设计简介

摘要

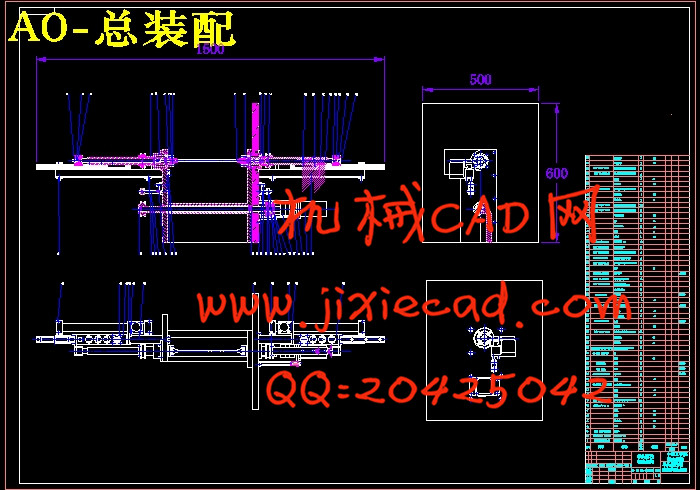

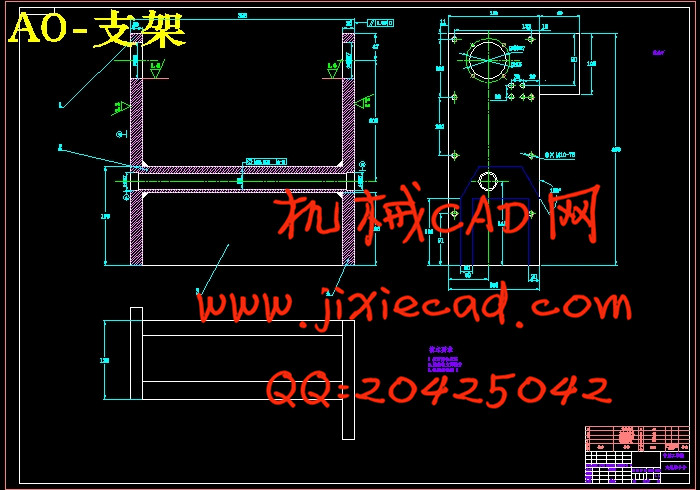

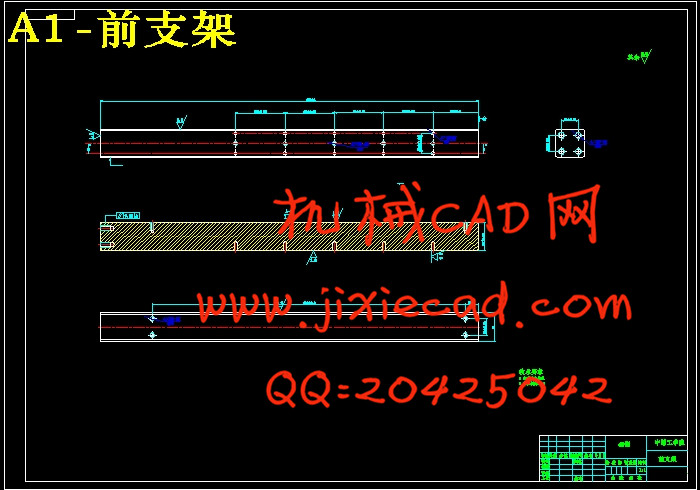

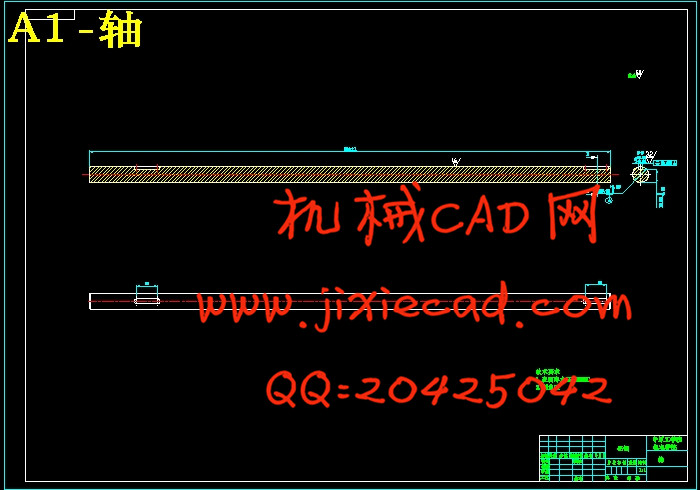

锂电池卷绕机卷绕机构是锂电卷绕设备中的重要的组成部分,它对电池的质量和寿命有很大的影响,它的设计对电池的自动化会有很大的作用。其设计的实质是,在完成总体的设计方案以后,就指各个主要零部件的设计、安装、定位等问题,并对个别零件进行强度校核和试验。并在相关专题中,对轴和轴承的寿命延长进行比较详细的分析。在各个零部件的设计中,要包括材料的选择、尺寸的确定、加工的要求,结构工艺性的满足,以及与其他零件的配合的要求等。在强度的校核是,要运用的相关公式,进行危险部位的分析、查表、作图和计算等。并随后对整体进行安装、工作过程以及工作后的各方面的检查,同时兼顾到维修、保险装置等方面的问题,最后对两个主要工作零件的加工精度、公差选择进行分析,以保证卷绕机构最终设计的经济性和可靠性。

