设计简介

柔性自动化机械系统虽然有许多优点,但投资大、控制难、维护费用高;传统的机械系统虽然具有很高的承载能力,能很好地满足高速大批量生产的要求, 但最大的不足是系统缺乏柔性。而混合驱动机构系统同时采用实时不可控电机 (主电机)和实时可控电机(伺服电机)作为其动力源,两种类型的输入运动通 过一个多自由度闭环机构合成后产生所需要的输出运动,因而大大地改善了传动机械系统的性能,在包装、食品、纺织、锻压等自动机械中,具有广泛的应用前棍合驱动机构中结构最为简单的典型机构是两自由度五杆机构,本文的研究对象是一含有螺旋副的两自由度五杆机构。目前,对混合驱动机构的研究主要为机构可动性与型综合方面,对辅助运动控制性能研究则关注较少。有些针对辅助运动控制的研究,主要还停留在简单的功能实现上,重点是辅助运动控制的可行性研究,对系统的控制输出精度研究则考虑较少,表现为未能很好地采用较先进而且合适的控制系统和控制算法。因此,针对这些问题,本文在辅助运动控制及性能方面开展了比较深入的研究。由于本系统采用全数字交流伺服随动控制系统,要求对电机转角实时调整,并有较快的跟踪速度和较高的跟踪精度,故对控制系统和控制方法都有较高要求。经过仔细地调查比较,最后确定采用最少拍无波纹半闭环控制系统,获得到了较好的效果。,

