设计简介

摘 要

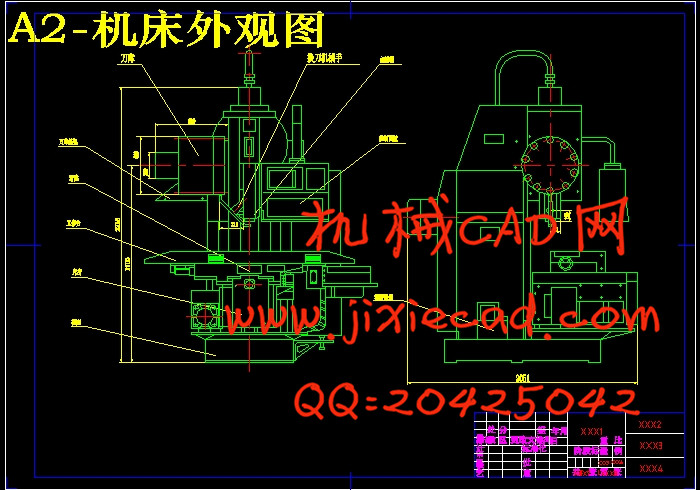

本论文介绍的是XKA5032A/C数控立式升降台铣床自动换刀机构的设计。自动换刀机构一方面可以减轻工人劳动强度,另一方面可以提高加工效率。刀库式的自动换刀机构是由刀库和刀具交换装置(换刀机械手)组成。换刀时,先在刀库中进行选刀,由机械手从刀库和主轴上取出刀具,然后交换位置,把新刀插入主轴,旧刀放回刀库。存放刀具的刀库具有较大的容量,其容量为六把刀具,采用盘形结构,安装在机床的左侧立柱上。数控机床的自动换刀装置中,实现刀库与机床主轴之间传递和装卸刀具的装置称为刀具交换装置。两手互相垂直的回转式单臂双手机械手的优点是换刀动作可靠,换刀时间短,缺点是刀柄精度要求高,结构复杂,联机调整的相关精度要求高,机械手离加工区较近。一般来说,这种机械手与刀库刀座轴线与机床主轴轴线垂直,刀库为径向存取刀具形式的自动换刀机构,因此,在XKA5032A/C数控立式升降铣床的自动换刀机构中可采用这种机械手形式。

关键词:数控铣床;自动换刀装置;刀库;换刀机械手

Abstract

This paper gives the design of the equipment of auto-exchange tool of XKA5032A/C vertical knee and column type milling machine (tool magazine type). Automatic tool change mechanism can reduce the labor intensity of workers, on the other hand, it can improve the machining efficiency. The auto-exchange equipment of tool magazine is composed of the tool magazine and the device of tool exchange. At first, the tool that fetched from the tool magazine should be proper posed into the spindle of the machine, and the tool fetched from the spindle should be put pack to the tool magazine. The tool magazine that has large capacity where has 6 tools and adopt plate structure is mounted in the left column of the machine.

Automatic tool changer of NC machine, realize the device between the knife and machine tool spindle transmission and handling tool called the tool switching device.The advantage of two perpendicular arms of the rotary auto-exchange device is the reliability and prompt of the exchange action. The disadvantage of the equipment of auto-exchange tool is the higher accuracy of the spindle and the compound structure of the tool magazine. The regulation of the machine become complex because of the tool exchange near the zero of the machining. Generally speaking, the axis of the tool magazine is perpendicular with the axis of the machine spindle. The type of the tool exchange is radial. So, the equipment of auto-exchange tool of XKA5032A/C vertical knee and column type milling machine adopt this type of the machine arm.

Keyword: NC milling machine , the equipment of auto-exchange tool, tool magazine, mechanical arm of tool exchange

