设计简介

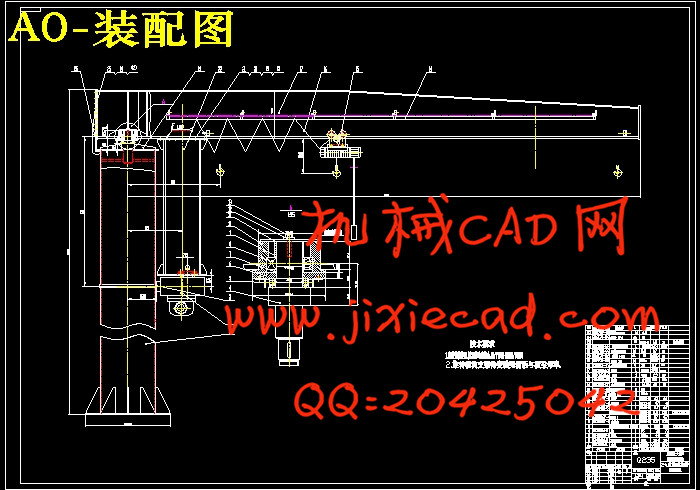

2T 立柱式旋臂起重机的设计

摘要:

起重机是工程实际中广泛应用的特种设备。而旋臂起重机是近年发展起来的中小型起重装备,安全可靠,具备高效、节能、省时省力、灵活和结构独特等特点.根据旋臂起重机的整体结构特点和规范规定,了解起重机的发展现状、分析起重机的工作原理、系统组成、所要求实现的功能和相应的结构上必不可少的。该设计主要针对起升机构选择相应的零部件及技术参数,使其既能很好的实现起重机的运行还不互相干涉且配合良好,也对回转机构做了详细的分析介绍。传统设计的定柱式旋臂起重机,存在着结构笨重和刚度不足的缺陷,随着市场竞争激烈,对产品提出了更高的要求,采用现代设计对传统设计和计算方法技术提升,已迫在眉睫。

关键词:起重机;起升机构;回转机构

The Design Of 2-Ton Column Jib Crane

Abstract:

Crane is widely applied in engineering, Slewing crane is small and medium lifting equipment which developed in recent years,the characteristics of which are safe and reliable、 with high efficiency、 energy saving、time-saving、flexible 、unique structure,etc.According to the feature of completed structure for slewing jib crane and the rule of design.Understand the development of the crane’status、analyze its operation principle、system configuration、the function and relative structure that the crane required is indispensable.thus this paper put its emphasis on the design of main hoisting mechanism,choosing the appropriate spare parts and technical parameters for it in order to be good for crane operation and non-interference.the slewing mechanism analysis is introduced in detail too.the structure of crane designed with tradition method is overdesigned in strength and not enough in stiffness,and with fierce competition in the market a higher requirement for product has been brought forward.So using modern design technology to upgrade traditional design and calculation method is extremely urgent.

