设计简介

摘要:

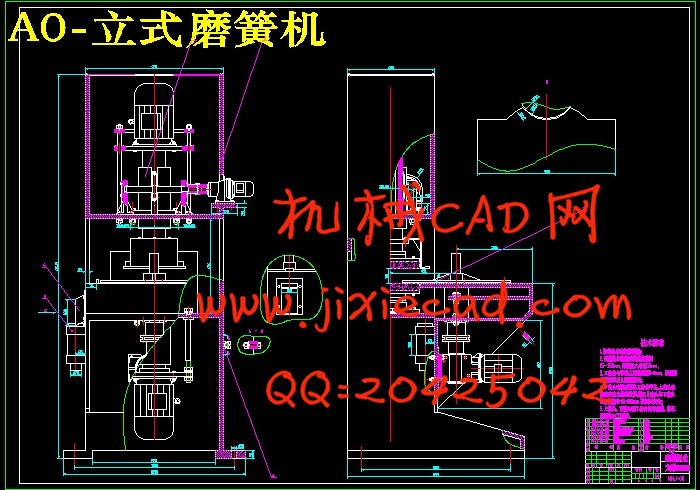

本课题主要完成立式磨簧机的设计,为满足弹簧业批量生产弹簧需求而设计。为提高磨削效率,减少装工件的次数和时间,把磨簧机设计成双面磨,即用两个砂轮同时对弹簧的两个端面进行磨削。先根据磨簧机的功能确定磨簧机的总体结构,为砂轮在磨削时实现进给运动和满足不同高度弹簧的磨削要求,砂轮必须实现轴向移动。为简化结构,只要一磨头实现进给,另一个磨头固定。综合各种因素,确定把下磨头固定,不实现进给,上磨头实现进给运动。

在结构上磨头实现自动进给、复位。降低了工人的劳动强度,改善了工人劳动条件。工人可以同时操作多台磨簧机,提高了生产力。在卸料上实现工件的自动卸料。解放工人的双手,进一步提高了工作效率。砂轮经过长时间磨削产生损耗,会引起弹簧加工精度的下降,该磨簧机在结构上实现了砂轮的补偿,磨削精度得到了保障。

设计的该磨簧机自动化程度高、磨削效率高,工人劳动强度低,结构紧凑,占地面积小,有效地利用了厂房空间。本次设计在满足工作可靠,结构简单等要求下,尽量使用了通用部件,降低了制造成本。

关键词:弹簧;磨簧机;磨头

Abstract: To meet the needs of volume mass spring production , this topic mainly completes the vertical spring grinding machine design, In order to enhance the grinding efficiency, and reduce the work piece the number of install times , I designed the spring grinding machine which doubling surface to rub, namely carries on the grinding with two grinding wheels at the same time to the spring two end surfaces. Acts according to first the spring grinding machine function to determine spring grinding machine overall structure, for grinding wheel when grinding realizes the feed motion and satisfies the different spring the grinding request, the grinding wheel must realize the end motion highly. In order to simplify the structure, so long as a grinding realization to feed, another grinding is fixed. Synthesizes each kind of factor, determined is fixed under grinding, does not realize to feed, on grinding realization feed motion.

In structure grinding realization auto-feed, replacement. Reduced worker's labor intensity, improved the worker work condition. The worker may concurrent operation multi-Taiwan rub the reed machine, enhanced the productive forces. Realizes the work piece self-dumping on the ex-denning. Liberates worker's both hands, further enhanced the working efficiency. The grinding wheel passes through the long time grinding to be able to have the batardeau to consume, can cause the spring processing precision drop, should rub the reed machine to realize the grinding wheel compensation in the structure, the processing precision has been high.

The machine has high automaticity high and the grinding efficiency, the workers labor intensity is low, the structure is compact, the area is small, the workshop space effectively is used. This design satisfies the demands of relable, structure simple and so on , the general part are used as far as possible, the production cost is reduced.

