设计简介

离心式切片机的设计

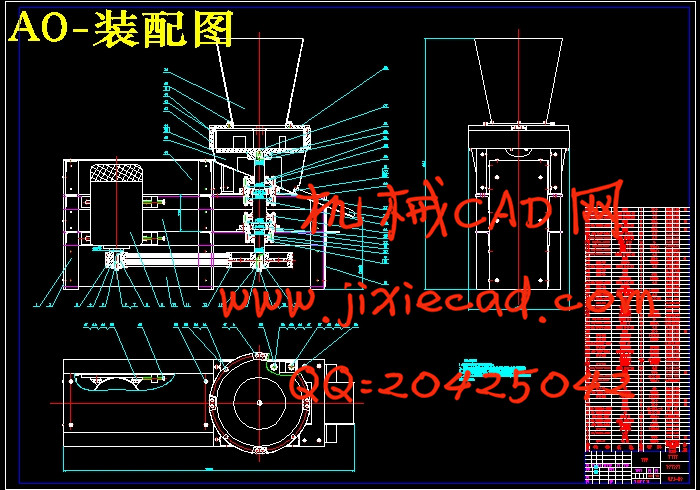

摘要:随着生活水平逐渐提高,人们对一些茎块作物的食用要求也越来越高。例如在加工土豆和一些薯类食品的时候,要将其切成片,因而离心式切片机应运而生。当食物的需求量比较大时,用手工进行切削工作量较大、效率低,且切出来的食物大小不一。对于一些食品深加工工厂来说,需要加工切成片的茎块状食品,切片机对工厂的重要性不言而喻,不仅提高了工厂的生产效率,而且还可严格控制食品的外观形状和大小。根据需求量的大小,改变离心式切片机的设计参数,可以设计出不同功率、不同形式的产品。本设计的切片机主要是针对中小型场合,例如加工作坊、食堂、家庭等,是针对一些茎块的形状而设计的,非常实用且效率较高。本设计按照切片的厚度和所要达到的生产效率,根据所产生的弯矩、扭矩对轴的作用,计算轴的大小及校核强度、刚度;根据受力的大小和方向合理选择轴承型号并计算轴承寿命;运用solidworks三维软件对机架进行了设计与受力分析,在保证强度要求前提下尽可能的优化结构,旨在设计和开发一种高效率、高质量的离心式切片机。

关键词: 离心式切片机;切片厚度;生产效率

A Design of Centrifugal Slice Machine

Abstract: As the improvement of people's living standard, the edible equirement of the tuber crops becomes higher and higher. For example, people want to cut the food like to potatoes into pieces, the use of the centrifugal slice machine appears consequently. When the demand of the food is large, the workload is relatively heavy and the efficiency is quite low by hand cutting. In addition the sizes of the food is inhomogeneous. To some of the food processing plant, they need the processed sliced stem massive food , it goes without saying that slicer is very important on the plant, it not only improves the production efficiency of the plant, but also strictly controls the appearance of the shape and size of the food . According to the demand, products with various powers and styles can be figured out by adjusting the parameters of the centrifugal slice machine. This design is aimed at medium and small occasions such as processing workshops, canteen and families. This design is very practical and efficient especially for the tuber crops. The design is accordance with thickness of a slice and production efficiency to be achieved, based on the effect generated by the bending moment, torque on the shaft , calculates the size of shaft and checks the strength, stiffness. Based on the size and direction of the force, we have a reasonable choice of bearing mode and calculate the life of bearing. This design uses solidworks 3D software to design and analysis stress of the support, optimizes the structure as much as possible under the premise of ensuring the strength requirements , aims to design and develop a high efficiency, high-quality centrifugal slicer.

