设计简介

摘 要

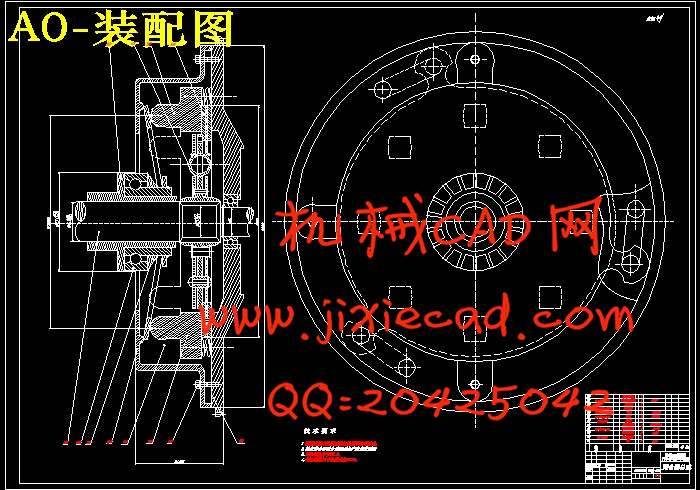

汽车离合器是汽车传动系统的重要组成部分,本设计主要进行汽车膜片弹簧离合器的结构设计。首先,分析汽车膜片弹簧离合器发展现状以及膜片弹簧离合器的系统组成和工作原理。然后,对膜片弹簧离合器部分的结构和工作原理进行详细论述,并针对哈飞路宝汽车阅路宝汽车相关技术参数根据离合器的发展现状,尚未解决的问题,而初选拉式膜片弹簧离合器的基本结构尺寸参数。之后,根据拉式膜片弹簧离合器的性能要求,确定各主要部件的材料选择,结构参数,并对具体尺寸参数进行设计计算、校核、修正。再次,根据各式操纵机构的优缺点,选择液压操纵系统为本次离合器设计的操纵系统。最后,利用Auto-CAD绘制拉式膜片弹簧离合器的主要零部件的零件图及系统装配图。

关键词:拉式;膜片弹簧;离合器;设计;液压操纵

ABSTRACT

Clutch auto transmission system is an important part of the design, were the main car diaphragm spring clutch structure design.The main design of a vehicle diaphragm spring clutch design of the structure. First, the diaphragm spring clutch of motor vehicles and development of the diaphragm spring clutch system components and principle. And then, of diaphragm spring clutch parts of the structure and the working principle, and in the light of the detailed discussion LuBao hafei car LuBao vehicles related technical parameters read according to the current situation of the development of the clutch, not yet solved problems, and primary rumsfeld diaphragm spring clutch of basic structure size parameters.Then, the diaphragm spring clutch part of the structure and working principle of a detailed exposition, and a model for access to the relevant national standards and diaphragm spring primaries push-type clutch size of the basic structure of parameters. , Under the push-type diaphragm spring dual-clutch performance requirements, and identify the major components of the structure, size and specific design parameters, check and correct. Finally, the use of Auto-CAD drawing push-type diaphragm spring clutch parts of the main components of the plan and the system assembly.