Key words: Spring ; Spring grinding machine ; Grinding head

目 录

1前言…………………………………………………………………………………1

2总体方案论证………………………………………………………………………2

2.1进给磨头的确定…………………………………………………………………2

2.2工作台高度的确定………………………………………………………………2

2.3工作台工作方式…………………………………………………………………2

3磨头设计……………………………………………………………………………3

3.1工件材料…………………………………………………………………………3

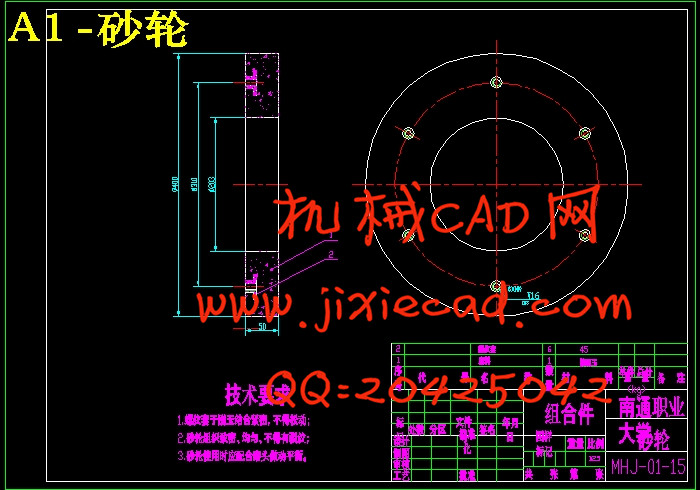

