设计简介

摘 要

在机床上加工工件时,定位和夹紧的全过程称为“安装”。在机床上用来完成工件安装任务的重要工艺装备,就是各类夹具中应用最为广泛的“机床夹具”。

机床夹具的种类很多,其中,使用范围最广的通用夹具,规格尺寸多已标准化,并且有专业的工厂进行生产。而广泛用于批量生产,专为某工件加工工序服务的专用夹具,则需要各制造厂根据工件加工工艺自行设计制造。本设计的主要内容是设计铣床夹具

零件上往往都有各种不同用途和不同精度的孔需要加工。在机械加工中,孔的加工量所占比例较大,其中钻头、扩孔钻、铰刀等定尺寸刀具加工占相当多数。这时,除了要保证孔的尺寸精度外,还要达到孔的位置精度要求。在单件小批量生产中,用划线后找正孔轴线位置方法加工。在批量生产中一般都采用夹具。

关键词 通用夹具 专用夹具 夹具 螺母

Abstract

In the machine machining, positioning and clamping process called "installation". The machine used to complete the task of workpiece installation of process equipment, is an important fixture in the most widely used "the machine tool's fixture.

There are many kinds of the machine tool's fixture, among them, use the widest range of general fixture, size, and there has been more standardized professional factory production. And widely used in mass production, designed for a workpiece machining processes and special fixture service to the factory according to the workpiece machining process to design and manufacture. The design of the main content is boring and milling machine fixture design jigs, need to pump body Φ 52 holes on the left end fine machining milling.

Pump body parts are usually different purposes and accuracy of the hole machining. In machining, the hole of manufactured, among which the proportion of drilling, reaming, reamer, boring tools for size of such a sizable majority. At this time, except to ensure the accuracy of the size of the hole hole, but also achieve the position precision requirements. In single small batch production, use crossed for positive hole axis position after processing methods. In batch production in general by drilling and boring fixture, drilling fixture and diamond fixture, boring fixture and say, boring, boring set by drilling tools for processing guide can accurately determine tool and the relative position between the workpiece.

