设计简介

轴套是某企业产品中的关键零件之一,本课题要求根据企业生产需要和轴套零件的加工要求,首先完成零件的加工工艺规程设计,在此基础之上,选择其关键工序之一进行专用夹具及加工用组合机床设计,并完成必要的设计计算。本机床所用夹具的通用性强,工件采用液压定位夹紧,快速方便。定位采用一面一心轴的定位方式,夹紧采用液压加紧,采用这种方式完全能够满足精度要求。而且简易方便,制造成本低,通用性好。由于轴套的生产量比较大,为了保证产品质量,提高加工效率,需要对其加工工艺进行优化设计,并在关键工序使用组合机床或专用机床进行加工。

通过设计,综合运用了大学期间的多数基础和专业知识,加深所学知识体系,掌握了运用各项绘图软件进行设计的方法和技巧,熟悉了工程应用设计。

关键词 轴套 零件分析 工艺路线 夹具设计 组合机床

Abstract

The axile bush is one of the key parts of an enterprise products, this text expounds mainly the machining technology and the design of clamping device of the connecting rod and modular machine tool of the axile bush.The precision of size, the precision of profile and the precision of position , of the connecting rod is demanded highly , and the rigidity of the connecting rod is not enough, easy to deform,so arranging the craft course, need to separate the each main and superficial thick finish machining process. Reduce the function of processing the surplus , cutting force and internal stress progressively , revise the deformation after processing, can reach the specification requirement for the part finally .As the output of the axile bush is very large ,it is need to make optimal design for the machining technology and use modular machine tool for pivotal machining process ,to ensure product quality and to improve the processing efficiency.

Through this design,the knowledge of more basic and specialty was synthetically applited.The system of knowledge we learned was intensified.Controlled to make use of various method and techniques that the painting software carry on a design,the design of engineering application was known well.

Keywords Axile Bush Precision Processing Technology Design of Clamping Device Modular Machine Tool

