设计简介

摘 要

零件的加工工艺编制,在机械加工中占有非常重要的地位,零件工艺编制得合不合理,这直接关系到零件最终能否达到质量要求;夹具的设计也是不可缺少的一部分,它关系到能否提高其加工效率的问题。因此这两者在机械加工行业中是至关重要的环节。这次设计主要经历了两个阶段:第一阶段是机械加工工艺规程设计,第二阶段是专用夹具设计。

通过对发动机档位器零件图的分析及结构形式的了解,从而对发动机档位器进行工艺分析、工艺说明及加工过程的技术要求和精度分析。本课题对发动机档位器加工进行探索,设计出切实可行的工艺流程及工艺装备。在产品的加工过程中,工件在夹具内的定位和夹紧显得特别重要。须根据六点定位对产品进行合理的定位,欠定位、完全定位还是过定位都须根据实际的生产过程决定。夹具是涵盖了从加工到组装的几乎所有操作过程的一种装夹设备。由于大量的加工操作需要装夹,夹具设计在制造系统中就变得非常重要,它直接影响加工质量,生产率和制造成本。本文通过分析支承套的结构特点和加工要求,制定了一套较合理的夹具设计,从而为保证该零件的加工精度将提供一种经济实用的工艺装备,具有一定的实用价值。通过对各种定位夹紧装置的分析比较,选择并组合了一套既能够满足加工要求的,又比较简洁的装置。

关键词:发动机档位器,工艺流程,工艺装备,夹具,专用夹具

Abstract

Preparation of parts of the processing technology, processing machinery occupies a very important position, part preparation process was reasonable, which is directly related to the final part quality requirements can be met; fixture design is an indispensable part, it is related to whether can improve its processing efficiency problem. Therefore, both in the machining industry is a very important link.This design mainly experienced two stages: the first stage is the machining process planning, the second stage is the special fixture design.

Based on the engine for parts of the analysis and the structural form of understanding, thus the engine gear position device for process analysis, process explanation and analysis the technical requirement and the precision. The subject of the engine for processing carries on the exploration, design a feasible process flow and process equipment. In the product processing process, the workpiece in jig localization and the clamp is particularly important. According to the six point positioning of products to carry on the reasonable localization, owes the localization, locates completely crosses the localization must be according to the actual production process decision. The jig is covered from the processing to the assembled nearly all operating process of a clamping device. Due to the large number of processing operations require fixture, fixture design in manufacturing system becomes very important, it directly affects the machining quality, the productivity and the production cost. In this paper, through the analysis of the supporting sleeve structure and characteristics of the processing requirements, the development of a more reasonable fixture design, so as to guarantee the machining accuracy of parts will provide an economical and practical technology equipment, has some practical value. Based on the analysis and comparison of all kinds of positioning and clamping device, and choose a combination of both to meet the demands of processing, and the relatively simple device.

Key Words: numerical control processing, technical process, craft equipment, jig design,General fixture,Special jig,Drilling fixture, fixture

