设计简介

摘要

随着工业生产的发展,提出了各种需求钳技术。一方面,由于在焊接过程中的工业生产提出了很高的要求的发展,另一方面,科学和技术,以提高焊接技术的发展开辟了新的途径。为了满足中国的现代化建设的需要,相信钳技术将更加快速发展,并在工业生产发展中发挥更重要的作用。叉基础的专用夹具设计流程规划和工艺设计上的零件。叉的外表面的主处理部分,所述台阶表面和孔。在一般情况下,确保加工精度的加工精度的平面内比确保容易。因此,遵循的首要原则槽面设计。过程并清除孔和平面分为粗加工和精加工处理的阶段,以确保孔的精度。第一系列的支承孔加工顶部位置的平面之后,除了后续过程与顶表面和其他加工主要处理操作的安排处理孔的定位孔和平面的每个过程。使用专用夹具,夹具,夹具夹紧,自动文件夹更多的选择,可靠的夹紧机构不自锁。因此,生产效率高。适用于大批量的生产线。能够满足设计要求。

关键词:拔叉类零件;工艺;夹具

Abstract

With the development of industrial production, a variety of needs-clamp technique. On the one hand, due to the welding process development of industrial production made high demands on the other hand, science and technology, in order to improve the development of welding technology has opened up new avenues. In order to meet the needs of China's modernization, believe clamp technique will be more rapid development, and play a more important role in the development of industrial production. Parts fork foundation dedicated fixture design process planning and process design. Fork portion of the outer surface of the main processing, the stepped surface and the bore. In general, to ensure the machining accuracy of the machining accuracy of the plane than to ensure easy. Therefore, the first principle to follow trough surface design. Process and clear the hole and the plane is divided into roughing and finishing stages of processing to ensure the accuracy of the hole. After the first series of supporting hole machining flat top position, except that each process subsequent arrangements for dealing with the process of the hole with the top surface and other machining operations mainly deal with the positioning holes and planes. The use of special fixtures, jigs, fixtures clamping, automatic folder more choices, reliable clamping mechanism is not self-locking. Therefore, high production efficiency. For high-volume production lines. Able to meet the design requirements.

