设计简介

机床中拖板加工工艺及夹具设计

摘要 由于本次毕业工艺设计的侧重点不同,该说明书主要针对的是车床中拖板上的孔和T型槽的加工工艺设计和夹具设计。本设计说明书详细的对中拖板的加工工艺流程进行了设计分析,并且根据老师所分配的工艺设计和夹具设计的任务进行了有侧重点的分析设计说明。根据所加工工序选用摇臂钻床来进行钻孔加工,选用立式铣床来进行对T型槽的铣削加工。该说明书将设计主要分为零件分析、工艺规程的设计、夹具设计三大部分。零件分析部分是指对中拖板这个零件进行了工艺性能和加工表面及技术要求的分析,对该零件有了充分的了解。工艺规程设计部分主要是对工件的加工步骤及方案的选择和计算作为重点。夹具设计是将根据所分配的工序对零件进行加工时的夹具设计,本说明书的夹具设计内容为钻床夹具和铣床夹具。

关键词 钻孔,铣T型槽,夹具,摇臂钻床,立式铣床

Machine in the carriage and fixture design process

Abstract

As the graduation process design different focus, the manual is aimed at turning the holes in the drag plate and T-slot design and fixture design process. The design of the detailed instructions in the extension units of the technological process for the design analysis and process according to the teacher assigned the task of design and fixture design was a focused analysis of design specification. Selected according to the processing operation for drilling radial drilling machine, vertical milling machine for use on the T-slot milling. The manual is divided into parts of the design, process planning design, fixture design three parts. Parts of some of the pallet is carried out in this part machined surface and process performance and technical requirements analysis, with a full understanding of the parts. Process planning part is an artifact of the processing steps and the selection and calculation program focus. Fixture design process will be allocated according to the processing of parts of the fixture design, fixture design content of this manual for the drill jig and milling fixture.

Keywords Drilling, milling T-slots, fixtures, radial drilling machine, vertical milling machine

