设计简介

摘 要

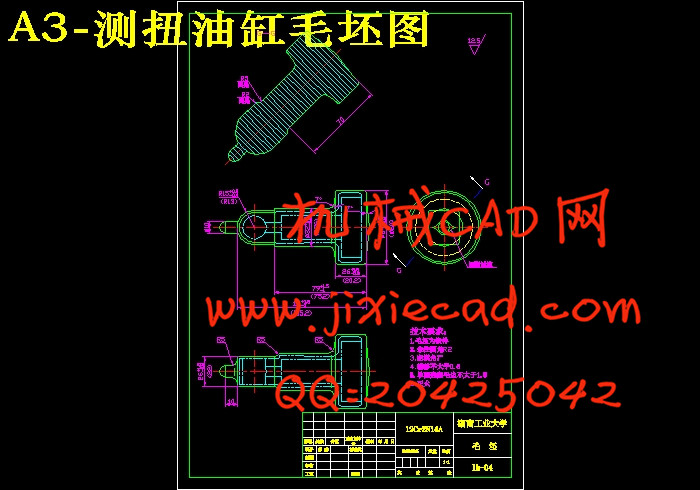

本次设计是飞机发动机上的一个测扭油缸零件的加工工艺规程及关键工序的专用夹具设计。测扭油缸零件是飞机发动机上经常遇到的典型零件之一。它属于长套筒薄壁类零件,体积小,结构形状较复杂,精度要求比较高,在发电机中起很大的作用。