摘 要 III

Abstract IV

目 录 V

1 绪论 1

1.1 数控机床发展历史及趋势 1

1.2 数控铣床的分类及组成 1

1.2.1 数控立式铣床 1

1.2.2 卧式数控铣床 2

1.2.3 立卧式两用数控铣床 2

1.2.4 数控铣床的组成 3

1.3 数控铣床的选用 3

1.4 数控铣床的主要功能及加工范围 4

1.4.1 数控铣床的主要功能 4

1.4.2数控铣床的加工范围 4

2 数控铣床自动换刀装置总体要求 6

2.1 数控铣床自动换刀装置产生背景及换刀方法 6

2.2 数控铣床自动换刀装置的总体要求 8

2.2.1 自动换刀装置的分类 8

2.2.2 对自动换刀装置的要求 8

3 自动换刀装置总体设计 9

3.1 自动换刀装置设计数据 9

3.2 XK5032数控铣床主要技术参数 9

3.2.1 结构参数 9

3.2.2 主要规格及技术参数 10

3.3 确定数控铣床加工工况 11

3.4 确定自动换刀装置的方式 11

4 自动换刀控制原理 13

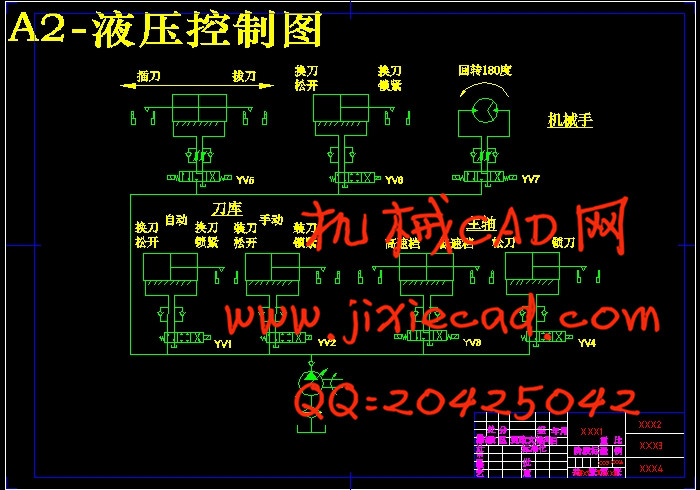

4.1 自动换刀机构液压系统的设计 13

4.1.1 液压的特点 13

4.1.2 自动换刀机构液压系统原理图 13

4.2 自动换刀装置换刀动作的顺序控制过程 14

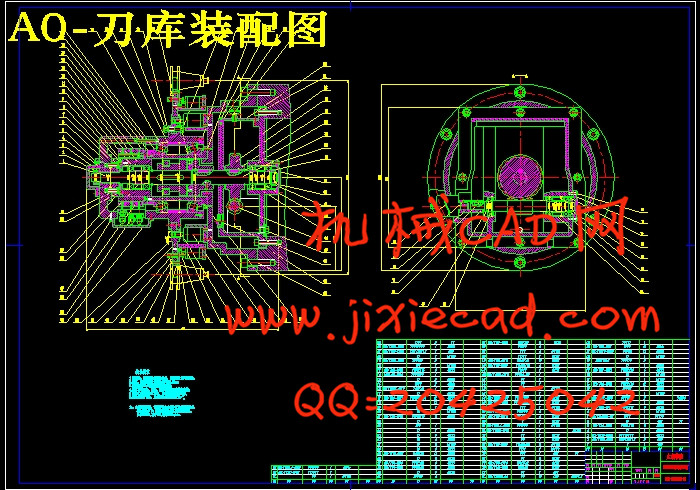

5 刀库结构设计 15

5.1 刀库类型 15

5.2 刀具识别 15

5.3 刀库容量的设计 16

5.4 刀库结构的设计 16

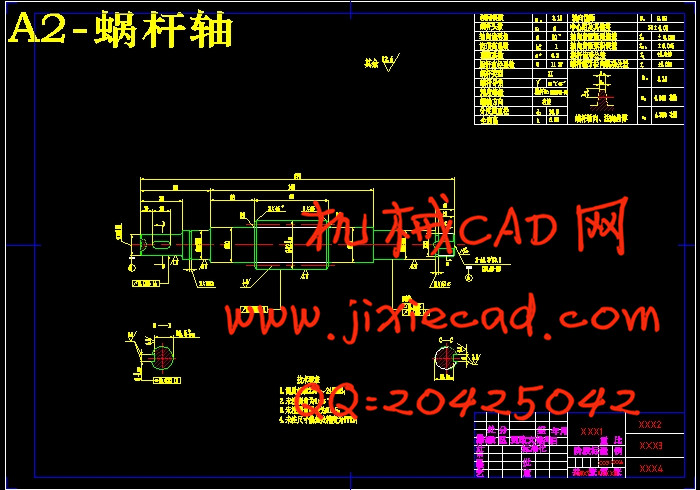

5.4.1 传动装置的选择 17

5.4.2 刀库回转机构的设计 18

5.4.3 确定刀具的选择方式 22

5.4.4 刀库的定位与刀具的松夹 22

6 刀具交换装置的设计 24

6.1 确定换刀机械手结构形式 24

6.2 换刀机械手的工作原理 25

6.3 自动换刀的动作顺序 26

6.4 机械手回转传动机构的设计 26

6.5 自动换刀装置对主轴准停的要求 27

6.6 换刀机械手的安装与调试 27

6.7 自动换刀程序的编制 27

7 结论与展望 29

7.1 结论29

7.2展望29

致谢 30

参考文献 31

附录 32