设计简介

缸体精铣两侧面机床总体设计及夹具设计

摘 要:本设计所加工的缸体为大批大量生产,为了提高加工精度和生产效率,需要设计一台组合机床来改善缸体的加工情况。本课题设计的是精铣缸体两侧面组合机床。主要完成对缸体前后两个面的铣削加工及其专用夹具的设计。本设计的组合机床为卧式铣床,先对被加工零件特点进行分析,选择采用刀具固定工件安装在滑台上的方法,一次走刀加工两个平面。在确定了机床配置型式的基础上,根据本道工序需要加工的内容,完成三图一卡的设计。夹具部分的设计主要是定位和夹紧方式的选择,以零件加工工序图为基础,该组合机床以“一面两孔”的方式定位,由于工件体积质量都较大,所以使用伸缩式定位销的结构。夹紧方式是用单螺栓夹紧方式由上平面相对于定位基面夹紧。按高度集中工序原则,以大量通用部件为基础,配以少量专用部件设计的组合机床,有利于提高生产效率,降低生产成本。

关键词:组合机床;精铣;三图一卡;一面两孔

The overall design of the Modular Machine for fine milling two sides of Cylinder and design the fixture

Abstract: The design of the cylinder is a product which needs mass production. In order to prove the disposition and the production efficiency, I need to design a modular machine to improve the the situation of machining. The task is the overall design of the modular machine for fine milling two sides of cylinder. The main design is about completion of milling the two sides of the cylinder and design the special jig. This design is horizontal milling machine. First, processing components characteristics should be ananlysed,next choose fixed tools, workpiece stage in the method of sliding. A tool path processes two planes. Based on determining the type of machine configurations,the three diagram and a card are supposed to be completed according to the needs of this procedure. Fixture part of the design is mainly the choice of location and clamping. Based on machining process drawing, The locating of the workpiece on this modular machine is "one side and two holes", As the quality and the workpiece size is larger, so we make use of the retractable pins structure 。and based on positioning plane clamped by means of singlebolt-clamping. by the principle of high concentration,it consists of a large number of common components together with a few specially-designed macthine tools,which will contribute to increasing manufacturing efficiency and reducing production costs.

Key word: modular machine; fine milling; Three diagram and a card ;one side and two holes .

