设计简介

摘 要

文章介绍了两轴实验型数控系统的设计。通过对各种实验型设备的调研,了解到现阶段我国用于实验型设备的数控系统设备的台套种类、数量与学生规模反差较大的现况,设备落后,加之由于各种客观和主观的原因,全国大专院校机电类学生工程实践能力普遍较差,其动手能力与理论更是难结合在一起,严重影响到实训、培训效果。

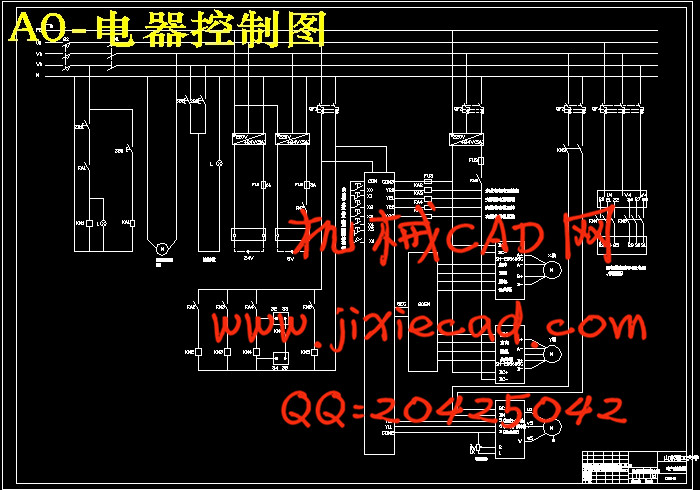

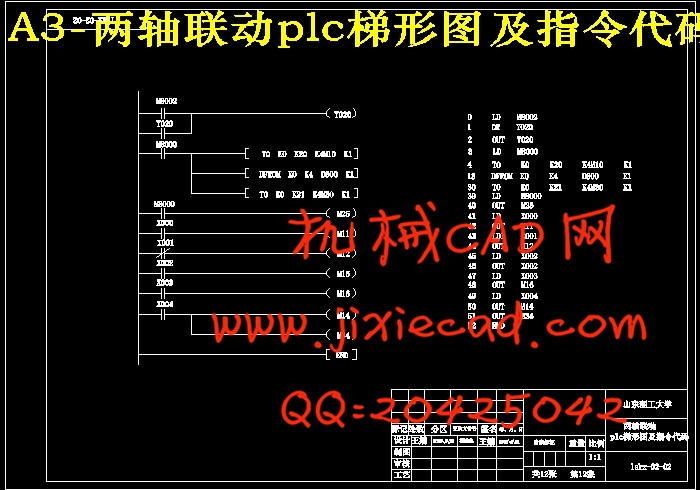

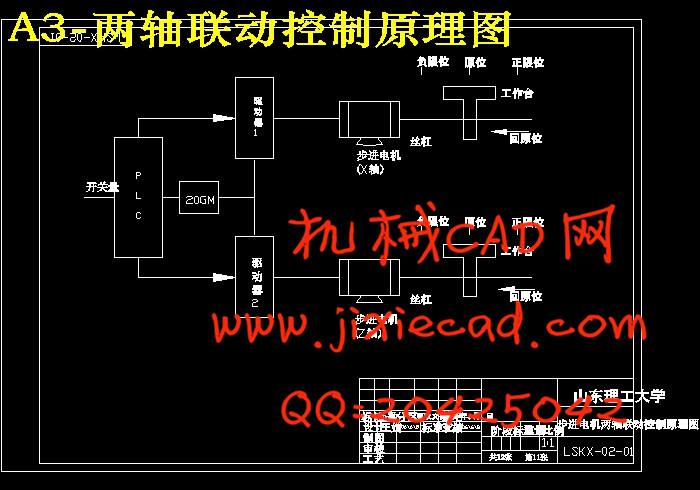

主要成果是:⑴本设计对已有的设备进行分析,结合实际教学要求,进行各零部件的设计计算,并最终进行校核。该设备可主要应用于高校及职业技术学校中相关专业的数控教学,它具有体积小、价格低、功能完善、安全系数高、性能优越等系列优点;⑵在设计过程中,同时进行了电器方面的改进,主要应用PLC进行控制,引入了数控部分,采用步进电动机,齿轮变速机构,安装了变频器、步进驱动器等设备。通过弱电控制强电,计算机数字化控制电路,并成功地实现了工作要求,使其具有能控制各进给方向电动机启停、正反转、变频调速、两轴联动等功能。在机械部分设计过程中,尽量考虑节约成本和可互换性,在保证X、Y进给选用相同的步进电机、滚珠丝杠等零部件。

关键词:数控铣床,两坐标,实验型

Abstract

This paper introduces the two coordinate Numerical control milling machine tool design. Study on the Numerical control milling machine tool of the excited states, Know that the total situation is, a interplanting of the numerical control equipment, quantity and student's scale have relatively large contrast. The machine that used can not catch up with the need, As well as other course, Students few can move the cell-phone independently , influence training in fact , result of training seriously.

The main results is:[First] , by doing ansys of the machine excited, connecting to the requires in the study. Do the design of some parts and recheck again. Teaching person who test miniature numerical control milling machine apply university and vocational technical school numerical control teaching and numerical control of workers of relevant speciality train mainly. It has small , the price is low , high , such serial advantages as performance is superior of safety coefficient with perfect function.[Second], In the numerical control transformation process, also do the electronic machines transformation and the research, the machine mainly controlled by the PLC, increases the primary device, to the machine part, the electricity has partially carried on the optimized design, introduced the numerical control to be partial, uses step-by-steps the electric motor, the gear changing organization, VFO and the step motor driver and so on. the weak electricity controlled the strong electricity, the computer numerical control electric circuit, successfully has realized the modification requirement, enable it to have the act, rotate one side and other side, the speed changed by VOF, and so on the function. In the machine part design process, Also consider the money and retransferability, make the same the step motor and the ball screw shaft and some other parts.

Key words: Numerical control milling machine, miniature, two coordinate.

