设计简介

摘要

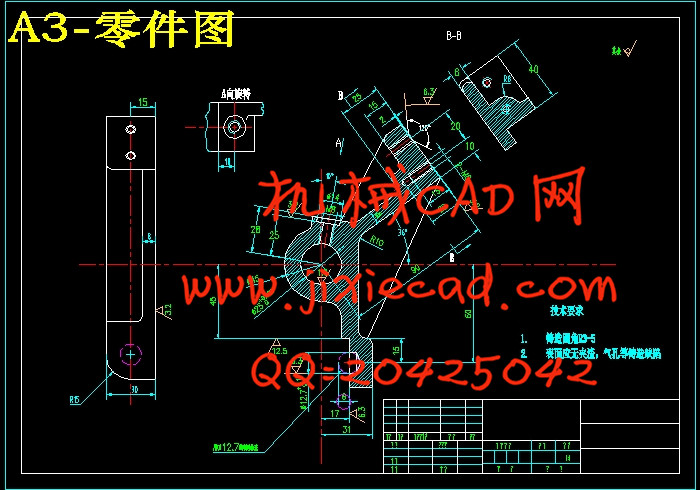

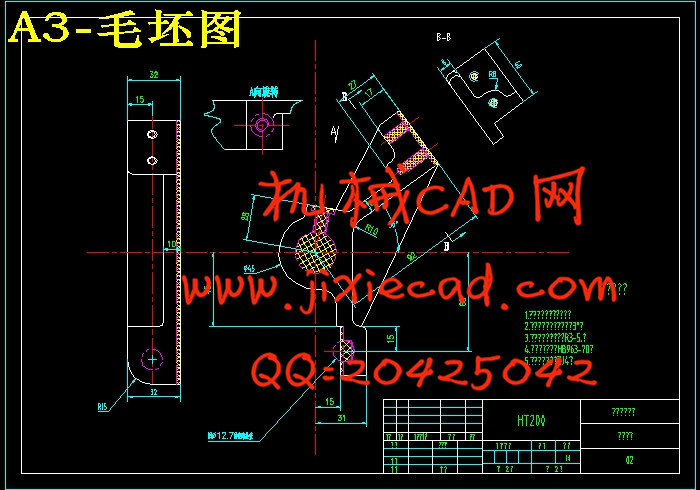

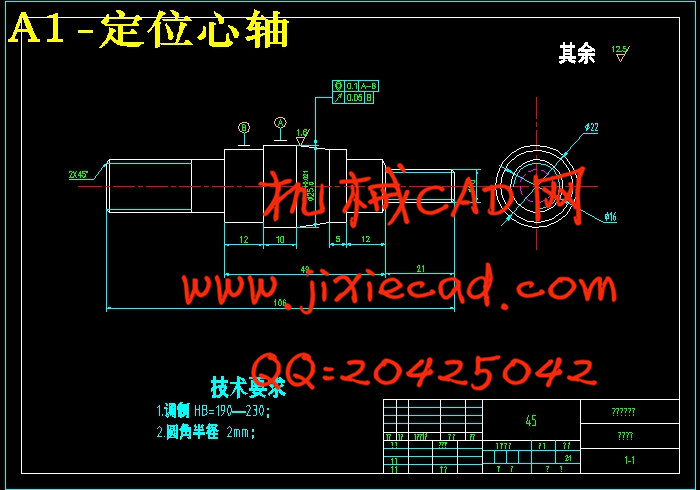

本设计是CA6140车床杠杆零件的加工工艺规程及一些工序的专用夹具设计。CA6140车床杠杆零件的主要加工表面是平面和孔。一般来说,保证平面的加工精度要比保证孔的加工精度容易。因此,本设计遵循先面后孔的原则,并将孔与平面的加工明确划分成粗加工和精加工阶段以保证孔和平面的加工精度。基准的选择以杠杆关键词:杠杆零件,加工工艺,夹具,定位,加紧

Abstract

This paper is to design the craft processes of making the CA6140lever spare parts and some specialized tongs in the process. The CA6140 lever spare part primarily processes the surface and bores. Generally speaking, to guarantee the accuracy of the flat surface process is easier than that of the bore. Therefore, this design follows the principle that surface first and then the bore, and definitely divides the process of flat surface and bore into coarse processes and precise processes to guarantee the bore process. The basic choice is to consider 45 outside circle as rough basis and to consider 25bore and its next surface as precise basis . The bottom is first processed out to be fixed position basis, and process the bore using the bottom as the precise basis. In the whole processes , specialized tongs are used. In consideration of the simple construction size of the spare parts, clipping by hands is adopted. It is simple, and the organization is simple, and can satisfy the design request.Key Words : Lever spare parts, craft process, tongs, fixed position, tight clip

目录

摘要 I

Abstract II

目录 Ⅲ

第一章 绪论 1

1.1课题背景及发展趋势 1

1.2夹具的基本结构及夹具设计的内容 1

第二章 杠杆加工工艺规程设计 3

2.1零件的作用 3

2.2零件的工艺分析 4

2.3 工艺规程的设计 4

2.4机械加工余量、工序尺寸及毛坯尺寸、工时的确定 7

第三章 专用夹具设计 27

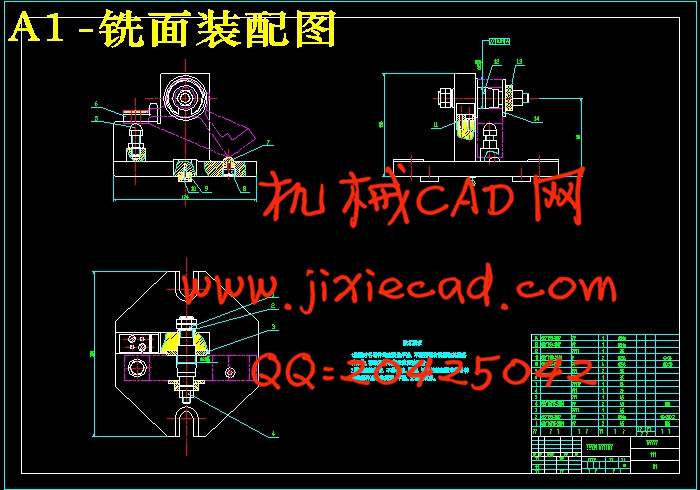

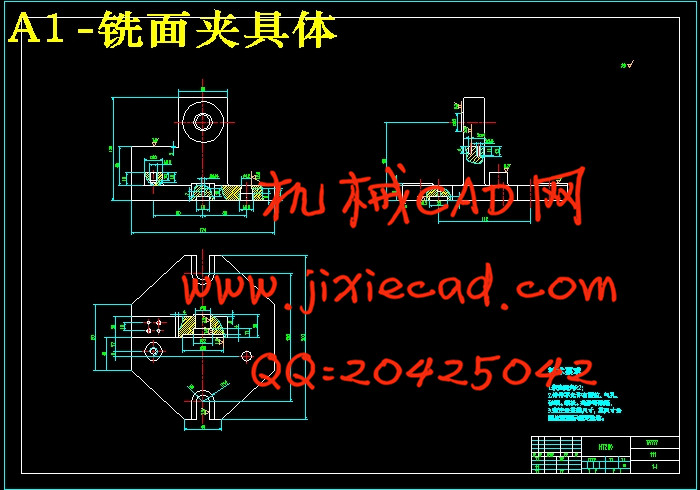

3.2粗、精铣宽度为30mm的下平台夹具设计 31

总结 37

参考文献 38

致谢 39