设计简介

摘 要

本文设计了二级减速器上箱体机械加工工艺规程,合理选择了工艺过程中的机床刀具和量具,设计了铣分割面工序和钻螺栓孔工序的专用机床夹具。并计算了该夹具使用的精度保证,计算结果表明两套夹具均可,保证了零件的加工要求。

关键词 机械加工工艺规程;机床夹具;定位;定位误差

Abstract

This text designs the last body machine of second class deceleration machine to process the craft rules distance, the reasonable chooses the tool machine knife within the craft process to have and measure, designing the 铣 to partition to face the work preface and drill the appropriation tool machine tongs of the stud bolt bore work preface.Also computed that tongs the accuracy of the usage assurance, the calculation as a result expresses that two sets of tongs all can, guarantee the spare parts to process the request.

The keyword machine processes the craft rules distance;Tool machine tongs;Fixed position;Position the error margin

目 录

摘要………………………………………………………………………..…. I

绪论………………………………………………………….….…………… 1

前言………………………………………………………….….…………… 3

第1章………………………………………………………….….…… ……5

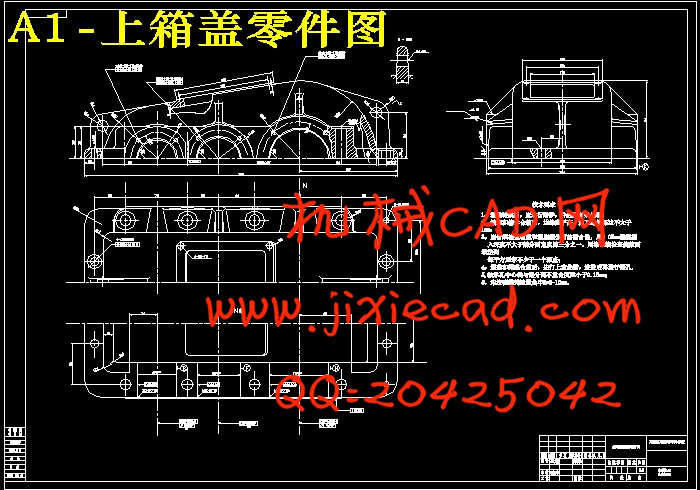

1.1 零件的作用………………………………………………………………5

1.2 零件的工艺性……………………………………………………………5

1.3 工艺规程的设计…………………………………………………………6

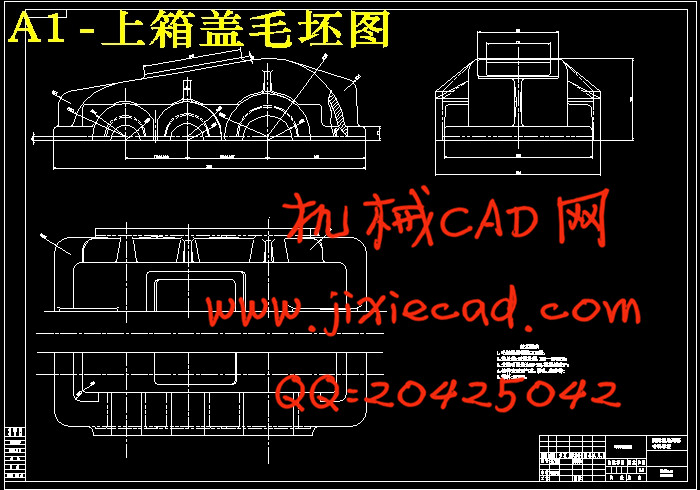

1.3.1确定毛坯的制造形式…………………………………………………6

1.3.2基准的选择……………………………………………………………7

1.4 制定工艺路线……………………………………………………………7

1.5 择加工设备及刀具、夹具、量具………………………………………10

1.6 加工工序设计……………………………………………………………11

1.7时间定额计算……………………………………………………………19

1.8填写工艺卡………………………………………………………………21

第2章……………………… …………………..……………….….…………22

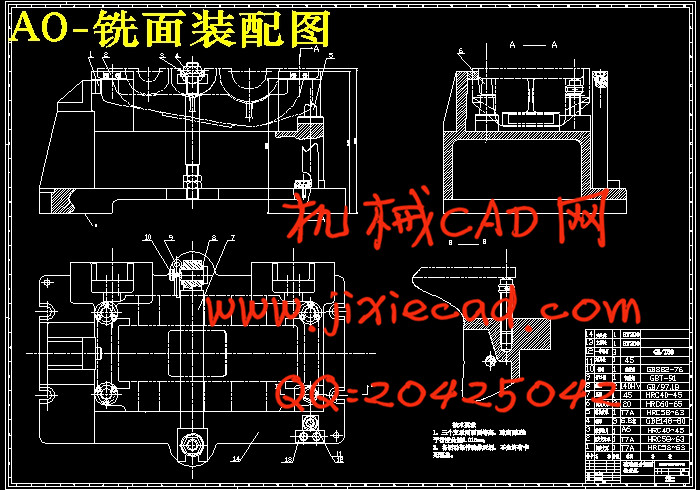

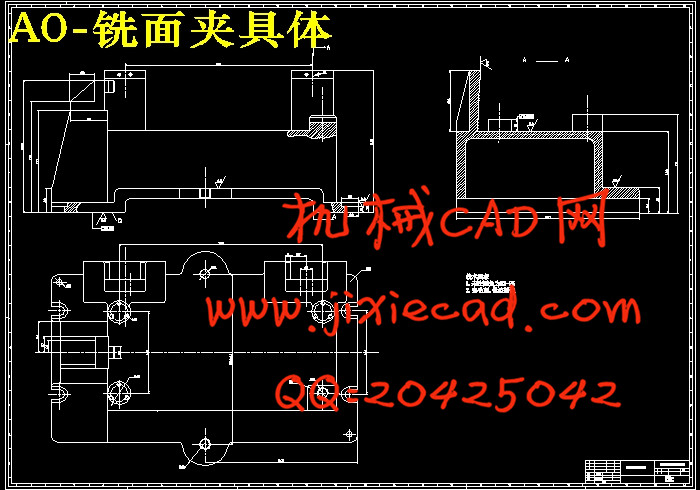

2.1.1 铣分割面夹具的设计………………………………………….………...22

2.1.1确立方案………………………………………….………………….. …22

2.1.2计算夹紧力………………………………………….…………………..22

2.1.3定位精度分析……………………………………….…………………..22

2.1.4操作说明………………………………………….………………….. …22

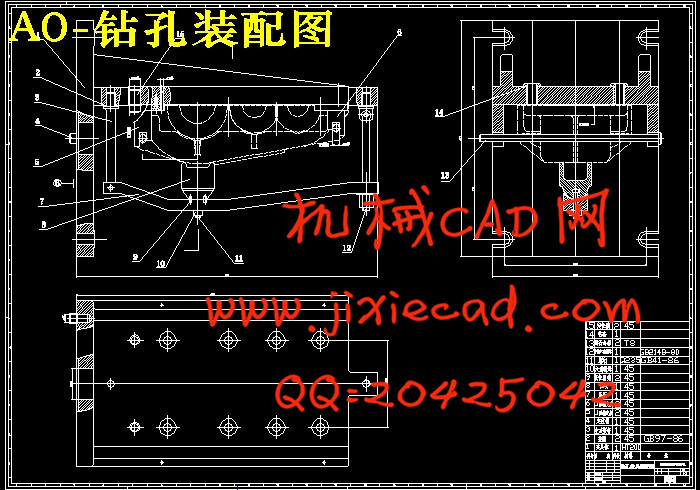

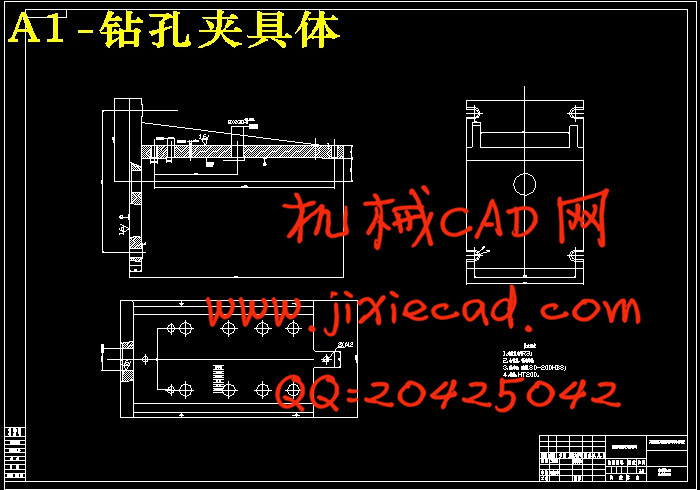

2.2 钻孔夹具的设计……………………….…………………………...……....22

2.2.1确立方案………………………………………….………………….. …23

2.2.2计算夹紧力………………………………………….…………………..23

2.2.3定位精度分析……………………………………….…………………..23