Key words: Push-type; diaphragm spring; clutch; Hydraulic control

目 录

摘要…………………………………………………………………… Ⅰ

Abstract.................................................Ⅱ

第1章 绪论............................................. 1

1.1离合器的发展历史............................................1

1.2离合器的功用................................................2

1.3离合器的工作原理..........................................3

1.4膜片弹簧离合器特点..........................................4

1.5 设计的主要内容....................................5

第2章 离合器的结构方案选取..............................6

2.1离合器设计的基本要求........................................6

2.2离合器结构设计..............................................6

2.2.1摩擦片的选择..........................................6

2.2.2压紧弹簧布置形式的选择................................6

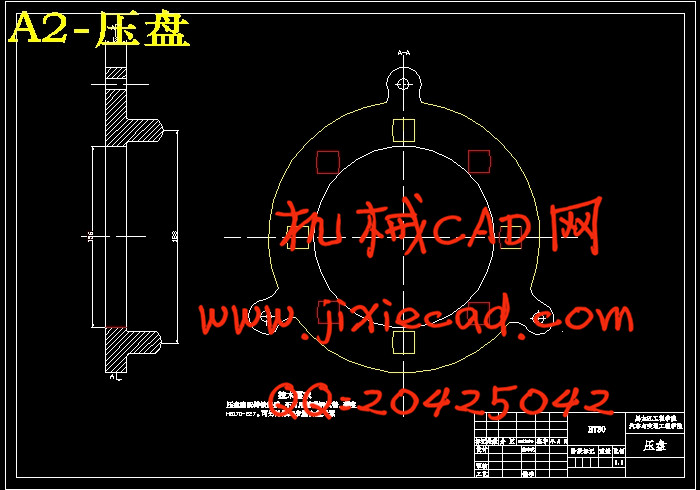

2.2.3压盘驱动方式的选择....................................7

2.3离合器主要零件材料的选择....................................8

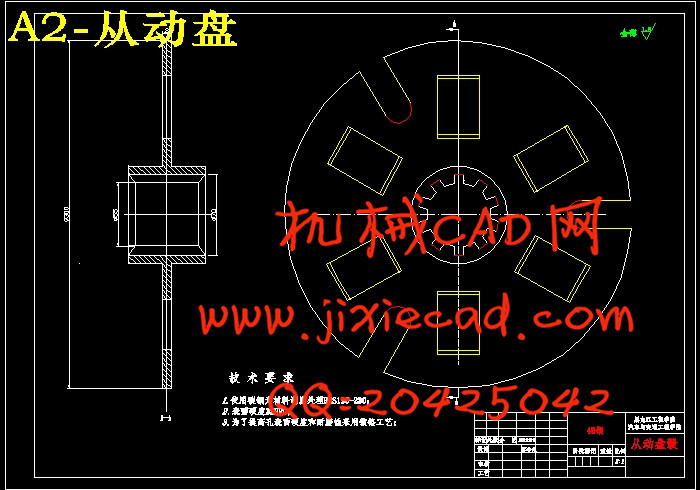

2.3.1从动盘的材料选择......................................8

2.3.2摩擦片的材料选择......................................8

2.3.3膜片弹簧的材料选择....................................8

2.3.4压盘的材料选择........................................8

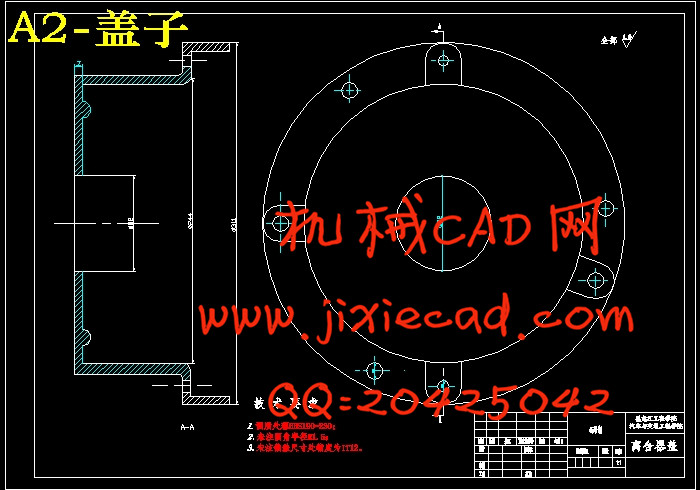

2.3.5离合器盖的材料选择....................................8

2.4离合器的通风散热............................................9

2.5本章小结....................................................9

第3章 离合器基本结构参数的确定.................. .... 10

3.1离合器设计所需数据.........................................10

3.2摩擦片主要参数的选择.......................................10

3.3摩擦片基本参数的优化.......................................12

3.4本章小结...................................................14

第4章 膜片弹簧设计................................ 15

4.1膜片弹簧的结构特点.......................... ...............15

4.1.1 H/h的选择............................................15