Keywords:crane;hoisting mechanism;Slewing mechanism

目 录

摘要……………………………………………………………………………………1

关键字…………………………………………………………………………………1

前言………………………………………………………………………………… 2

1 起重机设计总则………………………………………………………………… 3

1.1 我国起重机机械行业……………………………………………………3

1.2 国际起重机机械行业…………………………………………………… 3

1.3 起重机的作用和作业特点……………………………………………… 4

1.4起重机的组成………………………………………………………………4

1.5起重机的类型………………………………………………………………4

1.6旋臂起重机介绍……………………………………………………………5

2 起升机构的设计………………………………………………………………6

2.1 确定起升机构的方案 ……………………………………………………6

2.2 电动葫芦的选择 ……………………………………………………6

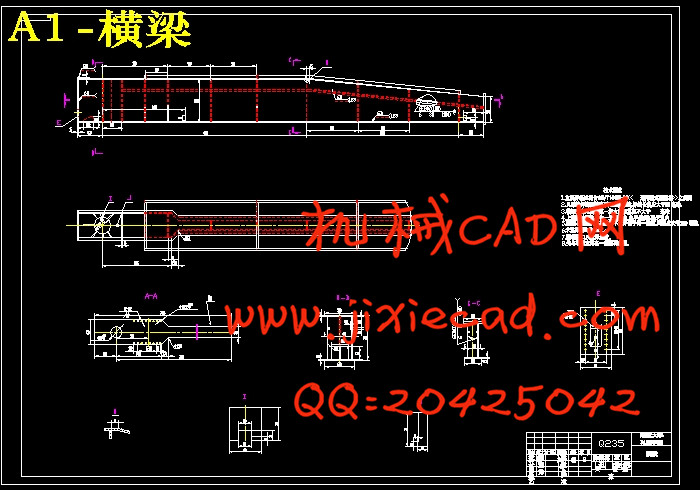

2.3 钢丝绳的选择与使用…………………………………………………… 7

2.4 确定滑轮参数…………………………………………………………… 8

2.5 确定卷筒尺寸并验算其强度…………………………………………… 9

2.6 电动机的选择……………………………………………………………11

2.7 验算起升速度和实际所需功率…………………………………………12

2.8 卷筒心轴的设计及强度计算……………………………………………13

2.9 取物装置计算……………………………………………………………15

2.10 钢丝绳在卷筒是的固定及计算…………………………………………16

2.11 验算启动及制动时间……………………………………………………17

3 运行机构的设计………………………………………………………19

3.1 运行阻力……………………………………………………19

3.2 验算电动机发热条件………………………………………………19

3.3 验算启动时间……………………………………………………20

3.6 选择制动器 ……………………………………………………20

3.8 验算制动时间……………………………………………………20

3.9 选择减速器……………………………………………………20

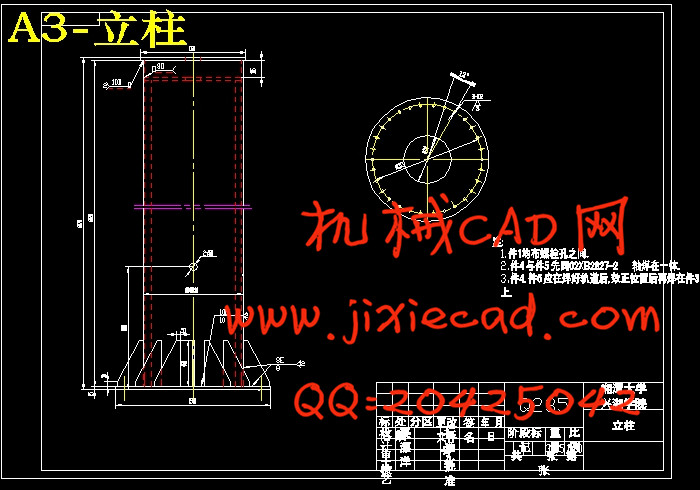

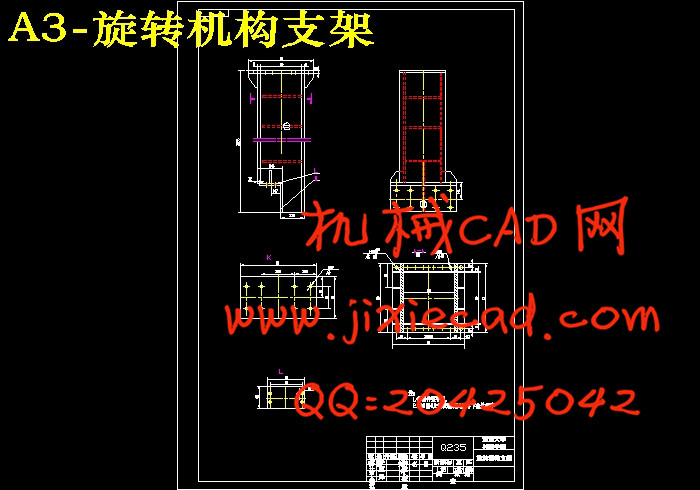

4 回转机构的设计………………………………………………………21

4.1 回转机构的组成及常用形式 …………………………………………21

4.2 载荷计算 ……………………………………………………23

4.3 回转驱动装置计算 ………………………………………………25

4.4 电动机的选择与校验…………………………………………………27

4.5 确定机构速比选择联轴器…………………………………………… 28

4.6 制动器的选择………………………………………………………… 28

4.7 减速器的选择………………………………………………………… 29

4.8 螺栓组连接的设计…………………………………………………… 29

4.9 强度的校核…………………………………………………………… 31

总结与发展………………………………………………………………………… 33

参考文献…………………………………………………………………………… 34

致谢………………………………………………………………………………… 35

摘要:

