设计简介

摘要 现代机械加工行业发生着深刻的结构性变化,工艺工装的设计与改良已成为企业生存和发展的必要条件。工艺工装的设计与改良直接影响着连杆盖的质量与性能。连杆盖行业作为一个传统而富有活力的行业,近十几年取得了突飞猛进的发展。在新经济时代,连杆盖行业呈现了新的发展趋势,由此对其连杆盖质量、性能产生了新的变化。

本文首先介绍了连杆盖的作用和工艺分析,其次确定毛坯尺寸,然后进行了工艺规程设计,最后对第30道工序和第50道工序进行了夹具设计

关键词:工艺分析 工艺规程设计 夹具设计

Abstract A profound structural movement is taking place in the modern machine process industry, so the design and improvement of the technical frock have become the necessary condition for the corporation to live and develop. the design and improvement of the technical frock directly affect the quality and performance of the connecting rod cap. The connecting rod cap industry which is traditional and vivid has much developed in recent ten years. In new economy times , The cap industry presents a new developing trend. So there is a new requirement to its quality and performance.

This paper introduces the effect and technical analyse of the Connecting rod cap at first , then makes sure the rough’s size, planning the technical rules , at last designs the modular for the 30th and 50th working procedure .

Key words technical analyse the technical rules plan modular design

目 录

引言………………………………………………………………………………… 3

第一章 零件的分析…………………………………………………………… 3

1.1 零件的作用……………………………………………………………… 3

1.2 零件的工艺分析………………………………………………………… 3

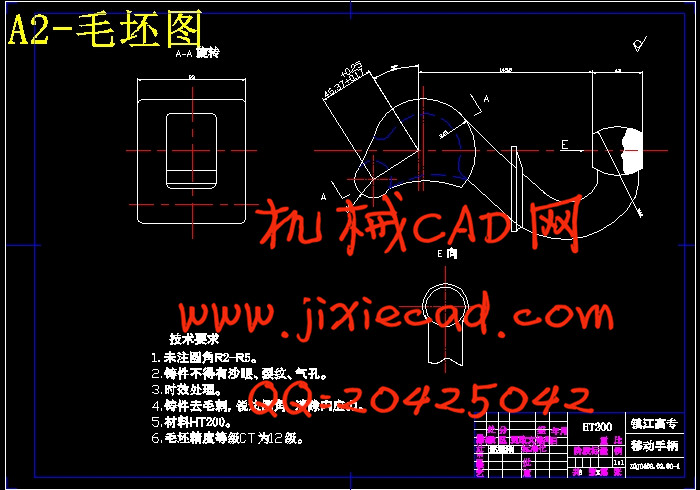

第二章 确定毛坯,画毛坯图……………………………………………… 4

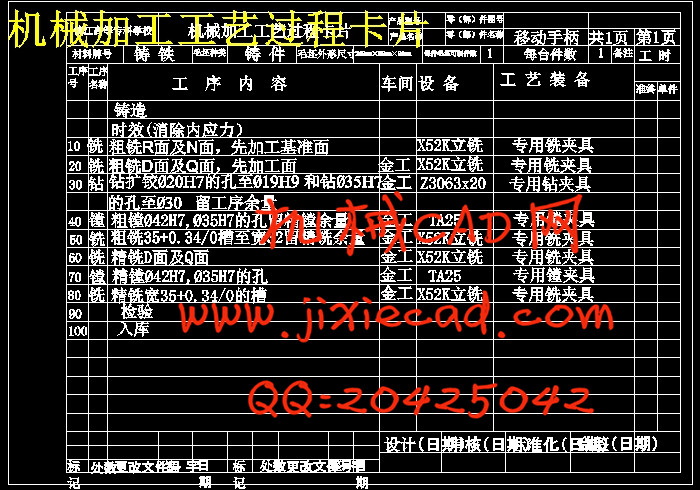

第三章 工艺规程设计……………………………………………………… 5

3.1 定位基准的选择………………………………………………………… 5

3.2 加工工艺路线…………………………………………………………… 6

3.3 选择加工设备及刀具,夹具,量具…………………………………………7

3.4 加工工序设计………………………………………………………………7

第四章 夹具设计 …………………………………………………………… 11

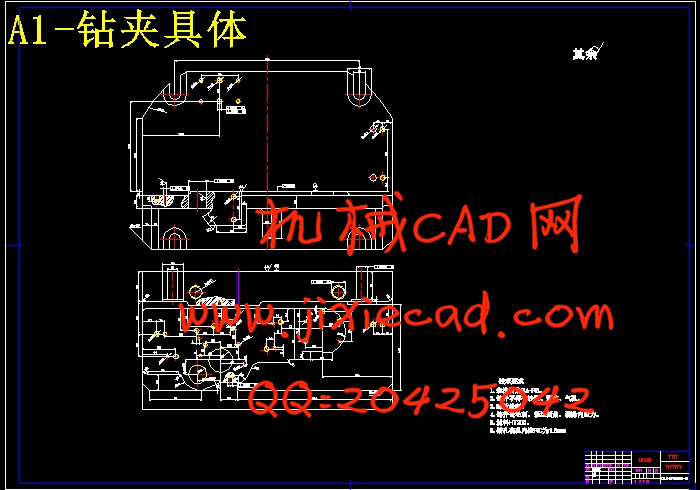

4.1 第30道工序的夹具设计………………………………………………11

4.1.1 确定设计方案…………………………………………………………11

4.1.2 计算夹紧力并确定螺杆的直径………………………………………12

4.1.3 定位精度分析………………………………………………………… 12

4.2 第50道工序的夹具设计……………………………………………… 13

4.2.1 确定设计方案………………………………………………………… 13