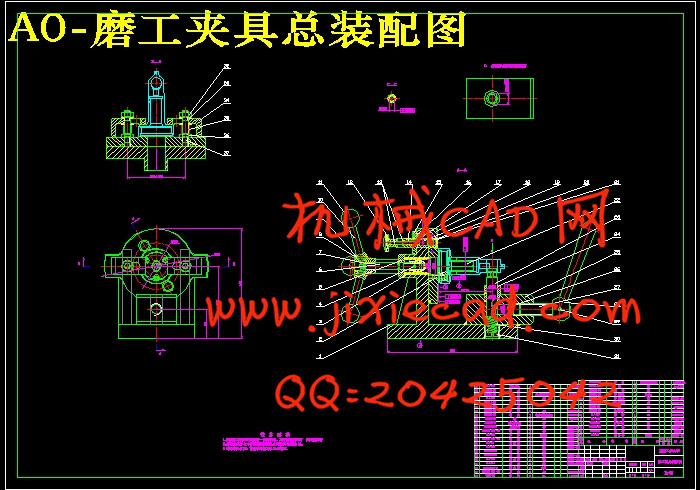

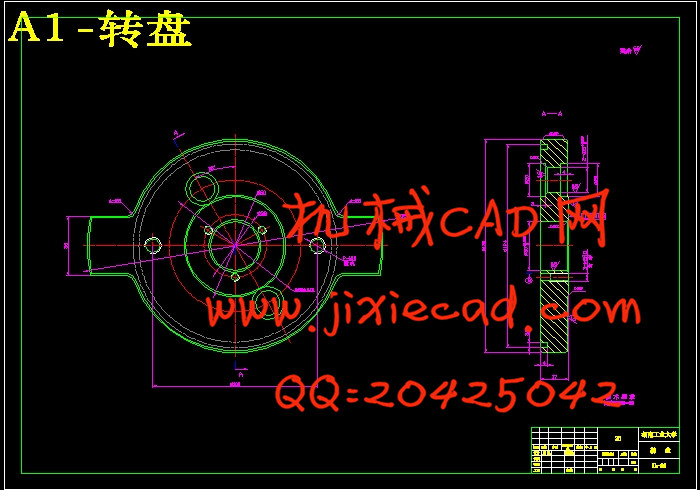

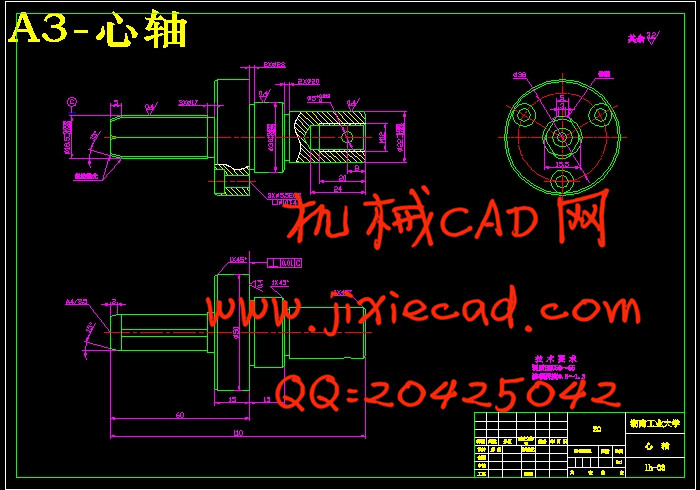

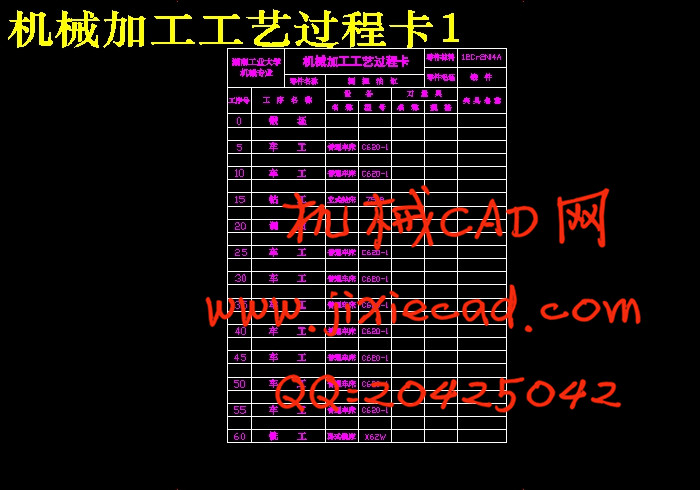

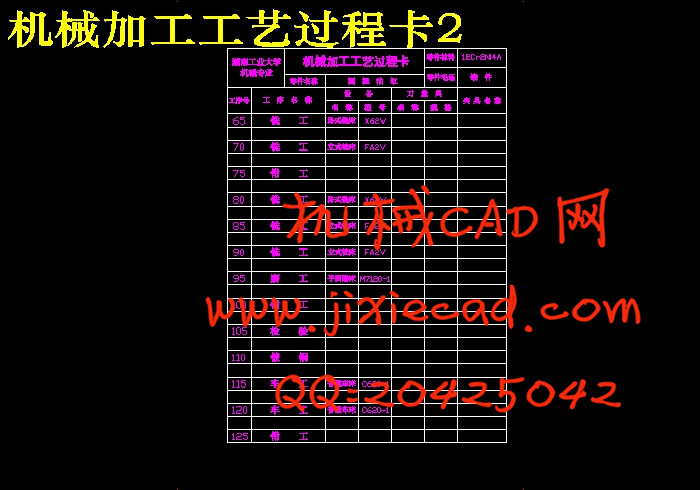

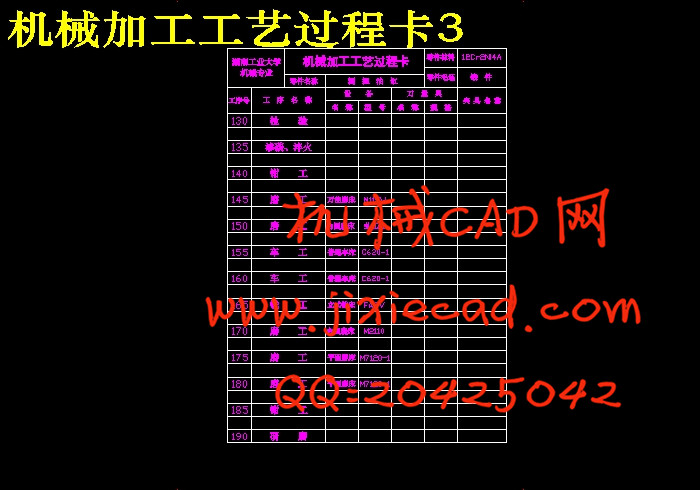

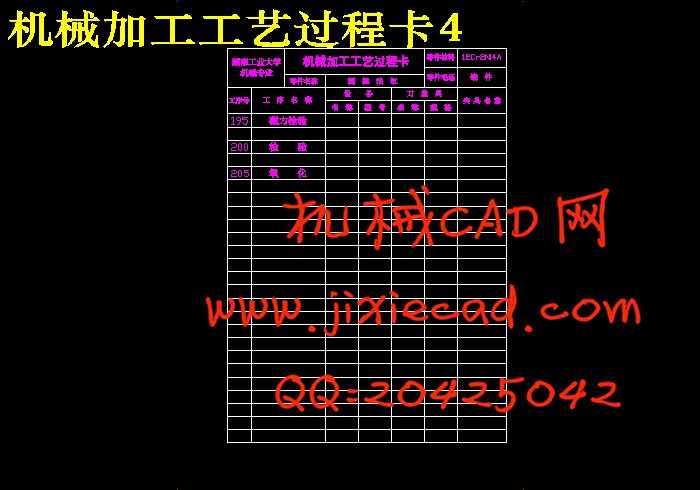

首先我对测扭油缸零件进行了工艺分析,然后针对其工艺特点设计了机械加工工艺规程,制定了加工工序卡;为保证生产效率较高,产品质量合格,结合生产加工的实际情况,在关键工序第95道工序上设计了专用磨工夹具。在磨工夹具的设计中,定位方式采用一面一内圆面一孔角向定位、夹紧装置采用螺旋压板机构。从而保证工件的加工精度,并使装夹方便、快捷可靠。在整个加工工艺过程中选用了车床、铣床和磨床。

关键词:测扭油缸,机械加工工艺,磨工夹具

ABSTRACT

This is a special fixture design used in the processing technical regulations and key process for a spare the fuel tank on certain engine. The fuel tank of a typical part in the aeroengine. It belongs to a long sleeve thin-walled parts, small size, shape more complex structure, relatively high accuracy in generating significantly in the role.

