设计简介

摘 要

最近,全球内带有夹子夹子或手的机械手系统已经发展起来了,多种方法应用其上,有拟人化和非拟人化的,不仅调查了这些系统的机械结构,而且还包括其必要的控制系统,如同人手一样,这些机械人系统可以用它们的手去抓不同的物体,而且不用改换夹子,这些机械手具备特殊的运动能力比如小质量和小惯量,这使被抓物体在机械手的工作范围内做更复杂、更精确的操作变得可能。这些复杂的操作被抓物体绕任意角度和轴旋转。

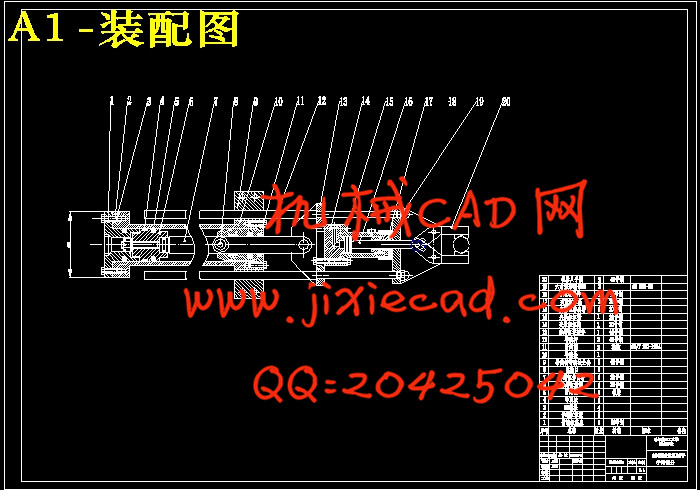

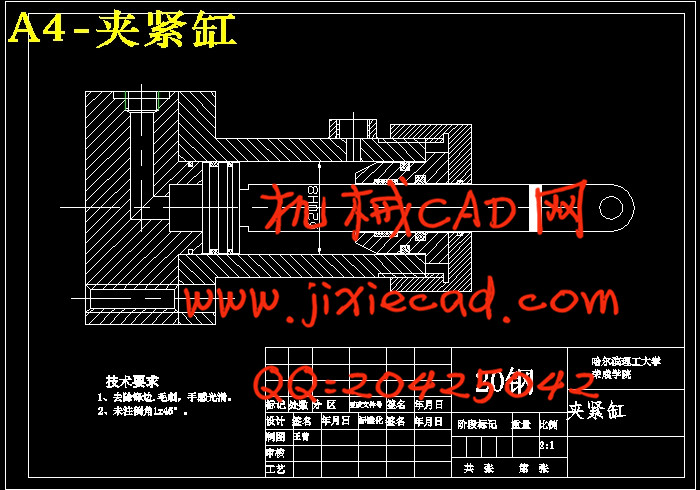

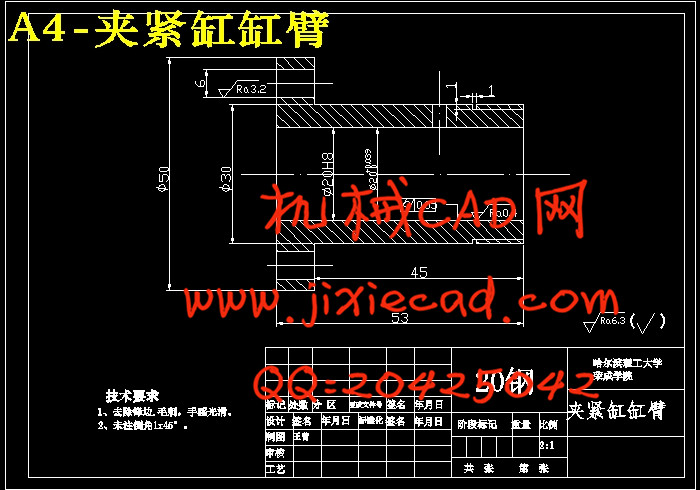

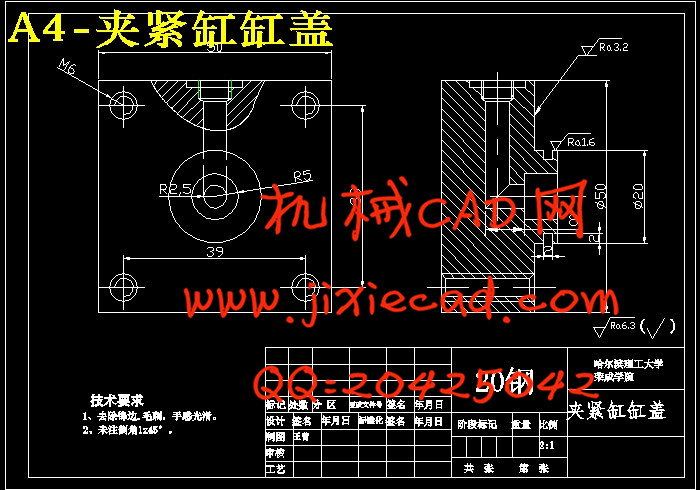

本论文介绍了用于夹持蜡模机械手的设计。它采用液压驱动,点位程序控制,动作平稳,控制方便。本论文主要阐述该机械手的夹紧、伸缩、升降和回转的设计和计算。首先从机械手的基础知识介绍有关机械手的组成、分类、臂部设计、液压控制的多种方案,再从本次设计所要求的功能原理设计开始,对于不同的方案加以比较和论证,从中可确定出最优方案,并采用其方案,在对其的结构设计的基础上,对其驱动力和驱动力力矩进行计算。着重阐述了机身的设计,具体阐述了机械手的设计原则和步骤,分析了设计时应注意的问题,并对机械手的平稳性及定位精度给予详细的论述。设计并分析了该机械手所用的液压控制的方法和过程。由于经验不足,知识有限,难免有误,有待改进。

关键词 液压;机械手;液压缸

This thesis introduces to used for clipping to hold the outside circle a design for and down anticipating machine hand. It adopts the liquid presses to drive, ordering a procedure control, acting steady, control convenience.

This thesis expatiates the rise and fall of the machine’s hand primarily with the design of the turn-over with compute. Constitute, divide into section form the relevant machine in introduction in knowledge in foundation of the machine hand first, wrist a various projects for and arm department designing, liquid pressing control, start from this design a function for requesting principle, take into the comparison to the different project with the argument, can make sure the superior project from the inside, combine to adopt its project, in as to it’s of the foundation of the construction design, as to it’s driver force and moment proceed the calculation. Emphasize the design that expatiated the fuselage, expatiated the design principle of the machine hand in a specific way with the step, analyzed the problem of design should notice, and give to the steady and fixed position accuracy of the machine hand detailed treatise. Because of experience shortage, the knowledge is limited, difficult do not need the mistake, treat to improve.

