设计简介

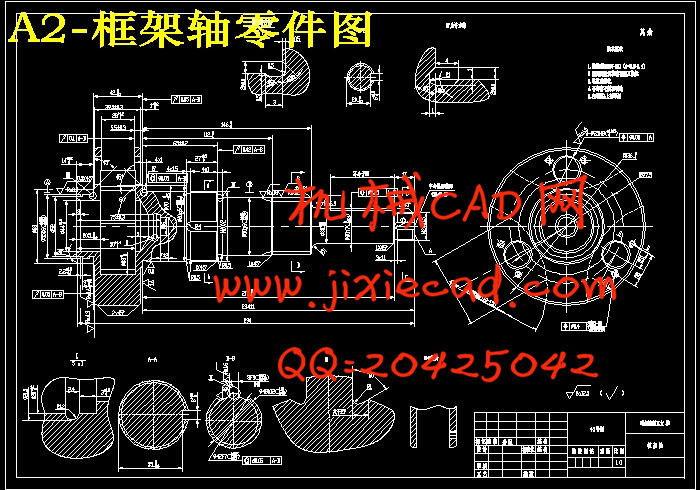

框架轴工艺规程制定和工装设计

摘要

框架轴是实现坦克炮塔旋转运动的重要机械零件,其质量得好坏对于保证坦克炮塔能否迅速准确旋转到指定角度,能否成功瞄准目标有重要影响。而关系到框架轴质量的根本因素则是其生产加工工艺和工装设备,在机械生产制造业中工装设备是机械制造的基础,机械加工工艺规程则是机械制造的核心技术。如果没有合适机械加工工艺,即使是一流的机械加工机床也无法制造出合格产品,可见机械加工工艺在机械生产中的重要性。并且机械加工工艺规程和工装对于提高产品生产效率、减少工作地面积、减少工件在加工过程中的装夹次数提高工件质量、降低工作人员的劳动工作量、提高工作人员的工作效率有重要作用。本文主要针对框架轴的工艺做一下工作:

1. 制定零件加工工艺、确定相应的加工数据。

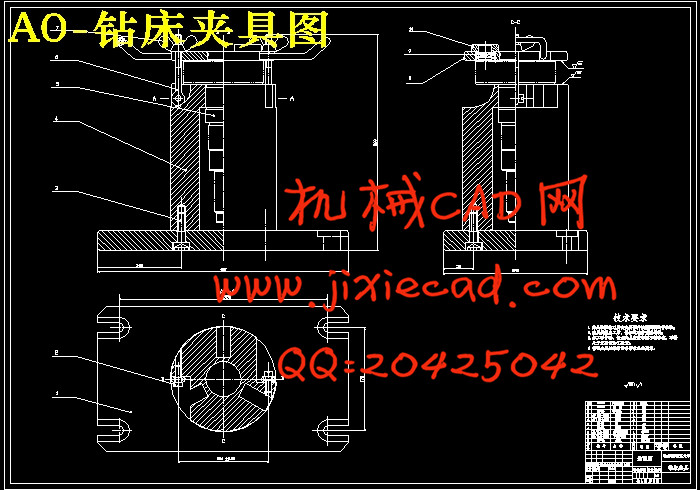

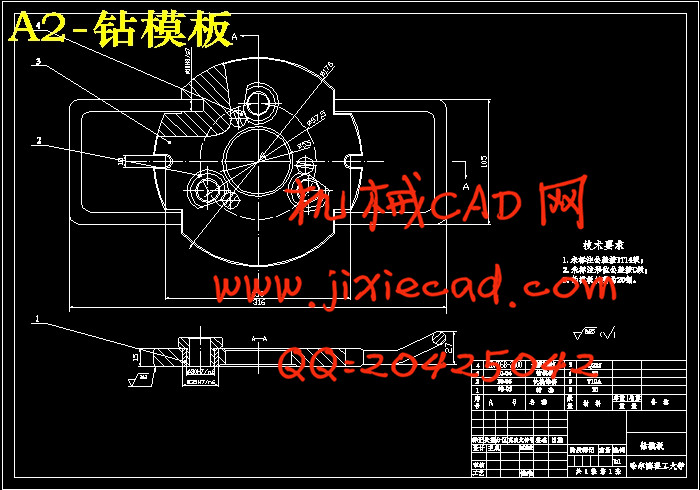

2. 制定零件加工时所需的专用夹具。

关键词 工艺规程;夹具;框架轴

Frame axis techniques procedure and Tooling

摘要

框架轴是实现坦克炮塔旋转运动的重要机械零件,其质量得好坏对于保证坦克炮塔能否迅速准确旋转到指定角度,能否成功瞄准目标有重要影响。而关系到框架轴质量的根本因素则是其生产加工工艺和工装设备,在机械生产制造业中工装设备是机械制造的基础,机械加工工艺规程则是机械制造的核心技术。如果没有合适机械加工工艺,即使是一流的机械加工机床也无法制造出合格产品,可见机械加工工艺在机械生产中的重要性。并且机械加工工艺规程和工装对于提高产品生产效率、减少工作地面积、减少工件在加工过程中的装夹次数提高工件质量、降低工作人员的劳动工作量、提高工作人员的工作效率有重要作用。本文主要针对框架轴的工艺做一下工作:

1. 制定零件加工工艺、确定相应的加工数据。

2. 制定零件加工时所需的专用夹具。

关键词 工艺规程;夹具;框架轴

Frame axis techniques procedure and Tooling

design

Abstract

Framework is to achieve the tank turret axis rotary motion of the important mechanical parts, to ensure its quality was good or bad for the tank turret can rotate quickly and accurately to a specified angle, the successful targeting have a major impact. The relationship to the frame axis fundamental factor is the quality of its production process and tooling equipment, machinery manufacturing tooling equipment is machinery manufacturing base, machining process is the core technology of mechanical manufacturing. If no suitable machining process, even the first-class machinery processing machine can not produce qualified products, visible in the mechanical machining process the importance of the production. And the machining process and tooling to improve production efficiency, reduce land area, reducing the workpiece during machining of the workpiece clamping times to improve quality, reduce labor staff workload and improve staff efficiency has an important role. This paper focuses framework axes do some craft work:Parts processing technology developed to determine the corresponding processing data.Machining parts needed to develop special fixtures.

Keywords Process planning; Fixture; Frame axis

目录Abstract

Framework is to achieve the tank turret axis rotary motion of the important mechanical parts, to ensure its quality was good or bad for the tank turret can rotate quickly and accurately to a specified angle, the successful targeting have a major impact. The relationship to the frame axis fundamental factor is the quality of its production process and tooling equipment, machinery manufacturing tooling equipment is machinery manufacturing base, machining process is the core technology of mechanical manufacturing. If no suitable machining process, even the first-class machinery processing machine can not produce qualified products, visible in the mechanical machining process the importance of the production. And the machining process and tooling to improve production efficiency, reduce land area, reducing the workpiece during machining of the workpiece clamping times to improve quality, reduce labor staff workload and improve staff efficiency has an important role. This paper focuses framework axes do some craft work:Parts processing technology developed to determine the corresponding processing data.Machining parts needed to develop special fixtures.

Keywords Process planning; Fixture; Frame axis

摘要 I

Abstract II

第一章 绪论……………………………………………………………….……1

1.1 课题来源 1

1.2 课题研究的背景和意义 1

1.3本章小结 2

第2章 零件的分析 3

2.1 零件的作用 3

2.2 零件的工艺分析 3

2.3 本章小结 4

第3章 毛坯的确定和基准的选择 5

3.1 毛坯 5

3.1.1 毛坯材料的确定 5

3.1.2 确定零件毛坯的制造形式 5

3.1.3 毛坯的技术要求 5

3.2 粗基准的选择 6

3.3 精基准的选择 7

3.4 本章小结 7

第4章 拟定机械加工工艺路线 8

4.1 工艺规程概念、原则及依据 8

4.1.1 工艺规程概念 8

4.1.2 制订工艺规程的原则 8

4.1.3 制订工艺规程的主要依据 8

4.1.4 零件规程的设计 9

4.2加工阶段的划分、加工方法的选择 10

4.2.1加工阶段的划分 10

4.2.2加工方法的选择 11

4.3两种工艺路线方案 11

4.3.1方案一、工艺路线 11

4.3.2方案二、工艺路线 13

4.4工艺方案分析比较 14

4.5本章小结 14

第5章 加工参数的确定 15

5.1确定加工量 15

5.2加工参数的确定(以粗车Φ60外圆表面为例) 15

5.2.1车刀的选择 15

5.2.2加工量的确定 15

5.2.3切削速度的选择 15

5.2.4切削力和切削功率的确定 16

5.2.5机床的选择 16

5.2.6机动时间 16

5.3本章小结 17

第6章 夹具体设计 18

6.1夹具结构设计 18

6.1.1定位元件的选择及要求 18

6.1.2夹具体的设计 18

6.2夹具设计及操作的简要说明 19

6.3本章小结 20

结论…………………………………………………………………………….21

致谢 22

参考文献 23