设计简介

摘 要

本次设计的题目是年产三十万件法兰盘机械加工工艺及工装设计,主要内容如下:

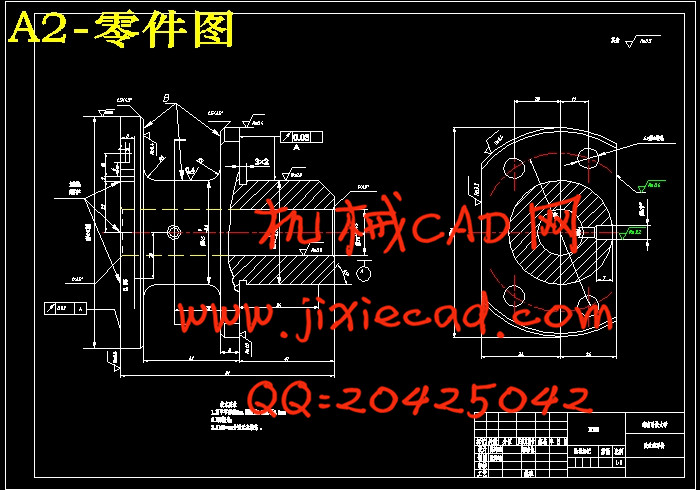

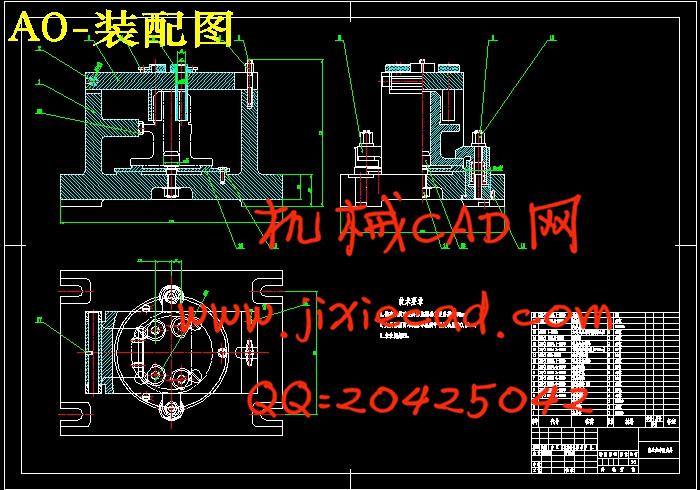

首先,对零件进行分析,主要是零件作用的分析和工艺性分析,通过零件分析可以了解零件的基本情况,而工艺分析可以知道零件的加工表面和加工要求。根据零件图提出的加工要求,确定毛坯的制造形式和尺寸。其次,进行基面的选择,确定加工过程中的粗基准和精基准。根据选好的基准,制订工艺路线,通常制订两种以上的工艺路线,通过工艺方案的比较与分析,再选择可以使零件的几何形状、尺寸精度及位置精度等技术要求得到合理的保证的一种较佳工序路线。然后,根据已经选定的工序路线,确定每一步的切削用量及基本工时,并选择合适的机床和刀具和量具。最后,设计车床夹具。设计车床夹具,首先要仔细分析被加工零件的技术要求,运用夹具设计的基本原理和方法,拟定夹具设计方案;在满足加工精度的条件下,合理的进行安装、定位、夹紧;在完成夹具草图后,进一步考虑零件间的连接关系和螺钉、螺母、定位销等的固定方式,设计合理的结构实现各零部件间的相对运动;根据各零件的使用要求,选择相应的材料。完成车床夹具的所有设计后,用AutoCAD进行二维图形的绘制,画装配图,然后从装配图上拆画零件图,标注相关尺寸及技术要求;

关键词:机械;法兰盘零件;加工工艺;夹具设计

本次设计的题目是年产三十万件法兰盘机械加工工艺及工装设计,主要内容如下:

首先,对零件进行分析,主要是零件作用的分析和工艺性分析,通过零件分析可以了解零件的基本情况,而工艺分析可以知道零件的加工表面和加工要求。根据零件图提出的加工要求,确定毛坯的制造形式和尺寸。其次,进行基面的选择,确定加工过程中的粗基准和精基准。根据选好的基准,制订工艺路线,通常制订两种以上的工艺路线,通过工艺方案的比较与分析,再选择可以使零件的几何形状、尺寸精度及位置精度等技术要求得到合理的保证的一种较佳工序路线。然后,根据已经选定的工序路线,确定每一步的切削用量及基本工时,并选择合适的机床和刀具和量具。最后,设计车床夹具。设计车床夹具,首先要仔细分析被加工零件的技术要求,运用夹具设计的基本原理和方法,拟定夹具设计方案;在满足加工精度的条件下,合理的进行安装、定位、夹紧;在完成夹具草图后,进一步考虑零件间的连接关系和螺钉、螺母、定位销等的固定方式,设计合理的结构实现各零部件间的相对运动;根据各零件的使用要求,选择相应的材料。完成车床夹具的所有设计后,用AutoCAD进行二维图形的绘制,画装配图,然后从装配图上拆画零件图,标注相关尺寸及技术要求;

