设计简介

摘 要

目录

1.零件的工艺分析

2.1 毛坯的制造形式

3.制订机械加工工艺路线

3.1表面加工方法的确定

3.3确定工艺路线

4.机械加工余量、工序尺寸及公差的确定

6. 夹具设计

7. 本夹具特点及有待改进处

8参考文献

9心得体会

|

| Abstract |

|

Rolling parts manufacturing process document Abstract: manufacturing process requires the elements of procedure documentation standards down in the form of a document of paper documents into integrated technology products to be a requirement to prepare a document clear and simple query to the product mix Simple production quantities occasion type of paper products manufacturing technology professional characteristics of Category 2002: Machine, the WTO is a challenge more opportunities experts pointed out that China's CNC machine tools to increase research and development efforts to speed up the popularization of CNC machine tools Talking about the development of China's machine tool manufacturing services competition Milling and processing centres in China market status and prospects at home and abroad lathe technology and development of the processing center of world production, demand and the development trends of world development trend of domestic and foreign machine tool CNC machining technology development trends and the development of CNC machine tools Product manufacturing process of the content and requirements in accordance with certain procedures for the preparation, documentation and standards in the form of fixed, the formation of a document. Technology files can be divided into two types: First General of documents, to be a product of all the requirements of unity in the preparation of a document, clear and simple, readily accessible and applicable to the product structure is simple, the production of small quantities of occasions. Second, the type of classified documents, namely, manufacturing technology products in accordance with the classification of professional characteristics, prominent professional characteristics, applicable to all types of products. Rolling as a standardized machine parts components, in addition to individual species, most species of similar production processes. Therefore, bearing parts of the manufacturing process for the preparation of documents to achieve standardized, and serialization. |

1.零件的工艺分析

2.机械加工工艺设计

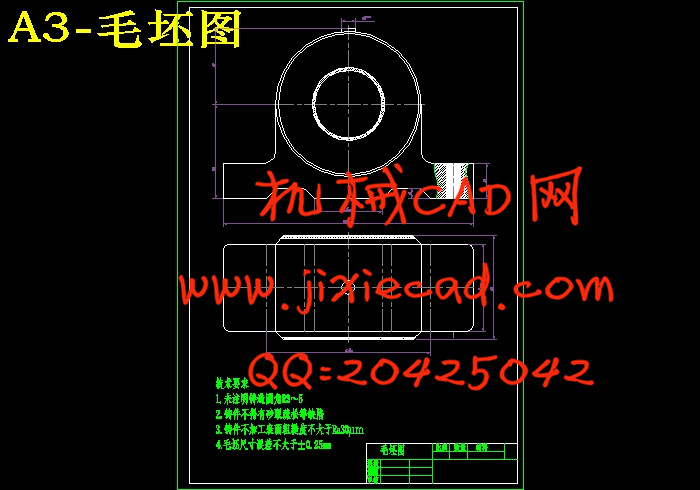

2.1 毛坯的制造形式

2.2基面

2.2.1 粗基面的选择

2.2.2 精基面的选择

3.制订机械加工工艺路线

3.1表面加工方法的确定

3.2工序顺序的安排

3.3确定工艺路线

4.机械加工余量、工序尺寸及公差的确定

4.1确定切削用量及时间定额

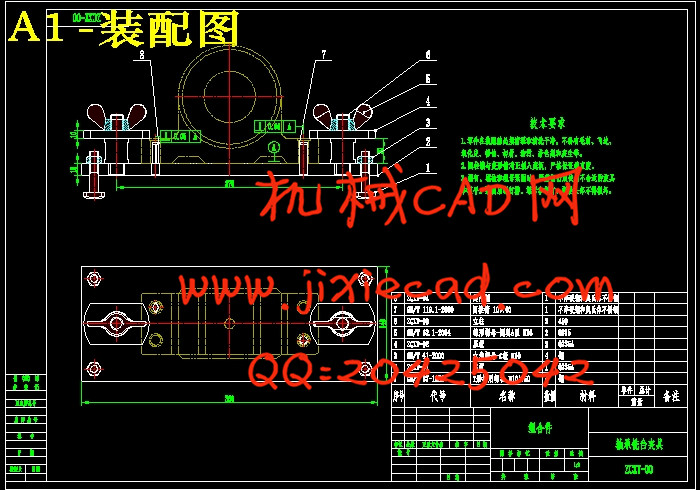

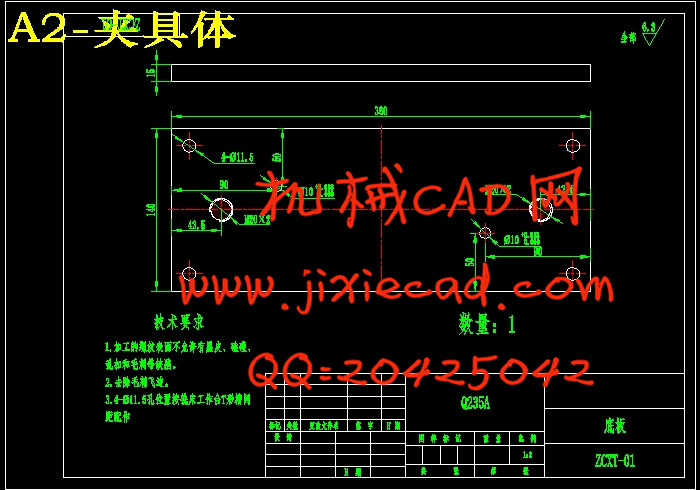

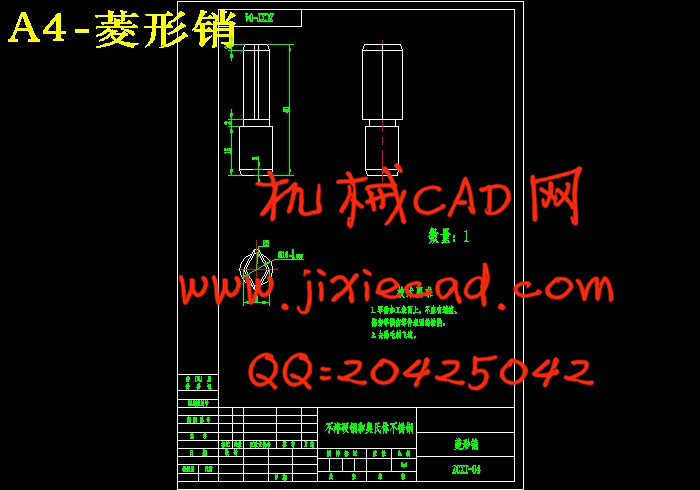

5. 夹具使用说明6. 夹具设计

7. 本夹具特点及有待改进处

8参考文献

9心得体会