设计简介

摘 要

矿山提升设备是矿山运输中的咽喉设备,占有特殊地位,是井下与地面联系的主要工具。

矿山提升设备的用途是沿井筒提运矿石和废石,升降人员,下放材料、工具和设备。矿山提升设备在工作中如果一旦发生机械和电气故障就会造成停产,甚至人身伤亡。为了保证生产和人员的安全要求矿山提升设备运行准确,安全可靠,井必须配有性能良好的控制设备和保护装置。

矿山提升设备的耗电量一般占矿井总耗电量的30%一40%,所以为了降低矿石的成本,必须经济合理地选择和使用矿山提升设备。矿山提升设备又是矿井最大固定设备之一,是—套较复杂的机械-电气机组。

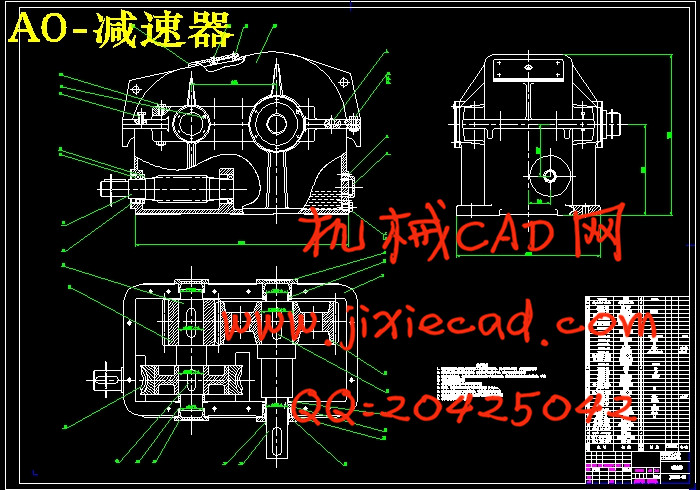

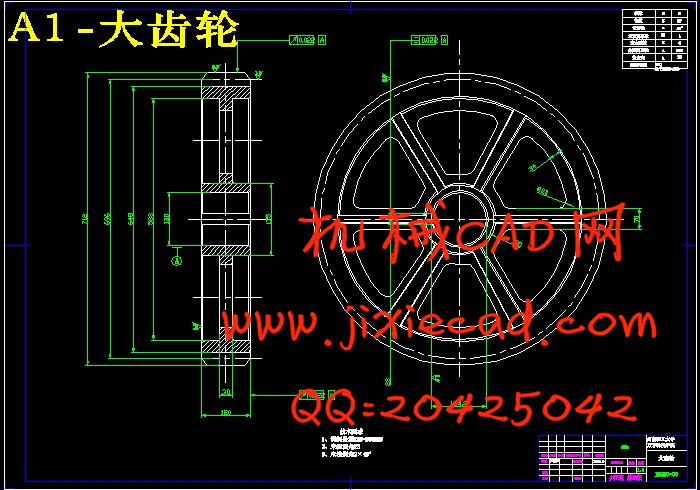

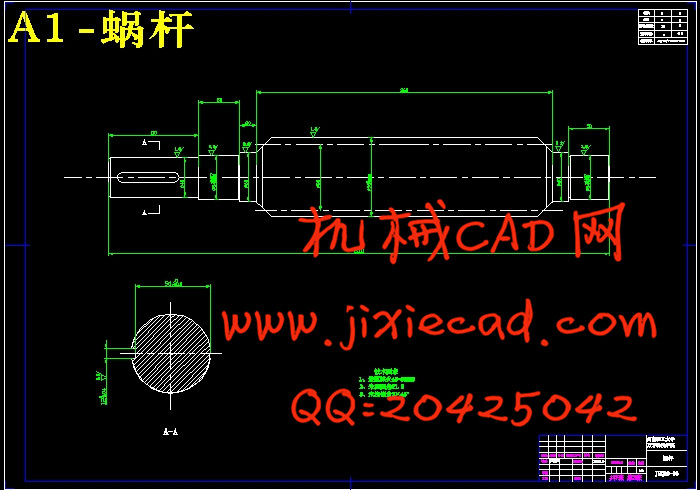

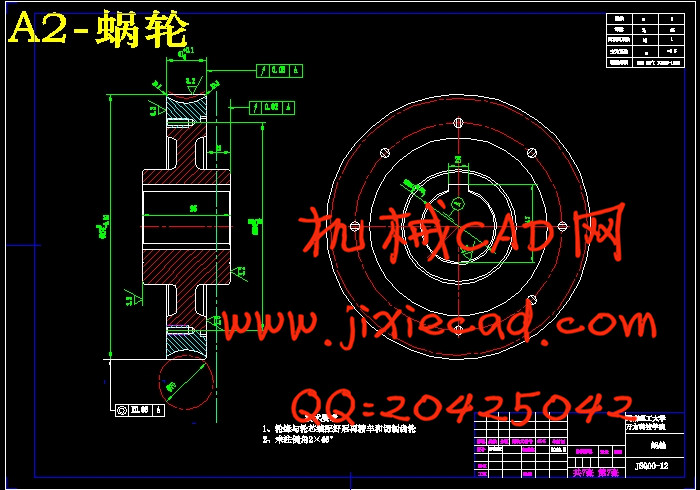

这篇毕业设计的论文主要阐述的是一套系统的关于环面蜗轮蜗杆减速器的设计方法。环面蜗轮蜗杆减速器是蜗轮蜗杆减速器的一种形式.这个方法是以加工过程和蜗轮减速器的使用条件的数学和物理公式为基础的。

目前,在环面蜗轮蜗杆减速器的设计、制造以及应用上,国内与国外先进水平相比仍有较大差距。国内在设计制造环面蜗轮蜗杆减速器过程中存在着很大程度上的缺点,正如论文中揭示的那样,重要的问题如:轮齿的根切;蜗杆毛坯的正确设计;蜗轮蜗杆的校核。

关键词:绞车 ;减速器 ;蜗轮 ;蜗杆

ABSTRACT

The mine lift technique is in the mine haulage pharynx and larynx equipment, holds the special status, and is the mine shaft and the ground relation main tool.

The mine lift technique use is picks up and ships the ore and the scrap rock along the well chamber, the fluctuation personnel, the release material, the tool and the equipment. Mine lift technique in work once if has the machinery and the electrical failure can create the production suspension, even person casualties. In order to guarantee the production and personnel's safety requirements mine lift technique movement is accurate, safe reliable, the well must have the performance good control device and the protective device.

The mine lift technique power consumption occupies the mine pit total power consumption generally 170%, therefore in order to reduce the ore the cost, must the economical reasonably choice and the use mine lift technique. The mine lift technique also is one of mine pit most greatly fixed equipments, is the complex machinery - electricity unit.