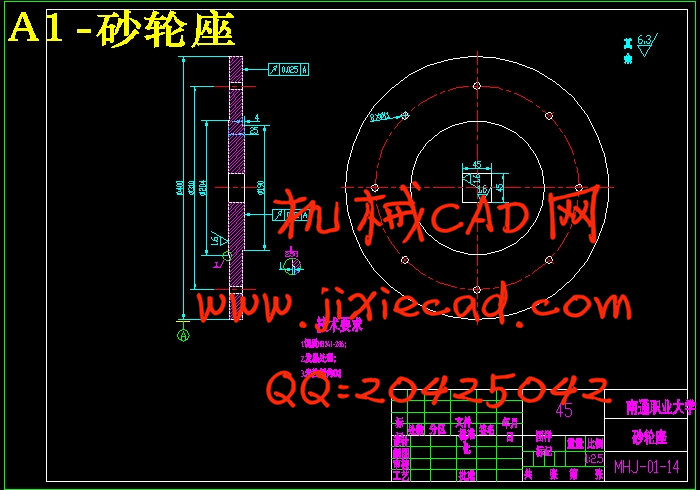

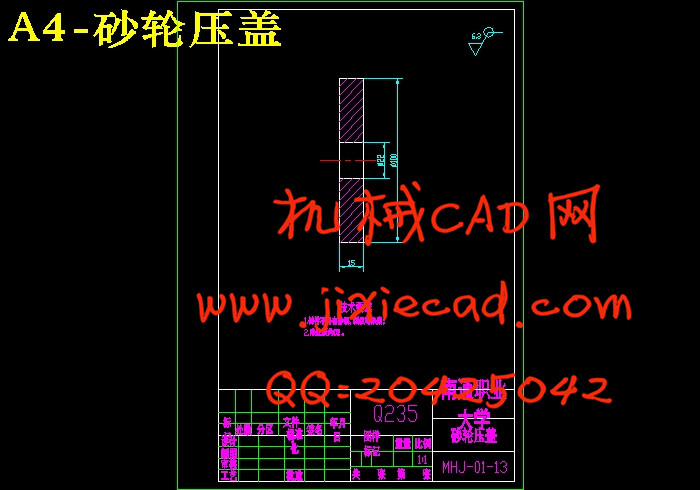

3.2砂轮的选择………………………………………………………………………3

3.2.1磨料的选择……………………………………………………………………3

3.2.2粒度的选择……………………………………………………………………4

3.2.3磨具硬度的选择………………………………………………………………4

3.2.4结合剂的选择…………………………………………………………………5

3.2.5磨具形状及尺寸的选择………………………………………………………5

3.3.1磨削功率计算…………………………………………………………………6

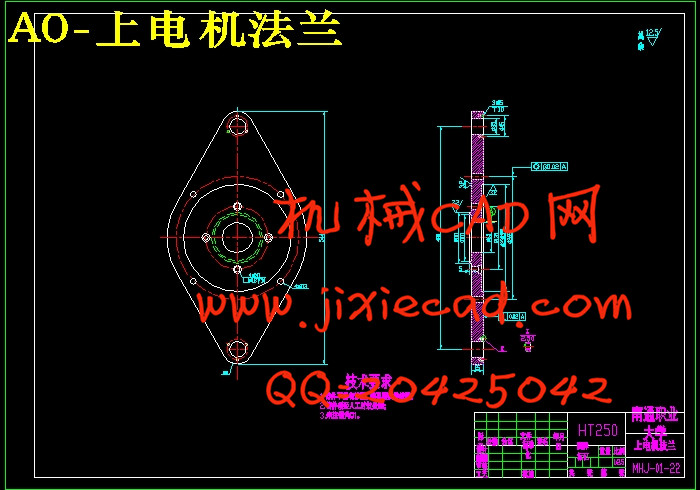

