设计简介

摘 要

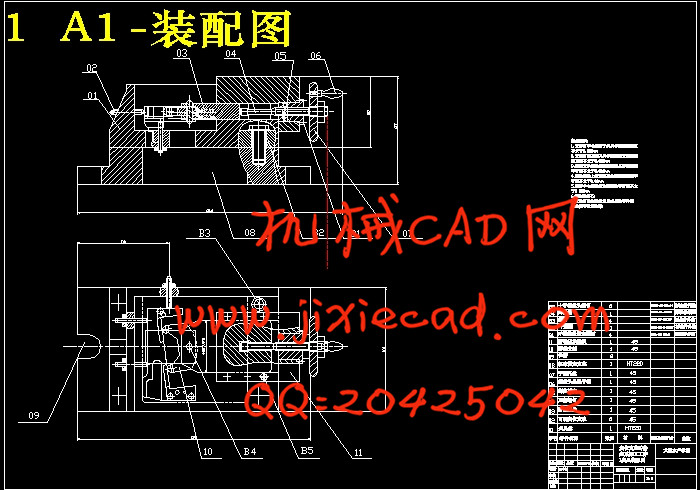

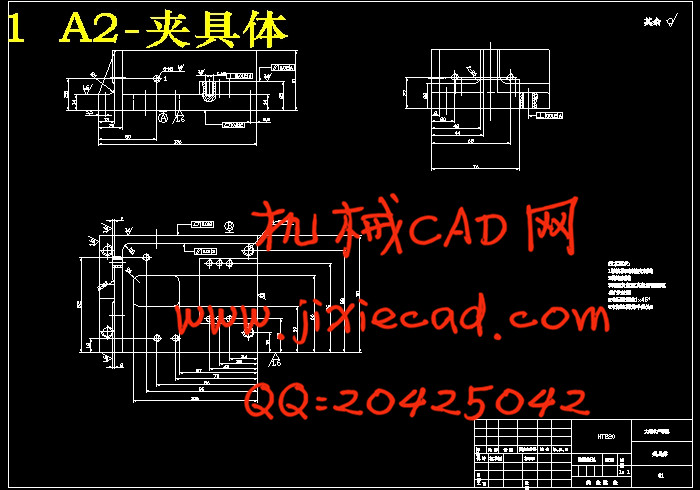

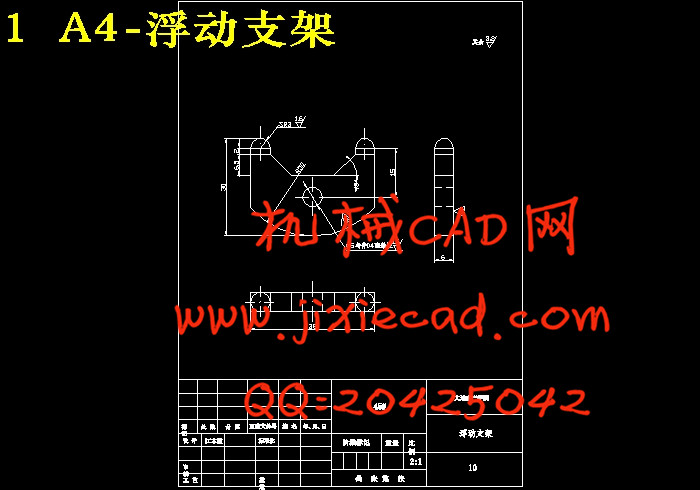

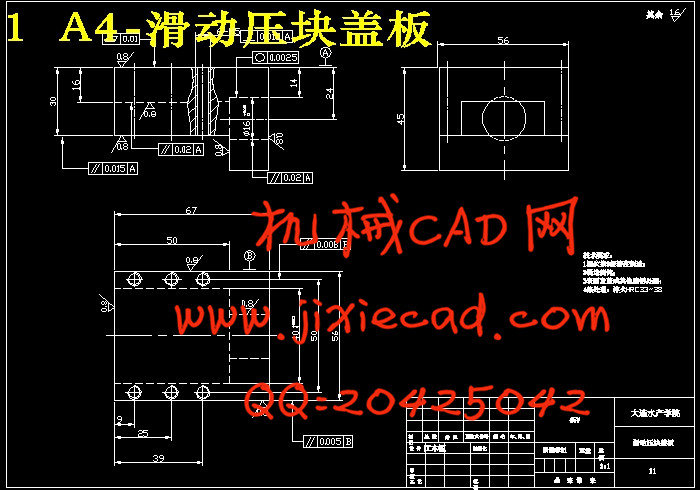

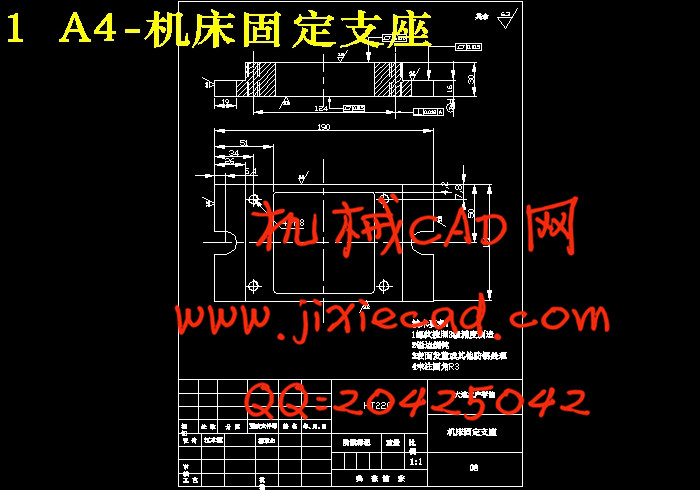

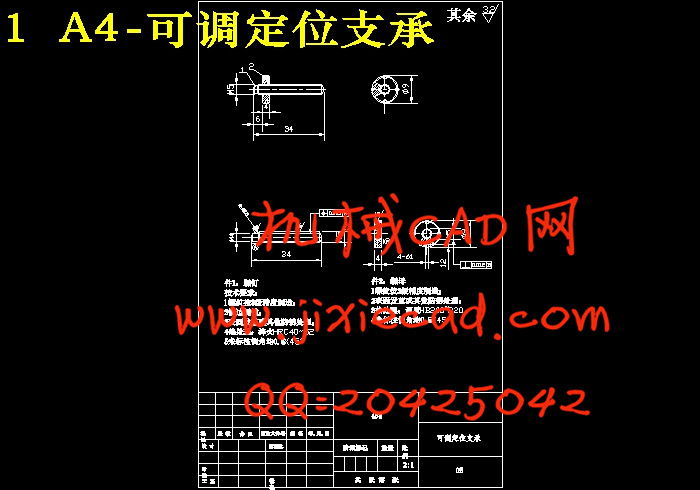

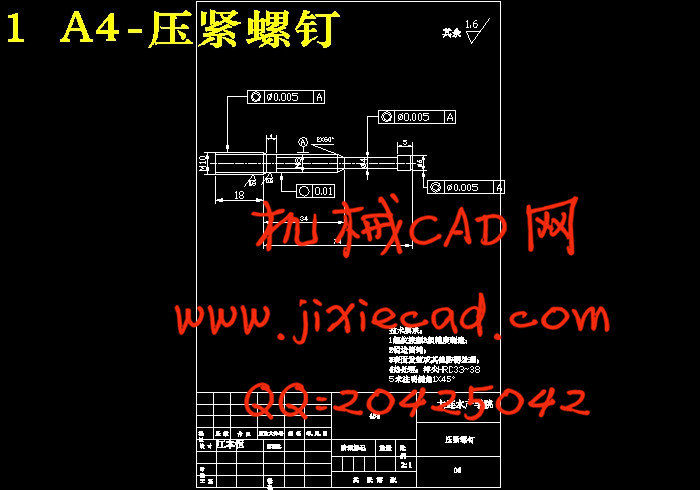

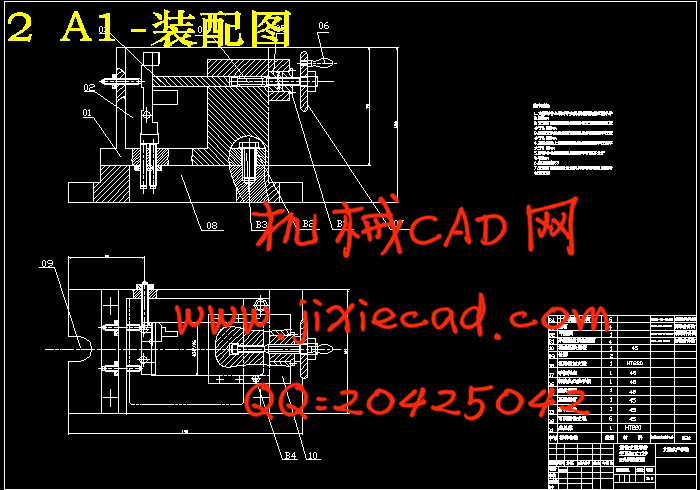

本文主要研究的是不规则零件在现代制造业中的广泛应用,那么保证此类零件的加工精度就显得尤为重要。本课题通过分析定位支座零件的结构特点和加工要求,用数控加工中心来达到多工位的加工目的,提高零件在大批量生产制造过程中的效率,同时制定了一套较为合理加工工艺规程,从而为保证该零件的加工精度将提供一种经济实用的夹具设备,具有一定的实用价值,在论文中会以研究零件的工艺规程开始着手设计最为适合的夹具,在不同的夹紧方案下进行比较,并且以平面加工为定位方法,通过夹紧力的计算和定位误差达到比较,选则最为恰当、最为合理的夹具设计方案,从而保证了被加工零件的精度以及工件在加工过程中定位的可靠和准确,夹具提供足够大的夹紧力以防止工件位移,工件在夹紧力的作用下形变小。从而使得夹具在装夹工件进行加工的过程中正真发挥其作用,提高劳动的生产效率、具备一定的实用价值。关键字:夹具装夹,定位,加工精度,平面加工,多工位

ABSTRACT

This paper is a study of irregular parts in the modern manufacturing a wide range of applications, then ensure that such parts of the machining accuracy is particularly important. Positioning the subject by analyzing the structure of parts bearing the characteristics and processing requirements to achieve the CNC Machining Center multi-purpose processing, high-volume production parts to improve manufacturing process efficiency, while more reasonable to develop a set of processing a point of order, so as to ensure that the machining accuracy will provide an economical and practical equipment of the fixture has a certain practical value, in the paper will be to study the parts of the process started to design a point of order most suitable for the fixture,In different comparison under clamping and positioning with planar processing method for the calculation of clamping force and position error to compare the election is the most appropriate and most reasonable design of the jig, thus ensuring the accuracy of parts processed and the workpiece during processing of reliable and accurate positioning, fixtures provide the clamping force is large enough to prevent displacement of the workpiece, the workpiece clamping force in the role of small deformation. So that the workpiece clamping fixture for processing in the process of Chiang Kai-shek really play its role in enhancing the productivity of labor, have a certain practical value.

Keywords: Fixture clamping, positioning, machining accuracy, planar processing, multi -