目 录

第1章 绪论.. 1

1.1 机械加工工艺概述.. 1

1.2机械加工工艺流程.. 1

1.3夹具概述.. 2

1.4机床夹具的功能.. 2

1.5机床夹具的发展趋势.. 3

1.5.1机床夹具的现状.. 3

1.5.2现代机床夹具的发展方向.. 3

第2章 零件的分析.. 5

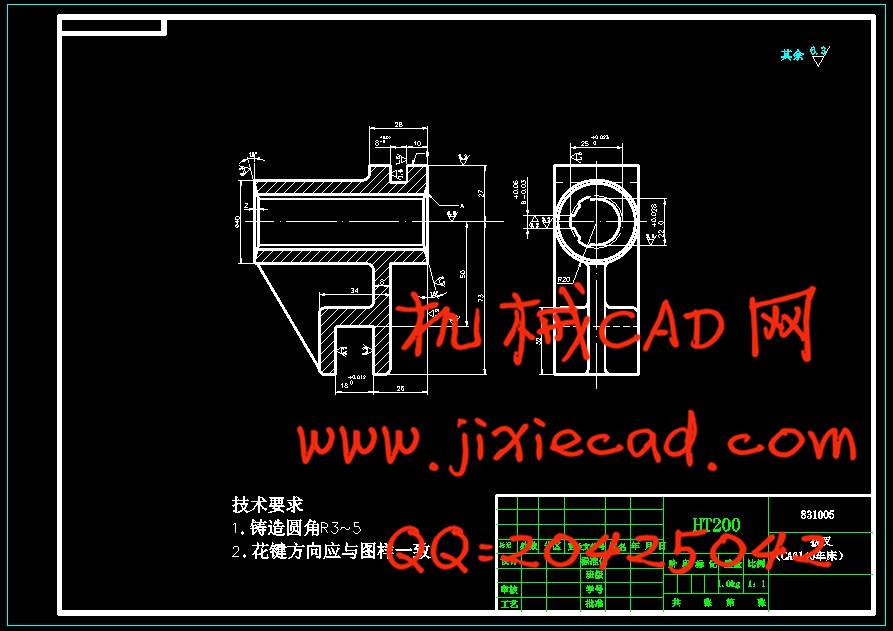

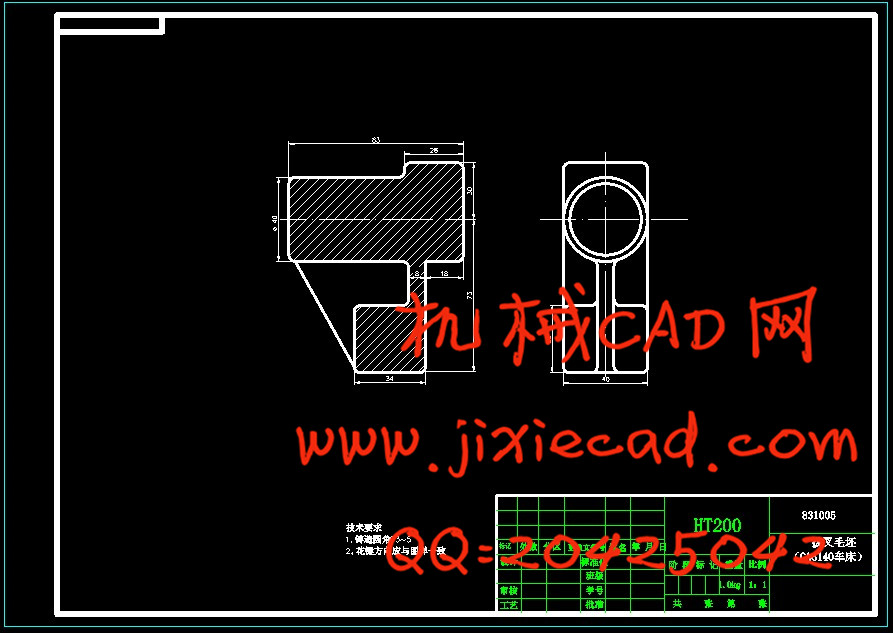

2.1零件的分析.. 5

2.1.1零件的作用.. 5

2.1.2零件的工艺分析.. 5

2.2工艺规程设计.. 5

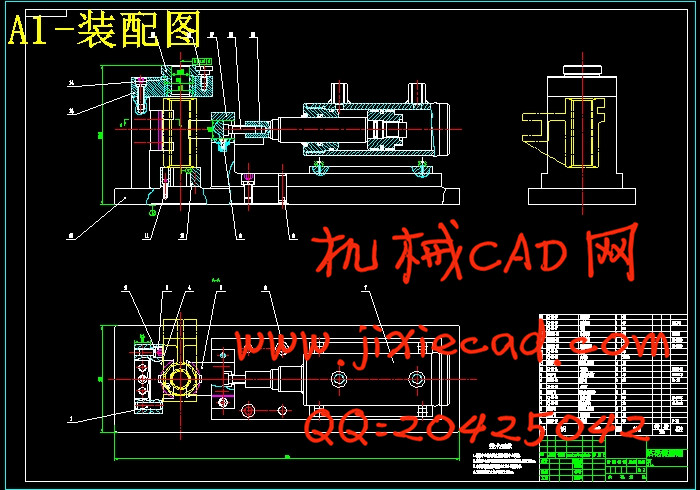

第3章 钻花键槽底孔液动夹具设计.. 15

3.1设计要求.. 15

3.2夹具设计.. 17

3.2.1 定位基准的选择.. 17

3.2.2 切削力及夹紧力的计算.. 17

3.3定位误差的分析.. 21

3.4 钻套、衬套、钻模板设计与选用.. 21

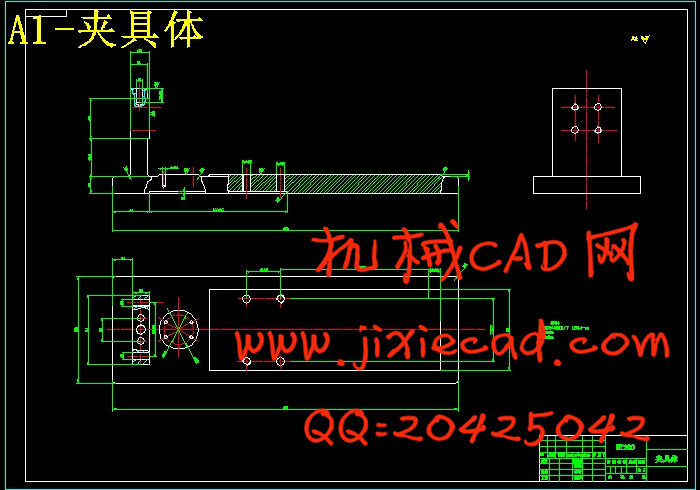

3.5 确定夹具体结构和总体结构.. 23

3.6夹具设计及操作的简要说明.. 24

总 结.. 25

致 谢.. 26

参 考 文 献.. 28

随着工业生产的发展,提出了各种需求钳技术。一方面,由于在焊接过程中的工业生产提出了很高的要求的发展,另一方面,科学和技术,以提高焊接技术的发展开辟了新的途径。为了满足中国的现代化建设的需要,相信钳技术将更加快速发展,并在工业生产发展中发挥更重要的作用。叉基础的专用夹具设计流程规划和工艺设计上的零件。叉的外表面的主处理部分,所述台阶表面和孔。在一般情况下,确保加工精度的加工精度的平面内比确保容易。因此,遵循的首要原则槽面设计。过程并清除孔和平面分为粗加工和精加工处理的阶段,以确保孔的精度。第一系列的支承孔加工顶部位置的平面之后,除了后续过程与顶表面和其他加工主要处理操作的安排处理孔的定位孔和平面的每个过程。使用专用夹具,夹具,夹具夹紧,自动文件夹更多的选择,可靠的夹紧机构不自锁。因此,生产效率高。适用于大批量的生产线。能够满足设计要求。

关键词:拔叉类零件;工艺;夹具

Abstract

With the development of industrial production, a variety of needs-clamp technique. On the one hand, due to the welding process development of industrial production made high demands on the other hand, science and technology, in order to improve the development of welding technology has opened up new avenues. In order to meet the needs of China's modernization, believe clamp technique will be more rapid development, and play a more important role in the