目录

1引言 1

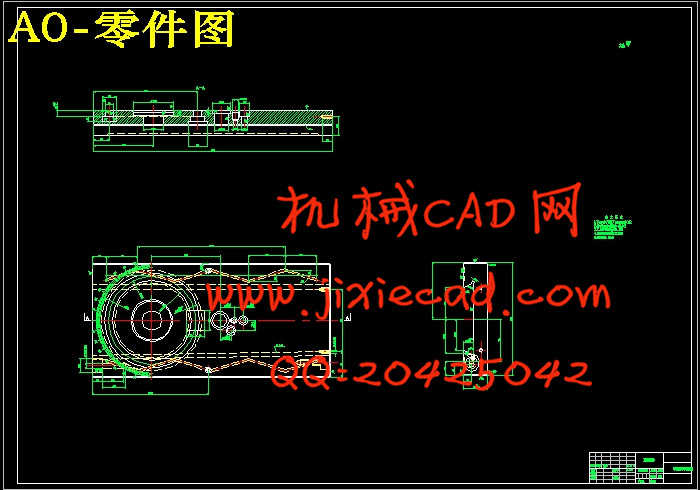

1.1零件的工艺分析 1

1.1.1零件的工艺性能 1

1.1.2零件主要加工表面及技术要求分析 1

2工艺规程的设计 2

2.1基面的选择 2

2.1.1粗基准的选择 2

2.1.2精基准的选择 2

2.2制定工艺路线 3

2.2.1工艺路线方案一 3

2.2.2工艺路线方案二 3

2.3工艺方案的比较与分析 4

2.3.1根据机械加工工序先后顺序的安排原则: 4

2.4选择加工设备及刀具、夹具、量具 5

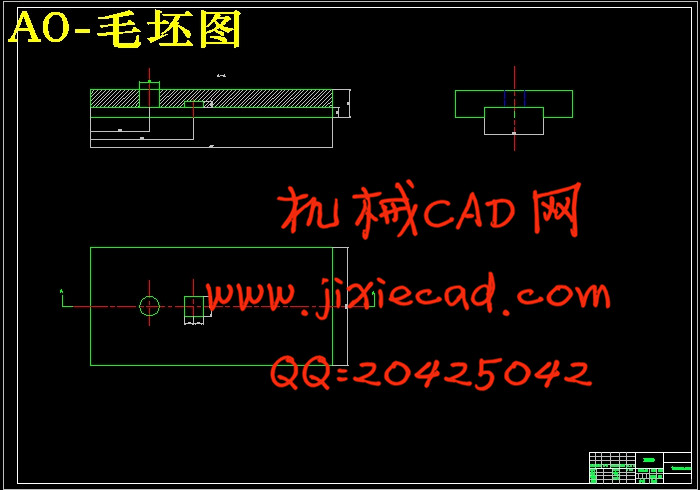

2.5机械加工余量、工序尺寸、及毛坯尺寸的确定 6

2.5.1上表面 6

2.5.2下表面 6

2.5.3左表面 6

2.5.4右表面 6

2.5.5前表面 7

2.5.6后表面 7

2.5.7镗Φ70孔 7

2.5.8铣T形槽 7

2.5.9钻上表面的孔 7

2.6确定切削用量及基本工时 7

2.6.1工序一:铣工件的六个表面切削用量及基本时间的确定 8

2.6.2工序二:镗 70孔 11

70孔 11

2.6.3工序三:铣T型槽 13

2.6.4工序四:加工上表面的孔 15

2.6.5工序五:加工两侧面的孔 23

2.6.7工序七铣油槽 31

3夹具设计 32

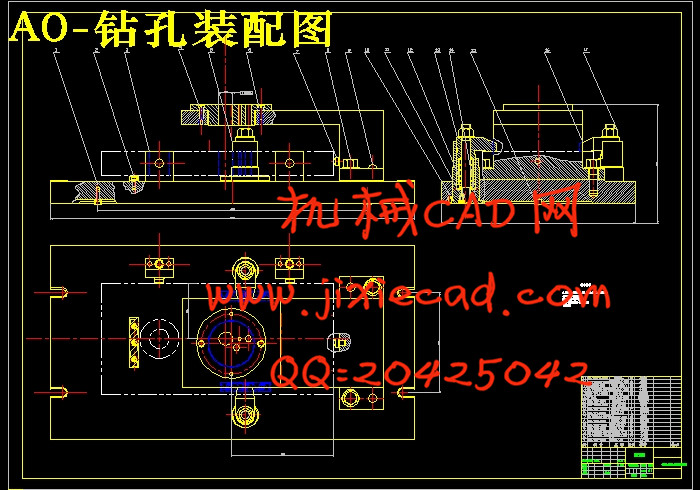

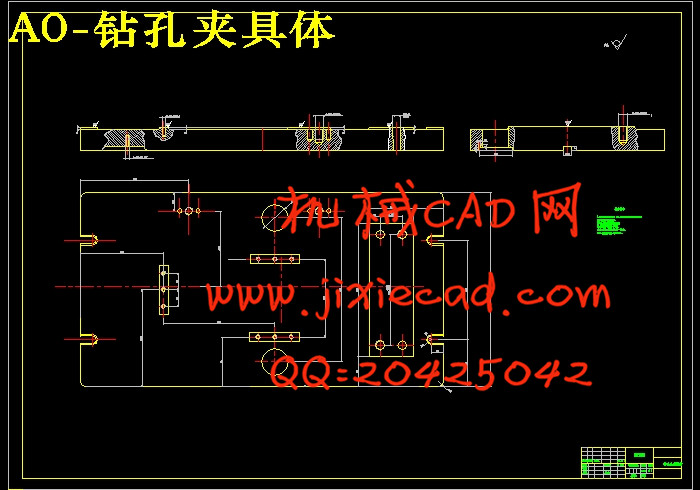

3.1.钻床夹具的设计 32

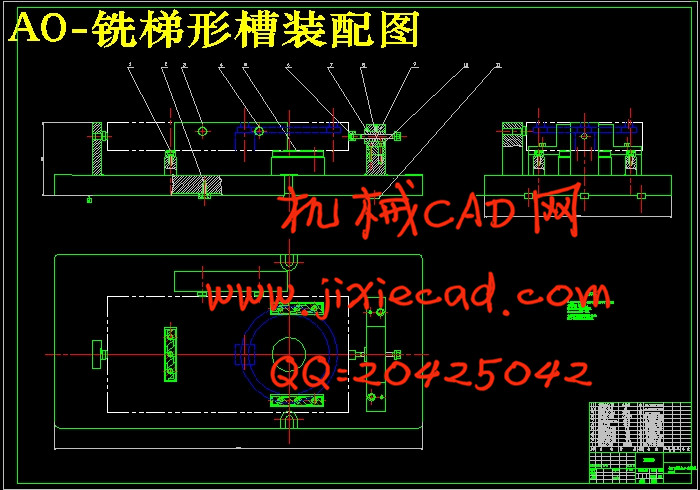

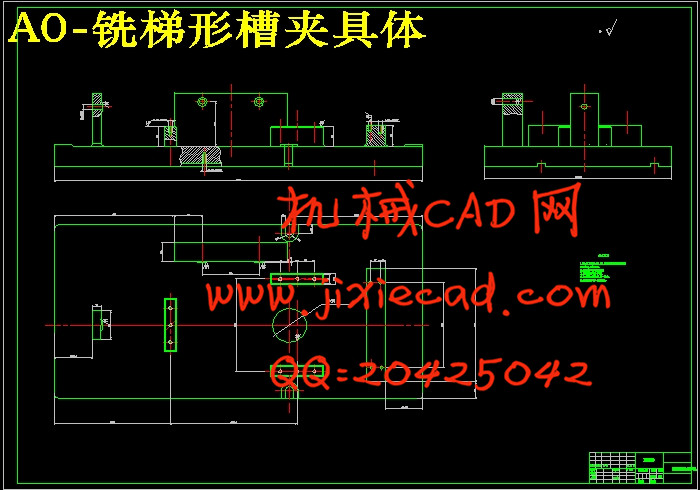

3.2.铣床夹具设计 35

参考文献 39

致谢 40

摘要 由于本次毕业工艺设计的侧重点不同,该说明书主要针对的是车床中拖板上的孔和T型槽的加工工艺设计和夹具设计。本设计说明书详细的对中拖板的加工工艺流程进行了设计分析,并且根据老师所分配的工艺设计和夹具设计的任务进行了有侧重点的分析设计说明。根据所加工工序选用摇臂钻床来进行钻孔加工,选用立式铣床来进行对T型槽的铣削加工。该说明书将设计主要分为零件分析、工艺规程的设计、夹具设计三大部分。零件分析部分是指对中拖板这个零件进行了工艺性能和加工表面及技术要求的分析,对该零件有了充分的了解。工艺规程设计部分主要是对工件的加工步骤及方案的选择和计算作为重点。夹具设计是将根据所分配的工序对零件进行加工时的夹具设计,本说明书的夹具设计内容为钻床夹具和铣床夹具。

关键词 钻孔,铣T型槽,夹具,摇臂钻床,立式铣床

Machine in the carriage and fixture design process

Abstract

As the graduation process design different focus, the manual is aimed at turning the holes in the drag plate and T-slot design and fixture design process. The design of the detailed instructions in the extension units of the technological process for the design