设计简介

机械菱锥式无级变速器结构设计

摘要:

机械无级变速器是一种传动装置,其功能特征主要是:在输入转速不变的情况下,能实现输出轴的转速在一定范围内连续变化,以满足及其或生产系统在运转过程中各种不同工况的要求。本文简要介绍了菱锥式机械无级变速器的基本结构、设计计算的方法、材质及润滑等方面的知识,并以此作为本次无级变速器设计的理论基础。

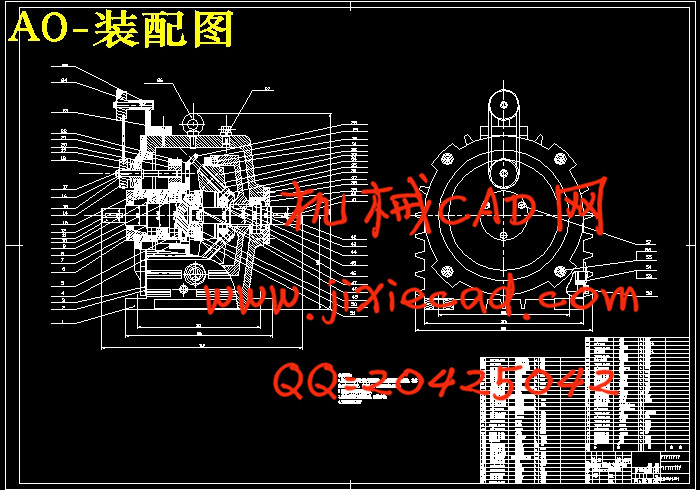

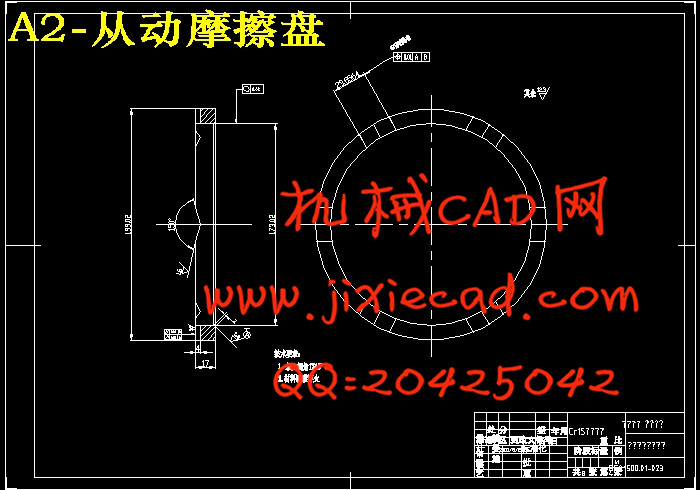

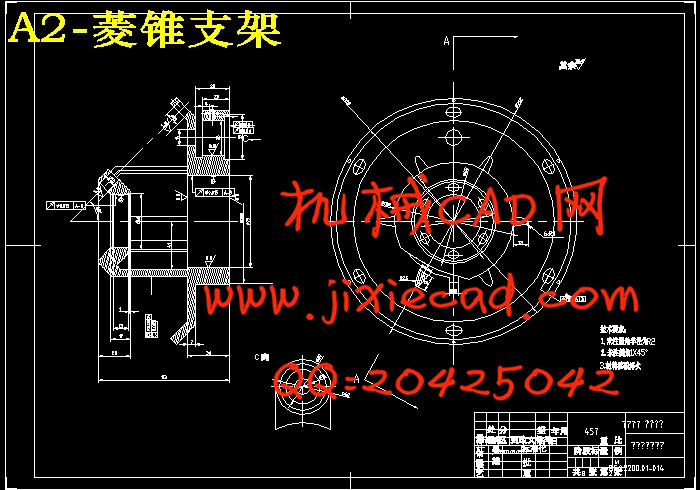

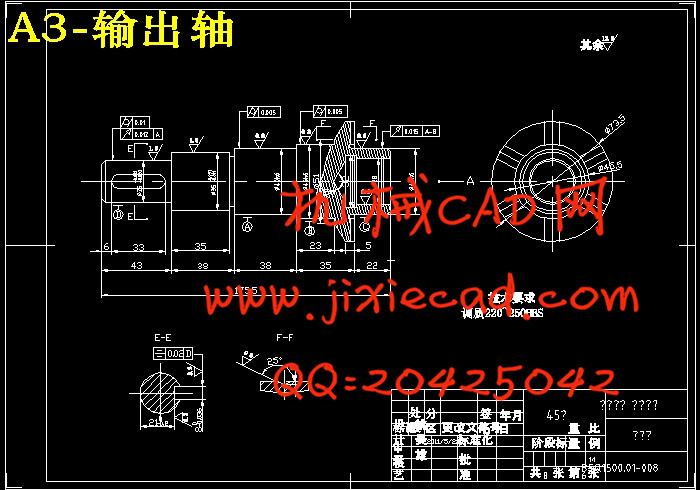

菱锥式无级变速器其主要特点是: 一是为升、降速型;二是采用多个菱锥分流传动,承载力大,变速范围宽,恒功率特性好,摩擦损耗小,传动效率高;三是可以正反转,并能使输入、输出端互换以获得低或高的输出转速;四是采用两套自动加压装置,工作可靠,调压迅速;五是运转平稳,抗冲击能力较强。这次设计采用的是以菱形锥轮作为中间传动元件,通过改变锥轮的工作半径来实现输出轴转速连续变化的菱锥锥轮式无级变速器。论文中分析了在传动过程中变速器的主动轮、菱锥、和外环的工作原理和受力关系;详细推导了实用的菱锥锥轮式无级变速器设计的计算公式;并针对设计所选择的参数进行了具体的设计计算;绘制了所计算的菱锥锥轮式无级变速器的装配图和主要传动元件的零件图,将此变速器的结构和工艺等方面的要求表达得更为清楚。

关键词:机械无级变速器 摩擦式 菱锥锥轮式

Ling cone CVT mechanical structure design

Abstract :The mechanical variable speed drives is a general purpose gearing which can realize a constant viaration of output shaft rotating speed in certain degree with the same input rotate speed so as to meet the production system’s demands during all kinds of operating situations. The article briefly introduces the basic structure, the way of design and calculation, material and lubricate of the pyramid type variable speed drives, and taking them as the theory basis of the design of mechanical variable speed drives.

The most specialties of Ling cone CVT mechanical: 1 capable of improve and lower the speed; 2 large bearing capacity, wide range of variable speed, constant output power, small friction loss and high transmission efficiency; 3 it can rotate positively and versedly so as to exchange the input and output with corresponding low or high output rotational speed; 4 precise control of speed and easy presure regulating; 5 stable accuracy of speed and strong impact resistance.This design uses the pyramid wheel as the middle transmission component, by changing its’ working radius to realize the continuous change of the output axis. This article analyzes the working theory and the working forces of the drive wheel, pyramid wheel and outer ring during the transmission process. It also deduces the practical calculation formula of the pyramid wheel type variable speed drives, it also goes on the material calculation aim at the selection parameter. It protracts the assemble-drawing of the pyramid wheel type variable speed drives and the accessory-drawing of the mostly drive component. So it can express more clearly of the structure and process planning of the variable speed drives.