目 录

1 绪论 1

2 组合机床总体设计 3

2.1 总体方案论证 3

2.1.1 工艺方案的拟定 3

2.1.2 机床配置形式的选择 3

2.1.3 定位基准的选择 4

2.1.4 滑台型式的选择 4

2.2 确定切削用量 4

2.2.1 选择切削用量 4

2.2.2计算切削力、切削扭矩及切削功率 5

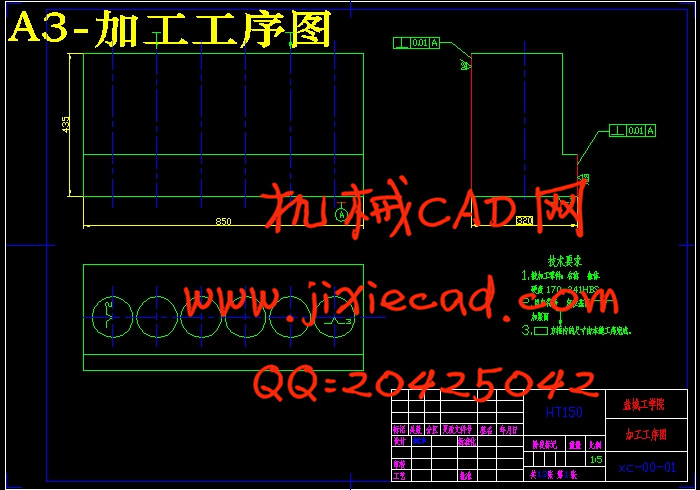

2.3 组合机床总体设计—三图一卡 6

2.3.1 被加工零件工序图 6

2.3.2 加工示意图 6

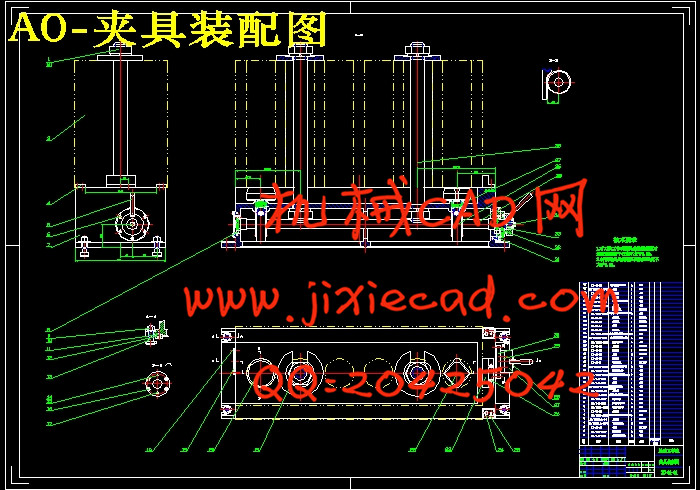

2.3.3 机床尺寸联系总图 7

2.3.4 机床生产率计算卡 8

3 夹具设计 11

3.1 夹具设计的基本要求 11

3.2 夹具设计的方法与步骤 11

3.2.1 设计前的准备 11

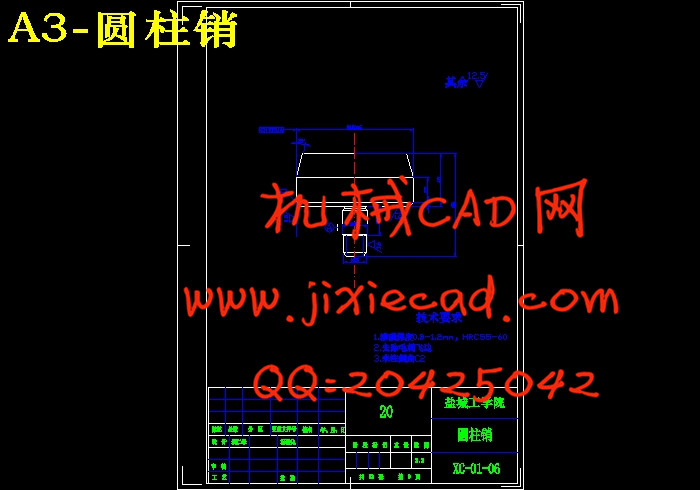

3.2.2 拟定夹具结构方案 绘制草图 11

3.2.3 定位误差分析.................................................... 13

3.2.4 夹紧力的计算.................................................... 14

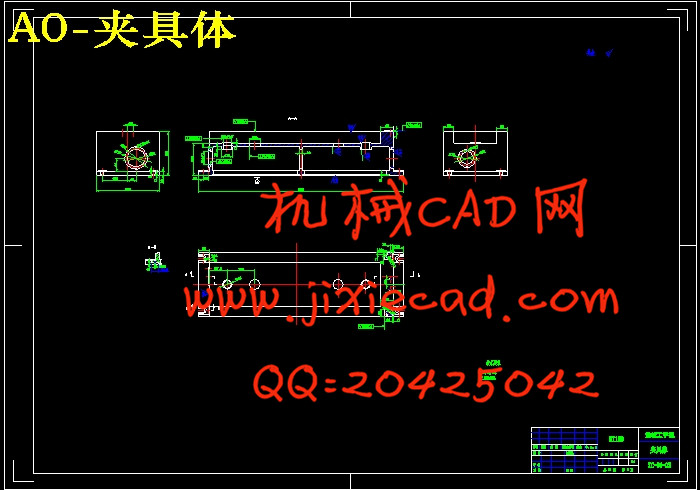

3.3 绘制夹具总图 15

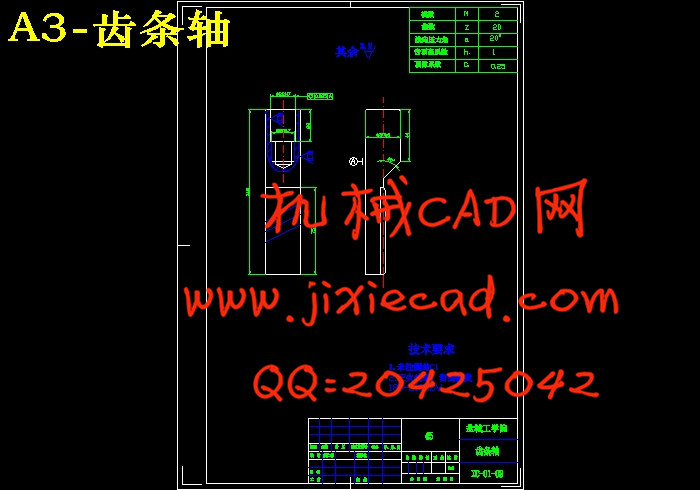

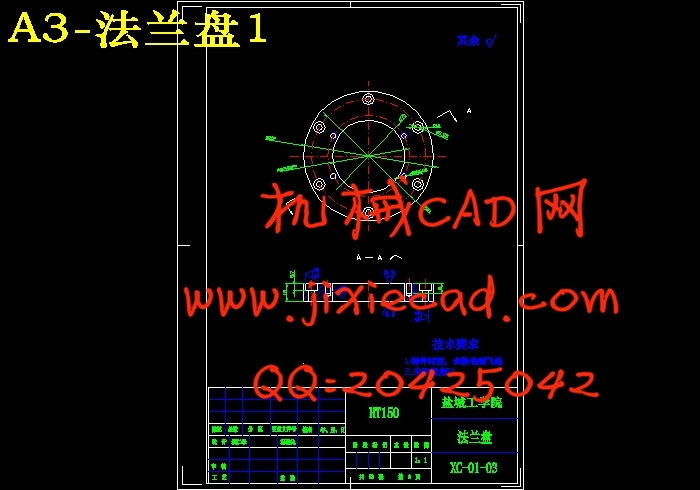

3.4 绘制夹具零件图 16

4 结论 17

参考文献 18

致 谢.............................................................. 19

摘 要:本设计所加工的缸体为大批大量生产,为了提高加工精度和生产效率,需要设计一台组合机床来改善缸体的加工情况。本课题设计的是精铣缸体两侧面组合机床。主要完成对缸体前后两个面的铣削加工及其专用夹具的设计。本设计的组合机床为卧式铣床,先对被加工零件特点进行分析,选择采用刀具固定工件安装在滑台上的方法,一次走刀加工两个平面。在确定了机床配置型式的基础上,根据本道工序需要加工的内容,完成三图一卡的设计。夹具部分的设计主要是定位和夹紧方式的选择,以零件加工工序图为基础,该组合机床以“一面两孔”的方式定位,由于工件体积质量都较大,所以使用伸缩式定位销的结构。夹紧方式是用单螺栓夹紧方式由上平面相对于定位基面夹紧。按高度集中工序原则,以大量通用部件为基础,配以少量专用部件设计的组合机床,有利于提高生产效率,降低生产成本。

关键词:组合机床;精铣;三图一卡;一面两孔

The overall design of the Modular Machine for fine milling two sides of Cylinder and design the fixture

Abstract: The design of the cylinder is a product which needs mass production. In order to prove the disposition and the production efficiency, I need to design a modular machine to improve the the situation of machining. The task is the overall design of the modular machine for fine milling two sides of cylinder. The main design is about completion of milling the