设计简介

摘 要

本设计介绍了一种林区割灌机产品:自走式割灌机。设计中根据林区路面状况,以及清林抚育的作业情况,而设计出能够适应林区崎岖路面及道路狭窄等恶劣环境的自走式割灌机,具有很高的实用性和推广价值。

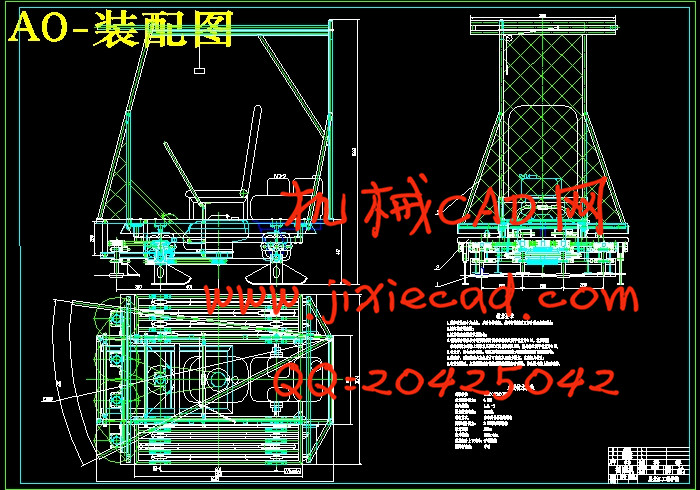

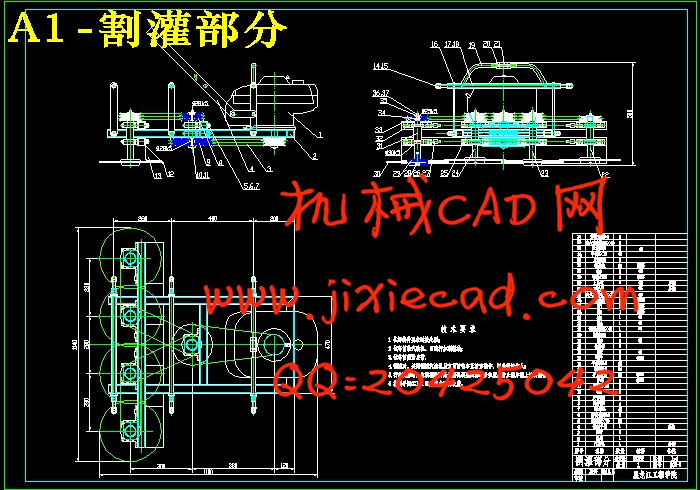

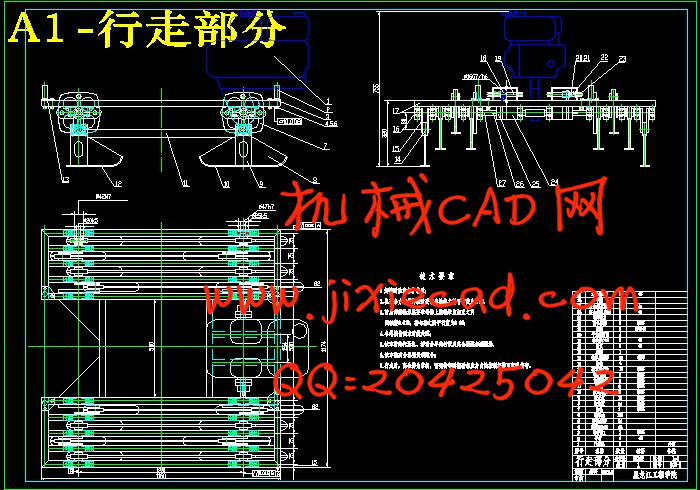

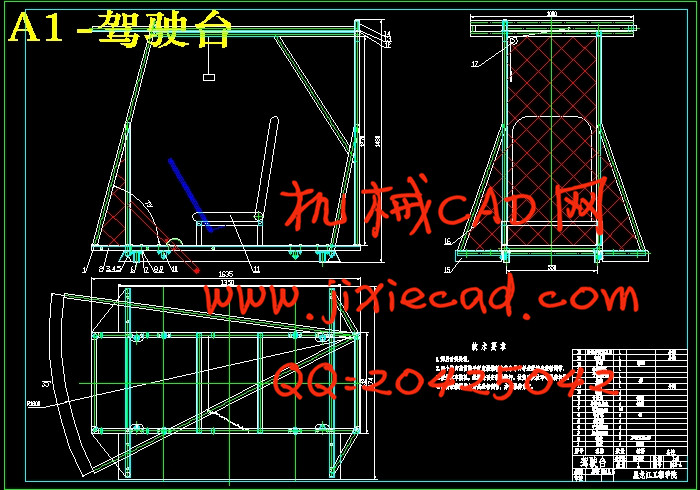

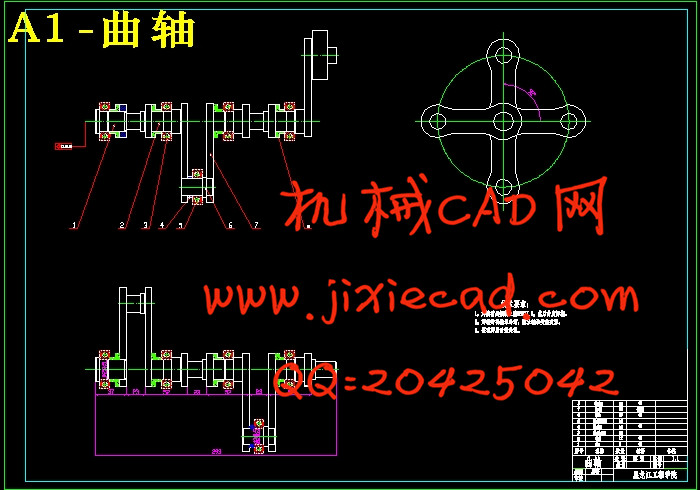

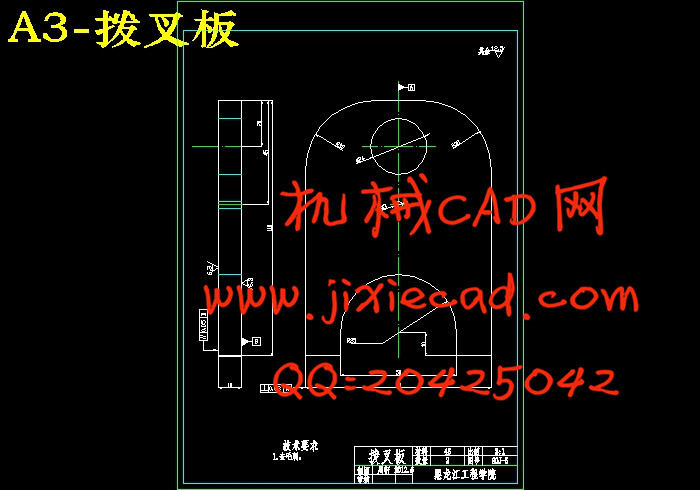

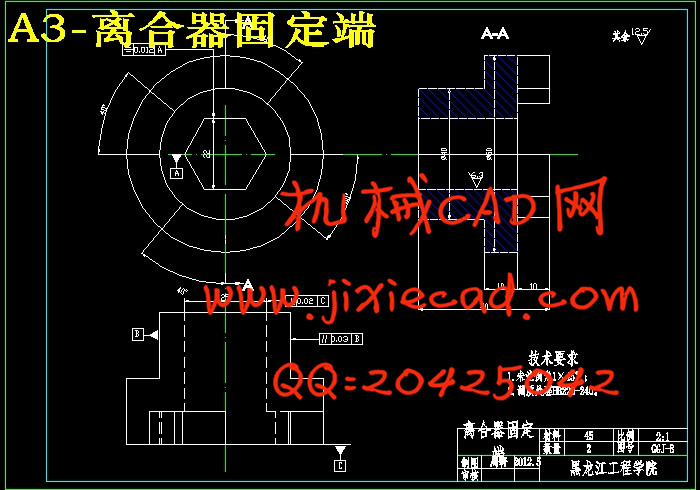

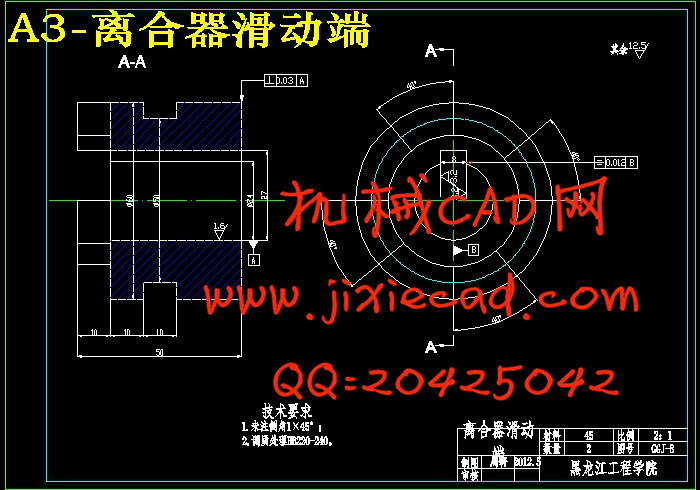

该自走式割灌机由行走部分,割灌部分,驾驶台以及排障部分等组成,可以锯切加工直径范围在10 ~80mm的灌木。整个机器由两个汽油机提供动力,一个提供行走动力,另一个提供割灌动力。锯片位于整个机器的前下端,由驾驶台控制杆控制其离地面高度,以适应林区路面状况。通过顶部的排障杆使高于机器顶部的灌木倒向预定方向,达到排障目的。该自走式割灌机结构简单,容易维修,操作简单。

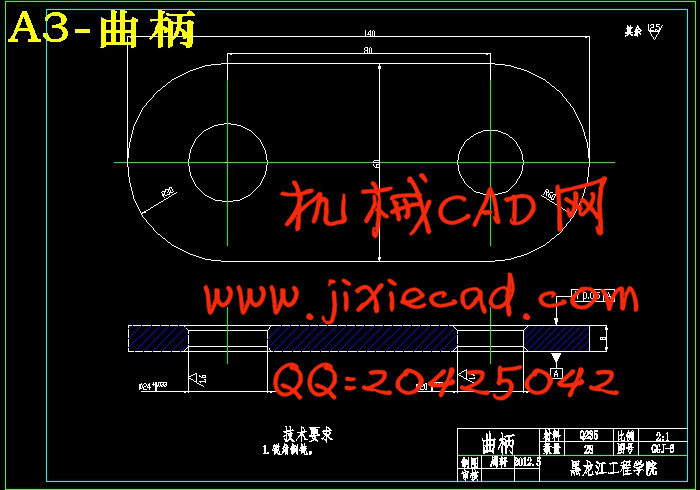