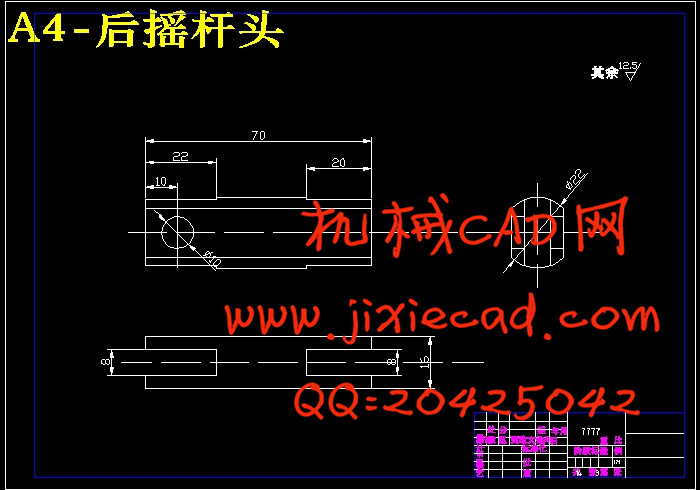

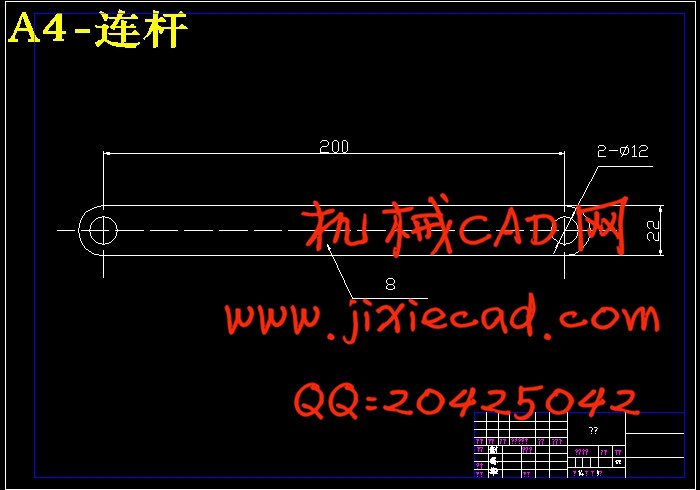

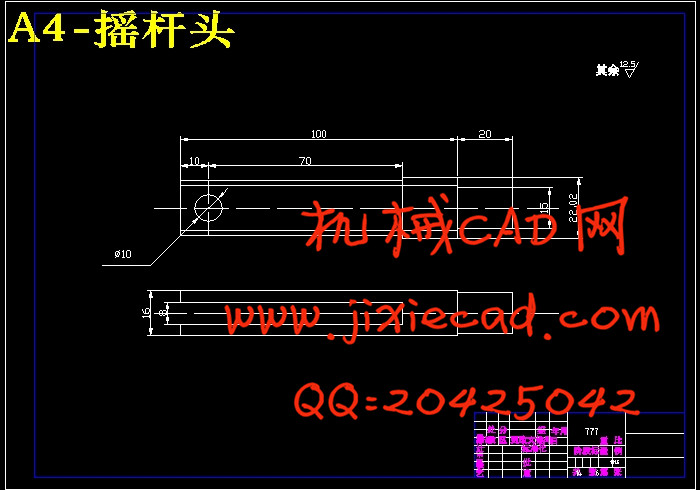

在混合驱动连杆机构研究中,原有构件均采用金属材料制成,因为金属材料强度高、价格低廉,易于制造。但金属材料比重大,快速运动时会产生较大惯性力与惯性力矩,尤其是在混合驱动连杆机构中,大多数构件的质心是作变速运动,产生的动载荷又难以完全平衡和消除,因而所需辅助电机功率就偏大,一般会达到主电机功率的30%以上,对辅助电机控制不利。因此,有必要寻找办法来克服混合驱动连杆机构中金属构杆惯性大的缺陷,降低负载,更好地满足给定曲线输出运动要求。为此,本文分别采用金属、尼龙棒、酚醛棉布模压棒以及三维编织复合材料制作机构中最长的连杆构轻质材料对于优化系统控制性能的影响。结果表明,轻质的尼龙棒和层合复合材料—酚醛棉布模压棒有助于提高系统控制性能;而三维编织复合材料由于固化工艺限制,尺寸和刚性均暂时无法满足工业使用。

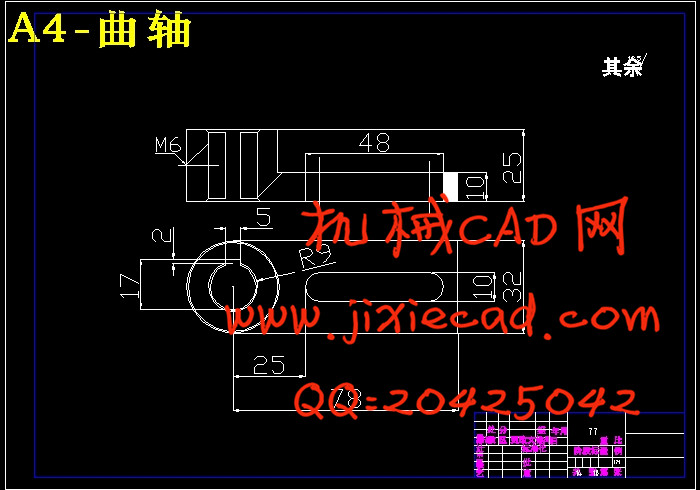

为了提高系统的性能,在研究过程中时刻遵循可靠性设计的理念。在元器件选择时,采用精度高、可靠性好的元件,如机构中的螺旋副,采用精密滚珠丝杠。在电路设计时,采用了抗干扰、提高可靠性的措施,并委托专业厂家将设计的电路制成PCB板。这些都为系统整体的良好表现打下了基础。

文章最后针对改进之前系统得到的实验数据,进行了详尽的统计学分析。通过对实验结果误差数据的采集、系统误差判别以及多元线性回归分析,揭示了误差的影响因素,得到了一些有益的结论。

混合驱动机构的设计包括运动设计、动力设计和控制设计三个方面。一方面,这些设计相互影响和关联,具有非常强的耦合关系。另一方面,各个设计方面的设计准则、设计目标却有所差别。串行设计是先进行机构的运动设计、动力设计,最后再进行控制设计。并行设计是将机构的运动设计、动力设计和控制设计一并考虑进行设计。对于混合驱动平面五杆机构,分别采用串行设计和并行设计等不同的设计策略,尽管设计所采用的优化方法都是微分进化方法,但是设计结果却有所不同。串行设计可以达到较高的机构运动要求,但控制系统的设计比较困难,而且控制效果不好。并行设计得到的设计结果是机构的运动控制效果得以改善,但是设计的数学模型变得复杂,机构的运动精度有所下降。

赵冬华(机械设计制造及其自动化)

导师:朱金龙教授

关键词:混合驱动连杆机构、辅助运动、最少拍无波纹

控制、检验

Abstract

Topic: Research On The Hybrid-drive Linkage Mechanism Although with many advantages, Flexible mechanical system needs heavy investment. Traditional mechanical system fits for scale economy,but it is not flexible. By using uncontrollable motor and controllable motor together, hybrid-drive mechanism combines two types of inputs and gets output needed, which makes it widely used in automationmachines.

The simplest hybrid-drive mechanism is five-bar linkage mechanism,which is used in this dissertation as execution mechanism. Present researches focused mostly on he mechanism mobility. Among those who researched the auxiliary motion controlling, they emphasized not on the control system performance but feasibility. In-depth earch on the control system is carried in this paper. The system discussed is an AC servo system, which needs high following precision. Through surveying and comparing, the least beats and no wave control system is used to control auxiliary motion to get good performance.

