设计简介

雷达频率调节机构设计

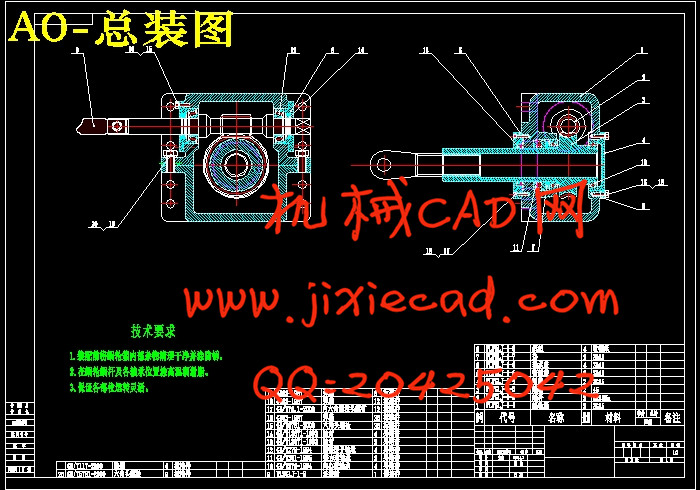

本设计介绍了雷达频率调频机构的现状,主要介绍了本设计的主要零件部分,即蜗轮蜗杆之间的传动特点和连接轴的应用与计算,说明了本机构的工作原理和相关计算。本设计的特点是原理简单,工作可靠,生产经济,便于安装与维修,符合设计要求与生产要求。

本设计对蜗轮蜗杆传动比,强度,润滑等方面都进行了比较完整的阐述,比较详细地对各传动部分做了具体分析,以确保其在实际生产中稳定高效地工作。并对本机构的链接部分即螺纹链接进行了说明和计算,满足了强度,寿命等一系列生产条件。

关键词 频率 调节 蜗轮 蜗杆 传动

The design of radar frequency regulation mechanism

Abstract

Radar frequency adjustment mechanism is an important part of the rader. In this design mainly through the worm gear transmission to adjust the radar frequency, Worm gear mechanism has the characteristics of simple structure, single stage transmission ratio, compact structure, stable transmission.

The design of the radar frequency FM mechanism present situation, introduced the main design of the main parts, namely the worm between the transmission characteristics and is connected to the shaft with applications and computing, explains the working principle of the mechanism and related calculation.。This design is characterized by simple principle, reliable work, convenient installation and production economy, repair, meets the requirements of design and production requirements

The design have quite complete elaboration,to transmission ratio, strength, lubrication etc of the worm gear,and more detailed on the drive parts did concrete analysis,in order to ensure its in the actual production of stable and efficient work.And the mechanism whereby the threaded portion of the link link are described and calculated, satisfies the intensity, lifetime and a series of production conditions.