Key word General fixture Special jig fixture support body

第1章 绪论

1.1机床夹具概述

1.1.1机床夹具

1.1.2机床夹具的功能

1.1.3机床夹具在机械加工中的作用

1.2机床夹具的发展趋势

1.2.1机床夹具的现状

1.2.2现代机床夹具的发展方向

第2章 工艺规程设计

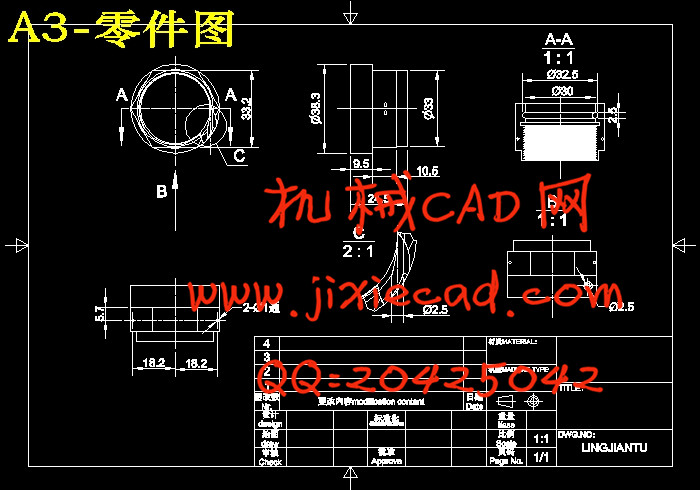

2.1 零件的分析

2.1.1零件的作用

2.1.2零件的工艺分析

2.2毛坏的选择

2.3工艺路线的拟定

2.3.1孔和平面加工分析

2.3.2定位基准的选择

2.3.3拟定工艺路线

2.4加工余量的确定

2.4.1左、右两侧面的加工余量

第3章 切削用量及工时的确定

3.1粗铣右侧面

3.1.1加工条件

3.1.2计算切削用量

3.1.3计算切削工时

3.2粗铣左侧面

3.2.1加工条件

3.2.2计算切削用量

3.2.3计算切削工时

3.3精铣右侧面

3.3.1加工条件

3.3.2计算切削用量

3.3.3计算切削工时

3.4精铣左侧面

3.4.1加工条件

3.4.2计算切削用量

3.4.3计算切削工时

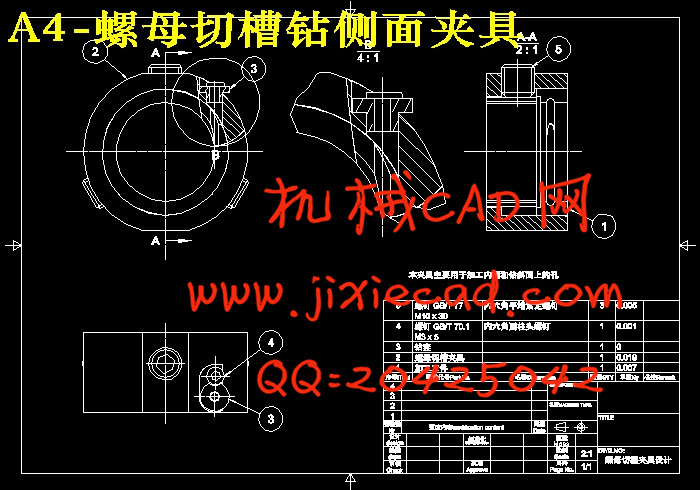

第4章 专用夹具设计

4.1车床夹具

4.1.1问题的提出

4.1.2夹具设计

4.1.2.1定位基准的选择

在机床上加工工件时,定位和夹紧的全过程称为“安装”。在机床上用来完成工件安装任务的重要工艺装备,就是各类夹具中应用最为广泛的“机床夹具”。

机床夹具的种类很多,其中,使用范围最广的通用夹具,规格尺寸多已标准化,并且有专业的工厂进行生产。而广泛用于批量生产,专为某工件加工工序服务的专用夹具,则需要各制造厂根据工件加工工艺自行设计制造。本设计的主要内容是设计铣床夹具

零件上往往都有各种不同用途和不同精度的孔需要加工。在机械加工中,孔的加工量所占比例较大,其中钻头、扩孔钻、铰刀等定尺寸刀具加工占相当多数。这时,除了要保证孔的尺寸精度外,还要达到孔的位置精度要求。在单件小批量生产中,用划线后找正孔轴线位置方法加工。在批量生产中一般都采用夹具。

关键词 通用夹具 专用夹具 夹具 螺母

Abstract

In the machine machining, positioning and clamping process called "installation". The machine used to complete the task of workpiece installation of process equipment, is an important fixture in the most widely used "the machine tool's fixture.

There are many kinds of the machine tool's fixture, among them, use the widest range of general fixture, size, and there has been more standardized professional factory production. And widely used in mass production, designed for a workpiece machining processes and special fixture service to the factory according to the workpiece machining process to design and manufacture. The design of the main content is boring and milling machine fixture design jigs, need to pump body Φ 52 holes on the left end fine machining milling.

Pump body parts are usually different purposes and accuracy of the hole machining. In machining, the hole of manufactured, among which the proportion of drilling, reaming, reamer, boring tools for size of such a sizable majority. At this time, except to ensure the accuracy of the size of the hole hole, but also achieve the position precision requirements. In single small batch production, use crossed for positive hole axis position after processing methods. In batch production in general by drilling and boring fixture, drilling fixture and diamond fixture, boring fixture and say, boring, boring set by drilling tools for processing guide can accurately determine tool and the relative position between the workpiece.

Key word General fixture Special jig fixture support body

第1章 绪论

1.1机床夹具概述

1.1.1机床夹具

1.1.2机床夹具的功能

1.1.3机床夹具在机械加工中的作用

1.2机床夹具的发展趋势

1.2.1机床夹具的现状

1.2.2现代机床夹具的发展方向

第2章 工艺规程设计

2.1 零件的分析

2.1.1零件的作用

2.1.2零件的工艺分析

2.2毛坏的选择

2.3工艺路线的拟定

2.3.1孔和平面加工分析

2.3.2定位基准的选择

2.3.3拟定工艺路线

2.4加工余量的确定

2.4.1左、右两侧面的加工余量

第3章 切削用量及工时的确定

3.1粗铣右侧面

3.1.1加工条件

3.1.2计算切削用量

3.1.3计算切削工时

3.2粗铣左侧面

3.2.1加工条件

3.2.2计算切削用量

3.2.3计算切削工时

3.3精铣右侧面

3.3.1加工条件

3.3.2计算切削用量

3.3.3计算切削工时

3.4精铣左侧面

3.4.1加工条件

3.4.2计算切削用量

3.4.3计算切削工时

第4章 专用夹具设计

4.1车床夹具

4.1.1问题的提出

4.1.2夹具设计

4.1.2.1定位基准的选择

4.1.2.2夹紧力和切削力的计算

4.1.2.3 定位误差分析

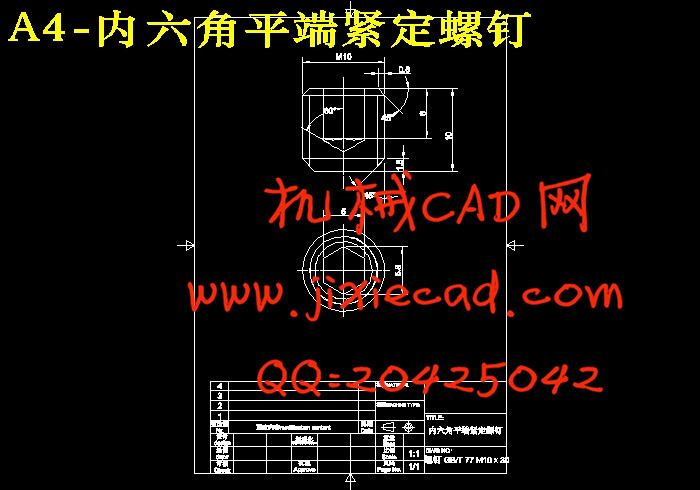

4.1.2.4 夹具设计及操作的简要说明4.2.2夹具设计

4.2.2.2夹紧力和切削力的计算

4.2.2.3 定位误差分析

4.2.2.4 夹具设计及操作的简要说明

第5章 结论

致 谢

参考文献