Linkages are all made of metal iu1 present researches. Metal linkages are cheap but heavy. It makes controlling more difficult. Approaches must be carried to deal with this problem. In this paper, metal material,nylon plastics, phenolic cotton cloth laminated and 3一composite material is respectively used as one of the 1inl}ages. We compare these four systemsto test the performance of light material in mechanism. We draw theconclusion that}nylon plastic and phenolic cotton cloth laminated tube are helpful to control system. 3-D composite material can't be used in the industry for the limiting of curing tech.

For increasing the performance of whole system, reliability design method is applied throughout the paper.

In the last of the paper, we collect the output error data of traditional hybrid-drive linkage mechanism. Systematic error is proved existing by statistical analysis. Multiple linear regression method is applied to analysis systematic error, which leads to a satisfying model and an approach to improve the output precision. eavy. Therefore, servomotor needs more power to drive

The design of a linkage with hybrid actuators involves three aspects. They are kinematic design, dynamic design and control design. On one hand, each of the aspects affects and relates to others. They are strongly coupled. On the other hand, they are different in design criteria and decision objective as well. In sequential design, the kinematic design is completed firstly, then the dynamic design, and finally the control design. Whereas in concurrent design, the optimizations of the three aspects are considered simulta...

Key words: Hybrid-drive Linkage Mechanism、Auxiliary Motion、

Least Beats with No Wave Control System, Statistical Analysis

目录

第一章绪论.”....................10

1.1混合驱动连杆机构概述...............................................................................................10

1.2连杆机构概述...................................................................................................... ........

1.3课题研究意义..................... ................................................................................. ....... 14

1.4课题研究的内容和实现目标........................................................................................14

第二章混合驱动连杆机构........................................ ...... ..................................................... 20