4.1.2 R/r选择..............................................16

4.1.3 圆锥底角.............................................16

4.1.4 切槽宽度.............................................16

4.1.5 压盘加载点半径和支承环加载点半径的确定...........16

4.1.6 公差与精度...........................................16

4.2膜片弹簧的优化设计......................................... 16

4.3膜片弹簧的载荷与变形关系....................................17

4.4膜片弹簧的应力计算..........................................19

4.5本章小结... ... ... ... ... ... ... ... ... ... ... ... ... 19

第5章 离合器从动盘设计...................................... 22

5.1从动盘结构..................................................22

5.2从动盘设计................................................. 23

5.2.1从动片的选择和设计................................... 23

5.2.2从动盘毂的设计....................................... 23

5.2.3摩檫片的材料选取及与从动片的固紧方式................ 25

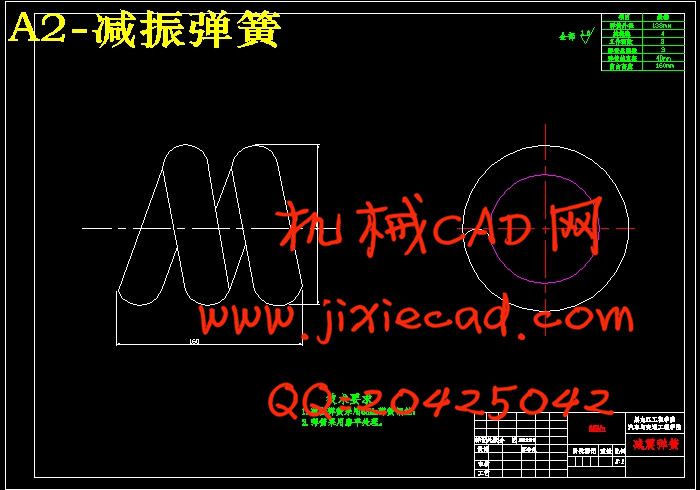

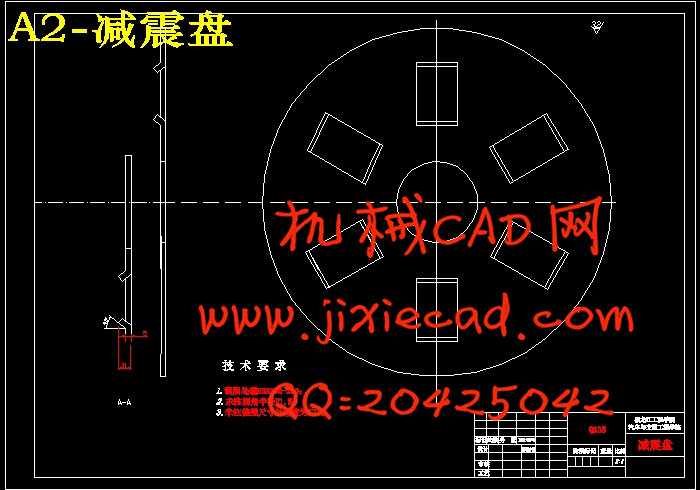

5.3扭转减震器设计..............................................25

5.4本章小结... ... ... ... ... ... ... ... ... ... ... ... ... ...25

第6章 操纵机构设计.......... ................................ 28

6.1离合器踏板行程计算......................................... 28

6.2踏板力的计算.............................................. 29

6.3分离轴承的选取............................................. 30

6.4本章小结... ... ... ... ... ... ... ... ... ... ... ... ... 31

结论................................................... . 32

参考文献.........................................................33

致谢.....................................................34

汽车离合器是汽车传动系统的重要组成部分,本设计主要进行汽车膜片弹簧离合器的结构设计。首先,分析汽车膜片弹簧离合器发展现状以及膜片弹簧离合器的系统组成和工作原理。然后,对膜片弹簧离合器部分的结构和工作原理进行详细论述,并针对哈飞路宝汽车阅路宝汽车相关技术参数根据离合器的发展现状,尚未解决的问题,而初选拉式膜片弹簧离合器的基本结构尺寸参数。之后,根据拉式膜片弹簧离合器的性能要求,确定各主要部件的材料选择,结构参数,并对具体尺寸参数进行设计计算、校核、修正。再次,根据各式操纵机构的优缺点,选择液压操纵系统为本次离合器设计的操纵系统。最后,利用Auto-CAD绘制拉式膜片弹簧离合器的主要零部件的零件图及系统装配图。

