设计简介

摘要

本课题名称是是刺辊座数控工艺、夹具、NC程序设计,包括工艺,夹具,NC程序设计三个主要部分。此毕业设计具体内容主要包括:对零件的加工工艺进行详细的分析,并制定出工艺文件,以加工出合格的刺辊座零件,保证零件的加工精度;工序的专业夹具的设计需要考虑该工序的定位基准,根据夹紧的原则,设计出合适的夹具;对重要工序的加工精度的保障或者是复杂表面的加工,可以采用数控加工的方法,保证零件的加工质量的和零件的精度;数控程序的编制利用自动编程软件,辅以人工修改,缩短了生产准备时间。设计出的工艺、夹具、NC程序,都是基于一定的技术参数和要求,能够保证该零件的合理、高效的加工出来,并保证产品的质量水平,满足生产对产品的需求。

关键词:刺辊座、工艺分析、专用夹具、数控加工

Abstract

The graduation project is the design of the CNC process, the special fixture and the NC program for licker-in seat. It includes mainly process, special fixture and NC program. The graduation project mainly includes: The detailed analysis of the machining process of the part, and to develop process documents is necessary, in order to manufacture qualified parts of the licker-in seat, and ensure the machining accuracy. The design of the special fixture of the process needs to consider the localization benchmark of the process. According to the principles of clamping, we can design the suitable fixture. The protection of machining accuracy of the important process or the machining of the complex surface can be carried out on NC machine to ensure machining quality and part accuracy. Programming of NC program makes better of the automated programming software, and is supplemented by artificial modification to shorten the ready time in production. The process, special fixture and NC program designed are based on certain technical parameters, to ensure that the part are rationally and effectively processing out, and then ensure the product quality level to meet the production for the demand of product.

Keywords: licker-in seat ; process analysis ; special fixture ; NC manufacturing

目录

1 引言 - 1 -本课题名称是是刺辊座数控工艺、夹具、NC程序设计,包括工艺,夹具,NC程序设计三个主要部分。此毕业设计具体内容主要包括:对零件的加工工艺进行详细的分析,并制定出工艺文件,以加工出合格的刺辊座零件,保证零件的加工精度;工序的专业夹具的设计需要考虑该工序的定位基准,根据夹紧的原则,设计出合适的夹具;对重要工序的加工精度的保障或者是复杂表面的加工,可以采用数控加工的方法,保证零件的加工质量的和零件的精度;数控程序的编制利用自动编程软件,辅以人工修改,缩短了生产准备时间。设计出的工艺、夹具、NC程序,都是基于一定的技术参数和要求,能够保证该零件的合理、高效的加工出来,并保证产品的质量水平,满足生产对产品的需求。

关键词:刺辊座、工艺分析、专用夹具、数控加工

Abstract

The graduation project is the design of the CNC process, the special fixture and the NC program for licker-in seat. It includes mainly process, special fixture and NC program. The graduation project mainly includes: The detailed analysis of the machining process of the part, and to develop process documents is necessary, in order to manufacture qualified parts of the licker-in seat, and ensure the machining accuracy. The design of the special fixture of the process needs to consider the localization benchmark of the process. According to the principles of clamping, we can design the suitable fixture. The protection of machining accuracy of the important process or the machining of the complex surface can be carried out on NC machine to ensure machining quality and part accuracy. Programming of NC program makes better of the automated programming software, and is supplemented by artificial modification to shorten the ready time in production. The process, special fixture and NC program designed are based on certain technical parameters, to ensure that the part are rationally and effectively processing out, and then ensure the product quality level to meet the production for the demand of product.