Keywords manipulator; liquid presses; driving force; fixed position accuracy

目录

摘 要 I

Abstract II

第1章 绪论 1

1.1 机械手在生产中的作用 1

1.2 机械手国内现状和发展趋势 1

1.3 论文研究的内容 2

第2章 蜡模机械手的总功能原及方案的选择与确定 4

2.1 功能原理设计 4

2.2 初选方案 5

2.2.1 方案一 5

2.2.2 方案二 5

2.3 方案选取 6

第3章 机械手总体方案总结 7

3.1 传动方案的确定 7

3.2 规格参数 7

3.3 结构特点 7

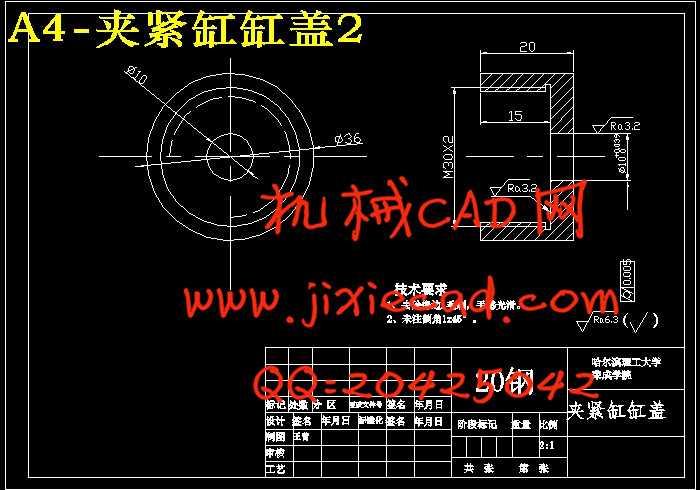

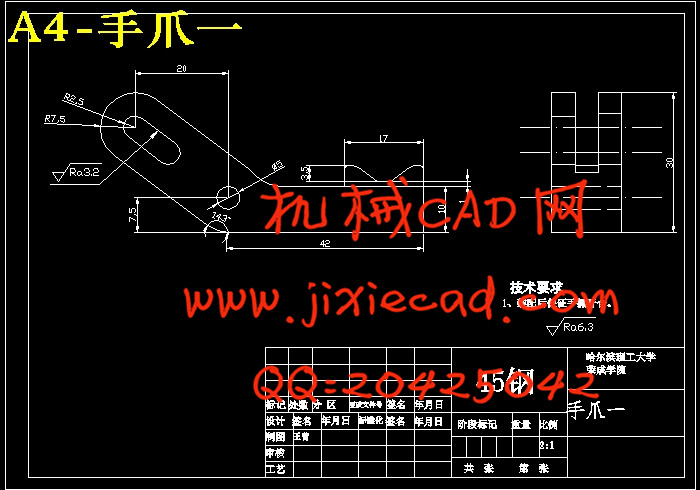

3.3.1 抓取机构 7

3.3.2 手臂的回转运动结构 8

3.3.3 手臂的升降运动机构 8

3.3.4 其它装置 8

3.4 机械手的液压传动系统 9

第4章 机械手的各部分设计 10

4.1 手部设计 10

4.1.1 手部设计要求: 10

4.1.2 手部的结构 10

4.1.3 机械手的力学分析 12

4.2 手臂部分设计 14

4.2.1 手臂部分设计要求 15

4.3 手臂部分结构 19

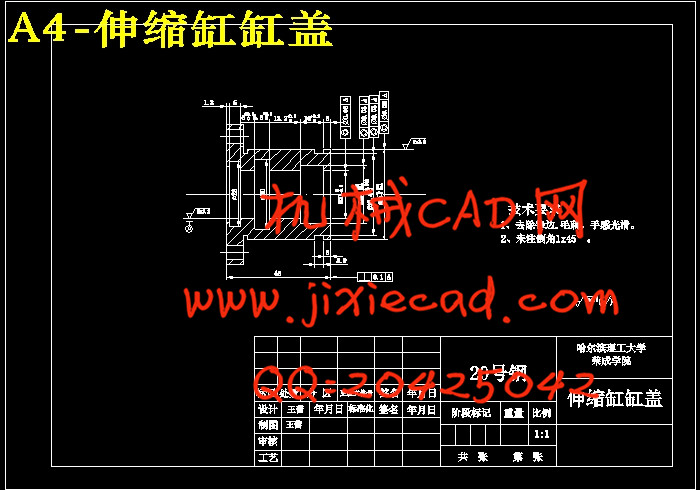

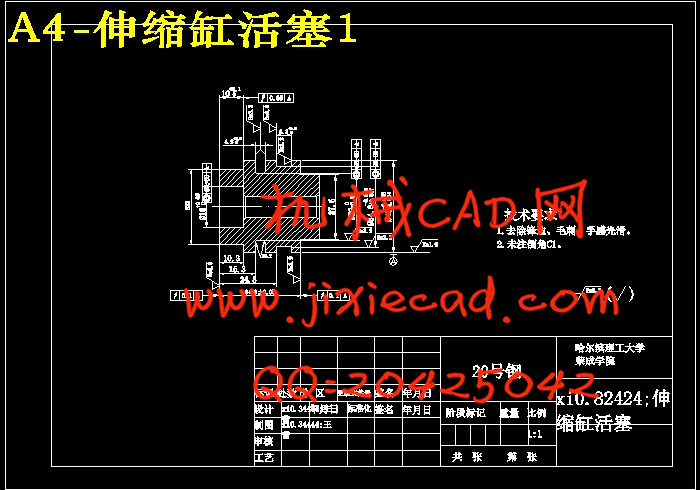

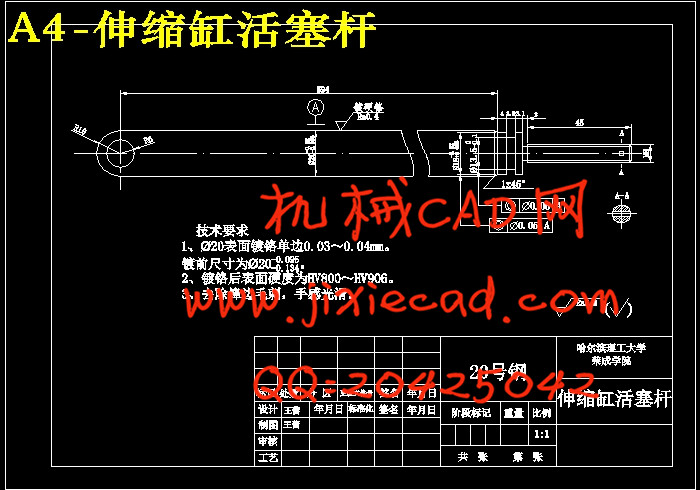

4.3.1 手臂伸缩运动结构 19

4.3.2 手臂伸缩油缸的计算 19

4.4 定位缸 22

结论 23

参考文献 24

致 谢 25

最近,全球内带有夹子夹子或手的机械手系统已经发展起来了,多种方法应用其上,有拟人化和非拟人化的,不仅调查了这些系统的机械结构,而且还包括其必要的控制系统,如同人手一样,这些机械人系统可以用它们的手去抓不同的物体,而且不用改换夹子,这些机械手具备特殊的运动能力比如小质量和小惯量,这使被抓物体在机械手的工作范围内做更复杂、更精确的操作变得可能。这些复杂的操作被抓物体绕任意角度和轴旋转。

本论文介绍了用于夹持蜡模机械手的设计。它采用液压驱动,点位程序控制,动作平稳,控制方便。本论文主要阐述该机械手的夹紧、伸缩、升降和回转的设计和计算。首先从机械手的基础知识介绍有关机械手的组成、分类、臂部设计、液压控制的多种方案,再从本次设计所要求的功能原理设计开始,对于不同的方案加以比较和论证,从中可确定出最优方案,并采用其方案,在对其的结构设计的基础上,对其驱动力和驱动力力矩进行计算。着重阐述了机身的设计,具体阐述了机械手的设计原则和步骤,分析了设计时应注意的问题,并对机械手的平稳性及定位精度给予详细的论述。设计并分析了该机械手所用的液压控制的方法和过程。由于经验不足,知识有限,难免有误,有待改进。

关键词 液压;机械手;液压缸

Wax molded shell robot mechanical part design

Abstract

Recently, the world inside with clamps clips or hand robotic systems have been developed, a variety of methods applied on it, there are anthropomorphic and non-anthropomorphic, not only the investigation of these systems mechanical structure, but also its necessary control system, as manpower, these robotic systems can use their hands to grab different objects, and do not change the clip, these robots possess exceptional athletic ability such as small mass and small inertia, which makes the grasped object in the robot's operating range done within a more complex, more precise operation becomes possible. These complex operations are grasping objects around any angle and axes.This thesis introduces to used for clipping to hold the outside circle a design for and down anticipating machine hand. It adopts the liquid presses to drive, ordering a procedure control, acting steady, control convenience.

This thesis expatiates the rise and fall of the machine’s hand primarily with the design of the turn-over with compute. Constitute, divide into section form the relevant machine in introduction in knowledge in foundation of the machine hand first, wrist a various projects for and arm department designing, liquid pressing control, start from this design a function for requesting principle, take into the comparison to the different project with the argument, can make sure the superior project from the inside, combine to adopt its project, in as to it’s of the foundation of the construction design, as to it’s driver force and moment proceed the calculation. Emphasize the design that expatiated the fuselage, expatiated the design principle of the machine hand in a specific way with the step, analyzed the problem of design should notice, and give to the steady and fixed position accuracy of the machine hand detailed treatise. Because of experience shortage, the knowledge is limited, difficult do not need the mistake, treat to improve.