目 录

摘 要 I

Abstract(英文摘要) II

目 录 III

第一章 引 言 1

1.1 课题的背景 1

1.2 课题的意义 2

第二章 两轴实验型数控系统的总体设计 3

2.1 数控系统总体方案的设计 3

2.2 两轴实验型数控系统的方案拟定 3

2.3 方案的比较与选择 4

2.4 两轴实验型数控系统的方案拟定 4

第三章 机械部件的计算和选择 5

3.1 切削力的计算 5

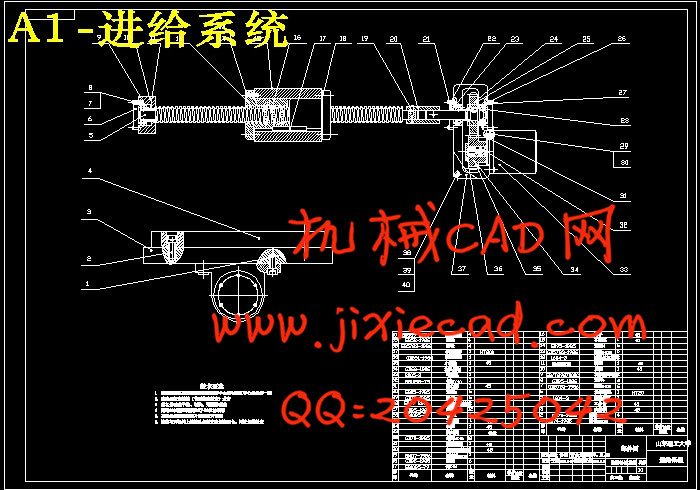

3.2 机械构件的选择 8

3.2.1 电动机的选择 8

3.2.2 丝杠的选择 12

3.2.3 轴承的选择 17

3.2.4 导轨的选择 18

3.2.5 联轴器的选择 21

3.2.6 传动装置的选择 21

3.3 Y轴进给系统设计实例 26

第四章 虚拟样机的制作 27

4.1 微型数控铣床部分零件图 27

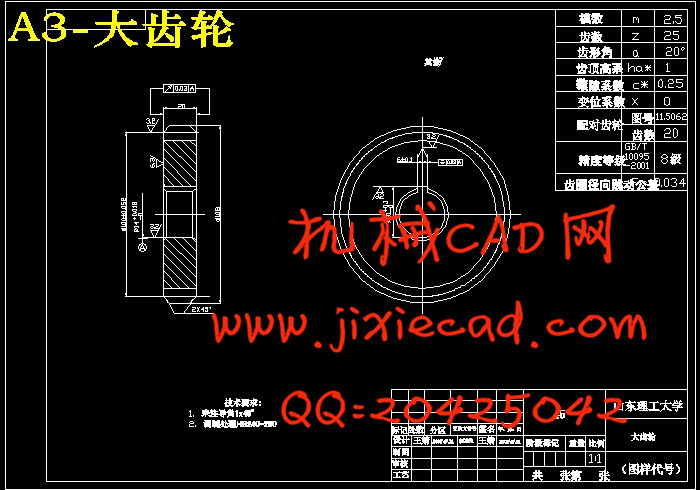

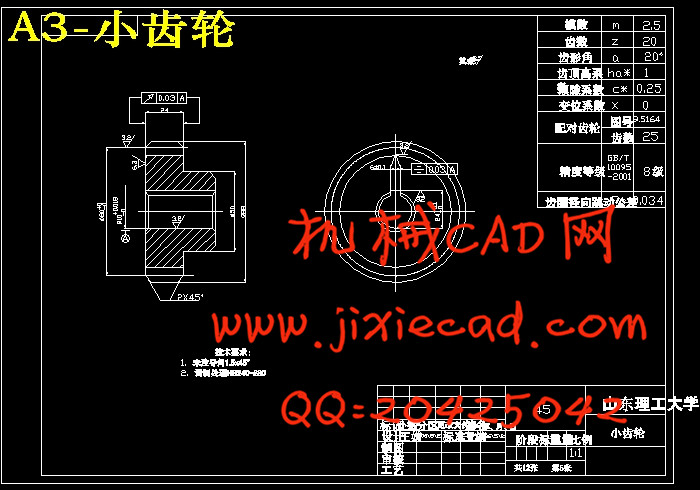

4.1.1 减速箱齿轮 27

4.1.2 工作台 28

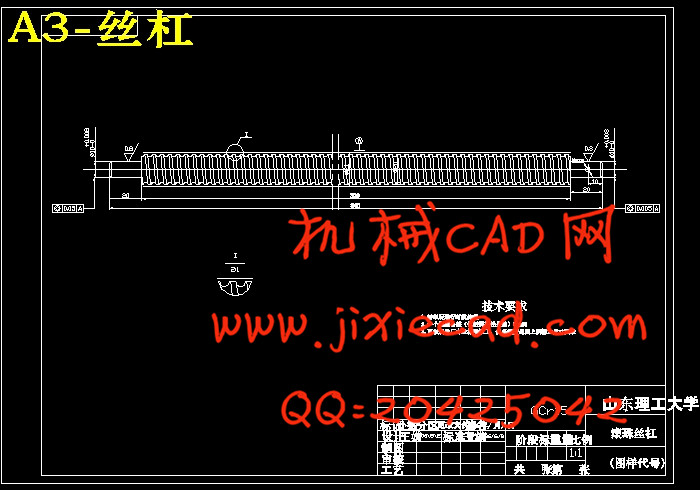