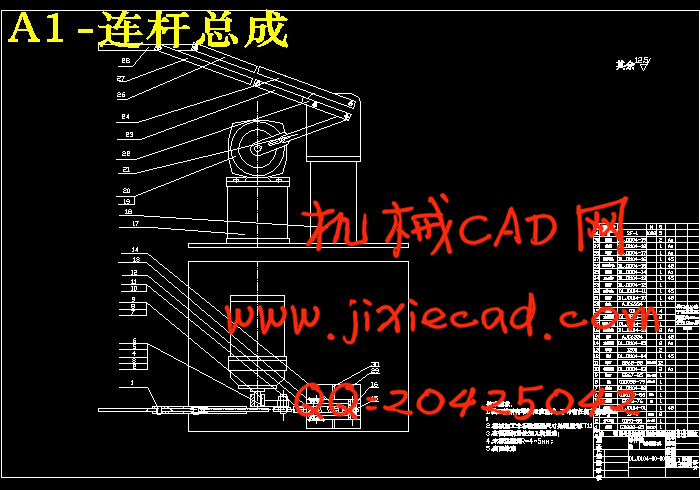

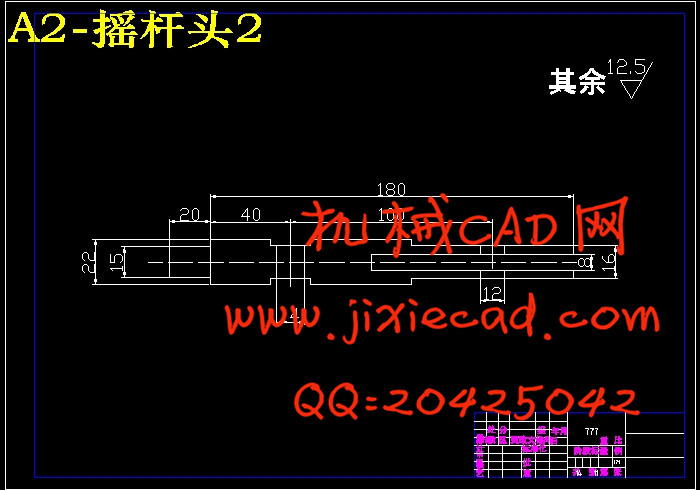

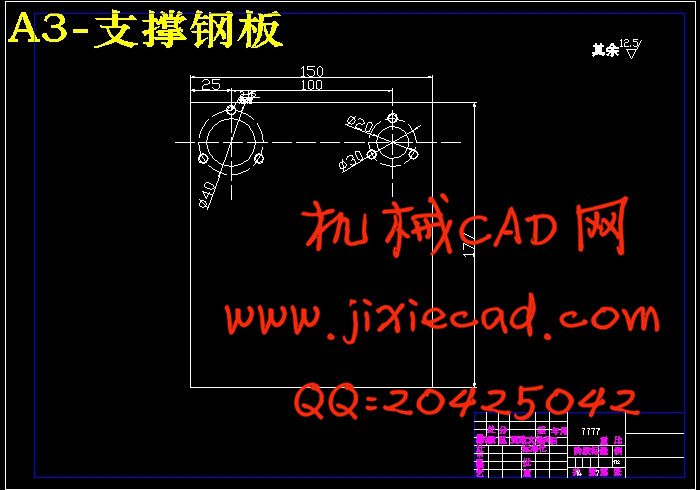

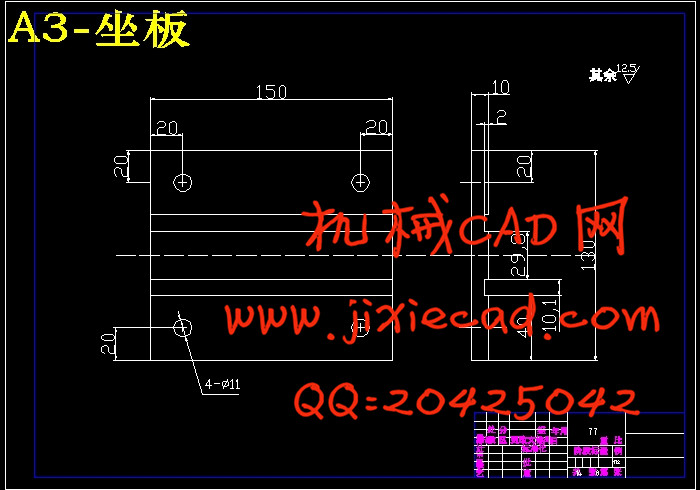

2.1混合驱动连杆机构组成.................................................................................... ..........20

2.2混合驱动连杆机构运动分析............. .............................................................. ..........23

第三章数字交流伺服随动控制系统.......................................................................................... 29

3.1交流伺服系统的发展....................................................... ...................................................29

3.2控制系统类型选择..............................................................................................................31

3.3控制方法选择,....................................................................................................................33

3.4最少拍无波纹半闭环控制系统的设计与仿真比较.................... .............................35

3.5最少拍无波纹半闭环控制的算法实现........................................................ .................39

3.6程序设计中几个重要问题................................................................................................41

第四章硬件系统及抗干扰拾施.............................. ......................................... ........ ................45

4.1硬件系统...................................................... .. ......................................... ........ .................45

4.2抗干扰措施............................................................. ................................... ........ ................49

4.3制作PCB板........................................................... ................................ ........ ................53

第五章全文总结及展望... ................................................ ................................. ........ ..............86

5.1全文总结....................................... .......................... .................................. ........ .............. 86

5,2展望...................................................................... .................... .......................................87

致谢............................................................................................................. ..................................88

附录.................................................................................................................. .............................90

在混合驱动连杆机构研究中,原有构件均采用金属材料制成,因为金属材料强度高、价格低廉,易于制造。但金属材料比重大,快速运动时会产生较大惯性力与惯性力矩,尤其是在混合驱动连杆机构中,大多数构件的质心是作变速运动,产生的动载荷又难以完全平衡和消除,因而所需辅助电机功率就偏大,一般会达到主电机功率的30%以上,对辅助电机控制不利。因此,有必要寻找办法来克服混合驱动连杆机构中金属构杆惯性大的缺陷,降低负载,更好地满足给定曲线输出运动要求。为此,本文分别采用金属、尼龙棒、酚醛棉布模压棒以及三维编织复合材料制作机构中最长的连杆构轻质材料对于优化系统控制性能的影响。结果表明,轻质的尼龙棒和层合复合材料—酚醛棉布模压棒有助于提高系统控制性能;而三维编织复合材料由于固化工艺限制,尺寸和刚性均暂时无法满足工业使用。

为了提高系统的性能,在研究过程中时刻遵循可靠性设计的理念。在元器件选择时,采用精度高、可靠性好的元件,如机构中的螺旋副,采用精密滚珠丝杠。在电路设计时,采用了抗干扰、提高可靠性的措施,并委托专业厂家将设计的电路制成PCB板。这些都为系统整体的良好表现打下了基础。

文章最后针对改进之前系统得到的实验数据,进行了详尽的统计学分析。通过对实验结果误差数据的采集、系统误差判别以及多元线性回归分析,揭示了误差的影响因素,得到了一些有益的结论。