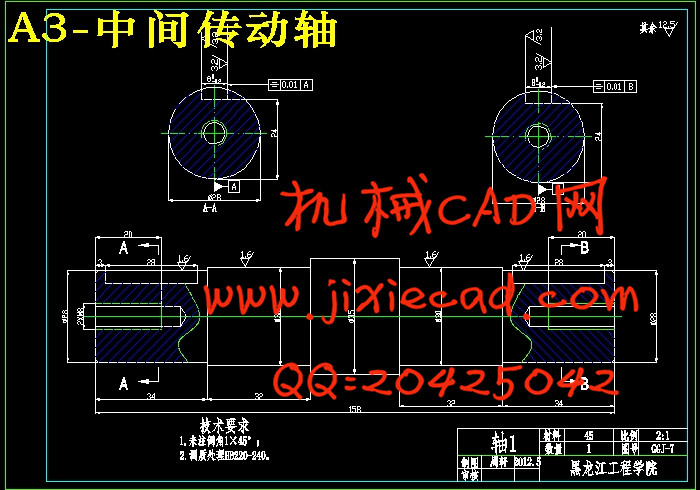

在文章中,对该自走式割灌机的主要部件进行了设计计算(例如:皮带轮,轴,轴承,键,四连杆等 ),并对主要部件进行了系统的介绍和说明,对使用中涉及到的润滑,保养及注意事项也作了说明。

关键词:自走式;割灌机;割灌部分;行走部分;驾驶台;排障杆

Abstract

A self preceded trash breaker, a new forestry machine has been presented in this paper. According to forest road surface conditions, and working situations of clearing fostering trees, the self-propelled brush breaker was designed to adapt to any atrocious environment, such as rugged road surface, narrowness of road and so on. It was highly practicability and generalizing value.

This self-propelled brush breaker is consist of walking port, cutting port,bridge and breaching of obstacles part and can saw brush in diameter range from 10mm to 80mm.The power of whole machine is supplied by two petrol motors, one is for running power,the other is for breaking brush power. Saw blade was under the machine,the control stick on driving stand control its height away from ground to adapt to the forest road surface condition. The bushes that are higher than the machine can be controlled by a pilot bar, which can make bushes fall along the pre-designed direction and get rid of obstacles. This structure of self-propelled brush breaker is simple, is easy to maintain, and is operated easily as well.