two sides of the cylinder and design the special jig. This design is horizontal milling machine. First, processing components characteristics should be ananlysed,next choose fixed tools, workpiece stage in the method of sliding. A tool path processes two planes. Based on determining the type of machine configurations,the three diagram and a card are supposed to be completed according to the needs of this procedure. Fixture part of the design is mainly the choice of location and clamping. Based on machining process drawing, The locating of the workpiece on this modular machine is "one side and two holes", As the quality and the workpiece size is larger, so we make use of the retractable pins structure 。and based on positioning plane clamped by means of singlebolt-clamping. by the principle of high concentration,it consists of a large number of common components together with a few specially-designed macthine tools,which will contribute to increasing manufacturing efficiency and reducing production costs.

Key word: modular machine; fine milling; Three diagram and a card ;one side and two holes .

目 录

1 绪论 1

2 组合机床总体设计 3

2.1 总体方案论证 3

2.1.1 工艺方案的拟定 3

2.1.2 机床配置形式的选择 3

2.1.3 定位基准的选择 4

2.1.4 滑台型式的选择 4

2.2 确定切削用量 4

2.2.1 选择切削用量 4

2.2.2计算切削力、切削扭矩及切削功率 5

2.3 组合机床总体设计—三图一卡 6

2.3.1 被加工零件工序图 6

2.3.2 加工示意图 6

2.3.3 机床尺寸联系总图 7

2.3.4 机床生产率计算卡 8

3 夹具设计 11

3.1 夹具设计的基本要求 11

3.2 夹具设计的方法与步骤 11

3.2.1 设计前的准备 11

3.2.2 拟定夹具结构方案 绘制草图 11

3.2.3 定位误差分析.................................................... 13

3.2.4 夹紧力的计算.................................................... 14

3.3 绘制夹具总图 15

3.4 绘制夹具零件图 16

4 结论 17

参考文献 18

致 谢.............................................................. 19