起重机是工程实际中广泛应用的特种设备。而旋臂起重机是近年发展起来的中小型起重装备,安全可靠,具备高效、节能、省时省力、灵活和结构独特等特点.根据旋臂起重机的整体结构特点和规范规定,了解起重机的发展现状、分析起重机的工作原理、系统组成、所要求实现的功能和相应的结构上必不可少的。该设计主要针对起升机构选择相应的零部件及技术参数,使其既能很好的实现起重机的运行还不互相干涉且配合良好,也对回转机构做了详细的分析介绍。传统设计的定柱式旋臂起重机,存在着结构笨重和刚度不足的缺陷,随着市场竞争激烈,对产品提出了更高的要求,采用现代设计对传统设计和计算方法技术提升,已迫在眉睫。

关键词:起重机;起升机构;回转机构

The Design Of 2-Ton Column Jib Crane

Abstract:

Crane is widely applied in engineering, Slewing crane is small and medium lifting equipment which developed in recent years,the characteristics of which are safe and reliable、 with high efficiency、 energy saving、time-saving、flexible 、unique structure,etc.According to the feature of completed structure for slewing jib crane and the rule of design.Understand the development of the crane’status、analyze its operation principle、system configuration、the function and relative structure that the crane required is indispensable.thus this paper put its emphasis on the design of main hoisting mechanism,choosing the appropriate spare parts and technical parameters for it in order to be good for crane operation and non-interference.the slewing mechanism analysis is introduced in detail too.the structure of crane designed with tradition method is overdesigned in strength and not enough in stiffness,and with fierce competition in the market a higher requirement for product has been brought forward.So using modern design technology to upgrade traditional design and calculation method is extremely urgent.

Keywords:crane;hoisting mechanism;Slewing mechanism

目 录

摘要……………………………………………………………………………………1

关键字…………………………………………………………………………………1

前言………………………………………………………………………………… 2

1 起重机设计总则………………………………………………………………… 3

1.1 我国起重机机械行业……………………………………………………3

1.2 国际起重机机械行业…………………………………………………… 3

1.3 起重机的作用和作业特点……………………………………………… 4

1.4起重机的组成………………………………………………………………4

1.5起重机的类型………………………………………………………………4

1.6旋臂起重机介绍……………………………………………………………5

2 起升机构的设计………………………………………………………………6

2.1 确定起升机构的方案 ……………………………………………………6

2.2 电动葫芦的选择 ……………………………………………………6

2.3 钢丝绳的选择与使用…………………………………………………… 7

2.4 确定滑轮参数…………………………………………………………… 8

2.5 确定卷筒尺寸并验算其强度…………………………………………… 9

2.6 电动机的选择……………………………………………………………11

2.7 验算起升速度和实际所需功率…………………………………………12

2.8 卷筒心轴的设计及强度计算……………………………………………13

2.9 取物装置计算……………………………………………………………15

2.10 钢丝绳在卷筒是的固定及计算…………………………………………16

2.11 验算启动及制动时间……………………………………………………17

3 运行机构的设计………………………………………………………19

3.1 运行阻力……………………………………………………19

3.2 验算电动机发热条件………………………………………………19

3.3 验算启动时间……………………………………………………20

3.6 选择制动器 ……………………………………………………20

3.8 验算制动时间……………………………………………………20

3.9 选择减速器……………………………………………………20

4 回转机构的设计………………………………………………………21

4.1 回转机构的组成及常用形式 …………………………………………21

4.2 载荷计算 ……………………………………………………23

4.3 回转驱动装置计算 ………………………………………………25

4.4 电动机的选择与校验…………………………………………………27

4.5 确定机构速比选择联轴器…………………………………………… 28

4.6 制动器的选择………………………………………………………… 28

4.7 减速器的选择………………………………………………………… 29

4.8 螺栓组连接的设计…………………………………………………… 29

4.9 强度的校核…………………………………………………………… 31

总结与发展………………………………………………………………………… 33

参考文献…………………………………………………………………………… 34

致谢………………………………………………………………………………… 35