Keywords manipulator; liquid presses; driving force; fixed position accuracy

目录

摘 要 I

Abstract II

第1章 绪论 1

1.1 机械手在生产中的作用 1

1.2 机械手国内现状和发展趋势 1

1.3 论文研究的内容 2

第2章 蜡模机械手的总功能原及方案的选择与确定 4

2.1 功能原理设计 4

2.2 初选方案 5

2.2.1 方案一 5

2.2.2 方案二 5

2.3 方案选取 6

第3章 机械手总体方案总结 7

3.1 传动方案的确定 7

3.2 规格参数 7

3.3 结构特点 7

3.3.1 抓取机构 7

3.3.2 手臂的回转运动结构 8

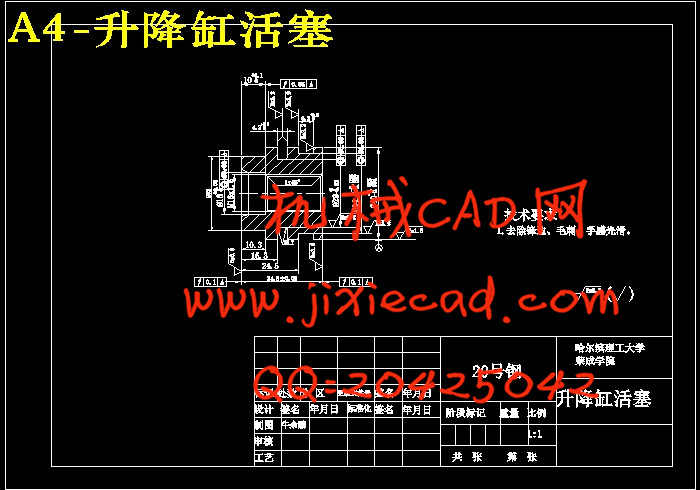

3.3.3 手臂的升降运动机构 8

3.3.4 其它装置 8

3.4 机械手的液压传动系统 9

第4章 机械手的各部分设计 10

4.1 手部设计 10

4.1.1 手部设计要求: 10

4.1.2 手部的结构 10

4.1.3 机械手的力学分析 12

4.2 手臂部分设计 14

4.2.1 手臂部分设计要求 15

4.3 手臂部分结构 19

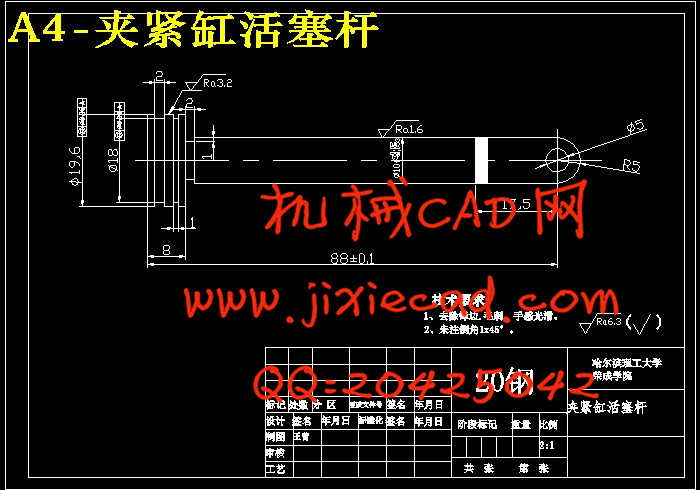

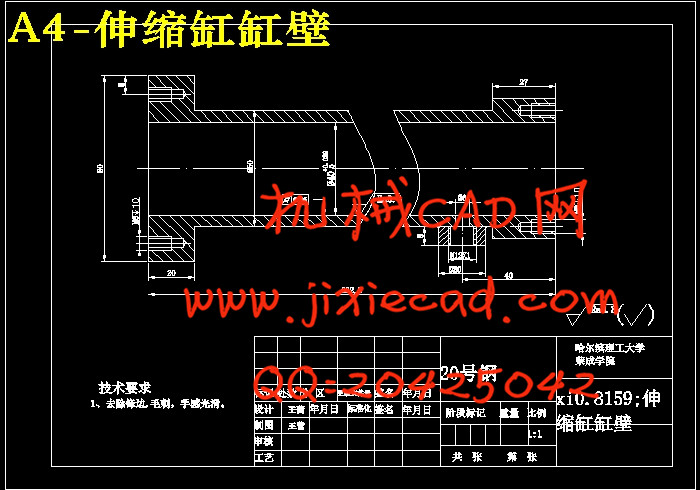

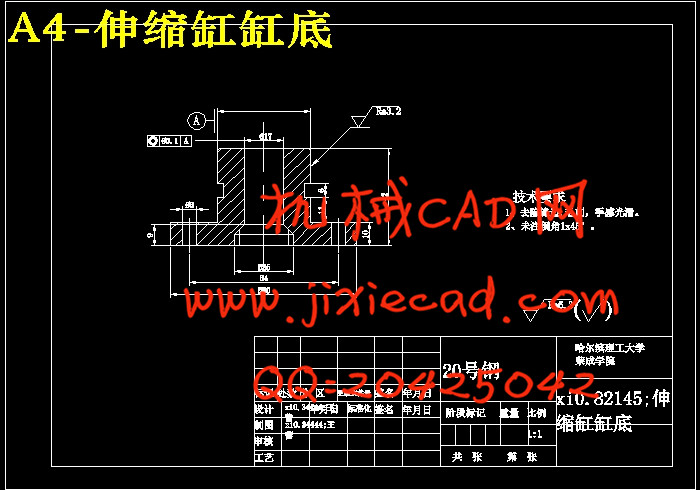

4.3.1 手臂伸缩运动结构 19

4.3.2 手臂伸缩油缸的计算 19

4.4 定位缸 22

结论 23

参考文献 24

致 谢 25