This paper of graduation project mainly presents a systematic approach for the design of circular worm gear reducer . circular worm gear reducer is one of the members in the worm gear reducer family . the approach is based on the mathematical formulations and physical formulation on the generation process and conditions for the type of worm reducer .

At present, we still fall far short of abroad advanced technology in design, manufacture and using. There are a lot of fault in the design of circular worm gear reduce. As can be revealed from the literature search , important problem such as: tooth undercutting ;proper design of worm gear blank;computations of worm and label gear.

Key words: Lifting hoist ;reducer ;worm ;ge

前 言 2矿山提升设备是矿山运输中的咽喉设备,占有特殊地位,是井下与地面联系的主要工具。

矿山提升设备的用途是沿井筒提运矿石和废石,升降人员,下放材料、工具和设备。矿山提升设备在工作中如果一旦发生机械和电气故障就会造成停产,甚至人身伤亡。为了保证生产和人员的安全要求矿山提升设备运行准确,安全可靠,井必须配有性能良好的控制设备和保护装置。

矿山提升设备的耗电量一般占矿井总耗电量的30%一40%,所以为了降低矿石的成本,必须经济合理地选择和使用矿山提升设备。矿山提升设备又是矿井最大固定设备之一,是—套较复杂的机械-电气机组。

这篇毕业设计的论文主要阐述的是一套系统的关于环面蜗轮蜗杆减速器的设计方法。环面蜗轮蜗杆减速器是蜗轮蜗杆减速器的一种形式.这个方法是以加工过程和蜗轮减速器的使用条件的数学和物理公式为基础的。

目前,在环面蜗轮蜗杆减速器的设计、制造以及应用上,国内与国外先进水平相比仍有较大差距。国内在设计制造环面蜗轮蜗杆减速器过程中存在着很大程度上的缺点,正如论文中揭示的那样,重要的问题如:轮齿的根切;蜗杆毛坯的正确设计;蜗轮蜗杆的校核。

关键词:绞车 ;减速器 ;蜗轮 ;蜗杆

ABSTRACT

The mine lift technique is in the mine haulage pharynx and larynx equipment, holds the special status, and is the mine shaft and the ground relation main tool.

The mine lift technique use is picks up and ships the ore and the scrap rock along the well chamber, the fluctuation personnel, the release material, the tool and the equipment. Mine lift technique in work once if has the machinery and the electrical failure can create the production suspension, even person casualties. In order to guarantee the production and personnel's safety requirements mine lift technique movement is accurate, safe reliable, the well must have the performance good control device and the protective device.