目 录

摘 要 I

ABSTRACT II

前 言 1

1零件的用途 2

1.1 计算零件生产纲领 确定零件的加工类型 2

1.2 研究分析被加共零件图和被加工零件的原始资料,审查改善零件的结构工艺性。 2

1.3 毛坯种类的选择 3

1.4零件毛坯的工艺性分析 3

2.数控加工工艺分析 5

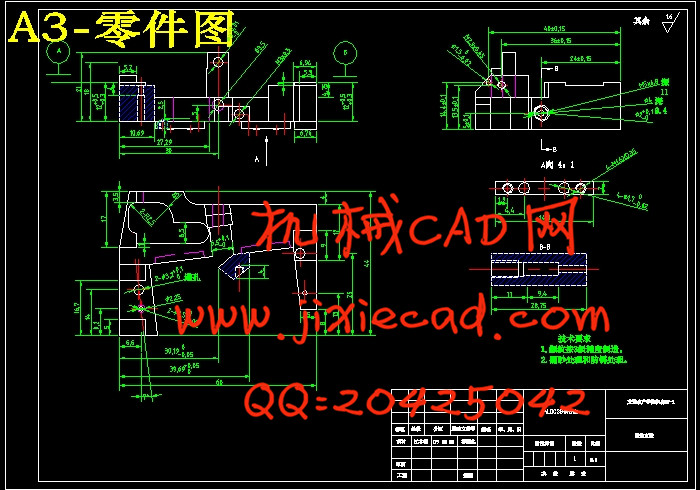

2.1零件介绍 5

2.2数控加工工艺的合理性分析 5

2.3 数控加工工艺的特点 5

2.4零件的工艺性分析 6

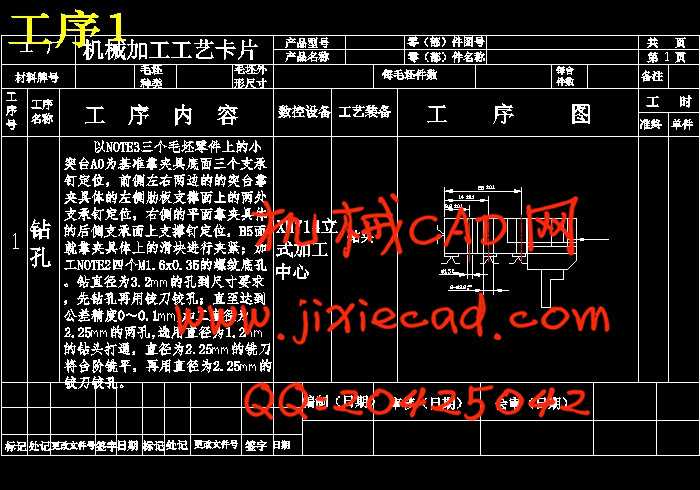

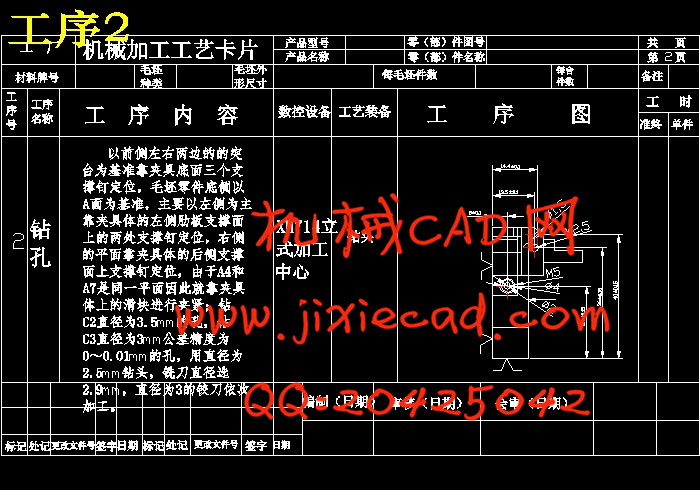