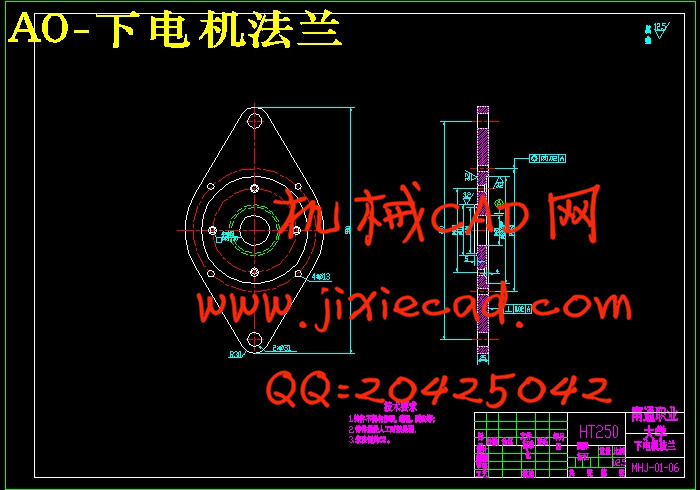

3.3.2选择电机………………………………………………………………………7

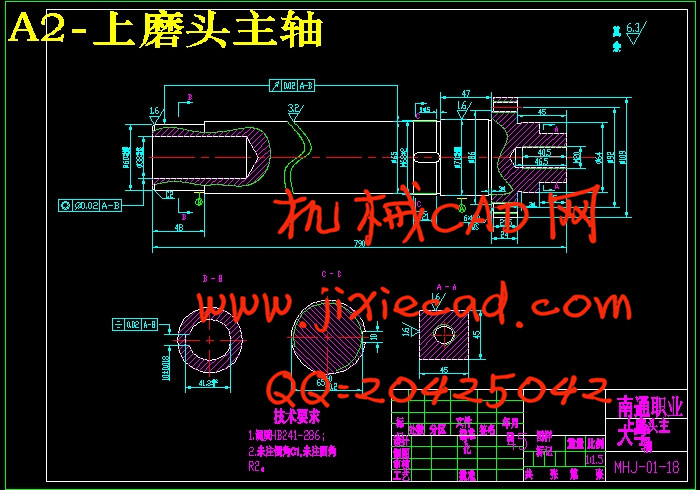

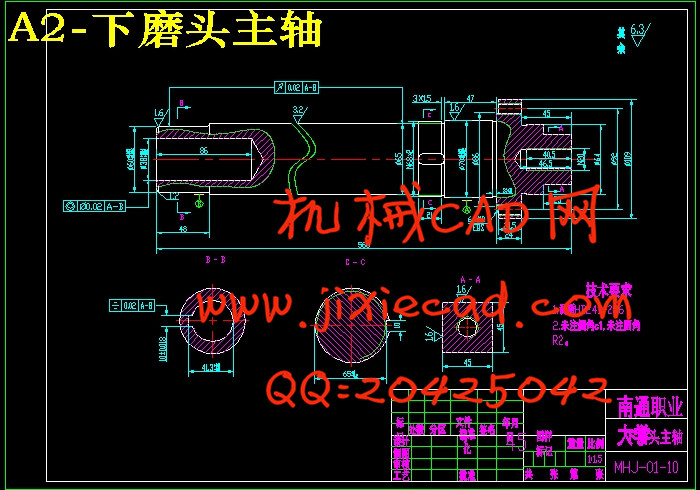

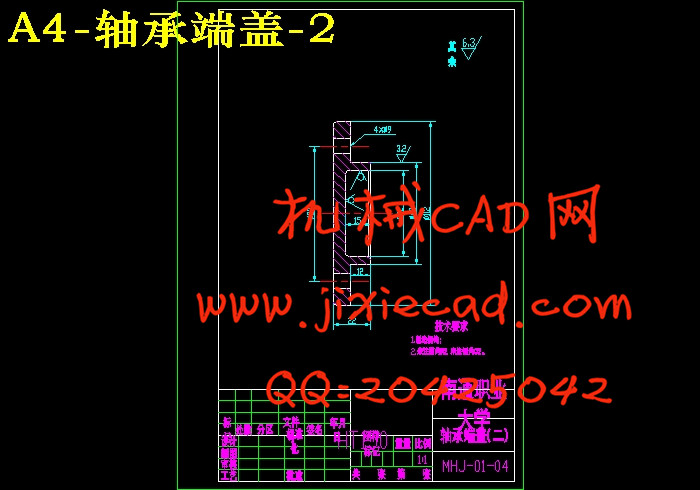

3.4磨头主轴的设计…………………………………………………………………8

3.4.1磨头主轴的结构设计…………………………………………………………8

3.4.2轴的最小直径估算……………………………………………………………9

3.4.3轴的总长度……………………………………………………………………9

