设计简介

两端面铰孔机床总体设计及电气控制部分设计

摘 要:此课题设计的组合机床是用于大批量生产的专用机床。本课题是两端面铰孔机床总体设计和电气控制部分设计。此机床用于加工机体的左、右两个面上的4个 ∅12的孔,一次装夹同时完成两面4个孔的加工。该机床设计的重点是总体设计和电气控制设计两部分。总体设计包括机床配置型式的确定、结构方案的选择以及机床尺寸联系图的绘制。控制部分要求的加工循环包括人工上料—液压夹紧工件—快进移至加工位置—工进加工—快退至原位—液压松开工件—下料,分别能实现调整、循环两种工作方式。根据机床的基本技术要求对机床进行电气总体分布设计,并根据该机床的电气控制原理对该机床电气控制部分的主电路进行设计。最后,详细介绍了PLC技术和三菱FX2N型PLC,同时使用三菱PLC编程软件对机床的夹具、滑台以及主轴的调整和循环动作进行PLC编程。将PLC技术应用于机体加工专用组合机床,使该机床实现了除装卸工件以外的全部自动循环过程,避免了过去由于大量使用继电器带来的种种麻烦,改善并提高了控制性能,减轻了工人的劳动强度,提高了生产效率,降低了生产成本。

关键词:铰孔;组合机床;电气控制;PLC编程

Reaming at Both ends of Machine Design and the Design of the Electrical Control

Abstract: The combination machine of this subject design is specialized machine tool used to yield mass production. This subject is the overall design and electrical controls design of the machine tool what reaming at the both ends. This machine tool is used to processing four ∅12 holes at both ends of body. It is need to finished this four holes at the same time in once clamping. The focus of the design for the machine tool is overall design and electrical control design. The overall design includes configuration type of machine tool, structure of the programmer and machine size contact mapping. The processing cycle of the control included feeding of artificial—hydraulic clamping work piece—fast moving to the processing location—work moving to processing—fast returning to position—hydraulic release work piece—unload, it have two kinds of working methods included adjust and cycle. According to the basic requirement of the machine tool, we do electrical overall design for the machine tool, and according to electrical control principle of the machine tool, we design the main circuit for electrical control. At last, we details introduce the technology of PLC and the PLC of Mitsubishi FX2N, and use programming software of Mitsubishi PLC to programming for the fixture, slider and adjustment with cycle of spindle. Using PLC in the machine tool can make the machine tool do anything itself except handle the work piece, avoid many troubles in using relays long ago, improve the control performance, reduced the labor intensity, improve the production efficiency, reduced the cost of production.

