设计简介

摘要

零件的加工工艺编制,在机械加工中占有非常重要的地位,零件工艺编制得合不合理,这直接关系到零件最终能否达到质量要求;夹具的设计也是不可缺少的一部分,它关系到能否提高其加工效率的问题。因此这两者在机械加工行业中是至关重要的环节。

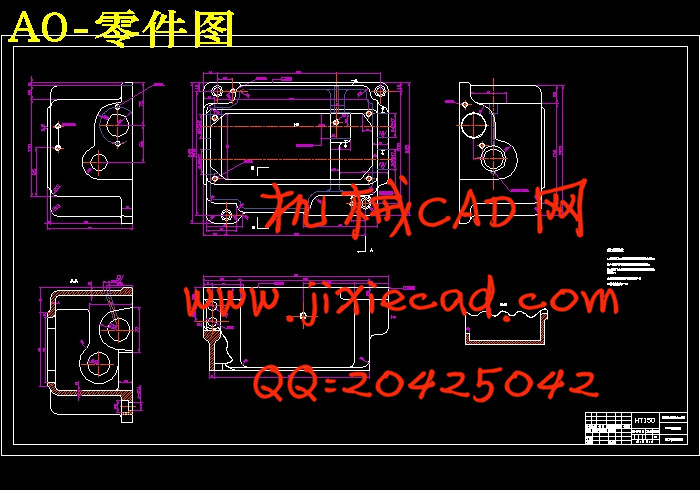

C615车床是现代制造业常用的机床之一,本零件为进给箱是c615车床六大组成部件之一,它位于机床的中前端,主要安装进给变速机构,它的作用是把从主组经挂轮机构传来的 运动传给光杆和丝杆,取得不同的进给量和螺距。其中 ,

, 三个同轴孔为联接光杆,

三个同轴孔为联接光杆, 两个同轴孔为丝杆联接孔,使进给箱和车床光杆,丝杆联接在一起。

两个同轴孔为丝杆联接孔,使进给箱和车床光杆,丝杆联接在一起。

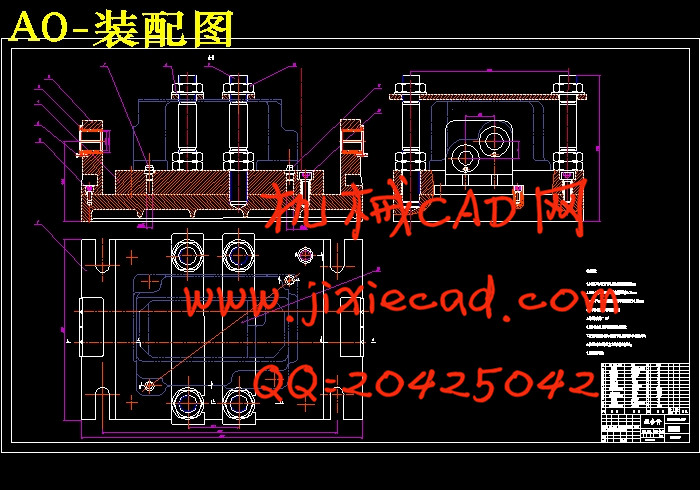

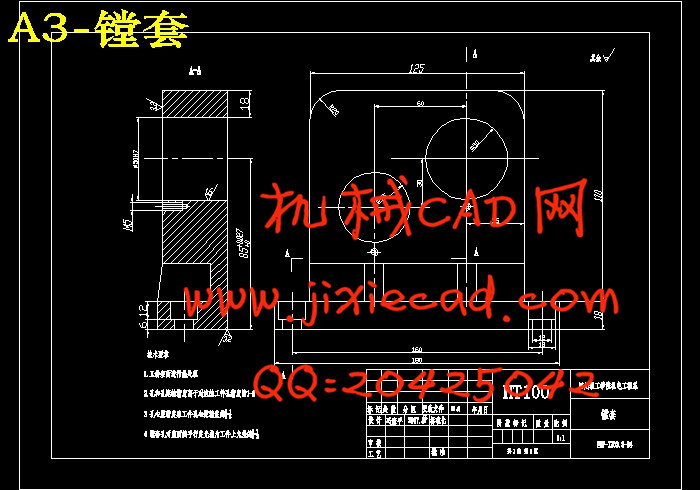

在设计加工 ,

, 三个同轴孔和

三个同轴孔和 两个同轴孔的专用夹具时,为了缩短加工每个孔的加工间隔时间,采用一个镗杆上装三把镗刀同时加工,通过加工完一个孔系后加工另一个孔系,无须装卸工件,这样降低了这些同轴孔加工位置误差以及提高了加工效率。

两个同轴孔的专用夹具时,为了缩短加工每个孔的加工间隔时间,采用一个镗杆上装三把镗刀同时加工,通过加工完一个孔系后加工另一个孔系,无须装卸工件,这样降低了这些同轴孔加工位置误差以及提高了加工效率。