Key words :Centrifugal Slice Machine; Slice Thickness ; Production Efficiency

目 录

1 绪 论 1

1.1 国外发展情况 2

1.2 国内发展概况 4

2 离心式切片机总体方案的确定 5

2.1 结构特点与工作原理 5

2. 2 机构的组成部分及特点 6

3 重要零部件的设计计算与校核 8

3.1 电动机的计算与选择 8

3.2 V带传动的设计计算 10

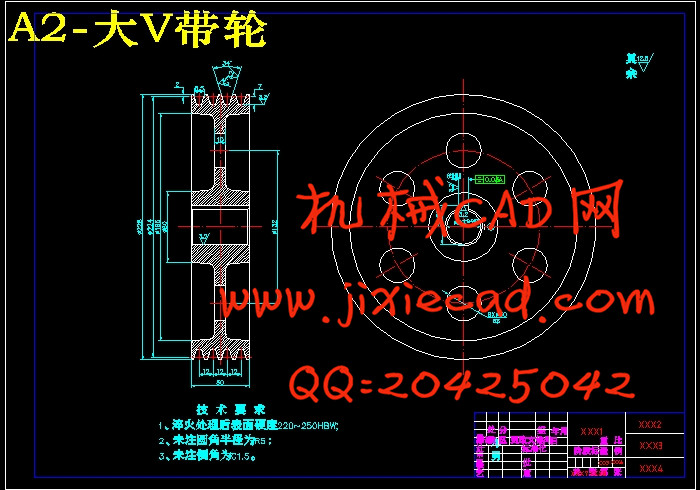

3.3 V带轮的设计 18

3.4 轴的设计与校核计算 21

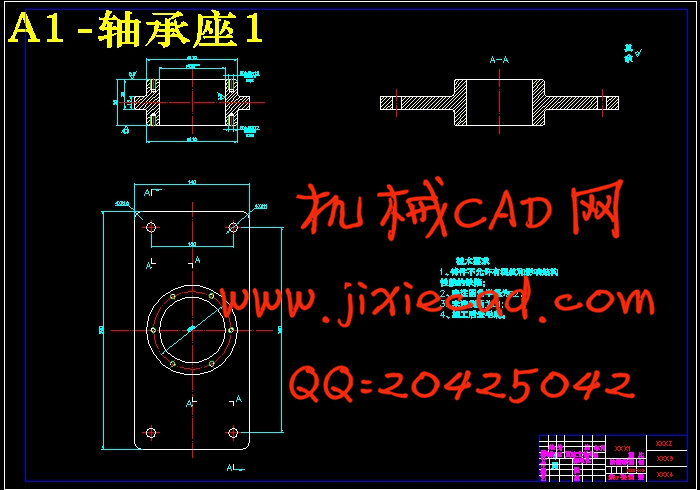

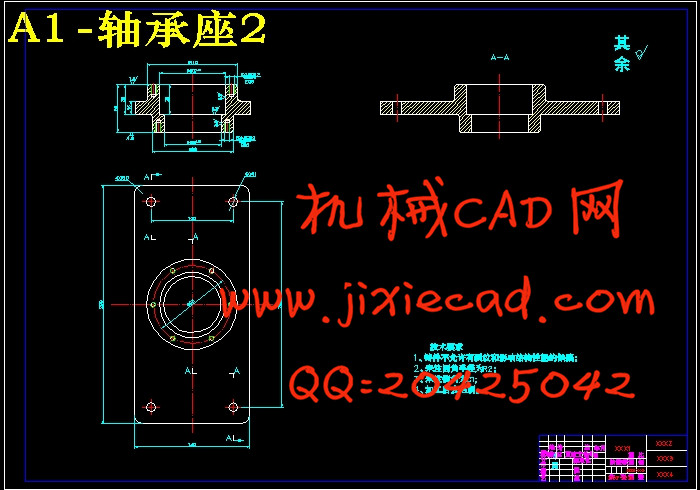

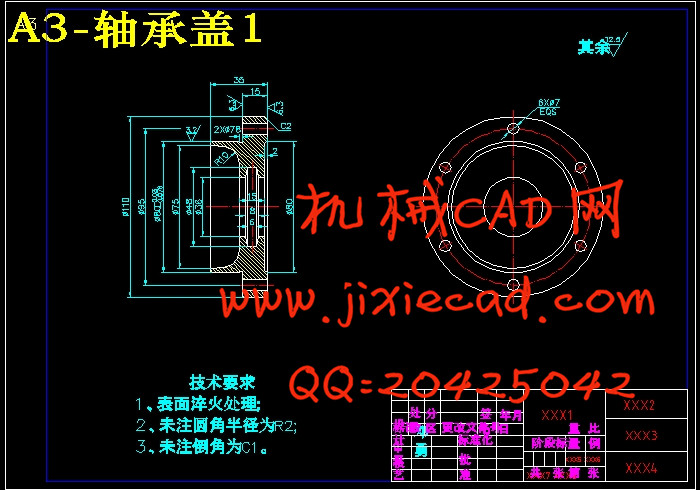

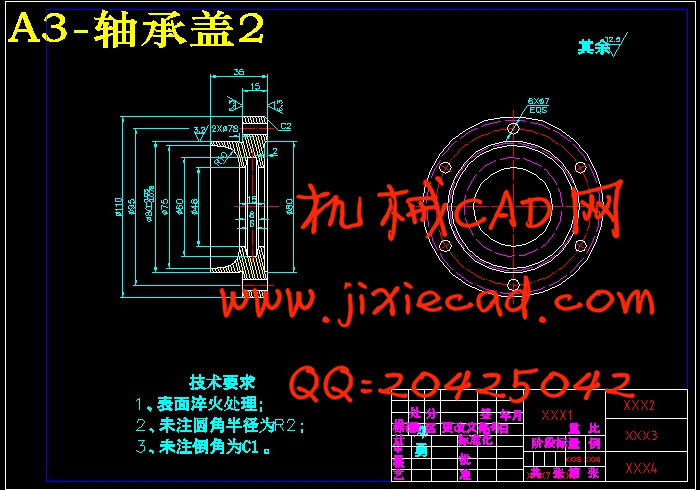

3.5 轴承计算与校核 31

3.6 键的选择与校核 34

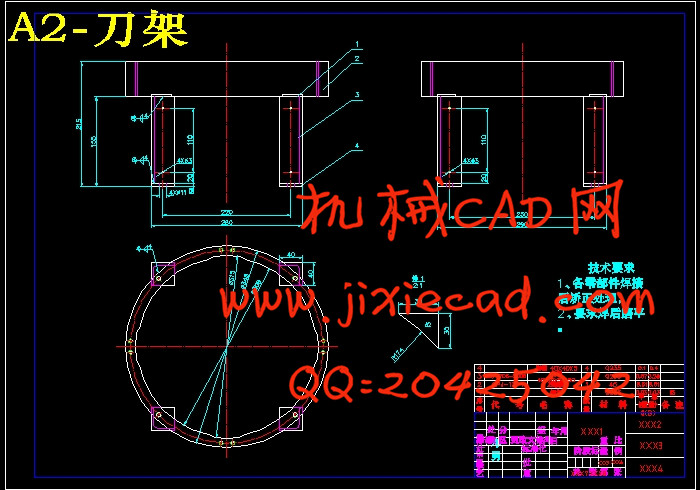

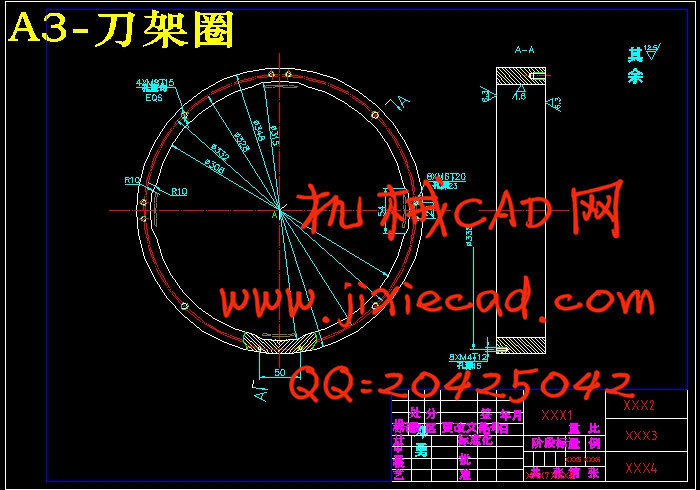

3.7 刀片的设计 37

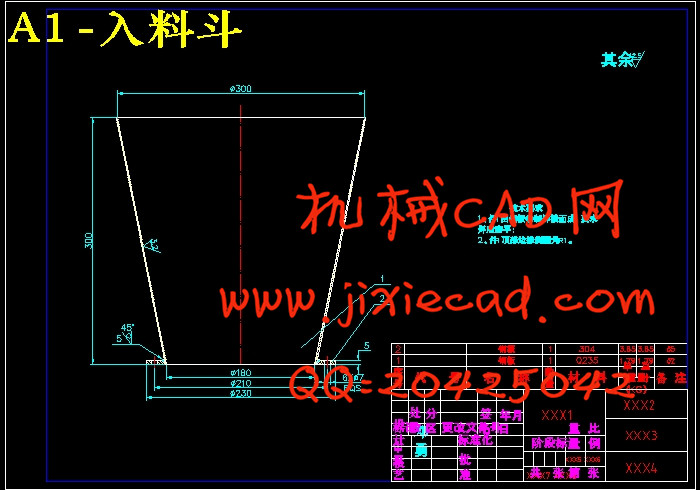

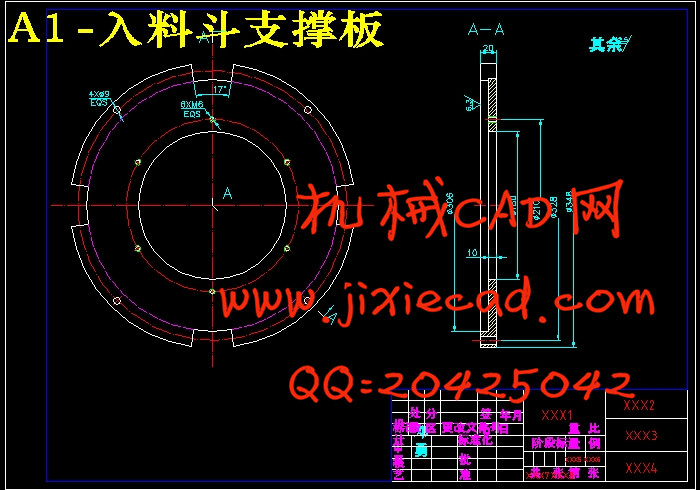

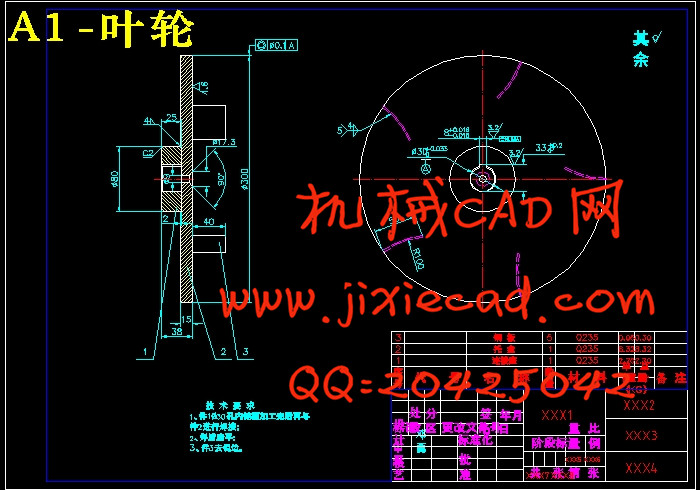

3.8 入料斗及叶轮的设计 39

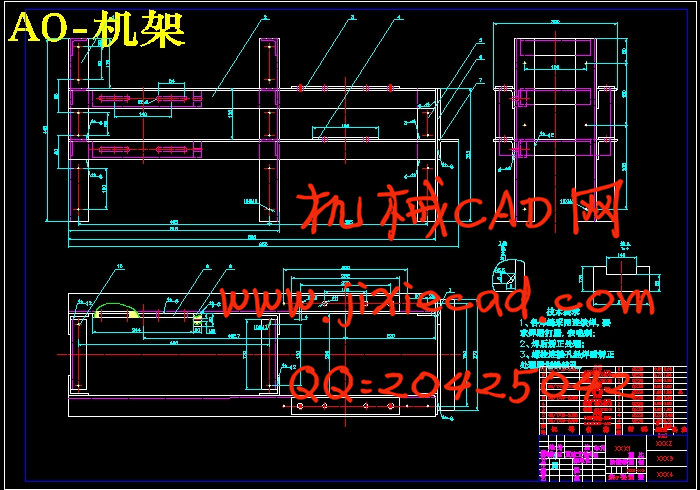

3.9 机架的设计 40

4 结 论 46

4.1 本设计的优点 46

4.2 存在的问题及改进的措施 46

参考文献 47

谢 辞 49