2.1.4操作说明………………………………………….………………….. …23

致谢………………………….……………………..………………...………...24

参考文献………………….…………………..……..………………. ………...25

本文设计了二级减速器上箱体机械加工工艺规程,合理选择了工艺过程中的机床刀具和量具,设计了铣分割面工序和钻螺栓孔工序的专用机床夹具。并计算了该夹具使用的精度保证,计算结果表明两套夹具均可,保证了零件的加工要求。

关键词 机械加工工艺规程;机床夹具;定位;定位误差

Abstract

This text designs the last body machine of second class deceleration machine to process the craft rules distance, the reasonable chooses the tool machine knife within the craft process to have and measure, designing the 铣 to partition to face the work preface and drill the appropriation tool machine tongs of the stud bolt bore work preface.Also computed that tongs the accuracy of the usage assurance, the calculation as a result expresses that two sets of tongs all can, guarantee the spare parts to process the request.

The keyword machine processes the craft rules distance;Tool machine tongs;Fixed position;Position the error margin

目 录

摘要………………………………………………………………………..…. I

绪论………………………………………………………….….…………… 1

前言………………………………………………………….….…………… 3

第1章………………………………………………………….….…… ……5

1.1 零件的作用………………………………………………………………5

1.2 零件的工艺性……………………………………………………………5

1.3 工艺规程的设计…………………………………………………………6

1.3.1确定毛坯的制造形式…………………………………………………6

1.3.2基准的选择……………………………………………………………7

1.4 制定工艺路线……………………………………………………………7

1.5 择加工设备及刀具、夹具、量具………………………………………10

1.6 加工工序设计……………………………………………………………11

1.7时间定额计算……………………………………………………………19

1.8填写工艺卡………………………………………………………………21

第2章……………………… …………………..……………….….…………22

2.1.1 铣分割面夹具的设计………………………………………….………...22

2.1.1确立方案………………………………………….………………….. …22

2.1.2计算夹紧力………………………………………….…………………..22

2.1.3定位精度分析……………………………………….…………………..22

2.1.4操作说明………………………………………….………………….. …22

2.2 钻孔夹具的设计……………………….…………………………...……....22

2.2.1确立方案………………………………………….………………….. …23

2.2.2计算夹紧力………………………………………….…………………..23

2.2.3定位精度分析……………………………………….…………………..23

2.1.4操作说明………………………………………….………………….. …23

致谢………………………….……………………..………………...………...24

参考文献………………….…………………..……..………………. ………...25