Key Words: mechanical variable speed drives, friction type, pyramid type

目录

第一章 绪论………………………………………………………………1

1.1机械无级变速器的发展概况………………………………………………………1

1.2机械无级变速器的特点……………………………………………………………1

1.2.1无级变速器的技术特性………………………………………………………………………1

1.2.2无级变速器优缺点……………………………………………………………………………2

1.2.3无级变速器类型………………………………………………………………………………3

1.3机械无级变速器的研究现状………………………………………………………5

1.3.1国内研究形式…………………………………………………………………………………5

1.3.2国际研究形式…………………………………………………………………………………5

1.3.3变速器技术未来发展趋势……………………………………………………………………6

1.3.4未来注重节能环保技术………………………………………………………………………6

1.4课题的研究内容和要求……………………………………………………………7

第二章 菱锥式无级变速器工作原理……………………………………8

2.1 CVT的工作原理……………………………………………………………………8

2.2 菱锥无级变速器的变速原理 ……………………………………………………9

第三章菱锥无级变速器部分零件的设计与计算 ………………………12

3.1、电动机的选择……………………………………………………………………12

3.2、变速器基本型号的确定…………………………………………………………12

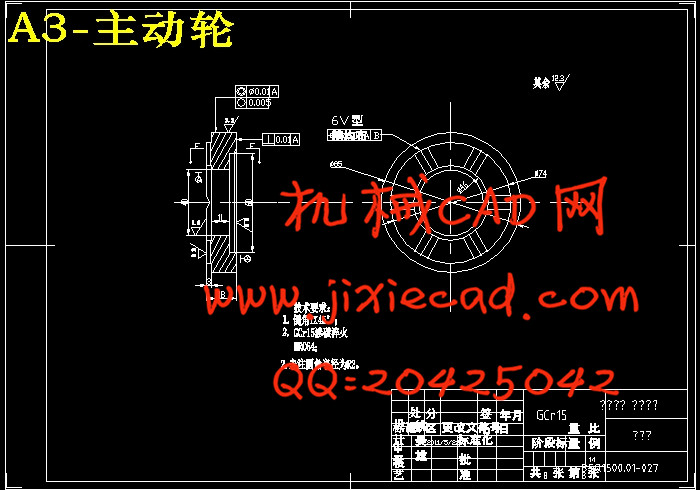

3.3、菱锥与主动轮结构尺寸的计算…………………………………………………12

3.4、输入侧加压装置…………………………………………………………………13

3.5、输出侧加压装置…………………………………………………………………13

3.6、强度校核计算……………………………………………………………………14

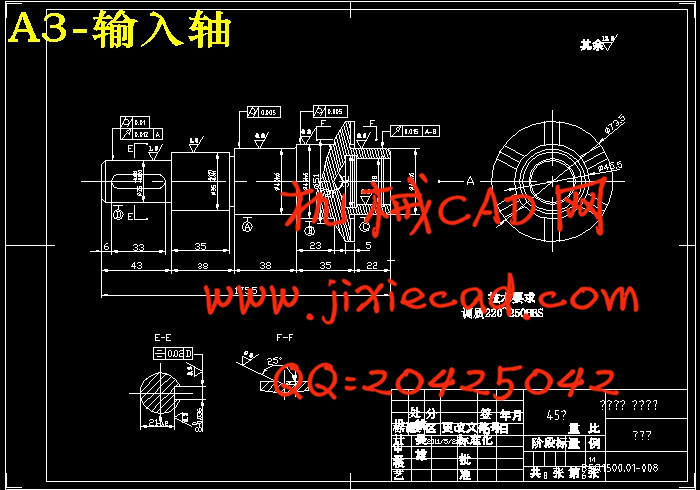

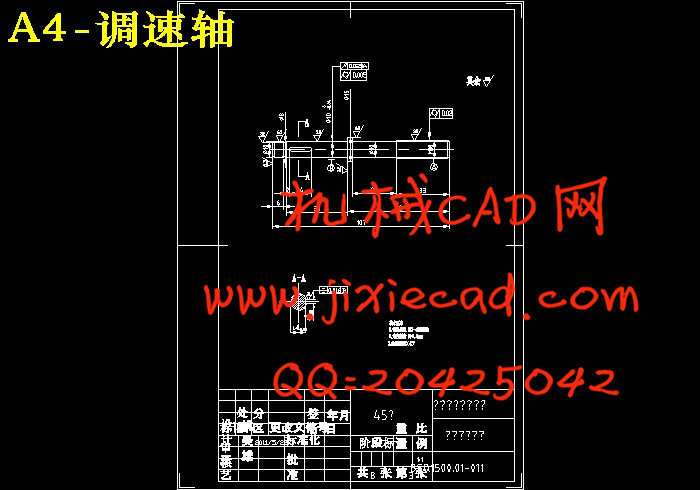

3.7、输入、输出轴的结构设计………………………………………………………14

3.8、输入、输出轴上轴承的选用……………………………………………………15

第四章 主要零件的校核…………………………………………………………16

4.1 输出、输入轴的校核……………………………………………………………16

4.2 轴承的校核………………………………………………………………………17

总结………………………………………………………………………………………18

致谢………………………………………………………………………………………19

参考文献………………………………………………………………………………20

摘要:

机械无级变速器是一种传动装置,其功能特征主要是:在输入转速不变的情况下,能实现输出轴的转速在一定范围内连续变化,以满足及其或生产系统在运转过程中各种不同工况的要求。本文简要介绍了菱锥式机械无级变速器的基本结构、设计计算的方法、材质及润滑等方面的知识,并以此作为本次无级变速器设计的理论基础。