Key word: Reaming; Combination Machine; Electrical Control; PLC Programming

目 录

1 前言………………………………………………………………………………1

2 组合机床总体设计………………………………………………………………3

2.1 总体方案论证…………………………………………………………………3

2.1.1 被加工零件的特点…………………………………………………………3

2.1.2 工艺路线的确定……………………………………………………………3

2.1.3 机床配置型式的选择………………………………………………………3

2.1.4 机体的定位与夹紧…………………………………………………………4

2.2 确定切削用量…………………………………………………………………4

2.2.1 切削用量选择………………………………………………………………5

2.2.2 切削力、切削扭矩及切削功率的计算……………………………………5

2.3 组合机床总体设计……………………………………………………………5

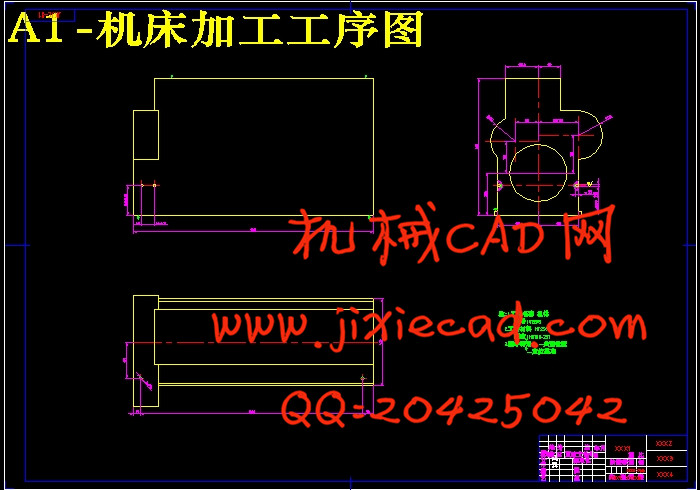

2.3.1 被加工零件工序图…………………………………………………………5

2.3.2 加工示意图…………………………………………………………………6

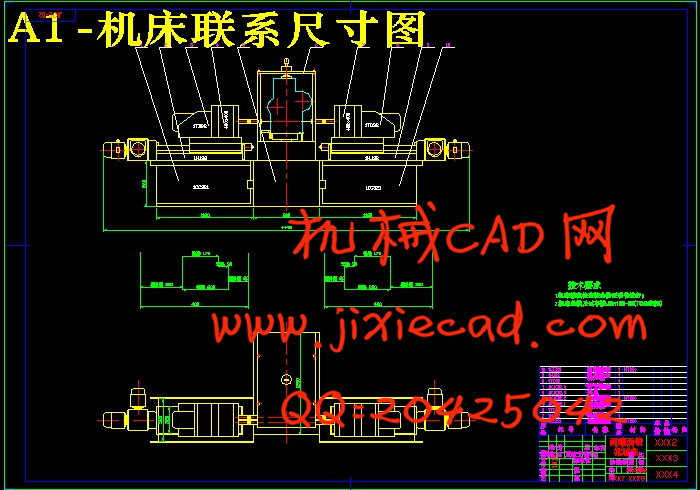

2.3.3 机床联系尺寸图……………………………………………………………8

3 机床电气控制部分的设计………………………………………………………12

3.1 机床控制方案的确定…………………………………………………………12

3.2 滑台电机………………………………………………………………………13

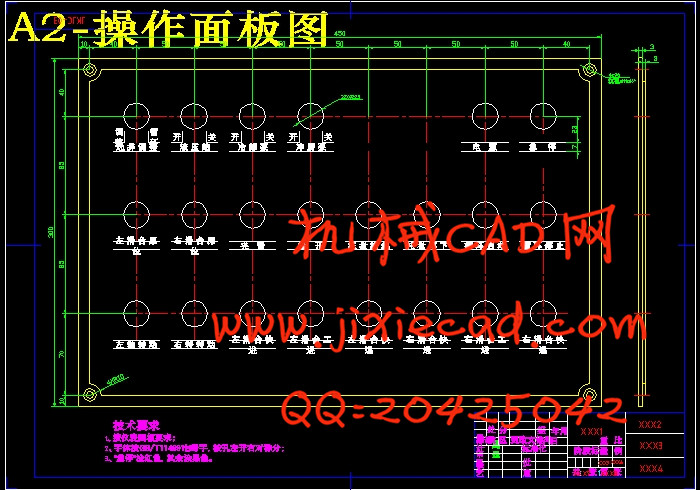

3.3 机床操作面板的设计…………………………………………………………14

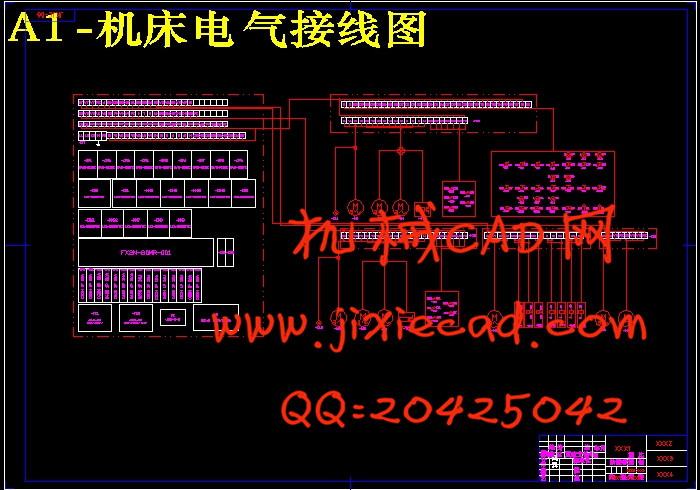

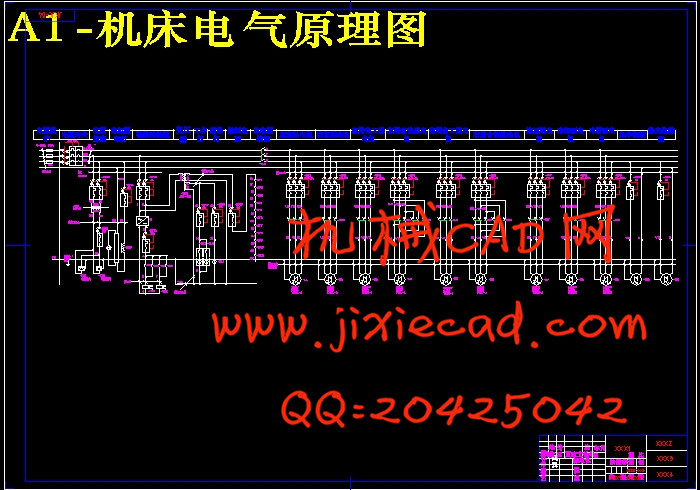

3.4 机床主电路的设计……………………………………………………………16

3.5 PLC控制部分硬件设计………………………………………………………16

3.5.1 PLC的种类…………………………………………………………………16

3.5.2 PLC各部分作用……………………………………………………………16

3.5.3 PLC型号的选择……………………………………………………………17

3.5.4 分配输入/输出点………………………………………………………… 18

3.6 PLC控制部分软件设计………………………………………………………20

4 结论………………………………………………………………………………21

参考文献……………………………………………………………………………22

致 谢……………………………………………………………………………23

附 录……………………………………………………………………………24

摘 要:此课题设计的组合机床是用于大批量生产的专用机床。本课题是两端面铰孔机床总体设计和电气控制部分设计。此机床用于加工机体的左、右两个面上的4个 ∅12的孔,一次装夹同时完成两面4个孔的加工。该机床设计的重点是总体设计和电气控制设计两部分。总体设计包括机床配置型式的确定、结构方案的选择以及机床尺寸联系图的绘制。控制部分要求的加工循环包括人工上料—液压夹紧工件—快进移至加工位置—工进加工—快退至原位—液压松开工件—下料,分别能实现调整、循环两种工作方式。根据机床的基本技术要求对机床进行电气总体分布设计,并根据该机床的电气控制原理对该机床电气控制部分的主电路进行设计。最后,详细介绍了PLC技术和三菱FX2N型PLC,同时使用三菱PLC编程软件对机床的夹具、滑台以及主轴的调整和循环动作进行PLC编程。将PLC技术应用于机体加工专用组合机床,使该机床实现了除装卸工件以外的全部自动循环过程,避免了过去由于大量使用继电器带来的种种麻烦,改善并提高了控制性能,减轻了工人的劳动强度,提高了生产效率,降低了生产成本。

关键词:铰孔;组合机床;电气控制;PLC编程

Reaming at Both ends of Machine Design and the Design of the Electrical Control

Abstract: The combination machine of this subject design is specialized machine tool used to yield mass production. This subject is the overall design and electrical controls design of the machine tool what reaming at the both ends. This machine tool is used to processing four ∅12 holes at both ends of body. It is need to finished this four holes at the same time in once clamping. The focus of the design for the