The mine lift technique power consumption occupies the mine pit total power consumption generally 170%, therefore in order to reduce the ore the cost, must the economical reasonably choice and the use mine lift technique. The mine lift technique also is one of mine pit most greatly fixed equipments, is the complex machinery - electricity unit.

This paper of graduation project mainly presents a systematic approach for the design of circular worm gear reducer . circular worm gear reducer is one of the members in the worm gear reducer family . the approach is based on the mathematical formulations and physical formulation on the generation process and conditions for the type of worm reducer .

At present, we still fall far short of abroad advanced technology in design, manufacture and using. There are a lot of fault in the design of circular worm gear reduce. As can be revealed from the literature search , important problem such as: tooth undercutting ;proper design of worm gear blank;computations of worm and label gear.

Key words: Lifting hoist ;reducer ;worm ;ge

第一章 回柱绞车的概况与方案的初步拟定 6

1.1、国内外回柱小绞车的概况 6

1.2、回柱绞车的主要传动方式类型 9

第二章 总体设计任务与方案的拟定 10

2.1总体方案的初步拟定 11

2.2主要组成部分 11

第三章 机械传动系统方案设计 13

3.1 电动机选择 15

3.2计算传动装置总传动比和分级传动比 16

3.3 传动装置的运动和动力参数 16

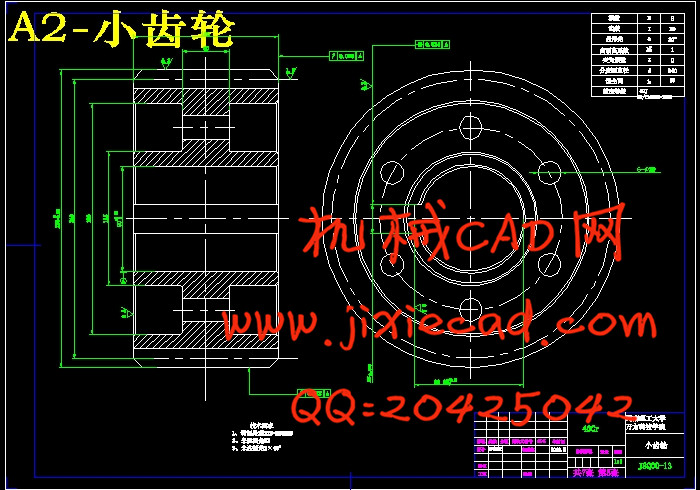

3.4 高速级传动件设计 17

3.5 低速级传动件设计 21

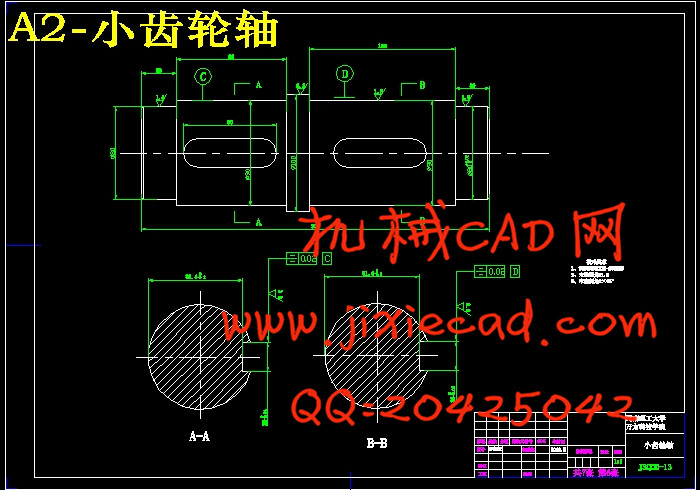

3.6高速轴设计(蜗杆轴) 25

3.7中间轴的设计(蜗轮齿轮轴) 30

3.8 低速轴的设计 33

3.9 蜗杆轴上的轴承寿命校核 36

第四章 箱体及附件设计与减速器的润滑 37

4.1 箱体主要基本结构尺寸 37

4.2减速器的润滑 38

第五章 回柱绞车制动器的设计 39

5.1常用绞车制动闸的形式 39

5.2绞车上应有的安全装置 39

5.3回柱绞车制动器的作用 40

5.4制动器的选用和设计 41

第六章 回柱绞车的操作要求及钢丝绳断裂原因分析 43

6.1回柱绞车的操作要求 43

6.2开车前必须认真检查 43

6.3运行中必须注意 44

6.4钢丝绳断丝原因分析 44

第七章 使用与维护 45

7.1绞车的安装操作 45

7.2后移 46

7.3维护与检修 47

小 结 47

参考文献 49

致 谢 50