The design of the first test on a twisted parts of the fuel tank and then for its design of the mechanical characteristics of a point of order processing, development of the processing card; So as to guarantee the high efficiency and qualified products ,combine the practical situation of producing and processing ,design a grinding fixture at the key process 95. In the design of grinding fixture ,locating system is to adopt one hole one plane angular allocation to positioning ,and holding fixture use the spiral clamping mechanism. Lathe ,miller and grinder machine are selected and put to use during the whole processing technical regulation .

Keywords: Twisted measured the fuel tank, Machining process, Mill workers Fixture

本次设计是飞机发动机上的一个测扭油缸零件的加工工艺规程及关键工序的专用夹具设计。测扭油缸零件是飞机发动机上经常遇到的典型零件之一。它属于长套筒薄壁类零件,体积小,结构形状较复杂,精度要求比较高,在发电机中起很大的作用。

首先我对测扭油缸零件进行了工艺分析,然后针对其工艺特点设计了机械加工工艺规程,制定了加工工序卡;为保证生产效率较高,产品质量合格,结合生产加工的实际情况,在关键工序第95道工序上设计了专用磨工夹具。在磨工夹具的设计中,定位方式采用一面一内圆面一孔角向定位、夹紧装置采用螺旋压板机构。从而保证工件的加工精度,并使装夹方便、快捷可靠。在整个加工工艺过程中选用了车床、铣床和磨床。

关键词:测扭油缸,机械加工工艺,磨工夹具

ABSTRACT

This is a special fixture design used in the processing technical regulations and key process for a spare the fuel tank on certain engine. The fuel tank of a typical part in the aeroengine. It belongs to a long sleeve thin-walled parts, small size, shape more complex structure, relatively high accuracy in generating significantly in the role.

The design of the first test on a twisted parts of the fuel tank and then for its design of the mechanical characteristics of a point of order processing, development of the processing card; So as to guarantee the high efficiency and qualified products ,combine the practical situation of producing and processing ,design a grinding fixture at the key process 95. In the design of grinding fixture ,locating system is to adopt one hole one plane angular allocation to positioning ,and holding fixture use the spiral clamping mechanism. Lathe ,miller and grinder machine are selected and put to use during the whole processing technical regulation .

Keywords: Twisted measured the fuel tank, Machining process, Mill workers Fixture

目 录

第1章 绪论······················································································································1

1.1 选题来源···········································································1

1.2 机械加工工艺及夹具设计现状···································································1

1.3 主要设计内容及思路·················································································3

1.4 预期设计成果···························································································3

第2章 测扭油缸工艺规程设计······································································4

2.1 零件分析·································································································4

2.1.1 测扭油缸的作用·············································································4

2.1.2 测扭油缸的工艺分析·············································································4

2.2 毛坯设计·································································································10

2.2.1 确定毛坯的生产类型·································································10

2.2.2 材料分析········································································10

2.2.3 确定毛坯的种类和制造方式·································································10

2.2.4 毛坯形状与尺寸的确定········································································11

2.3 工艺路线的制订······················································································12

2.3.1 加工方法的选择································································································13

2.3.2 加工阶段的划分································································································17

2.3.3 工序集中与分散···························································································18

2.3.4 工序顺序的安排································································································19

2.3.5 工艺路线方案的确定························································································20

2.4 工序设计·································································································26

2.4.1 基准的选择········································································································26

2.4.2 加工余量的确定································································································28

2.4.3 工序尺寸及其公差的确定················································································30

2.4.4 设备、工艺装备的选择······················································································34

第3章 磨床夹具的设计················································································35

3.1 分析原始资料、明确设计任务····································································35

3.2 磨床夹具的作用及设计要求·····································································35

3.3 磨床夹具定位装置设计············································································36

3.3.1 定位所需限制的自由度分析·································································36

3.3.2 定位元件设计······················································································37

3.4 磨床夹具夹紧装置设计·························································································38

3.4.1 夹紧方案的选择··················································································38

3.3.2 夹紧力的计算······················································································39

3.3.3 夹紧机构设计····················································································39

3.5 夹具体及其它装置设计············································································41

3.6 磨床夹具的精度计算与分析·····································································41

3.7 夹具使用及维护注意事项········································································43

结论·······································································································································45

参考文献·····························································································································46

致谢······································································································································47