3.4.4各轴段直径和长度的确定…………………………………………………10

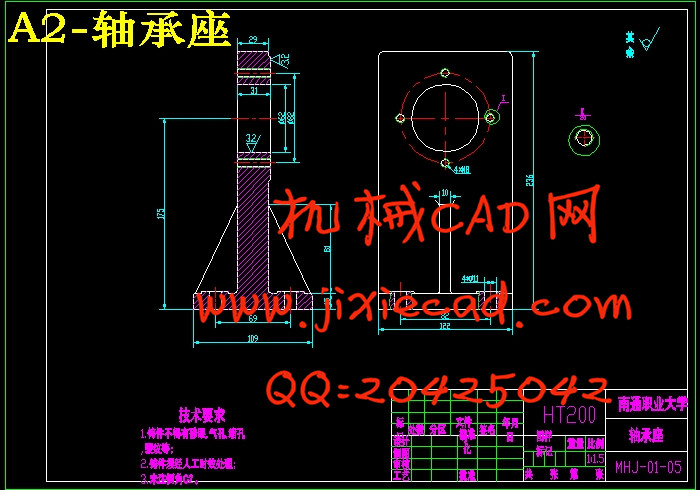

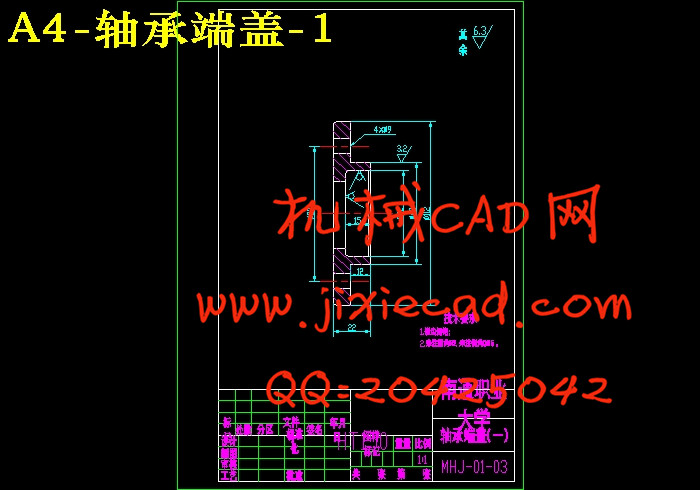

3.4.5轴承的选择…………………………………………………………………11

3.4.6轴承的润滑…………………………………………………………………11

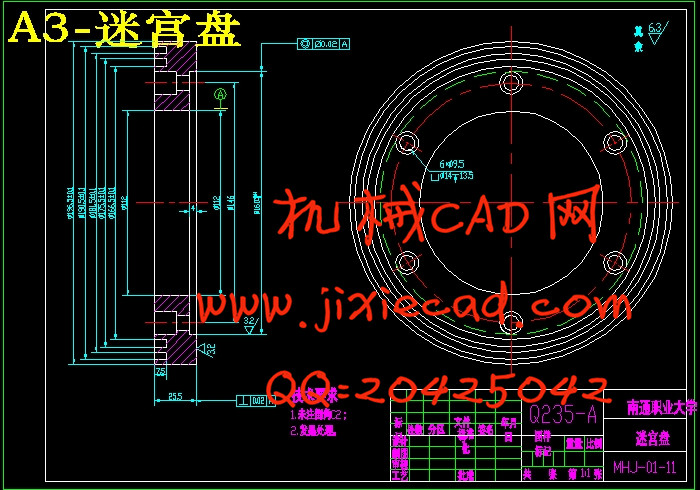

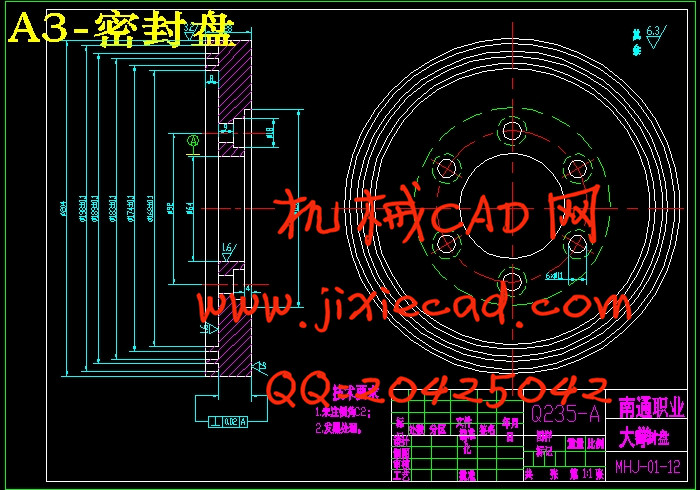

3.4.7滚动轴承的密封……………………………………………………………11

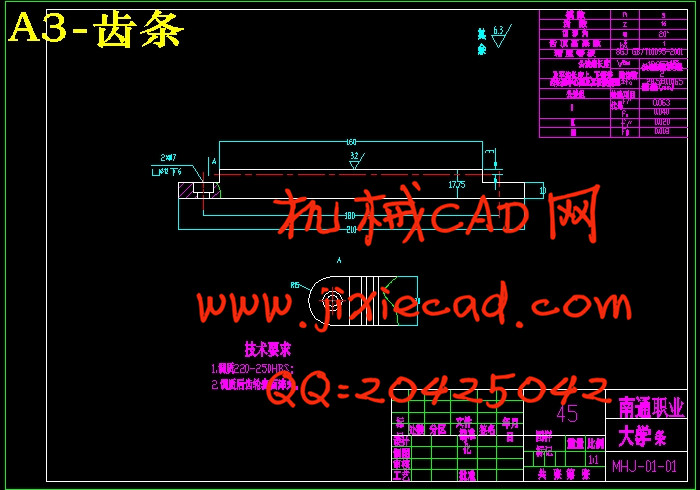