菱锥式无级变速器其主要特点是: 一是为升、降速型;二是采用多个菱锥分流传动,承载力大,变速范围宽,恒功率特性好,摩擦损耗小,传动效率高;三是可以正反转,并能使输入、输出端互换以获得低或高的输出转速;四是采用两套自动加压装置,工作可靠,调压迅速;五是运转平稳,抗冲击能力较强。这次设计采用的是以菱形锥轮作为中间传动元件,通过改变锥轮的工作半径来实现输出轴转速连续变化的菱锥锥轮式无级变速器。论文中分析了在传动过程中变速器的主动轮、菱锥、和外环的工作原理和受力关系;详细推导了实用的菱锥锥轮式无级变速器设计的计算公式;并针对设计所选择的参数进行了具体的设计计算;绘制了所计算的菱锥锥轮式无级变速器的装配图和主要传动元件的零件图,将此变速器的结构和工艺等方面的要求表达得更为清楚。

关键词:机械无级变速器 摩擦式 菱锥锥轮式

Ling cone CVT mechanical structure design

Abstract :The mechanical variable speed drives is a general purpose gearing which can realize a constant viaration of output shaft rotating speed in certain degree with the same input rotate speed so as to meet the production system’s demands during all kinds of operating situations. The article briefly introduces the basic structure, the way of design and calculation, material and lubricate of the pyramid type variable speed drives, and taking them as the theory basis of the design of mechanical variable speed drives.

The most specialties of Ling cone CVT mechanical: 1 capable of improve and lower the speed; 2 large bearing capacity, wide range of variable speed, constant output power, small friction loss and high transmission efficiency; 3 it can rotate positively and versedly so as to exchange the input and output with corresponding low or high output rotational speed; 4 precise control of speed and easy presure regulating; 5 stable accuracy of speed and strong impact resistance.This design uses the pyramid wheel as the middle transmission component, by changing its’ working radius to realize the continuous change of the output axis. This article analyzes the working theory and the working forces of the drive wheel, pyramid wheel and outer ring during the transmission process. It also deduces the practical calculation formula of the pyramid wheel type variable speed drives, it also goes on the material calculation aim at the selection parameter. It protracts the assemble-drawing of the pyramid wheel type variable speed drives and the accessory-drawing of the mostly drive component. So it can express more clearly of the structure and process planning of the variable speed drives.

Key Words: mechanical variable speed drives, friction type, pyramid type

目录

第一章 绪论………………………………………………………………1

1.1机械无级变速器的发展概况………………………………………………………1

1.2机械无级变速器的特点……………………………………………………………1

1.2.1无级变速器的技术特性………………………………………………………………………1

1.2.2无级变速器优缺点……………………………………………………………………………2

1.2.3无级变速器类型………………………………………………………………………………3

1.3机械无级变速器的研究现状………………………………………………………5

1.3.1国内研究形式…………………………………………………………………………………5

1.3.2国际研究形式…………………………………………………………………………………5

1.3.3变速器技术未来发展趋势……………………………………………………………………6

1.3.4未来注重节能环保技术………………………………………………………………………6

1.4课题的研究内容和要求……………………………………………………………7

第二章 菱锥式无级变速器工作原理……………………………………8

2.1 CVT的工作原理……………………………………………………………………8

2.2 菱锥无级变速器的变速原理 ……………………………………………………9

第三章菱锥无级变速器部分零件的设计与计算 ………………………12

3.1、电动机的选择……………………………………………………………………12

3.2、变速器基本型号的确定…………………………………………………………12

3.3、菱锥与主动轮结构尺寸的计算…………………………………………………12

3.4、输入侧加压装置…………………………………………………………………13

3.5、输出侧加压装置…………………………………………………………………13

3.6、强度校核计算……………………………………………………………………14

3.7、输入、输出轴的结构设计………………………………………………………14

3.8、输入、输出轴上轴承的选用……………………………………………………15

第四章 主要零件的校核…………………………………………………………16

4.1 输出、输入轴的校核……………………………………………………………16

4.2 轴承的校核………………………………………………………………………17

总结………………………………………………………………………………………18

致谢………………………………………………………………………………………19

参考文献………………………………………………………………………………20