设计简介

立卧式44轴组合钻床上主轴箱设计

摘 要

组合机床及其自动线是集机电于一体的综合自动化程度较高的制造技术和成套工艺装备。它的特征是高效、高质、经济实用,因而被广泛应用于工程机械、交通、能源、军工、轻工、家电等行业。组合机床使用系列化、标准化的通用部件和少量的专用部件组成的多轴、多刀、多工序、多面或多工位同时加工的高效专用机床,其生产率比通用机床高几倍至几十倍,可进行钻、镗、铰、攻丝、车削、铣削等切削加工。组合机床的通用部件和标准件约占70%-80%,这些部件是系列化的,可以进行成批生产,其余20%-30%的专用部件是由被加工零件的形状,轮廓尺寸,工艺和工序来决定。

在批量生产中为了提高生产率,必须要缩短加工时间和辅助时间,而且尽可能使辅助时间和加工时间重合,使每个装夹多外工件同时进行多刀加工,实行工序高度集中,因而广泛采用组合机床及自动线。

关键词:组合机床,主轴箱,切削

CNC Laser Engraving Machine Design

Abstract

Machines and mechanical and electrical auto line is an intergrated set of higher degree of automation of manufacturing technology and complete sets of technical equipment. It is characterized by high efficiency, high-quality, economical and practical, they have been widely used in construction machinery, transportation, energy, military industry, light industry, household appliances and other industries. Combination machine tool series, standardized and specialized parts and components with a small amount of multi-axis, multi-tool, multi-process, multi-faceted or multi-station machine tool while processing the university, its productivity is several times higher than the universal machine to a few times, can be drilled, boring, hinge, tapping, turning, milling and other machining. Universal combined machine parts and standard parts account for about 70%-80%, these parts are serialized, can be batch production. The remaining 20%-30% the specific components to be processed by the part shape, outline dimensions, process and procedure to decide.

In mass production in order to increase productivity, we must shorten the processing time and support time, and assisted as much as possible coincidence of time, so that each clamping workpieces at the same time more and more outside cutter process, the implementation process highly concentrated, and therefore widely used Combination machine tool and automatic line,