混合驱动机构的设计包括运动设计、动力设计和控制设计三个方面。一方面,这些设计相互影响和关联,具有非常强的耦合关系。另一方面,各个设计方面的设计准则、设计目标却有所差别。串行设计是先进行机构的运动设计、动力设计,最后再进行控制设计。并行设计是将机构的运动设计、动力设计和控制设计一并考虑进行设计。对于混合驱动平面五杆机构,分别采用串行设计和并行设计等不同的设计策略,尽管设计所采用的优化方法都是微分进化方法,但是设计结果却有所不同。串行设计可以达到较高的机构运动要求,但控制系统的设计比较困难,而且控制效果不好。并行设计得到的设计结果是机构的运动控制效果得以改善,但是设计的数学模型变得复杂,机构的运动精度有所下降。

赵冬华(机械设计制造及其自动化)

导师:朱金龙教授

关键词:混合驱动连杆机构、辅助运动、最少拍无波纹

控制、检验

Abstract

Topic: Research On The Hybrid-drive Linkage Mechanism Although with many advantages, Flexible mechanical system needs heavy investment. Traditional mechanical system fits for scale economy,but it is not flexible. By using uncontrollable motor and controllable motor together, hybrid-drive mechanism combines two types of inputs and gets output needed, which makes it widely used in automationmachines.

The simplest hybrid-drive mechanism is five-bar linkage mechanism,which is used in this dissertation as execution mechanism. Present researches focused mostly on he mechanism mobility. Among those who researched the auxiliary motion controlling, they emphasized not on the control system performance but feasibility. In-depth earch on the control system is carried in this paper. The system discussed is an AC servo system, which needs high following precision. Through surveying and comparing, the least beats and no wave control system is used to control auxiliary motion to get good performance.

Linkages are all made of metal iu1 present researches. Metal linkages are cheap but heavy. It makes controlling more difficult. Approaches must be carried to deal with this problem. In this paper, metal material,nylon plastics, phenolic cotton cloth laminated and 3一composite material is respectively used as one of the 1inl}ages. We compare these four systemsto test the performance of light material in mechanism. We draw theconclusion that}nylon plastic and phenolic cotton cloth laminated tube are helpful to control system. 3-D composite material can't be used in the industry for the limiting of curing tech.

For increasing the performance of whole system, reliability design method is applied throughout the paper.

In the last of the paper, we collect the output error data of traditional hybrid-drive linkage mechanism. Systematic error is proved existing by statistical analysis. Multiple linear regression method is applied to analysis systematic error, which leads to a satisfying model and an approach to improve the output precision. eavy. Therefore, servomotor needs more power to drive

The design of a linkage with hybrid actuators involves three aspects. They are kinematic design, dynamic design and control design. On one hand, each of the aspects affects and relates to others. They are strongly coupled. On the other hand, they are different in design criteria and decision objective as well. In sequential design, the kinematic design is completed firstly, then the dynamic design, and finally the control design. Whereas in concurrent design, the optimizations of the three aspects are considered simulta...

Key words: Hybrid-drive Linkage Mechanism、Auxiliary Motion、

Least Beats with No Wave Control System, Statistical Analysis

目录

第一章绪论.”....................10

1.1混合驱动连杆机构概述...............................................................................................10

1.2连杆机构概述...................................................................................................... ........

1.3课题研究意义..................... ................................................................................. ....... 14

1.4课题研究的内容和实现目标........................................................................................14

第二章混合驱动连杆机构........................................ ...... ..................................................... 20

2.1混合驱动连杆机构组成.................................................................................... ..........20

2.2混合驱动连杆机构运动分析............. .............................................................. ..........23

第三章数字交流伺服随动控制系统.......................................................................................... 29

3.1交流伺服系统的发展....................................................... ...................................................29

3.2控制系统类型选择..............................................................................................................31

3.3控制方法选择,....................................................................................................................33

3.4最少拍无波纹半闭环控制系统的设计与仿真比较.................... .............................35

3.5最少拍无波纹半闭环控制的算法实现........................................................ .................39

3.6程序设计中几个重要问题................................................................................................41

第四章硬件系统及抗干扰拾施.............................. ......................................... ........ ................45

4.1硬件系统...................................................... .. ......................................... ........ .................45

4.2抗干扰措施............................................................. ................................... ........ ................49

4.3制作PCB板........................................................... ................................ ........ ................53

第五章全文总结及展望... ................................................ ................................. ........ ..............86

5.1全文总结....................................... .......................... .................................. ........ .............. 86

5,2展望...................................................................... .................... .......................................87

致谢............................................................................................................. ..................................88

附录.................................................................................................................. .............................90