目 录

摘 要 IAbstract II

目 录 III

第1章 绪论 1

1.1课题背景 1

1.2机床夹具的功能 1

1.3机床夹具的发展趋势 2

1.3.1机床夹具的现状 2

1.3.2现代机床夹具的发展方向 2

第2章发动机档位器的加工工艺规程设计 4

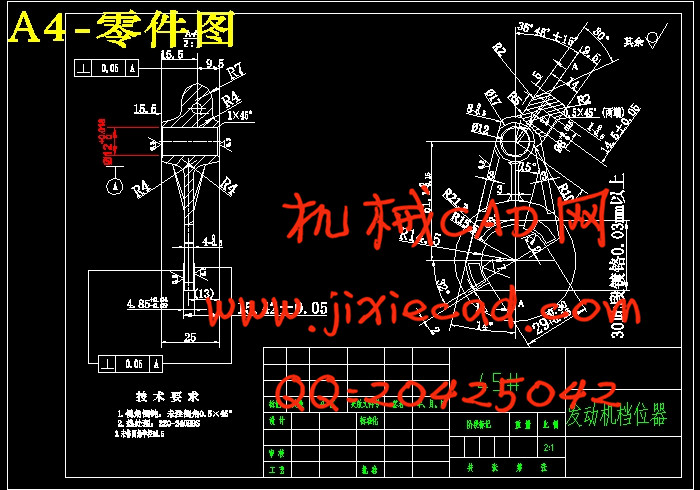

2.1零件的分析 4

2.1.1零件的作用 4

2.1.2零件的工艺分析 4

2.2确定生产类型 4

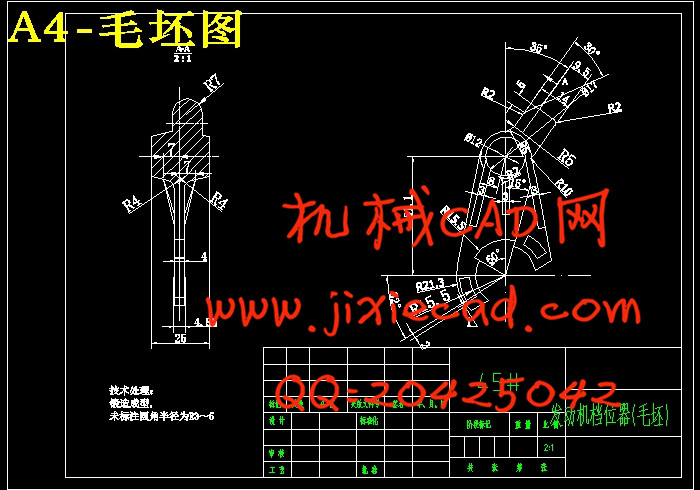

2.3确定毛坯 4

2.3.1确定毛坯种类 4

2.3.2确定铸件加工余量及形状 4

2.3.3绘制铸件零件图 5

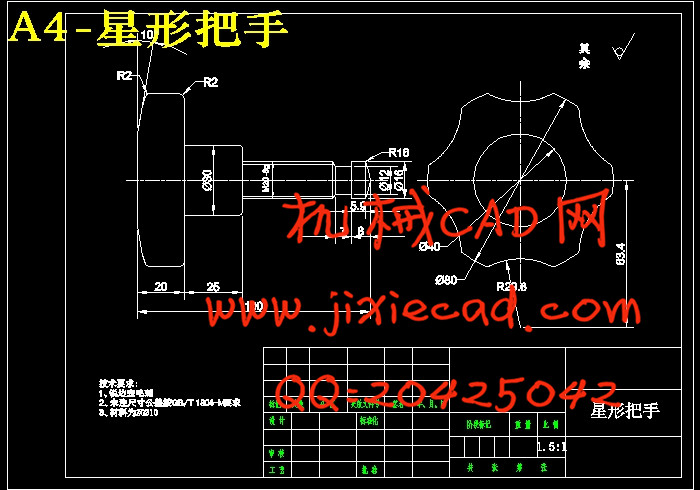

图2.1 零件毛坯图 5

2.4工艺规程设计 5

2.4.1选择定位基准 5

2.4.2制定工艺路线 5

2.4.3选择加工设备和工艺设备 7

2.4.4机械加工余量、工序尺寸及公差的确定 7

2.5确定切削用量及基本工时 9

2.5.1工序1:粗铣Φ12H7的两侧面 9

2.5.3工序3:钻Φ12H7的通孔 10

2.5.4工序4:扩Φ12H7的通孔 11

2.5.5工序5:铰Φ12H7的通孔 12

2.5.6工序6:粗铣a、b面 13

2.5.7工序7:粗铣Φ29孔的两面 14

2.5.8工序8:精铣Φ29孔的两面 15

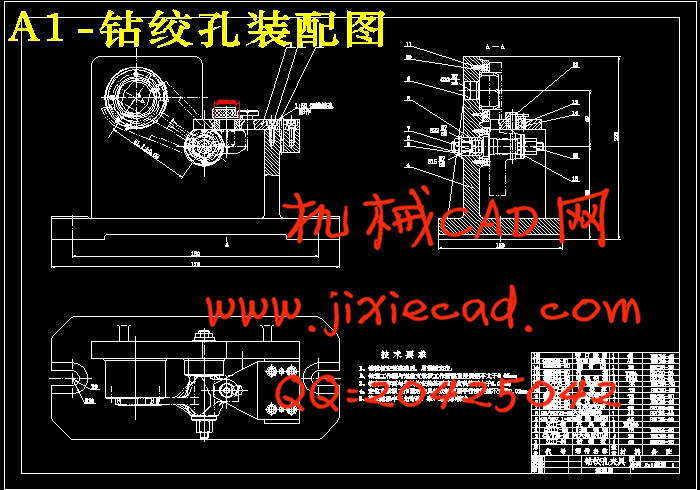

2.5.13工序13:钻铰Φ8的孔 16

2.6本章小结 17

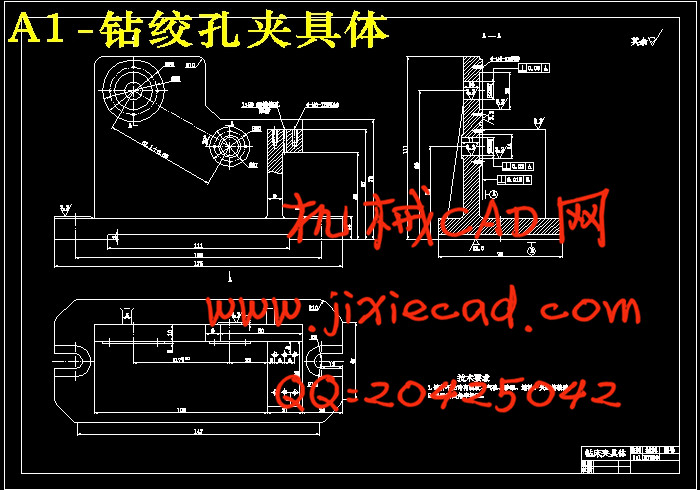

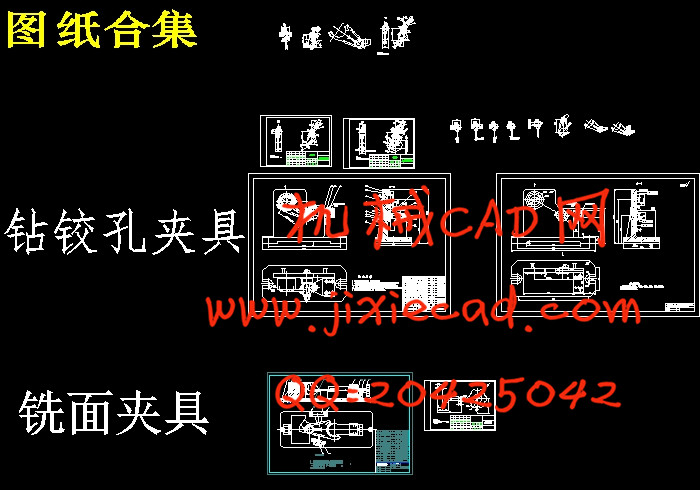

3 专用夹具设计 18

3.1钻孔夹具设计 18

3.1.1问题的提出 18

3.1.2夹具的设计 18

3.4本章小结 24

结论 29

参 考 文 献 30