is used as a fixed processing objects, and make the possession of the correct position, to accept processing or testing and ensure the processing requirements of machine tool attachment.

Keyword: Fixture Modular Machine Tool Locate

目 录

摘 要

ABSTRACT

目 录 I

第一章 前 言 1

第二章 拟定工艺方案 2

2.1 工艺方案的制定 2

2.2 确定切削用量及选择刀具 6

2.2.1 选择切削用量 6

2.2.2 确定切削力,切削扭矩,切削功率及刀具的耐用度 6

2.3 选择刀具的结构 7

第三章 组合机床总体设计 8

3.1 被加工零件图 8

3.1.1 作用和内容 8

3.1.2 注意事项........ 8

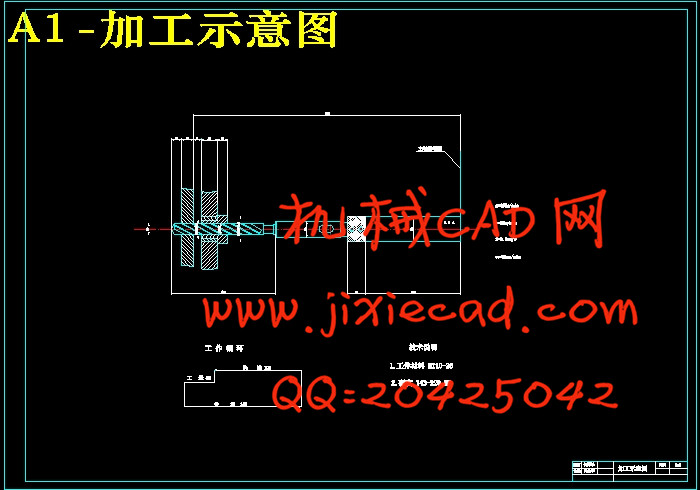

3.2 加工示意图 8

3.2.1作用和内容 8

3.2.2 选择刀具、导向装置并注明其相关位置及尺寸 9

3.2.3 初定主轴类型、尺寸、外伸长度和选择接杆 10

3.2.4 确定动力部件的工作循环与工作行程。 11

3.3 联系尺寸图 12

3.3.1 作用及内容 12

3.3.2 选择动力部件 12

3.3.3 应考虑的主要问题 12

3.3.4 联系尺寸图的画法和步骤 15

3.4 机床生产率计算卡 15

3.4.1 实际生产率Q1 16

3.4.2 理想生产率Q 16

3.4.3 机床负荷率

3.4.4 生产率计算卡 17

第四章 组合机床夹具设计 19

4.1组合机床夹具的现状及发展........................................................................................................19

4.1.1组合机床的现状..................................................................................................................19

4.1.2组合机床的发展方向..........................................................................................................19

4.2合机床夹具的特点........................................................................................................................20

4.3组合机床夹具的组成和分类 21

4.4 组合机床夹具设计程序和方法 21

4.5 定位支承系统 22

4.6 导向装置 23

4.7 夹紧机构 23

4.7.1 夹紧动力 24

4.7.2 夹紧元件 24

4.7.3 中间传动机构 24

4.7.4 夹紧力的计算: 24

总 结 27

致 谢 28

参考文献 29