development of industrial production. Parts fork foundation dedicated fixture design process planning and process design. Fork portion of the outer surface of the main processing, the stepped surface and the bore. In general, to ensure the machining accuracy of the machining accuracy of the plane than to ensure easy. Therefore, the first principle to follow trough surface design. Process and clear the hole and the plane is divided into roughing and finishing stages of processing to ensure the accuracy of the hole. After the first series of supporting hole machining flat top position, except that each process subsequent arrangements for dealing with the process of the hole with the top surface and other machining operations mainly deal with the positioning holes and planes. The use of special fixtures, jigs, fixtures clamping, automatic folder more choices, reliable clamping mechanism is not self-locking. Therefore, high production efficiency. For high-volume production lines. Able to meet the design requirements.

目 录

第1章 绪论.. 1

1.1 机械加工工艺概述.. 1

1.2机械加工工艺流程.. 1

1.3夹具概述.. 2

1.4机床夹具的功能.. 2

1.5机床夹具的发展趋势.. 3

1.5.1机床夹具的现状.. 3

1.5.2现代机床夹具的发展方向.. 3

第2章 零件的分析.. 5

2.1零件的分析.. 5

2.1.1零件的作用.. 5

2.1.2零件的工艺分析.. 5

2.2工艺规程设计.. 5

第3章 钻花键槽底孔液动夹具设计.. 15

3.1设计要求.. 15

3.2夹具设计.. 17

3.2.1 定位基准的选择.. 17

3.2.2 切削力及夹紧力的计算.. 17

3.3定位误差的分析.. 21

3.4 钻套、衬套、钻模板设计与选用.. 21

3.5 确定夹具体结构和总体结构.. 23

3.6夹具设计及操作的简要说明.. 24

总 结.. 25

致 谢.. 26

参 考 文 献.. 28