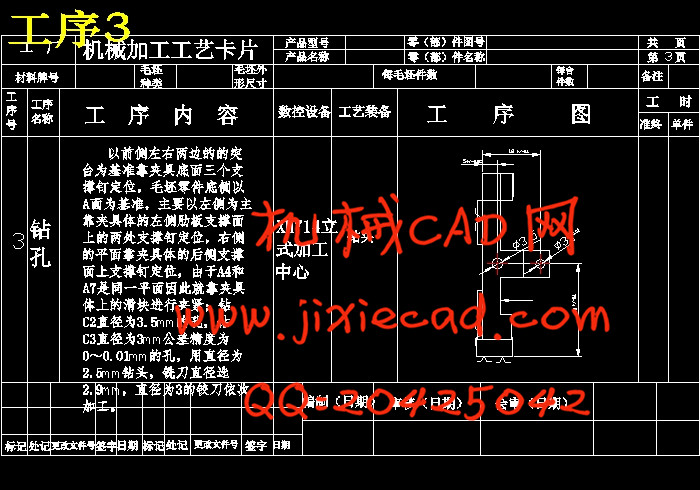

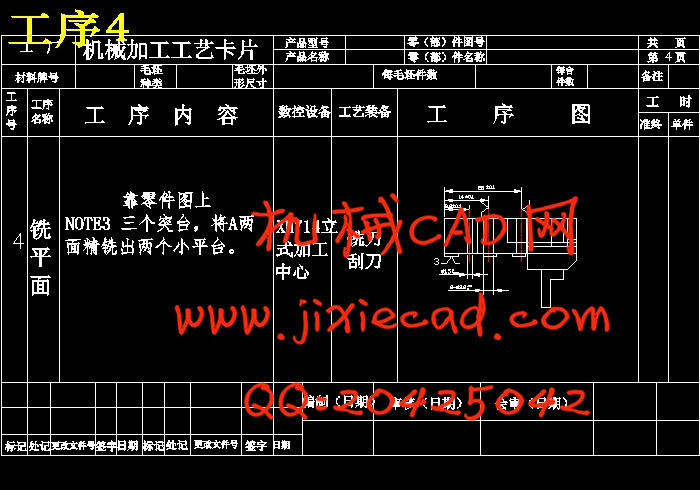

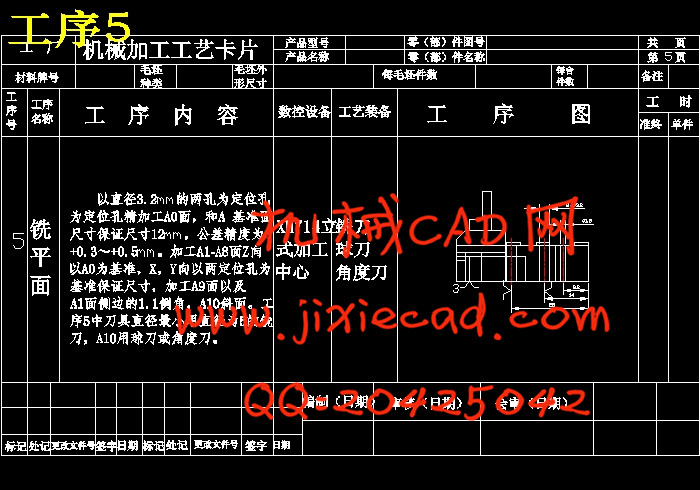

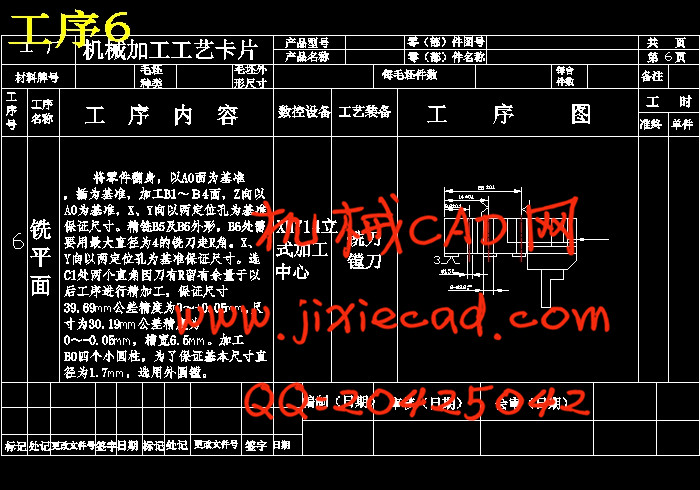

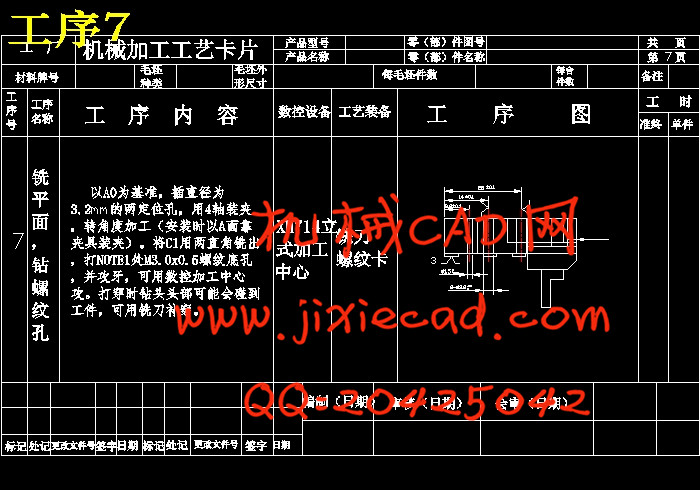

2.5数控加工工艺过程的拟定 8

2.6进给路线的确定 8

2.7 工件的装夹 9

2.8切削用量的确定 10

2.9加工刀具的选择 11

3.工艺规程的制订 13

3.1零件的工艺性分析 13

总 结 15

致 谢 16

参 考 文 献 17