The main parts of the self-propelled brush breaker have been compeered and tested in this paper, such as pulley, axes, bearing, bond,four link rods and so on, and the main parts have been introduced and explained systemically, and have lubrication ,maintenance and other matters n related in using.

Key words:Self-propelled; brush breaker; the cutting port;the walking port;bridge,;pilot bar

本设计介绍了一种林区割灌机产品:自走式割灌机。设计中根据林区路面状况,以及清林抚育的作业情况,而设计出能够适应林区崎岖路面及道路狭窄等恶劣环境的自走式割灌机,具有很高的实用性和推广价值。

该自走式割灌机由行走部分,割灌部分,驾驶台以及排障部分等组成,可以锯切加工直径范围在10 ~80mm的灌木。整个机器由两个汽油机提供动力,一个提供行走动力,另一个提供割灌动力。锯片位于整个机器的前下端,由驾驶台控制杆控制其离地面高度,以适应林区路面状况。通过顶部的排障杆使高于机器顶部的灌木倒向预定方向,达到排障目的。该自走式割灌机结构简单,容易维修,操作简单。

在文章中,对该自走式割灌机的主要部件进行了设计计算(例如:皮带轮,轴,轴承,键,四连杆等 ),并对主要部件进行了系统的介绍和说明,对使用中涉及到的润滑,保养及注意事项也作了说明。

关键词:自走式;割灌机;割灌部分;行走部分;驾驶台;排障杆

Abstract

A self preceded trash breaker, a new forestry machine has been presented in this paper. According to forest road surface conditions, and working situations of clearing fostering trees, the self-propelled brush breaker was designed to adapt to any atrocious environment, such as rugged road surface, narrowness of road and so on. It was highly practicability and generalizing value.

This self-propelled brush breaker is consist of walking port, cutting port,bridge and breaching of obstacles part and can saw brush in diameter range from 10mm to 80mm.The power of whole machine is supplied by two petrol motors, one is for running power,the other is for breaking brush power. Saw blade was under the machine,the control stick on driving stand control its height away from ground to adapt to the forest road surface condition. The bushes that are higher than the machine can be controlled by a pilot bar, which can make bushes fall along the pre-designed direction and get rid of obstacles. This structure of self-propelled brush breaker is simple, is easy to maintain, and is operated easily as well.

The main parts of the self-propelled brush breaker have been compeered and tested in this paper, such as pulley, axes, bearing, bond,four link rods and so on, and the main parts have been introduced and explained systemically, and have lubrication ,maintenance and other matters n related in using.

Key words:Self-propelled; brush breaker; the cutting port;the walking port;bridge,;pilot bar

目 录

摘要……………………………………………………………………………………………Ⅰ

Abstract……………………………………………………………………………………Ⅱ

第1章绪论……………………………………………………………………………………1

1.1引言……………………………………………………………………………………1

1.2割灌机的应用范围……………………………………………………………………1

1.3割灌机的发展现状……………………………………………………………………2

1.4我国割灌机的市场及前景……………………………………………………………6

1.5割灌机的发展方向……………………………………………………………………7

1.6自走式割灌机设计的意义……………………………………………………………8

第2章 结构概述 ………………………………………………………………………… 9

2.1工作原理……………………………………………………………………………… 9

2.2结构分析……………………………………………………………………………… 9

2.3本章小结…………………………………………………………………………… 10

第3章 行走部分设计…………………………………………………………………… 11

3.1 方案的确定…………………………………………………………………………11

3.2 机构选择……………………………………………………………………………12

3.3 动力选择……………………………………………………………………………13

3.4 主要设计参数………………………………………………………………………13

3.5本章小结……………………………………………………………………………14

第4章 割灌部分设计…………………………………………………………………… 15

4.1 方案的确定…………………………………………………………………………15

4.2 汽油机输出带轮设计 ……………………………………………………………15

4.3 中间传动轴的计算…………………………………………………………………20

4.4 中间传动轴的校核 …………………………………………………………………20

4.5中间传动轴轴承的校核 ……………… ……………………………………………24

4.6 中间轴的键的选择和校核 …………………………………………………………27

4.7本章小结……………………………………………………………………………28

第5章 驾驶台设计………………………………………………………………………29

5.1方案确定……………………………………………………………………………29

5.2本章小结……………………………………………………………………………30

第6章 排障部分设计 …………………………………………………………………31

6.1方案确定……………………………………………………………………………31

6.2本章小结……………………………………………………………………………32

结论……………………………………………………………………………………………33

参考文献……………………………………………………………………………………34

致谢……………………………………………………………………………………………35