Key words frequency regulation worm gear worm drive

目 录

1 绪论 1

1.1 频率调节机构 1

1.2 蜗轮蜗杆简介 2

1.3 本课题研究的背景 3

1.4 探究本课题的研究意义 4

2 雷达频率调节机构的工作原理和设计方案 8

2.1频率调节机构工作原理 8

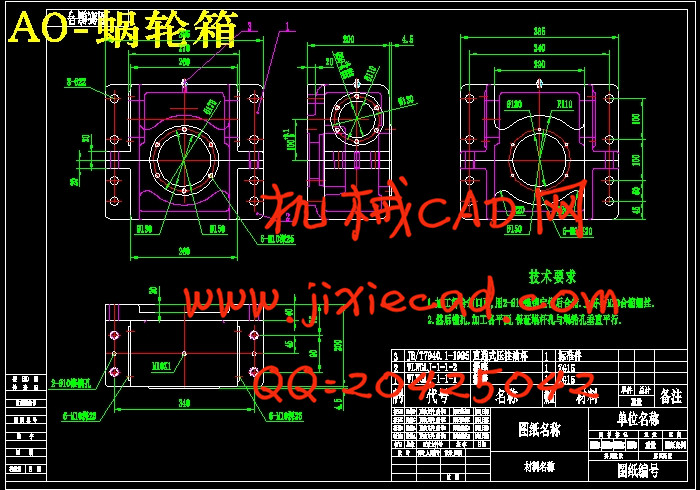

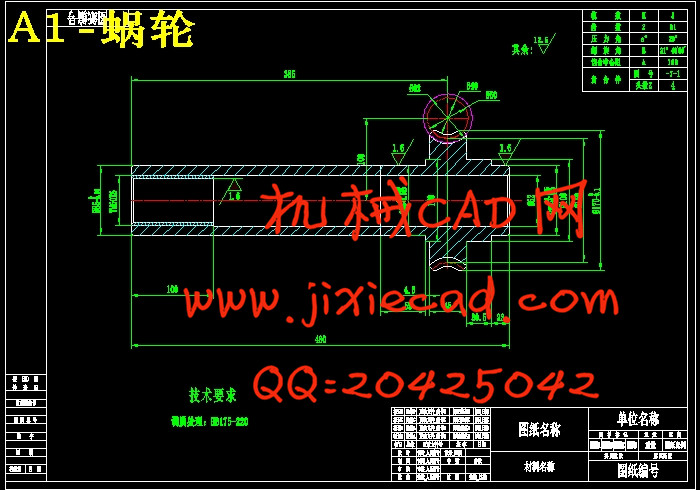

2.1.1 蜗轮部分 8

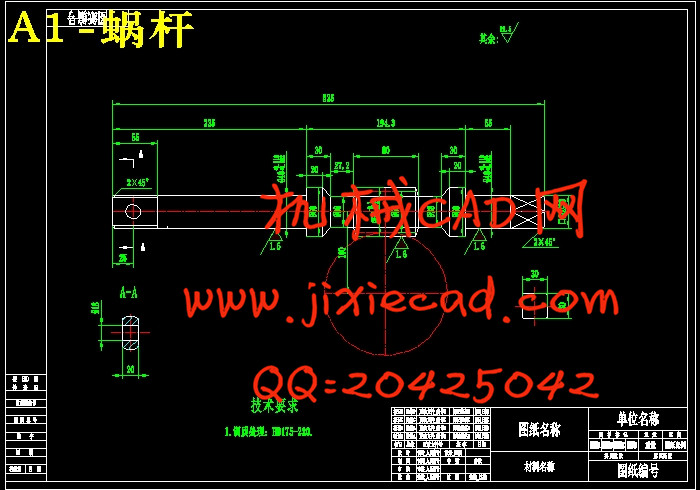

2.1.2 蜗杆部分 9

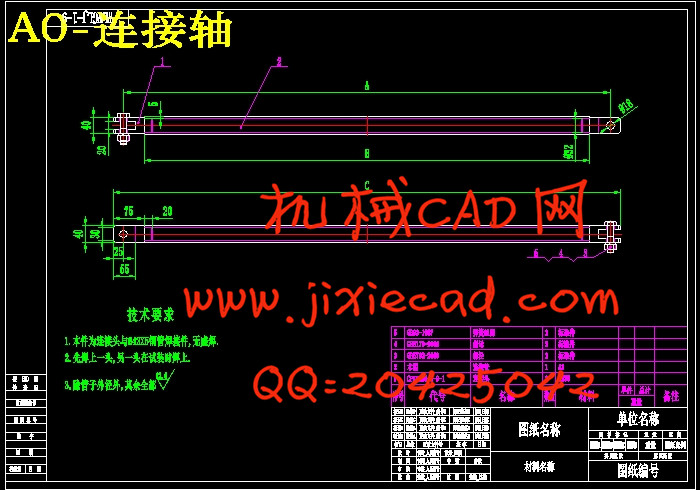

2.1.3 连轴部分 9

2.1.4轴结构设计 10

2.1.5 轴扭转刚度 10

2.1.6 磨损分析 11

3 总体设计计算 12

3.1蜗轮蜗杆的传动设计 12

3.2.蜗杆、蜗轮的基本尺寸设计 18

3.2.1蜗杆基本尺寸设计 18

3.2.3 蜗轮轴的尺寸设计与校核 19

3.3 轴的计算设计 20

3.3.1 轴的基本计算 20

3.3.2.轴的校核计算如表3-3 21

3.3.3 轴承寿命的计算 23

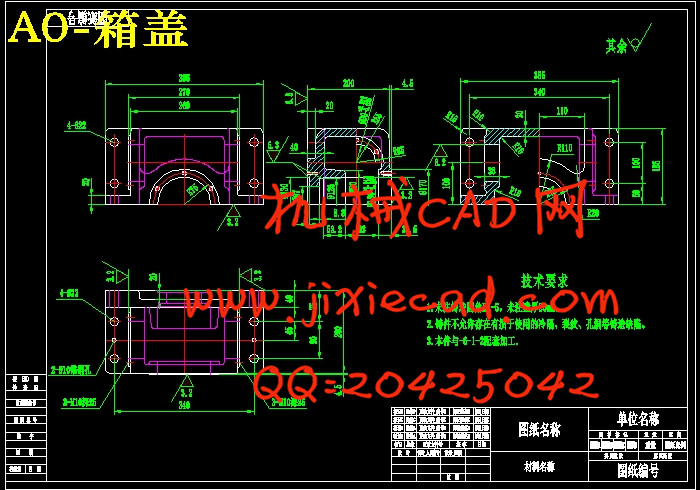

3.4 螺栓联结的强度计算 26

3.4.1 螺纹连接的强度计算 26

3.4.2螺栓联接的强度计算 26

3.4.3螺栓强度计算 26

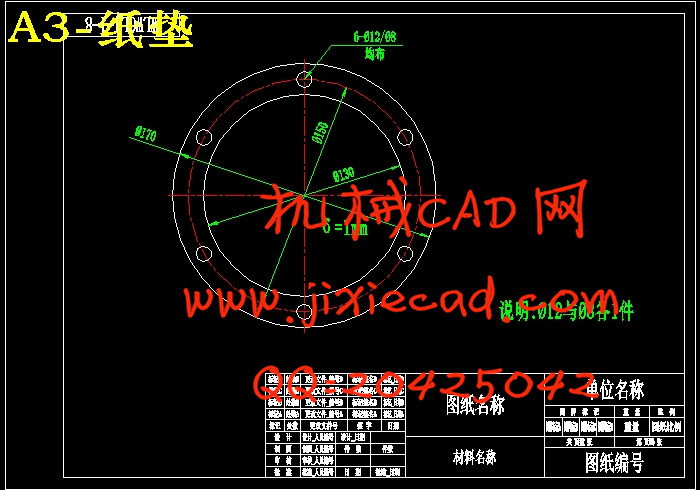

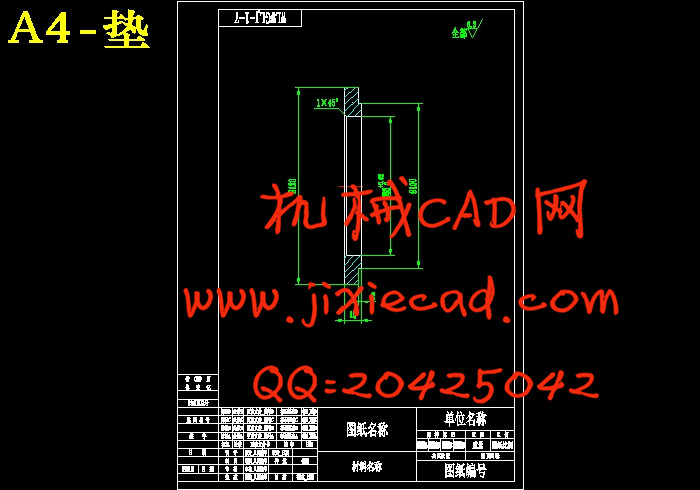

3.4.4 螺栓组联接的设计 27

3.4.5 提高螺纹联接强度的措施 27

结束语 29

致 谢 30

参考文献 31

摘 要

频率调节机构是雷达的一个重要的组成部分。在本设计中主要通过蜗轮蜗杆的传动来调节雷达频率,蜗轮蜗杆机构具有结构简单、单级传动比大、结构紧凑,传动平稳等特点。本设计介绍了雷达频率调频机构的现状,主要介绍了本设计的主要零件部分,即蜗轮蜗杆之间的传动特点和连接轴的应用与计算,说明了本机构的工作原理和相关计算。本设计的特点是原理简单,工作可靠,生产经济,便于安装与维修,符合设计要求与生产要求。

本设计对蜗轮蜗杆传动比,强度,润滑等方面都进行了比较完整的阐述,比较详细地对各传动部分做了具体分析,以确保其在实际生产中稳定高效地工作。并对本机构的链接部分即螺纹链接进行了说明和计算,满足了强度,寿命等一系列生产条件。

关键词 频率 调节 蜗轮 蜗杆 传动

The design of radar frequency regulation mechanism

Abstract

Radar frequency adjustment mechanism is an important part of the rader. In this design mainly through the worm gear transmission to adjust the radar frequency, Worm gear mechanism has the characteristics of simple structure, single stage transmission ratio, compact structure, stable transmission.