Key words: Machine tool, Spindle boxes, Cutting

目 录

1 绪 论 1

2 组合机床概述 2

2.1组合机床的组成 2

2.2 通用部件的分类 3

2.3通用部件的选用 4

3 加工工艺分析 5

4 多轴箱的基本结构及表达方法 7

4.1多轴箱的组成 7

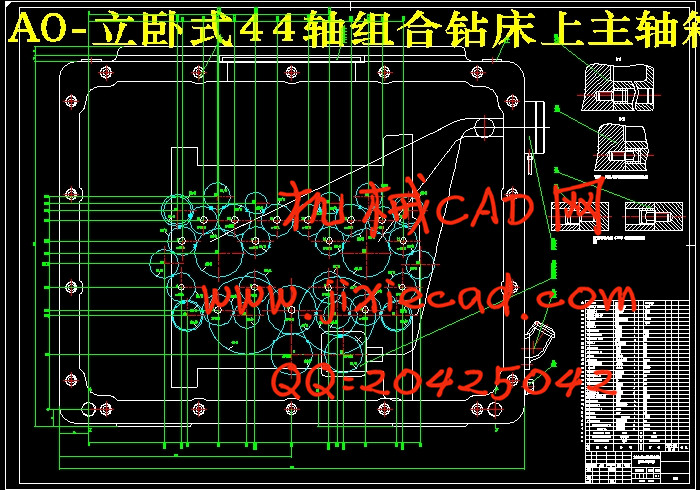

4.2多轴箱总图绘制方法特点 7

5 多轴箱的设计 9

5.1绘制多轴箱设计原始依据图 9

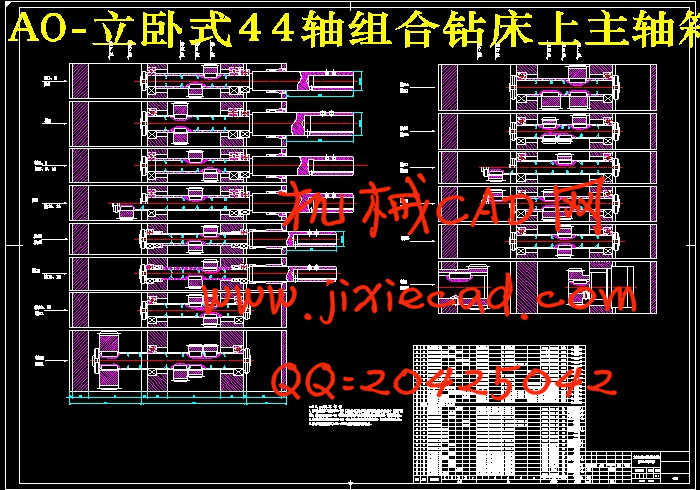

5.2主轴、齿轮的确定及动力计算 11

5.2.1 主轴型式和直径、齿轮模数的确定 11

5.2.2 多轴箱所需动力的计算 12

5.3 多轴箱传动设计 14

5.3.1 拟定传动路线 14

5.3.2 确定驱动轴、主轴坐标尺寸 15

5.3.3 确定传动轴位置及齿轮齿数 15

5.4 绘制多轴箱总图及零件图 17

5.4.1 多轴箱零件设计 17

5.4.2 多轴箱总图设计 17

结 论 20

致 谢 21

参考文献 22

摘 要

组合机床及其自动线是集机电于一体的综合自动化程度较高的制造技术和成套工艺装备。它的特征是高效、高质、经济实用,因而被广泛应用于工程机械、交通、能源、军工、轻工、家电等行业。组合机床使用系列化、标准化的通用部件和少量的专用部件组成的多轴、多刀、多工序、多面或多工位同时加工的高效专用机床,其生产率比通用机床高几倍至几十倍,可进行钻、镗、铰、攻丝、车削、铣削等切削加工。组合机床的通用部件和标准件约占70%-80%,这些部件是系列化的,可以进行成批生产,其余20%-30%的专用部件是由被加工零件的形状,轮廓尺寸,工艺和工序来决定。

在批量生产中为了提高生产率,必须要缩短加工时间和辅助时间,而且尽可能使辅助时间和加工时间重合,使每个装夹多外工件同时进行多刀加工,实行工序高度集中,因而广泛采用组合机床及自动线。

关键词:组合机床,主轴箱,切削

CNC Laser Engraving Machine Design

Abstract

Machines and mechanical and electrical auto line is an intergrated set of higher degree of automation of manufacturing technology and complete sets of technical equipment. It is characterized by high efficiency, high-quality, economical and practical, they have been widely used in construction machinery, transportation, energy, military industry, light industry, household appliances and other industries. Combination machine tool series, standardized and specialized parts and components with a small amount of multi-axis, multi-tool, multi-process, multi-faceted or multi-station machine tool while processing the university, its productivity is several times higher than the universal machine to a few times, can be drilled, boring, hinge, tapping, turning, milling and other machining. Universal combined machine parts and standard parts account for about 70%-80%, these parts are serialized, can be batch production. The remaining 20%-30% the specific components to be processed by the part shape, outline dimensions, process and procedure to decide.

In mass production in order to increase productivity, we must shorten the processing time and support time, and assisted as much as possible coincidence of time, so that each clamping workpieces at the same time more and more outside cutter process, the implementation process highly concentrated, and therefore widely used Combination machine tool and automatic line,

Key words: Machine tool, Spindle boxes, Cutting

目 录

1 绪 论 1

2 组合机床概述 2

2.1组合机床的组成 2

2.2 通用部件的分类 3

2.3通用部件的选用 4

3 加工工艺分析 5

4 多轴箱的基本结构及表达方法 7

4.1多轴箱的组成 7

4.2多轴箱总图绘制方法特点 7

5 多轴箱的设计 9

5.1绘制多轴箱设计原始依据图 9

5.2主轴、齿轮的确定及动力计算 11

5.2.1 主轴型式和直径、齿轮模数的确定 11

5.2.2 多轴箱所需动力的计算 12

5.3 多轴箱传动设计 14

5.3.1 拟定传动路线 14

5.3.2 确定驱动轴、主轴坐标尺寸 15

5.3.3 确定传动轴位置及齿轮齿数 15

5.4 绘制多轴箱总图及零件图 17

5.4.1 多轴箱零件设计 17

5.4.2 多轴箱总图设计 17

结 论 20

致 谢 21

参考文献 22