Keywords: licker-in seat ; process analysis ; special fixture ; NC manufacturing

目录

2 刺辊座的用途和外形 - 2 -

3 刺辊座的加工工艺的缺陷以及解决措施 - 3 -

3.1 刺辊座的加工工艺缺陷 - 3 -

3.2 解决当前加工缺陷的措施 - 4 -

4 刺辊座的加工工艺分析 - 5 -

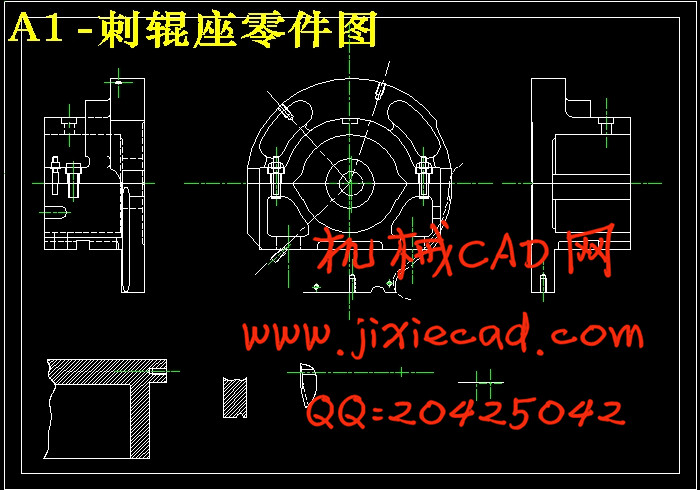

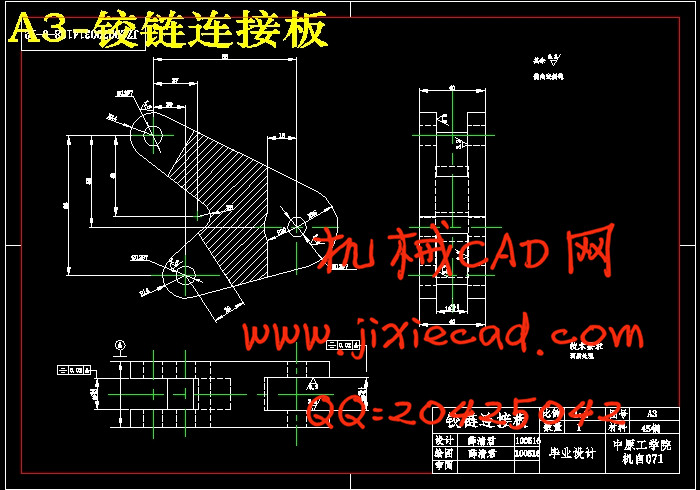

4.1 刺辊座的零件图分析 - 5 -

4.1.1 零件的材料 - 5 -

4.1.2 零件图样特点 - 5 -

4.2 刺辊座的结构工艺性分析 - 5 -

4.2.1 零件的结构特点 - 5 -

4.2.2 零件的尺寸精度和粗糙度要求 - 6 -

4.3 毛坯的选择 - 6 -

5 刺辊座加工工艺设计 - 7 -

5.1 加工方法的选择 - 7 -

5.2 加工路线的确定 - 7 -

5.3 定位基准的选择 - 8 -

5.4 刀具的选择 - 9 -

5.5 工序加工余量的确定 - 10 -

5.6 切削用量的确定 - 11 -

5.6.1 切削用量的计算 - 11 -

5.6.2 计算主轴转速和进给速度 - 13 -