3.5磨头进给系统设计……………………………………………………………12

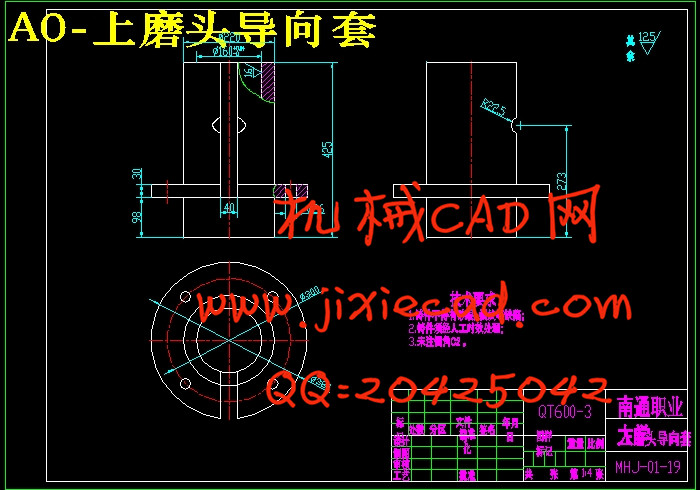

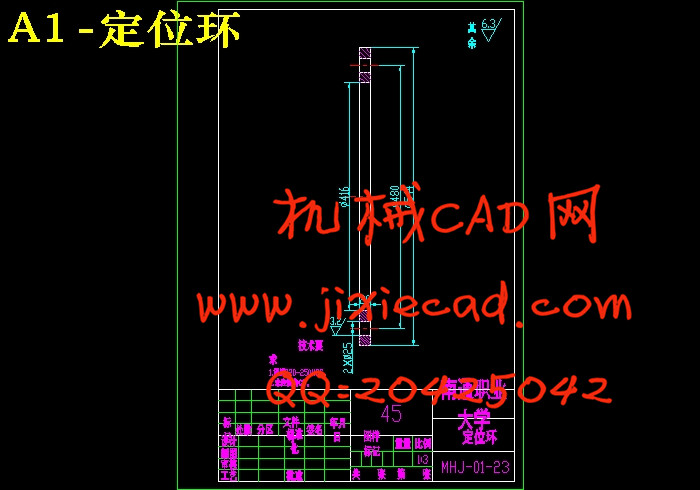

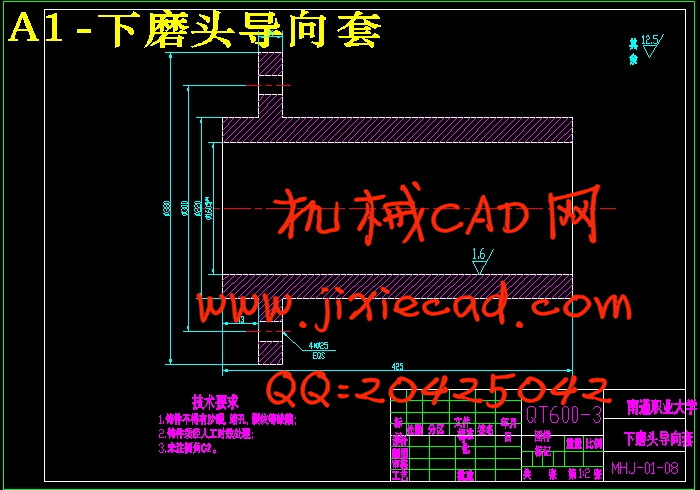

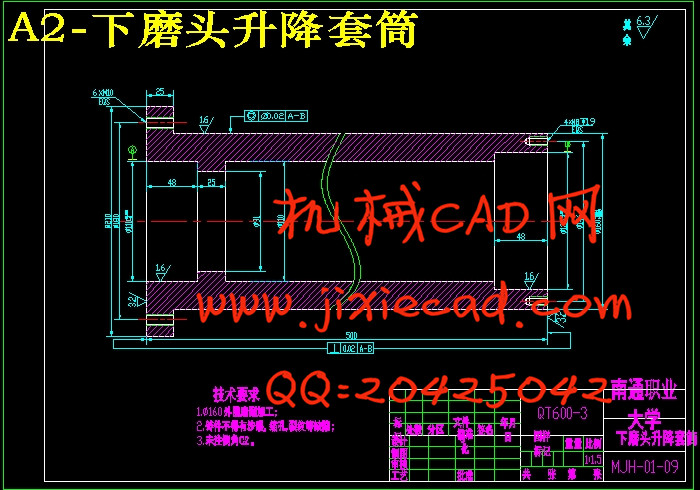

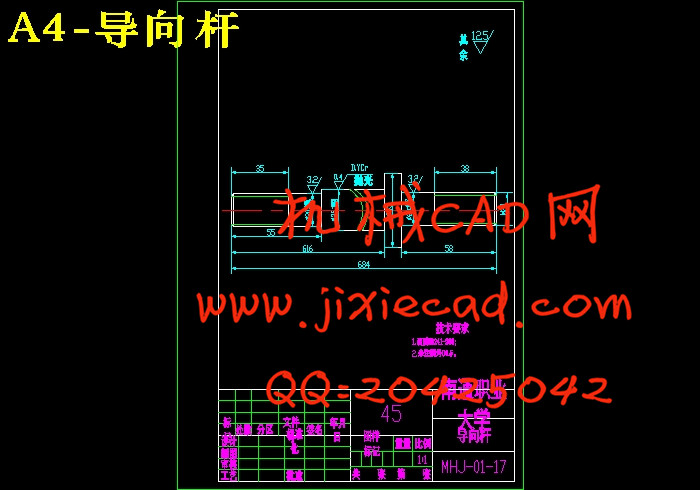

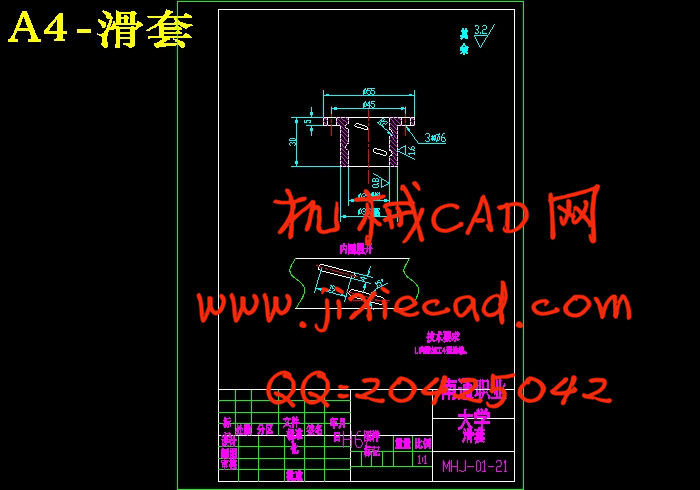

3.5.1套筒和导向套的设计………………………………………………………12

3.5.2上磨头进给系统设计………………………………………………………13