The design of the radar frequency FM mechanism present situation, introduced the main design of the main parts, namely the worm between the transmission characteristics and is connected to the shaft with applications and computing, explains the working principle of the mechanism and related calculation.。This design is characterized by simple principle, reliable work, convenient installation and production economy, repair, meets the requirements of design and production requirements

The design have quite complete elaboration,to transmission ratio, strength, lubrication etc of the worm gear,and more detailed on the drive parts did concrete analysis,in order to ensure its in the actual production of stable and efficient work.And the mechanism whereby the threaded portion of the link link are described and calculated, satisfies the intensity, lifetime and a series of production conditions.

Key words frequency regulation worm gear worm drive

目 录

1 绪论 1

1.1 频率调节机构 1

1.2 蜗轮蜗杆简介 2

1.3 本课题研究的背景 3

1.4 探究本课题的研究意义 4

2 雷达频率调节机构的工作原理和设计方案 8

2.1频率调节机构工作原理 8

2.1.1 蜗轮部分 8

2.1.2 蜗杆部分 9

2.1.3 连轴部分 9

2.1.4轴结构设计 10

2.1.5 轴扭转刚度 10

2.1.6 磨损分析 11

3 总体设计计算 12

3.1蜗轮蜗杆的传动设计 12

3.2.蜗杆、蜗轮的基本尺寸设计 18

3.2.1蜗杆基本尺寸设计 18

3.2.3 蜗轮轴的尺寸设计与校核 19

3.3 轴的计算设计 20

3.3.1 轴的基本计算 20

3.3.2.轴的校核计算如表3-3 21

3.3.3 轴承寿命的计算 23

3.4 螺栓联结的强度计算 26

3.4.1 螺纹连接的强度计算 26

3.4.2螺栓联接的强度计算 26

3.4.3螺栓强度计算 26

3.4.4 螺栓组联接的设计 27

3.4.5 提高螺纹联接强度的措施 27

结束语 29

致 谢 30

参考文献 31