analysis and process according to the teacher assigned the task of design and fixture design was a focused analysis of design specification. Selected according to the processing operation for drilling radial drilling machine, vertical milling machine for use on the T-slot milling. The manual is divided into parts of the design, process planning design, fixture design three parts. Parts of some of the pallet is carried out in this part machined surface and process performance and technical requirements analysis, with a full understanding of the parts. Process planning part is an artifact of the processing steps and the selection and calculation program focus. Fixture design process will be allocated according to the processing of parts of the fixture design, fixture design content of this manual for the drill jig and milling fixture.

Keywords Drilling, milling T-slots, fixtures, radial drilling machine, vertical milling machine

目录

1引言 1

1.1零件的工艺分析 1

1.1.1零件的工艺性能 1

1.1.2零件主要加工表面及技术要求分析 1

2工艺规程的设计 2

2.1基面的选择 2

2.1.1粗基准的选择 2

2.1.2精基准的选择 2

2.2制定工艺路线 3

2.2.1工艺路线方案一 3

2.2.2工艺路线方案二 3

2.3工艺方案的比较与分析 4

2.3.1根据机械加工工序先后顺序的安排原则: 4

2.4选择加工设备及刀具、夹具、量具 5

2.5机械加工余量、工序尺寸、及毛坯尺寸的确定 6

2.5.1上表面 6

2.5.2下表面 6

2.5.3左表面 6

2.5.4右表面 6

2.5.5前表面 7

2.5.6后表面 7

2.5.7镗Φ70孔 7

2.5.8铣T形槽 7

2.5.9钻上表面的孔 7

2.6确定切削用量及基本工时 7

2.6.1工序一:铣工件的六个表面切削用量及基本时间的确定 8

2.6.2工序二:镗

2.6.3工序三:铣T型槽 13

2.6.4工序四:加工上表面的孔 15

2.6.5工序五:加工两侧面的孔 23

2.6.7工序七铣油槽 31

3夹具设计 32

3.1.钻床夹具的设计 32

3.2.铣床夹具设计 35

参考文献 39

致谢 40