关键词:工艺、基准、切削用量、定位基准、定位误差。

ABSTRCT

零件的加工工艺编制,在机械加工中占有非常重要的地位,零件工艺编制得合不合理,这直接关系到零件最终能否达到质量要求;夹具的设计也是不可缺少的一部分,它关系到能否提高其加工效率的问题。因此这两者在机械加工行业中是至关重要的环节。

C615车床是现代制造业常用的机床之一,本零件为进给箱是c615车床六大组成部件之一,它位于机床的中前端,主要安装进给变速机构,它的作用是把从主组经挂轮机构传来的 运动传给光杆和丝杆,取得不同的进给量和螺距。其中

在设计加工

关键词:工艺、基准、切削用量、定位基准、定位误差。

ABSTRCT

Is the components craft establishment, holds the very important status in the machine-finishing, the components craft establishes reasonable, whether do this direct relation components achieve the quality requirement finally; Jig's design is also an essential part, whether does it relate raises its processing efficiency the question. Therefore this both in the machine-finishing profession are the important links.

The C615 lathe is one of modern manufacturing industry commonly used engine beds, This components for the gear box are c615 lathe one of six big building blocks, it located at engine bed's front end, mainly installs to feed gearshift mechanism, its function is after hangs from the main group the movement which the wheel work transmits to pass to the polished rod and the lead screw, obtains the different to feed quantity and the pitch. And,

When design processing,

Key word: Craft, datum, cutting specifications, localization datum, position error.

目 录

中文摘要 Ⅰ

英文摘要 Ⅱ

前言 1

第1章 零件的分析 1

1.1 零件的作用 1

1.2 零件的工艺分析 1

第2章 工艺规程的设计 2

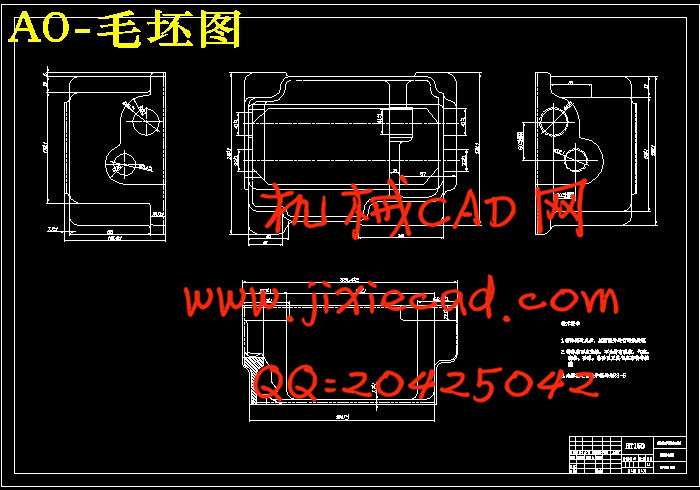

2.1 确定毛坯的制造形式 2

2.2 基准的选择 2

2.2.1 粗基准的选择 2

2.2.1 精基准的选择 2

2.3 制定工艺路线 3

2.3.1 制定工序路线的依据 3

2.3.2 两种工艺路线方案 3

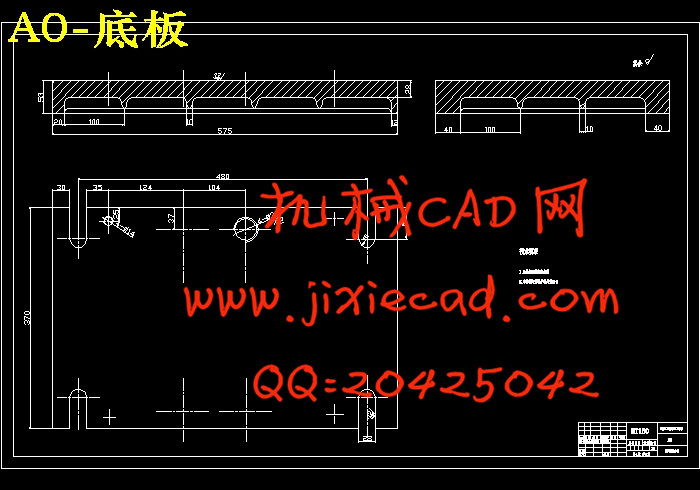

2.4 机械加工余量.工序尺寸及毛坯的确定 5

2.5 确定各工序装备.切削用量及基本工时 6

第3章 专用夹具的设计 27

3.1 问题的指出 27

3.2 夹具的设计 27

3.2.1 定位基准的选择 27

3.2.2切削力及夹紧力的计算 27

3.2.3定位误差的分析 28

3.2.4夹具设计及操作的简要说明 29

第4章 设计体会 34

参考文献 35

致谢 36