附 录 50

摘要:随着生活水平逐渐提高,人们对一些茎块作物的食用要求也越来越高。例如在加工土豆和一些薯类食品的时候,要将其切成片,因而离心式切片机应运而生。当食物的需求量比较大时,用手工进行切削工作量较大、效率低,且切出来的食物大小不一。对于一些食品深加工工厂来说,需要加工切成片的茎块状食品,切片机对工厂的重要性不言而喻,不仅提高了工厂的生产效率,而且还可严格控制食品的外观形状和大小。根据需求量的大小,改变离心式切片机的设计参数,可以设计出不同功率、不同形式的产品。本设计的切片机主要是针对中小型场合,例如加工作坊、食堂、家庭等,是针对一些茎块的形状而设计的,非常实用且效率较高。本设计按照切片的厚度和所要达到的生产效率,根据所产生的弯矩、扭矩对轴的作用,计算轴的大小及校核强度、刚度;根据受力的大小和方向合理选择轴承型号并计算轴承寿命;运用solidworks三维软件对机架进行了设计与受力分析,在保证强度要求前提下尽可能的优化结构,旨在设计和开发一种高效率、高质量的离心式切片机。

关键词: 离心式切片机;切片厚度;生产效率

A Design of Centrifugal Slice Machine

Abstract: As the improvement of people's living standard, the edible equirement of the tuber crops becomes higher and higher. For example, people want to cut the food like to potatoes into pieces, the use of the centrifugal slice machine appears consequently. When the demand of the food is large, the workload is relatively heavy and the efficiency is