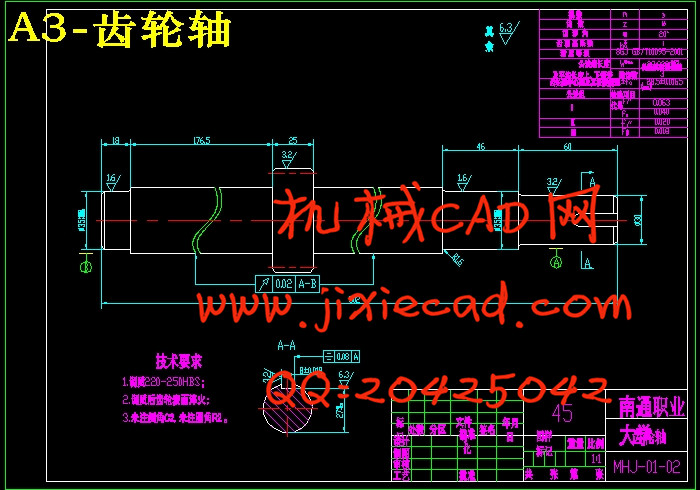

3.5.3齿轮轴的校核………………………………………………………………18

4结论………………………………………………………………………………21

参考文献……………………………………………………………………………22

致谢…………………………………………………………………………………23

本课题主要完成立式磨簧机的设计,为满足弹簧业批量生产弹簧需求而设计。为提高磨削效率,减少装工件的次数和时间,把磨簧机设计成双面磨,即用两个砂轮同时对弹簧的两个端面进行磨削。先根据磨簧机的功能确定磨簧机的总体结构,为砂轮在磨削时实现进给运动和满足不同高度弹簧的磨削要求,砂轮必须实现轴向移动。为简化结构,只要一磨头实现进给,另一个磨头固定。综合各种因素,确定把下磨头固定,不实现进给,上磨头实现进给运动。