关键词:拉式;膜片弹簧;离合器;设计;液压操纵

ABSTRACT

Clutch auto transmission system is an important part of the design, were the main car diaphragm spring clutch structure design.The main design of a vehicle diaphragm spring clutch design of the structure. First, the diaphragm spring clutch of motor vehicles and development of the diaphragm spring clutch system components and principle. And then, of diaphragm spring clutch parts of the structure and the working principle, and in the light of the detailed discussion LuBao hafei car LuBao vehicles related technical parameters read according to the current situation of the development of the clutch, not yet solved problems, and primary rumsfeld diaphragm spring clutch of basic structure size parameters.Then, the diaphragm spring clutch part of the structure and working principle of a detailed exposition, and a model for access to the relevant national standards and diaphragm spring primaries push-type clutch size of the basic structure of parameters. , Under the push-type diaphragm spring dual-clutch performance requirements, and identify the major components of the structure, size and specific design parameters, check and correct. Finally, the use of Auto-CAD drawing push-type diaphragm spring clutch parts of the main components of the plan and the system assembly.

Key words: Push-type; diaphragm spring; clutch; Hydraulic control

目 录

摘要…………………………………………………………………… Ⅰ

Abstract.................................................Ⅱ

第1章 绪论............................................. 1

1.1离合器的发展历史............................................1

1.2离合器的功用................................................2

1.3离合器的工作原理..........................................3

1.4膜片弹簧离合器特点..........................................4

1.5 设计的主要内容....................................5

第2章 离合器的结构方案选取..............................6

2.1离合器设计的基本要求........................................6

2.2离合器结构设计..............................................6

2.2.1摩擦片的选择..........................................6

2.2.2压紧弹簧布置形式的选择................................6

2.2.3压盘驱动方式的选择....................................7

2.3离合器主要零件材料的选择....................................8

2.3.1从动盘的材料选择......................................8

2.3.2摩擦片的材料选择......................................8

2.3.3膜片弹簧的材料选择....................................8

2.3.4压盘的材料选择........................................8

2.3.5离合器盖的材料选择....................................8

2.4离合器的通风散热............................................9

2.5本章小结....................................................9

第3章 离合器基本结构参数的确定.................. .... 10

3.1离合器设计所需数据.........................................10

3.2摩擦片主要参数的选择.......................................10

3.3摩擦片基本参数的优化.......................................12

3.4本章小结...................................................14

第4章 膜片弹簧设计................................ 15

4.1膜片弹簧的结构特点.......................... ...............15

4.1.1 H/h的选择............................................15

4.1.2 R/r选择..............................................16

4.1.3 圆锥底角.............................................16

4.1.4 切槽宽度.............................................16

4.1.5 压盘加载点半径和支承环加载点半径的确定...........16

4.1.6 公差与精度...........................................16

4.2膜片弹簧的优化设计......................................... 16

4.3膜片弹簧的载荷与变形关系....................................17

4.4膜片弹簧的应力计算..........................................19

4.5本章小结... ... ... ... ... ... ... ... ... ... ... ... ... 19

第5章 离合器从动盘设计...................................... 22

5.1从动盘结构..................................................22

5.2从动盘设计................................................. 23

5.2.1从动片的选择和设计................................... 23

5.2.2从动盘毂的设计....................................... 23

5.2.3摩檫片的材料选取及与从动片的固紧方式................ 25

5.3扭转减震器设计..............................................25

5.4本章小结... ... ... ... ... ... ... ... ... ... ... ... ... ...25

第6章 操纵机构设计.......... ................................ 28

6.1离合器踏板行程计算......................................... 28

6.2踏板力的计算.............................................. 29

6.3分离轴承的选取............................................. 30

6.4本章小结... ... ... ... ... ... ... ... ... ... ... ... ... 31

结论................................................... . 32

参考文献.........................................................33

致谢.....................................................34