关键词:机械;法兰盘零件;加工工艺;夹具设计

ABSTRACT

The topic of this graduation design is an annual output of three hundred thousand flange machining process and tooling design, the main contents are as follows:

First of all, analyse , it is mainly analysis of the function of the part and craft analysis to the part , through part analyse can find out about basic situation of part, and craft analyse may know the processing surface of the part and is it require to process. The processing demand put forward according to the part picture, confirm the manufacture form. of the blank and sureness of the size. The second step, carry on the choice the base , confirm thick datum and precise datum in the processing course. According to the datum chosen , make the craft route , usually make the craft route of more than two kinds, with analysing through the comparison of the craft scheme, and then choosing be able to make such specification requirements as the precision of geometry form. size of the part and precision of position ,etc. get a kind of process of the rational assurance s. The third step, according to the already selected process route, confirm for every steps of cutting consumption and basic man-hour , choose suitable lathe and cutter. To rough machining , will check the power of the lathe . Finally , design the jig getting into the hole of the ring flange. Designed drilling fixture, the first careful analysis is the technical requirements for processing components, fixture design using the basic principles and methods.Prepared the fixture design scheme ;Meet the conditions of precision ,then reasonable installation, positioning, clamping;After the completion of draft fixture, and further consider the connection relation between parts and screws, nuts, pins and other fixed means,designing the reasonable structure to achieve relative motion between the various components;Requirements of the various components, select the appropriate materials.Completion of all drilling fixture design, using the AutoCAD drawing two-dimensional graphics,first draw assembly drawing, and then removed from the part drawing on the painting Parts,marking the related to size and technical requirements,finally, write a thesis, organize, edit, complete the graduation project.

KeyWords:machine;flange;process the craft;the tongs design

The topic of this graduation design is an annual output of three hundred thousand flange machining process and tooling design, the main contents are as follows:

First of all, analyse , it is mainly analysis of the function of the part and craft analysis to the part , through part analyse can find out about basic situation of part, and craft analyse may know the processing surface of the part and is it require to process. The processing demand put forward according to the part picture, confirm the manufacture form. of the blank and sureness of the size. The second step, carry on the choice the base , confirm thick datum and precise datum in the processing course. According to the datum chosen , make the craft route , usually make the craft route of more than two kinds, with analysing through the comparison of the craft scheme, and then choosing be able to make such specification requirements as the precision of geometry form. size of the part and precision of position ,etc. get a kind of process of the rational assurance s. The third step, according to the already selected process route, confirm for every steps of cutting consumption and basic man-hour , choose suitable lathe and cutter. To rough machining , will check the power of the lathe . Finally , design the jig getting into the hole of the ring flange. Designed drilling fixture, the first careful analysis is the technical requirements for processing components, fixture design using the basic principles and methods.Prepared the fixture design scheme ;Meet the conditions of precision ,then reasonable installation, positioning, clamping;After the completion of draft fixture, and further consider the connection relation between parts and screws, nuts, pins and other fixed means,designing the reasonable structure to achieve relative motion between the various components;Requirements of the various components, select the appropriate materials.Completion of all drilling fixture design, using the AutoCAD drawing two-dimensional graphics,first draw assembly drawing, and then removed from the part drawing on the painting Parts,marking the related to size and technical requirements,finally, write a thesis, organize, edit, complete the graduation project.

KeyWords:machine;flange;process the craft;the tongs design

目 录

第一章 绪论 1

1.1课题背景A 1

1.2 夹具的发展史 1

1.3 小结 2

第二章 零件的结构工艺性分析 3

2.1 零件的作用 3

2.2 零件的工艺性分析 3

第三章 工艺规程设计 5

3.1 确定毛坯的制造形式 5

3.2 基准的选择 5

3.2.1 粗基准的选择 5

3.2.2 精基准的选择 5

3.3 工艺路线的拟定 5

3.3.1 选择加工方法 5

3.3.2 划分加工阶段 6

3.3.3 安排加工顺序 6

3.4 机械加工余量、工序尺寸及毛坯尺寸的确定 8

3.5 确定切削用量及基本工时 12

第四章 夹具的设计 31

4.1 设计夹具的目的 31

4.2 夹具的分类 31

4.3专用夹具的组成 32

4.4典型的定位元件 33

4.5夹具中的夹紧机构 34

4.6夹具的发展趋势 35

4.7 问题的提出 37

4.8 夹具设计 4-

4.8.1 定位方案的设计 38

4.8.2 定位误差分析与计算 40

4.8.3 定位元件尺寸公差的确定 40

4.8.4 导向元件设计 41

4.8.5 钻套高度和排屑间隙 41

4.8.6 夹紧装置的设计 42

4.8.7 夹具结构设计及操作简要说明 42

4.8.8 方案综合评价与结论 42

结 论 43

参考文献 44

致 谢 45