4.1.3 滚珠丝杠 28

4.1.4 套筒式联轴器 29

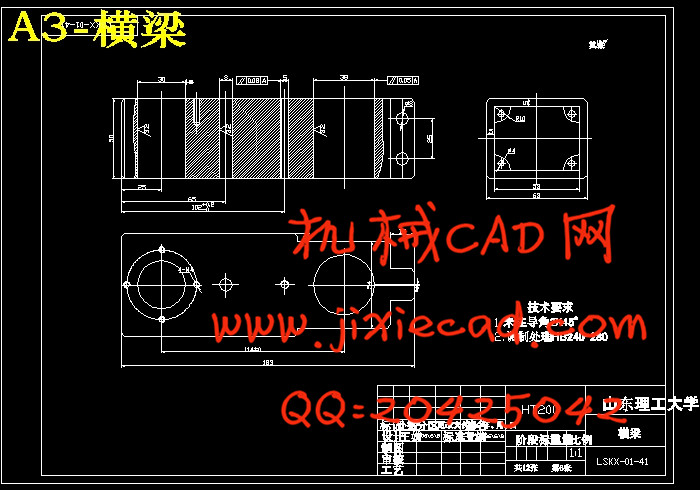

4.1.5 横梁 29

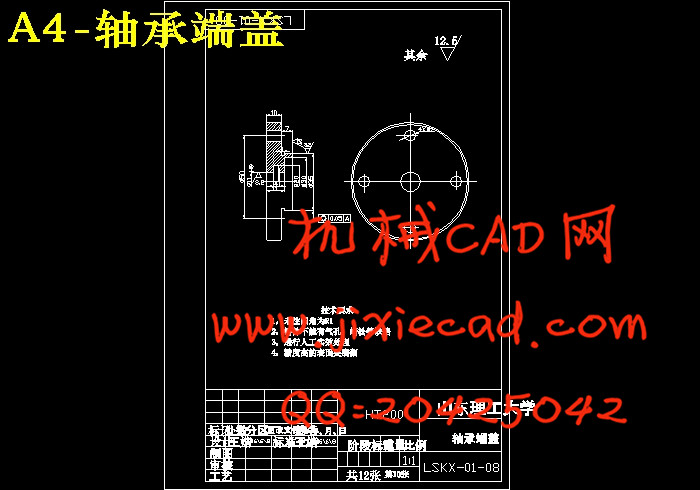

4.1.6 滚动轴承 30

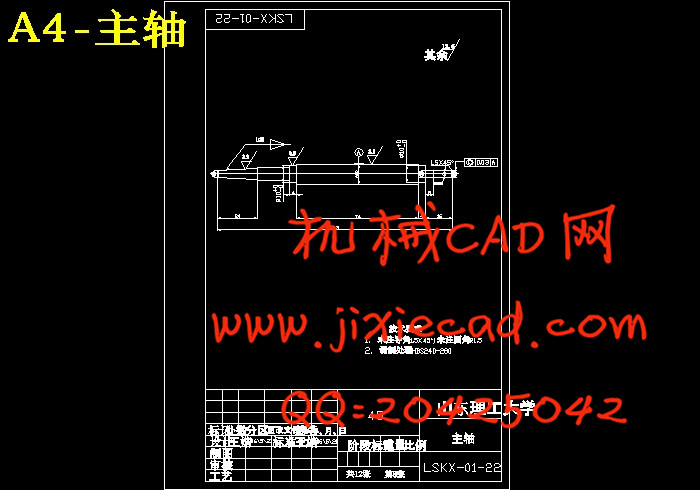

4.1.7 轴 30

4.2两轴实验型数控系统总装配图 31

第五章 控制系统 32

5.1 步进电机驱动器的选择 32

5.2 变频器的选择 35

5.2.1 外部结构 36

5.2.2 运行方式 37

5.3 定位模块的选择 37 5.4 其他辅助电路的选择. 38

5.4.1越程报警电路 38

5.4.2 掉电保护电路 38

结论 39

参考文献 40

致谢及声明 41

文章介绍了两轴实验型数控系统的设计。通过对各种实验型设备的调研,了解到现阶段我国用于实验型设备的数控系统设备的台套种类、数量与学生规模反差较大的现况,设备落后,加之由于各种客观和主观的原因,全国大专院校机电类学生工程实践能力普遍较差,其动手能力与理论更是难结合在一起,严重影响到实训、培训效果。