machine tool is overall design and electrical control design. The overall design includes configuration type of machine tool, structure of the programmer and machine size contact mapping. The processing cycle of the control included feeding of artificial—hydraulic clamping work piece—fast moving to the processing location—work moving to processing—fast returning to position—hydraulic release work piece—unload, it have two kinds of working methods included adjust and cycle. According to the basic requirement of the machine tool, we do electrical overall design for the machine tool, and according to electrical control principle of the machine tool, we design the main circuit for electrical control. At last, we details introduce the technology of PLC and the PLC of Mitsubishi FX2N, and use programming software of Mitsubishi PLC to programming for the fixture, slider and adjustment with cycle of spindle. Using PLC in the machine tool can make the machine tool do anything itself except handle the work piece, avoid many troubles in using relays long ago, improve the control performance, reduced the labor intensity, improve the production efficiency, reduced the cost of production.

Key word: Reaming; Combination Machine; Electrical Control; PLC Programming

目 录

1 前言………………………………………………………………………………1

2 组合机床总体设计………………………………………………………………3

2.1 总体方案论证…………………………………………………………………3

2.1.1 被加工零件的特点…………………………………………………………3

2.1.2 工艺路线的确定……………………………………………………………3

2.1.3 机床配置型式的选择………………………………………………………3

2.1.4 机体的定位与夹紧…………………………………………………………4

2.2 确定切削用量…………………………………………………………………4

2.2.1 切削用量选择………………………………………………………………5

2.2.2 切削力、切削扭矩及切削功率的计算……………………………………5

2.3 组合机床总体设计……………………………………………………………5

2.3.1 被加工零件工序图…………………………………………………………5

2.3.2 加工示意图…………………………………………………………………6

2.3.3 机床联系尺寸图……………………………………………………………8

3 机床电气控制部分的设计………………………………………………………12

3.1 机床控制方案的确定…………………………………………………………12

3.2 滑台电机………………………………………………………………………13

3.3 机床操作面板的设计…………………………………………………………14

3.4 机床主电路的设计……………………………………………………………16

3.5 PLC控制部分硬件设计………………………………………………………16

3.5.1 PLC的种类…………………………………………………………………16

3.5.2 PLC各部分作用……………………………………………………………16

3.5.3 PLC型号的选择……………………………………………………………17

3.5.4 分配输入/输出点………………………………………………………… 18

3.6 PLC控制部分软件设计………………………………………………………20

4 结论………………………………………………………………………………21

参考文献……………………………………………………………………………22

致 谢……………………………………………………………………………23

附 录……………………………………………………………………………24