4.2.2 定位精度分析………………………………………………………… 13

结论………………………………………………………………………………… 14

致谢………………………………………………………………………………… 15

参考文献…………………………………………………………………………… 16

本文首先介绍了连杆盖的作用和工艺分析,其次确定毛坯尺寸,然后进行了工艺规程设计,最后对第30道工序和第50道工序进行了夹具设计

关键词:工艺分析 工艺规程设计 夹具设计

Abstract A profound structural movement is taking place in the modern machine process industry, so the design and improvement of the technical frock have become the necessary condition for the corporation to live and develop. the design and improvement of the technical frock directly affect the quality and performance of the connecting rod cap. The connecting rod cap industry which is traditional and vivid has much developed in recent ten years. In new economy times , The cap industry presents a new developing trend. So there is a new requirement to its quality and performance.

This paper introduces the effect and technical analyse of the Connecting rod cap at first , then makes sure the rough’s size, planning the technical rules , at last designs the modular for the 30th and 50th working procedure .

Key words technical analyse the technical rules plan modular design

目 录

引言………………………………………………………………………………… 3

第一章 零件的分析…………………………………………………………… 3

1.1 零件的作用……………………………………………………………… 3

1.2 零件的工艺分析………………………………………………………… 3

第二章 确定毛坯,画毛坯图……………………………………………… 4

第三章 工艺规程设计……………………………………………………… 5

3.1 定位基准的选择………………………………………………………… 5

3.2 加工工艺路线…………………………………………………………… 6

3.3 选择加工设备及刀具,夹具,量具…………………………………………7

3.4 加工工序设计………………………………………………………………7

第四章 夹具设计 …………………………………………………………… 11

4.1 第30道工序的夹具设计………………………………………………11

4.1.1 确定设计方案…………………………………………………………11

4.1.2 计算夹紧力并确定螺杆的直径………………………………………12

4.1.3 定位精度分析………………………………………………………… 12

4.2 第50道工序的夹具设计……………………………………………… 13

4.2.1 确定设计方案………………………………………………………… 13

4.2.2 定位精度分析………………………………………………………… 13

结论………………………………………………………………………………… 14

致谢………………………………………………………………………………… 15

参考文献…………………………………………………………………………… 16