目 录

1 引言………………………………………………………………………………1

1.1机械制造业及其现状…………………………………………………………1

1.2机械制造业的发展趋势………………………………………………………2

1. 3 设计目的…………………………………………………………………… 2

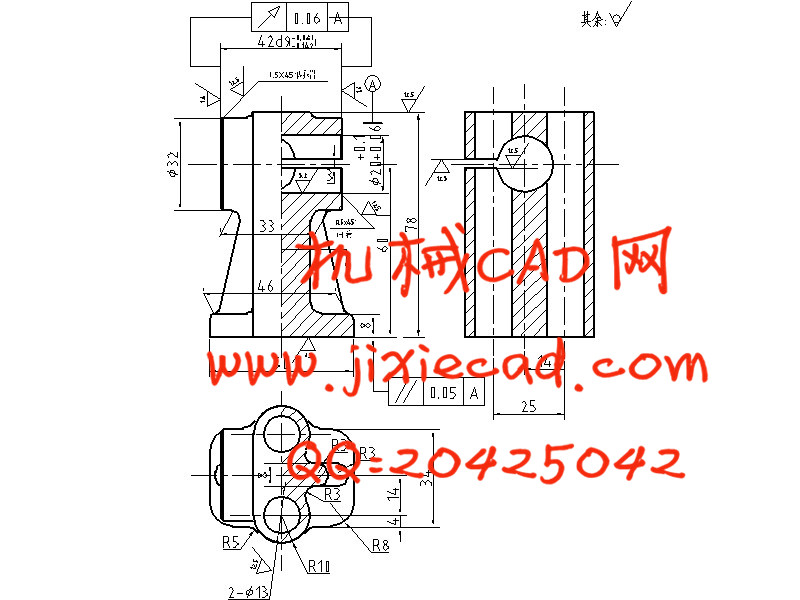

2 零件工艺性分析…………………………………………………………………3

2.1零件的作用……………………………………………………………………3

2.2零件的工艺分析 ………………………………………………………………3

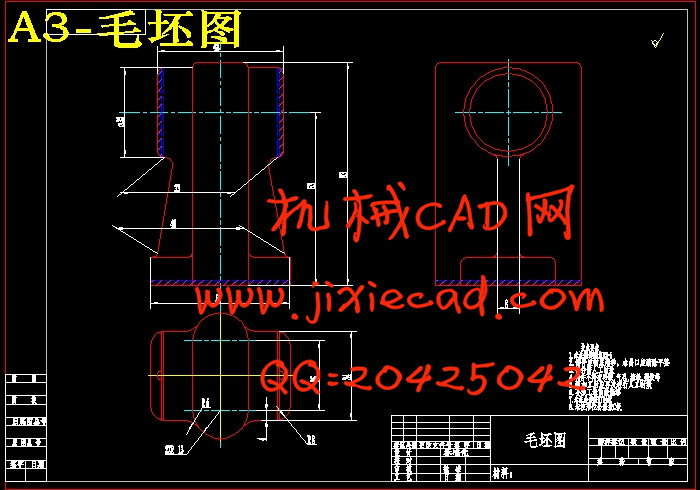

3 毛坯的选择………………………………………………………………………5

3.1毛坯材料的种类…………………………………………………………………5

3.2确定毛坯是应考虑到的因素……………………………………………………5

3.3确定毛坯时的几项工艺措施……………………………………………………5

3.4毛坯的确定………………………………………………………………………6

4 工艺规程设计……………………………………………………………………7

4.1工艺规程的作用…………………………………………………………………7

4.2定位基准的选择…………………………………………………………………7

4.3制定工艺路线……………………………………………………………………8

4.4毛坯尺寸的确定与机械加工余量………………………………………………9

4.5确定切削用量及基本工时……………………………………………………10

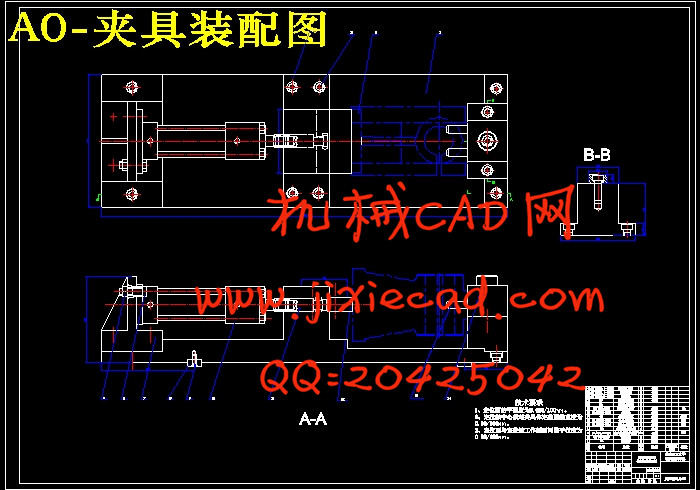

5 夹具设计…………………………………………………………………………15

5.1夹具的概述……………………………………………………………………15

5.2夹具的设计及操作简要说明…………………………………………………17

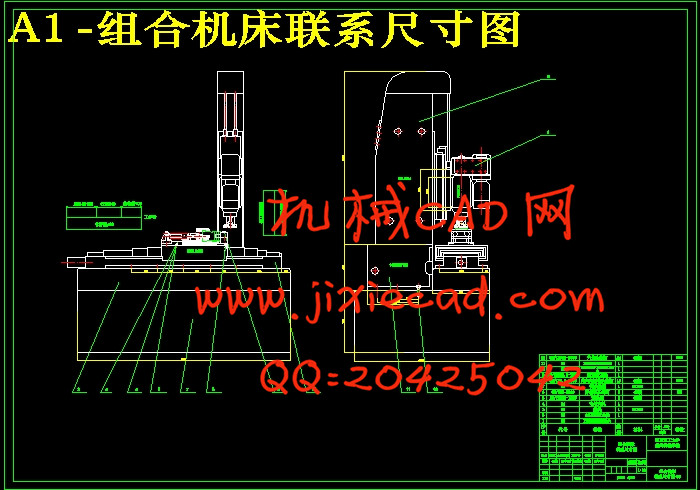

6 组合机床设计……………………………………………………………………20

6.1 组合机床总体设计“三图一卡”………………………………………… …20

结束语………………………………………………………………………………26

致谢 …………………………………………………………………………………27

参考文献……………………………………………………………………………28

通过设计,综合运用了大学期间的多数基础和专业知识,加深所学知识体系,掌握了运用各项绘图软件进行设计的方法和技巧,熟悉了工程应用设计。

关键词 轴套 零件分析 工艺路线 夹具设计 组合机床

Abstract

The axile bush is one of the key parts of an enterprise products, this text expounds mainly the machining technology and the design of clamping device of the connecting rod and modular machine tool of the axile bush.The precision of size, the precision of profile and the precision of position , of the connecting rod is demanded highly , and the rigidity of the connecting rod is not enough, easy to deform,so arranging the craft course, need to separate the each main and superficial thick finish machining process. Reduce the function of processing the surplus , cutting force and internal stress progressively , revise the deformation after processing, can reach the specification requirement for the part finally .As the output of the axile bush is very large ,it is need to make optimal design for the machining technology and use modular machine tool for pivotal machining process ,to ensure product quality and to improve the processing efficiency.

Through this design,the knowledge of more basic and specialty was synthetically applited.The system of knowledge we learned was intensified.Controlled to make use of various method and techniques that the painting software carry on a design,the design of engineering application was known well.

Keywords Axile Bush Precision Processing Technology Design of Clamping Device Modular Machine Tool

目 录

1 引言………………………………………………………………………………1

1.1机械制造业及其现状…………………………………………………………1

1.2机械制造业的发展趋势………………………………………………………2

1. 3 设计目的…………………………………………………………………… 2

2 零件工艺性分析…………………………………………………………………3

2.1零件的作用……………………………………………………………………3

2.2零件的工艺分析 ………………………………………………………………3

3 毛坯的选择………………………………………………………………………5

3.1毛坯材料的种类…………………………………………………………………5

3.2确定毛坯是应考虑到的因素……………………………………………………5

3.3确定毛坯时的几项工艺措施……………………………………………………5

3.4毛坯的确定………………………………………………………………………6

4 工艺规程设计……………………………………………………………………7

4.1工艺规程的作用…………………………………………………………………7

4.2定位基准的选择…………………………………………………………………7

4.3制定工艺路线……………………………………………………………………8

4.4毛坯尺寸的确定与机械加工余量………………………………………………9

4.5确定切削用量及基本工时……………………………………………………10

5 夹具设计…………………………………………………………………………15

5.1夹具的概述……………………………………………………………………15

5.2夹具的设计及操作简要说明…………………………………………………17

6 组合机床设计……………………………………………………………………20

6.1 组合机床总体设计“三图一卡”………………………………………… …20

结束语………………………………………………………………………………26

致谢 …………………………………………………………………………………27

参考文献……………………………………………………………………………28