关键词:锂电池、卷绕机、经济性

Abstract

Lithium battery winding machine winding winding device body is lithium important part of its quality and longevity of the battery has a great influence, and its automated design of the battery will have a significant role. The essence of its design, the completion of the overall design of the future, they refer to each of the major components of the design, installation, positioning and other issues, and checking the strength of individual components and testing. And related topics in the life of the shaft and bearings to extend the more detailed analysis. In various parts of the design, to include material selection, determine the size, processing requirements, the structure of the meeting process, and with other parts of the matching requirements. Check the intensity is related to the use of formula for risk parts of the analysis, look-up table, mapping and computing. And the subsequent installation of the whole work process and work in all aspects of the inspection, taking into account the maintenance, insurance, equipment and other issues, the last of the two main working parts of the machining accuracy, Tolerance analysis in order to ensure the winding Final design of economic institutions and reliability.

Keywords: lithium battery, winding machine, economy

字典

锂电池卷绕机卷绕机构是锂电卷绕设备中的重要的组成部分,它对电池的质量和寿命有很大的影响,它的设计对电池的自动化会有很大的作用。其设计的实质是,在完成总体的设计方案以后,就指各个主要零部件的设计、安装、定位等问题,并对个别零件进行强度校核和试验。并在相关专题中,对轴和轴承的寿命延长进行比较详细的分析。在各个零部件的设计中,要包括材料的选择、尺寸的确定、加工的要求,结构工艺性的满足,以及与其他零件的配合的要求等。在强度的校核是,要运用的相关公式,进行危险部位的分析、查表、作图和计算等。并随后对整体进行安装、工作过程以及工作后的各方面的检查,同时兼顾到维修、保险装置等方面的问题,最后对两个主要工作零件的加工精度、公差选择进行分析,以保证卷绕机构最终设计的经济性和可靠性。

关键词:锂电池、卷绕机、经济性

Abstract

Lithium battery winding machine winding winding device body is lithium important part of its quality and longevity of the battery has a great influence, and its automated design of the battery will have a significant role. The essence of its design, the completion of the overall design of the future, they refer to each of the major components of the design, installation, positioning and other issues, and checking the strength of individual components and testing. And related topics in the life of the shaft and bearings to extend the more detailed analysis. In various parts of the design, to include material selection, determine the size, processing requirements, the structure of the meeting process, and with other parts of the matching requirements. Check the intensity is related to the use of formula for risk parts of the analysis, look-up table, mapping and computing. And the subsequent installation of the whole work process and work in all aspects of the inspection, taking into account the maintenance, insurance, equipment and other issues, the last of the two main working parts of the machining accuracy, Tolerance analysis in order to ensure the winding Final design of economic institutions and reliability.

Keywords: lithium battery, winding machine, economy

字典

前言

时间匆匆,四年一挥而过,毕业在即,需要自己完成最后一个任务:完成毕业设计,为自己能毕业画上一个圆满的句号。本来打算是在学校里做毕业设计的,所以上学期的时候我选的是肖老师的课题,后来由于我找了份工作,这个公司和学校里有一个合作计划:也就是让学生去公司里做毕业设计。就在这学期刚开学的时候,我们几个人就风尘仆仆的坐火车到赢合科技有限公司去做毕业设计了,顺便去那边实习,刚到公司恰好赶上公司搬家,于是我们几个就像干苦力似地在那干了一个星期的体力活,厂搬完了之后,我们就开始在厂里干起了装配活,在装配的过程中,我们学到了很多东西,了解了车技的装配工艺和零件的加工工艺,在装配过程中也发现了很多的问题。我们发现车间里没有装配工艺图和相关的指导文件,我们的装配就是完全在师傅的指导下进行的。

后来我们就在工程师的指导下选择了自己的毕业设计课题,而我选的就是:单头全自动卷绕机构,我的任务就是合理的设计各零部件之间的形状配合尺寸,使结构更加的合理完善。

1 引言 1

1.1锂电池的概述 1

1.2锂电池卷绕设备的的概述 1

1.3锂电池卷绕设备的现状 1

1.2.1圆型锂电池半自动卷绕机 1

1.2.2圆柱锂离子电池全自动卷绕机 2

1.4毕业设计任务分析 2

2 方案设计 3

2.1电机类型的设计 3

2.2轴间传动方案的设计 7

2.2.1同步带传动的优缺点 7

2.2.2轴承传动的优缺点 7

2.2.3链条传动的优缺点 8

2.2.4最终传动方案的选择 8

2.3 联轴器的选择 8

2.4轴的设计 9

2.4.1输入轴的设计 9

2.5 轴承的选择 10

2.6 气缸的选择 10

2.7卷绕机构三维图 11

3 设计计算 12

3.1电机的选择 12

3.1.1电机型号和结构形式的选择 12

3.1.2电机功率的选择 12

3.1.3电动机转速的选择 14

3.1.4确定电机的型号 14

3.2同步轮和同步带的选择 15

3.2.1步带和同步轮型号的选择 15

3.2.2步轮和同步带安装时需注意的事项 15

3.3轴强度的校核 16

3.4深沟球轴承的校核计算 19

4 结论 21

参考文献 25

致谢 27