quite low by hand cutting. In addition the sizes of the food is inhomogeneous. To some of the food processing plant, they need the processed sliced stem massive food , it goes without saying that slicer is very important on the plant, it not only improves the production efficiency of the plant, but also strictly controls the appearance of the shape and size of the food . According to the demand, products with various powers and styles can be figured out by adjusting the parameters of the centrifugal slice machine. This design is aimed at medium and small occasions such as processing workshops, canteen and families. This design is very practical and efficient especially for the tuber crops. The design is accordance with thickness of a slice and production efficiency to be achieved, based on the effect generated by the bending moment, torque on the shaft , calculates the size of shaft and checks the strength, stiffness. Based on the size and direction of the force, we have a reasonable choice of bearing mode and calculate the life of bearing. This design uses solidworks 3D software to design and analysis stress of the support, optimizes the structure as much as possible under the premise of ensuring the strength requirements , aims to design and develop a high efficiency, high-quality centrifugal slicer.

Key words :Centrifugal Slice Machine; Slice Thickness ; Production Efficiency

目 录

1 绪 论 1

1.1 国外发展情况 2

1.2 国内发展概况 4

2 离心式切片机总体方案的确定 5

2.1 结构特点与工作原理 5

2. 2 机构的组成部分及特点 6

3 重要零部件的设计计算与校核 8

3.1 电动机的计算与选择 8

3.2 V带传动的设计计算 10

3.3 V带轮的设计 18

3.4 轴的设计与校核计算 21

3.5 轴承计算与校核 31

3.6 键的选择与校核 34

3.7 刀片的设计 37

3.8 入料斗及叶轮的设计 39

3.9 机架的设计 40

4 结 论 46

4.1 本设计的优点 46

4.2 存在的问题及改进的措施 46

参考文献 47

谢 辞 49

附 录 50