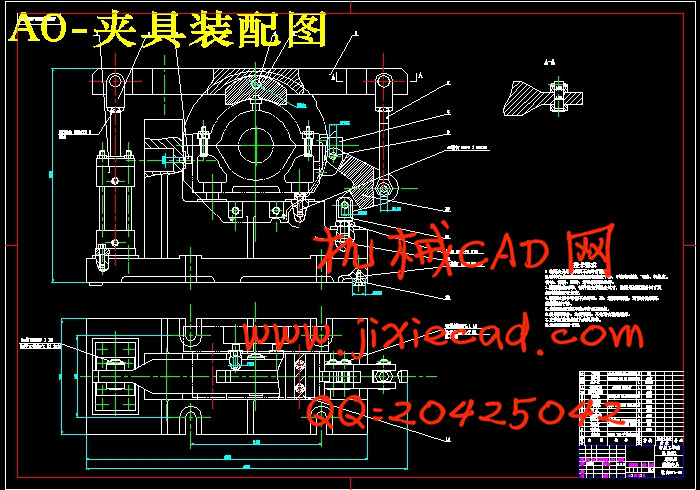

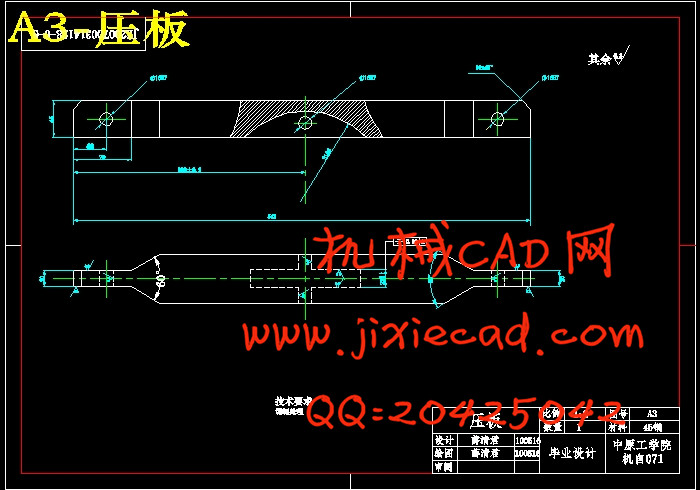

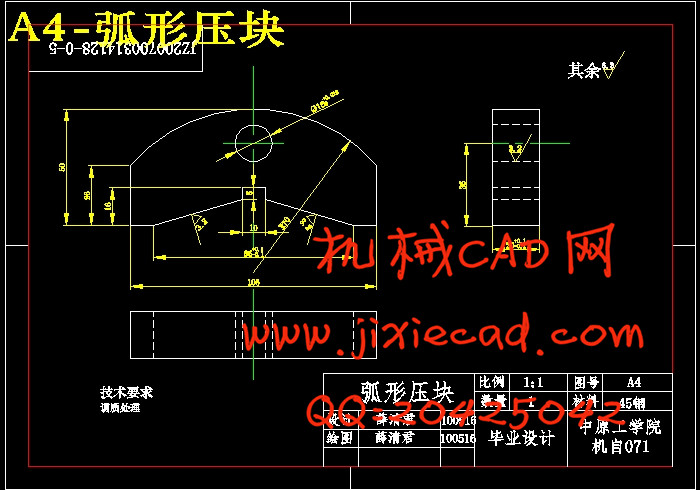

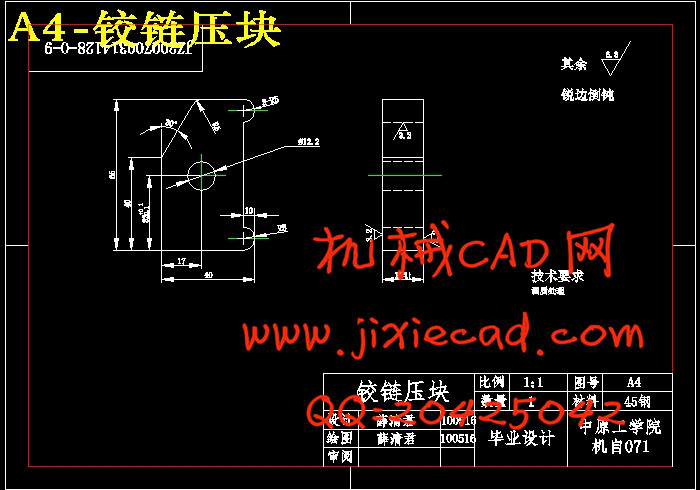

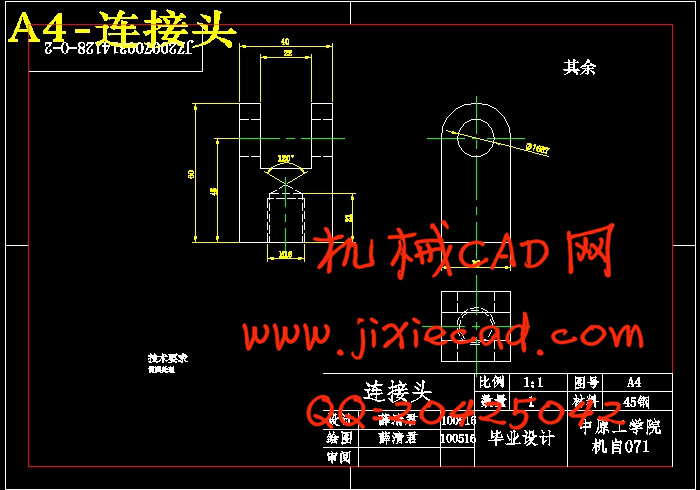

6 数控工序夹具的设计 - 15 -

6.1 定位方案的确定 - 16 -

6.2 定位元件的确定 - 16 -

6.3 定位误差分析 - 17 -

6.4 夹紧方案的确定 - 17 -

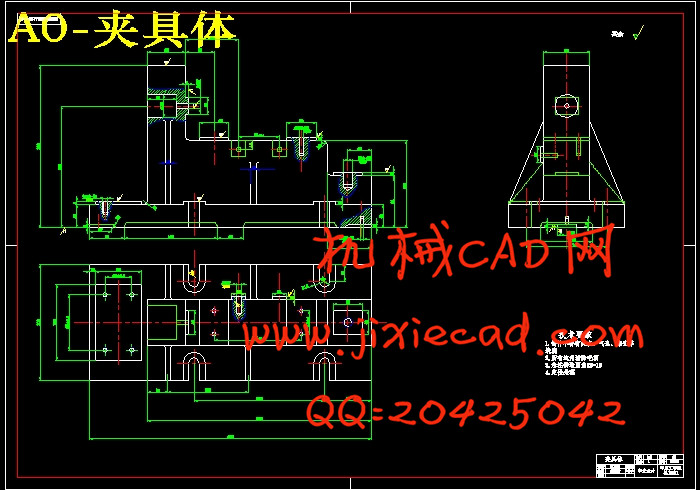

6.5 夹具体的设计 - 18 -

6.6 夹紧力的计算 - 19 -

6.7 夹具的具体结构 - 20 -

7 数控加工工艺的设计 - 20 -

7.1 数控加工工艺路线的确定 - 20 -

7.2 数控机床的选择 - 20 -

7.3 确定编程原点,对刀点对刀方法 - 21 -

8 数控程序的编写 - 21 -

8.1 CAXA制造工程师加工过程 - 21 -

8.2 编写数控代码 - 29 -

9 经济性分析 - 29 -

10 结论 - 30 -

参考资料 - 33 -

致谢 - 34 -