主要成果是:⑴本设计对已有的设备进行分析,结合实际教学要求,进行各零部件的设计计算,并最终进行校核。该设备可主要应用于高校及职业技术学校中相关专业的数控教学,它具有体积小、价格低、功能完善、安全系数高、性能优越等系列优点;⑵在设计过程中,同时进行了电器方面的改进,主要应用PLC进行控制,引入了数控部分,采用步进电动机,齿轮变速机构,安装了变频器、步进驱动器等设备。通过弱电控制强电,计算机数字化控制电路,并成功地实现了工作要求,使其具有能控制各进给方向电动机启停、正反转、变频调速、两轴联动等功能。在机械部分设计过程中,尽量考虑节约成本和可互换性,在保证X、Y进给选用相同的步进电机、滚珠丝杠等零部件。

关键词:数控铣床,两坐标,实验型

Abstract

This paper introduces the two coordinate Numerical control milling machine tool design. Study on the Numerical control milling machine tool of the excited states, Know that the total situation is, a interplanting of the numerical control equipment, quantity and student's scale have relatively large contrast. The machine that used can not catch up with the need, As well as other course, Students few can move the cell-phone independently , influence training in fact , result of training seriously.

The main results is:[First] , by doing ansys of the machine excited, connecting to the requires in the study. Do the design of some parts and recheck again. Teaching person who test miniature numerical control milling machine apply university and vocational technical school numerical control teaching and numerical control of workers of relevant speciality train mainly. It has small , the price is low , high , such serial advantages as performance is superior of safety coefficient with perfect function.[Second], In the numerical control transformation process, also do the electronic machines transformation and the research, the machine mainly controlled by the PLC, increases the primary device, to the machine part, the electricity has partially carried on the optimized design, introduced the numerical control to be partial, uses step-by-steps the electric motor, the gear changing organization, VFO and the step motor driver and so on. the weak electricity controlled the strong electricity, the computer numerical control electric circuit, successfully has realized the modification requirement, enable it to have the act, rotate one side and other side, the speed changed by VOF, and so on the function. In the machine part design process, Also consider the money and retransferability, make the same the step motor and the ball screw shaft and some other parts.

Key words: Numerical control milling machine, miniature, two coordinate.

目 录

摘 要 I

Abstract(英文摘要) II

目 录 III

第一章 引 言 1

1.1 课题的背景 1

1.2 课题的意义 2

第二章 两轴实验型数控系统的总体设计 3

2.1 数控系统总体方案的设计 3

2.2 两轴实验型数控系统的方案拟定 3

2.3 方案的比较与选择 4

2.4 两轴实验型数控系统的方案拟定 4

第三章 机械部件的计算和选择 5

3.1 切削力的计算 5

3.2 机械构件的选择 8

3.2.1 电动机的选择 8

3.2.2 丝杠的选择 12

3.2.3 轴承的选择 17

3.2.4 导轨的选择 18

3.2.5 联轴器的选择 21

3.2.6 传动装置的选择 21

3.3 Y轴进给系统设计实例 26

第四章 虚拟样机的制作 27

4.1 微型数控铣床部分零件图 27

4.1.1 减速箱齿轮 27

4.1.2 工作台 28

4.1.3 滚珠丝杠 28

4.1.4 套筒式联轴器 29

4.1.5 横梁 29

4.1.6 滚动轴承 30

4.1.7 轴 30

4.2两轴实验型数控系统总装配图 31

第五章 控制系统 32

5.1 步进电机驱动器的选择 32

5.2 变频器的选择 35

5.2.1 外部结构 36

5.2.2 运行方式 37

5.3 定位模块的选择 37 5.4 其他辅助电路的选择. 38

5.4.1越程报警电路 38

5.4.2 掉电保护电路 38

结论 39

参考文献 40

致谢及声明 41