在结构上磨头实现自动进给、复位。降低了工人的劳动强度,改善了工人劳动条件。工人可以同时操作多台磨簧机,提高了生产力。在卸料上实现工件的自动卸料。解放工人的双手,进一步提高了工作效率。砂轮经过长时间磨削产生损耗,会引起弹簧加工精度的下降,该磨簧机在结构上实现了砂轮的补偿,磨削精度得到了保障。

设计的该磨簧机自动化程度高、磨削效率高,工人劳动强度低,结构紧凑,占地面积小,有效地利用了厂房空间。本次设计在满足工作可靠,结构简单等要求下,尽量使用了通用部件,降低了制造成本。

关键词:弹簧;磨簧机;磨头

Abstract: To meet the needs of volume mass spring production , this topic mainly completes the vertical spring grinding machine design, In order to enhance the grinding efficiency, and reduce the work piece the number of install times , I designed the spring grinding machine which doubling surface to rub, namely carries on the grinding with two grinding wheels at the same time to the spring two end surfaces. Acts according to first the spring grinding machine function to determine spring grinding machine overall structure, for grinding wheel when grinding realizes the feed motion and satisfies the different spring the grinding request, the grinding wheel must realize the end motion highly. In order to simplify the structure, so long as a grinding realization to feed, another grinding is fixed. Synthesizes each kind of factor, determined is fixed under grinding, does not realize to feed, on grinding realization feed motion.

In structure grinding realization auto-feed, replacement. Reduced worker's labor intensity, improved the worker work condition. The worker may concurrent operation multi-Taiwan rub the reed machine, enhanced the productive forces. Realizes the work piece self-dumping on the ex-denning. Liberates worker's both hands, further enhanced the working efficiency. The grinding wheel passes through the long time grinding to be able to have the batardeau to consume, can cause the spring processing precision drop, should rub the reed machine to realize the grinding wheel compensation in the structure, the processing precision has been high.

The machine has high automaticity high and the grinding efficiency, the workers labor intensity is low, the structure is compact, the area is small, the workshop space effectively is used. This design satisfies the demands of relable, structure simple and so on , the general part are used as far as possible, the production cost is reduced.

Key words: Spring ; Spring grinding machine ; Grinding head

目 录

1前言…………………………………………………………………………………1

2总体方案论证………………………………………………………………………2

2.1进给磨头的确定…………………………………………………………………2

2.2工作台高度的确定………………………………………………………………2

2.3工作台工作方式…………………………………………………………………2

3磨头设计……………………………………………………………………………3

3.1工件材料…………………………………………………………………………3

3.2砂轮的选择………………………………………………………………………3

3.2.1磨料的选择……………………………………………………………………3

3.2.2粒度的选择……………………………………………………………………4

3.2.3磨具硬度的选择………………………………………………………………4

3.2.4结合剂的选择…………………………………………………………………5

3.2.5磨具形状及尺寸的选择………………………………………………………5

3.3.1磨削功率计算…………………………………………………………………6

3.3.2选择电机………………………………………………………………………7

3.4磨头主轴的设计…………………………………………………………………8

3.4.1磨头主轴的结构设计…………………………………………………………8

3.4.2轴的最小直径估算……………………………………………………………9

3.4.3轴的总长度……………………………………………………………………9

3.4.4各轴段直径和长度的确定…………………………………………………10

3.4.5轴承的选择…………………………………………………………………11

3.4.6轴承的润滑…………………………………………………………………11

3.4.7滚动轴承的密封……………………………………………………………11

3.5磨头进给系统设计……………………………………………………………12

3.5.1套筒和导向套的设计………………………………………………………12

3.5.2上磨头进给系统设计………………………………………………………13

3.5.3齿轮轴的校核………………………………………………………………18

4结论………………………………………………………………………………21

参考文献……………………………………………………………………………22

致谢…………………………………………………………………………………23